Data Sheet - Red Lion Controls

advertisement

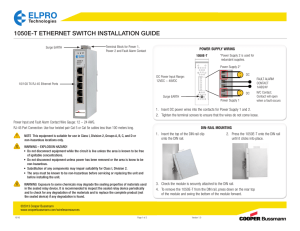

Bulletin No. NT100-X Drawing No. LP0871 Effective 06/11 Tel +1 (717) 767-6511 Fax +1 (717) 764-0839 www.redlion.net MODEL NT100 SERIES – UNMANAGED INDUSTRIAL ETHERNET SWITCHES UNMANAGED SWITCH REQUIRES NO CONFIGURATION SUPPORTS 10/100 MBPS NETWORKS AUTO HALF/FULL DUPLEX NEGOTIATION REDUNDANT POWER INPUTS AUTO-CROSSING DETECTION SUPPORTS STANDARD AND CROSSOVER ETHERNET CABLES C UL R LISTED 65SN US FOR USE IN HAZARDOUS LOCATIONS: Class I, Division 2, Groups A, B, C, and D or unclassified or non-hazardous locations only. GENERAL DESCRIPTION SPECIFICATIONS The NT series is a range of compact IEEE 802.3 layer two network switches with automatic speed, duplex and cable sensing. The series features ultra-robust construction, capable of withstanding environmental extremes for use in mission critical applications. These affordable, Class I, Division 2 switches feature redundant power inputs, hardened metal enclosures, and 16 kV port protection. Each switch is capable of auto negotiating 10/100 Mb and half/full duplex communications. 1. POWER: 10-30 VDC NT104TX/NT105TX: 215 mA max. @ 24VDC NT108TX: 250 mA max. @ 24VDC 2. LEDs: LED LNK/ACT SAFETY SUMMARY All safety related regulations, local codes and instructions that appear in the literature or on equipment must be observed to ensure personal safety and to prevent damage to either the instrument or equipment connected to it. If equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. SPD COLOR DESCRIPTION ON OFF ON BLINKING OFF ON OFF Power is Applied. Power is OFF. Link established, no Activity on cable. Link established, Activity on cable No link activity on cable. Link is 100Mbps. Link is 10Mbs. 3. ENVIRONMENTAL CONDITIONS: Operating Temperature Range: NT104TX/NT105TX: -40 to +80 °C NT108TX: -40 to +70 °C Storage Temperature Range: -40 to +85 °C Operating Humidity: 10-95%, non-condensing Altitude: Up to 3000 meters. 4. CONSTRUCTION: Brushed aluminum housing 5. CONNECTIONS: Power: Removable wire clamp screw terminal block. Wire Gage Capacity: 28 AWG to 16 AWG Torque: 2 in/lb (0.22 Nm) Ethernet: RJ-45 UTP ports 6. MOUNTING: Snaps onto standard DIN style top hat (T) profile mounting rail according to EN50022 -35 x 7.5 and -35 x 15. 7. CERTIFICATIONS AND COMPLIANCES: UL Listed (N-Tron Incorporated, Part numbers 104TX, 105TX, 108TX. File #E214222) Safety: Suitable for use in Class I, Division 2, Groups A, B, C and D Hazardous locations, or non-hazardous locations only. Immunity to Industrial Locations: EMI: EN61000-6-4, EN55011 - Class A FCC Title 47, Part 15, Subpart B - Class A ICES-003 – Class A EMS: EN61000-6-2 EN61000-4-2 (ESD) EN61000-4-3 (RS) EN61000-4-4 (EFT) EN61000-4-5 (Surge) EN61000-4-6 (Conducted Disturbances) 8. WEIGHT: NT104TX/NT105TX: 0.6 lbs. (0.27 Kg) NT108TX0: 0.7 lbs. (0.31 Kg) CAUTION: Risk of Danger. Read complete instructions prior to installation and operation of the unit. WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I, DIVISION 2 WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT WHILE THE CIRCUIT IS LIVE OR UNLESS THE AREA IS KNOWN TO BE FREE OF IGNITABLE CONCENTRATIONS. WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF OR AREA IS KNOWN TO BE NON-HAZARDOUS. For 108TX: Use 60/75°C rated copper wire, (0.22Nm) 2 inch-lbs. tightening torque for field installed connectors. For 104TX & 105TX: Use 95°C rated copper wire, (0.22Nm) 2 inch-lbs. tightening torque for field installed connectors. 1 DIMENSIONS In inches (mm) 4.22 (107.19) 3.97 (100.95) 3.53 (89.62) 1.49 (37.85) 1.49 (37.85) Powered by Powered by PWR PWR 1 12 2.87 (72.90) 23 3.17 (80.52) 3.53 (89.62) 2.87 (72.90) 45 34 105TX 104TX DIMENSIONS In inches (mm) Powered by PWR 12 3.50 (88.90) 3.50 (88.90) 4.22 (107.19) 34 56 3.53 (89.62) 1.71 (43.43) 78 3.80 (96.52) 108TX 1.49 (37.85) POWER MOUNTING Either V1 or V2 can be connected to power for minimal operation. For redundant power operation, V1 and V2 plugs must be connected to separate DC Voltage sources. Use wire sizes of 16-28 gauge. To install the plastic clip units to 35mm industrial DIN rail, place the top edge of the included mounting bracket on the back of the unit against the DIN rail at a 15° angle as shown. Rotate the bottom of the unit to the back (away from you) until it snaps into place. NOTE: Must use an NEC Class 2 or Limited Power Source (LPS) rated power supply. 