iC-HL NON-VOLATILE LASER BIAS POTENTIOMETER

advertisement

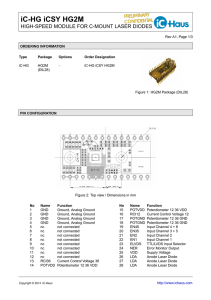

iC-HL NON-VOLATILE LASER BIAS POTENTIOMETER iC-HL is a high-precision 1024-step logarithmic potentiometer for flexible power adjustment of laser diodes with monitor currents from 7 µA to 1.4 mA. The logarithmic characteristic of iC-HL guarantees constant power adjustment accuracy in steps better than 2% (1% typical) over a wide resistance range from 350 Ω to 80 kΩ. Features – High-precision programmable logarithmic potentiometer – Wide resistance range from 350 Ω to 80 kΩ – Calibration accuracy with resistance steps better 2% (typical 1%) – Best APC driver performance (iC-WK series) with monitor currents of 7 µA to 1.4 mA – Wireless optical laser power adjustment capability – Dual-mode programming by optical/electrical coupling – Simple up/down clock interface to step the resistance – Internal E²PROM – Programmable device ID allows for parallel connection of up to 16 devices Applications – Laser diode power adjustment – Remote power adjustment of laser modules – Adjustment of encapsulated devices – Ideal for use with iC-Haus’ laser diode driver family: iC-WK/L, iC-WKM and iC-WKN LDA Suitable lase diodes (depends on APC) CLDA MD LD LD MD LD MD MDA MD LDK VDD 20 BITS EEPROM REGISTER =1 EEPROM CONTROLLER AND CHARGE PUMP DIGITAL FILTER + REFH − REFL WE CI iC−WK iC−WKL iC−WKN iC−WKM CI COMMUNICATION INTERFACE HYSTERESIS GENERATOR MDA iC−HL ACK LD UPND 10 Bits SERIAL PROGRAMMING INTERFACE POWER−DOWN RESET 1 MHz OSCILLATOR CLK R OVERTEMP SHUTDOWN 0 GND 1023 AGND Am Kuemmerling 18 • D -55294 Bodenheim, Germany Tel. +49 61 35 / 92 92-30 0 • Fax +49 61 35 / 92 92-19 2 • http://www.ichaus.com AGND iC-HL NON-VOLATILE LASER BIAS POTENTIOMETER iC-HL resistance values can be easily programmed via an innovative wireless optical system based on the transmission of modulated light pulses into the laser device monitor diode. Pin Functions In addition, programming commands can be sent over a TTLcompatible serial interface. For simple closed loop controlled systems, an up/down clock interface is also available to ease laser power adjustment. Key Specifications General No. Name Function 1 VDD 3.3 to 5 V Power Supply Voltage 2 ACK Communication Acknowledge Input 3 UPND UP/DOWN Selection Input 4 CLK UP/DOWN Clock Input 5 GND Ground 6 AGND Potentiometer Ground 7 MDA Monitor Diode Anode 8 WE Write Enable Input Permissible Supply Voltage Normal function EEPROM write cycle 3.3 to 5.5 V 4.75 to 5.5 V Standby Current in VDD VDD = 5 V @ 27 °C 700 µA max. VDD Voltage at MDA 0.7 V max. ACK Pin Configuration TSSOP8 4.4 mm 1 iC−HL Code UPND EEPROM Characteristics CLK Data Retention Time min. 10 years @ 125 °C Number of Erase/Write Cycles min. 1000 cycles @ 25 °C Number of Read Cycles min. 106 cycles WE MDA AGND GND Resistance Characteristic Programmable Resistor 80000 Maximum Resistor Value set to max. 54 to 93 kΩ Minimum Resistor Value set to min. 190 to 350 Ω Resistor Increments typ. 1% per step Temperature Coefficient 350 ppm/K 70000 Resistance 60000 50000 40000 30000 20000 10000 Up/Down Clock Interface 0 Frequency at CLK pin 5 kHz max. 0 200 400 600 800 1000 Register Value Application Example VCC 1 WE VDD 8 1 GND SERIAL INTERFACE EEPROM 2 MDA ACK UPND 7 2 CI 8 LDA 7 C4 1uF 100nF C3 AGND LDK J I iC−HL 3 iC−WK/L/N 6 + 3 − AGND 0.5V 6 VCC C2 1uF RESISTOR CONTROL UP/DOWN INTERFACE 4 CLK GND 5 4 MDK MDA 5 Am Kuemmerling 18 • D -55294 Bodenheim, Germany Tel. +49 61 35 / 92 92-30 0 • Fax +49 61 35 / 92 92-19 2 • http://www.ichaus.com Rev. 1.0