2 To remove the unit from the DIN rail, place a flat head screwdriver into the release clip found at the bottom of the unit, and apply downward force on the clip until it disengages the bottom of the unit from the DIN rail. Rotate the bottom of the unit towards you and up at an approximate 15° upward angle to completely remove the unit. that there is no voltage difference between the power supply’s negative output terminal and the chassis grounding point of the switch. As an alternative grounding method, both V- legs of the power input connector are connected to the chassis internally on the PCB. Connecting a drain wire to earth ground from one of the V- terminal plugs will ground the switch and the chassis. The power leads from the power source should be limited to 3 meters or less in length. If the use of shielded cables is required, it is generally recommended to only connect the shield at one end to prevent ground loops and interference with low level signals (i.e. thermocouples, RTD, etc.). Cat5e cables manufactured to EIA-568A or 568B specifications are required for use with NT series switches. NT series switches are designed to be grounded, but the user has been given the flexibility to float the unit when required. The best noise immunity and emissions are obtained when the unit’s chassis is connected to earth ground via a drain wire. Users may run a drain wire & lug from the screw provided on the back face of the enclosure. In the event the provided grounding screw has been lost, care should be taken to limit the penetration of the outer skin by less than 1/4". Failure to do so may cause irreversible damage to the internal components of the switch. Note: Ensure the power supply is grounded properly before applying power to the grounded switch. This may be verified by using a voltmeter to determine TROUBLESHOOTING For further technical assistance, contact technical support at the appropriate company numbers listed. ORDERING INFORMATION MODEL NO. NT100 DESCRIPTION PART NUMBER 4-Port Ethernet Switch NT104TX0 5-Port Ethernet Switch NT105TX0 8-Port Ethernet Switch NT108TX0 3 LIMITED WARRANTY The Company warrants the products it manufactures against defects in materials and workmanship for a period limited to two years from the date of shipment, provided the products have been stored, handled, installed, and used under proper conditions. The Company’s liability under this limited warranty shall extend only to the repair or replacement of a defective product, at The Company’s option. The Company disclaims all liability for any affirmation, promise or representation with respect to the products. The customer agrees to hold Red Lion Controls harmless from, defend, and indemnify RLC against damages, claims, and expenses arising out of subsequent sales of RLC products or products containing components manufactured by RLC and based upon personal injuries, deaths, property damage, lost profits, and other matters which Buyer, its employees, or sub-contractors are or may be to any extent liable, including without limitation penalties imposed by the Consumer Product Safety Act (P.L. 92-573) and liability imposed upon any person pursuant to the Magnuson-Moss Warranty Act (P.L. 93-637), as now in effect or as amended hereafter. No warranties expressed or implied are created with respect to The Company’s products except those expressly contained herein. The Customer acknowledges the disclaimers and limitations contained herein and relies on no other warranties or affirmations. Red Lion Controls Headquarters 20 Willow Springs Circle York PA 17406 Tel +1 (717) 767-6511 Fax +1 (717) 764-0839 Red Lion Controls Europe Printerweg 10 NL - 3821 AD Amersfoort Tel +31 (0) 334 723 225 Fax +31 (0) 334 893 793 Red Lion Controls India 54, Vishvas Tenement GST Road, New Ranip, Ahmedabad-382480 Gujarat, India Tel +91 987 954 0503 Fax +91 79 275 31 350 4 Red Lion Controls China Unit 101, XinAn Plaza Building 13, No.99 Tianzhou Road ShangHai, P.R. China 200223 Tel +86 21 6113-3688 Fax +86 21 6113-3683