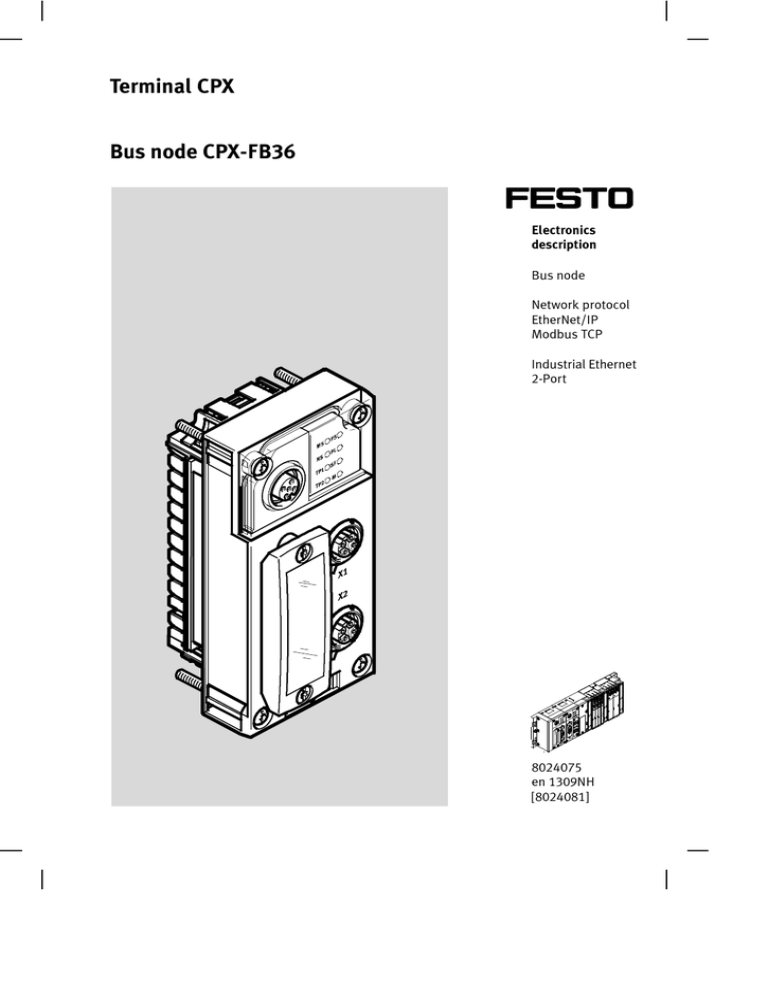

Terminal CPX

Bus node CPX-FB36

Electronics

description

Bus node

Network protocol

EtherNet/IP

Modbus TCP

Industrial Ethernet

2-Port

8024075

en 1309NH

[8024081]

Contents and general instructions

Original . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . de

Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . en 1309NH

Designation . . . . . . . . . . . . . . . . . . . . . . . P.BE-CPX-FB36-EN

Order no. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8024075

E (Festo AG & Co., 73726 Esslingen, Germany, 2013)

Internet: http://www.festo.com

E-Mail: service_international@festo.com

Reproduction, distribution and utilisation of this document,

as well as the communication of its contents to others

without explicit authorisation, is prohibited. Offenders will

be liable for damages. All rights are reserved, in particular

the right to file patent, utility model or registered design

applications.

Festo P.BE-CPX-FB36-EN en 1309NH English

I

Contents and general instructions

EtherNet/IP®, Modbus®, RSLogix®, RSNetWorx®, SPEEDCON® and TORX®

are registered trademarks of the respective trademark owners in certain countries.

II

Festo P.BE-CPX-FB36-EN en 1309NH English

Contents and general instructions

Table of contents

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Target group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Information regarding this description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important user information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VII

VIII

VIII

IX

X

1.

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1.1

1.4

1.5

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1

Electrical connection and display elements . . . . . . . . . . . . . . . . . . .

1.1.2

Dismantling and mounting of the bus node . . . . . . . . . . . . . . . . . . .

Setting the DIL switches on the bus node . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1

Setting the operating mode and protocol . . . . . . . . . . . . . . . . . . . .

1.2.2

Setting the diagnostics mode for Remote I/O . . . . . . . . . . . . . . . . .

1.2.3

Setting the data field size for Remote Controller . . . . . . . . . . . . . . .

1.2.4

Setting IP addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1

General information about networks . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2

Overview of connections, network connectors and cables . . . . . . .

1.3.3

Network connections of the CPX-FB36 . . . . . . . . . . . . . . . . . . . . . . .

1.3.4

Setting the IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.5

Advanced network settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ensuring protection classIP65/IP67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3

1-4

1-5

1-7

1-9

1-10

1-11

1-12

1-13

1-13

1-14

1-17

1-18

1-22

1-23

1-24

2.

Preparing for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2.1

EtherNet/IP protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3

2.1.1

Multicast telegram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3

2.1.2

QuickConnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.1.3

Device Level Ring protocol (DLR) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Modbus/TCP protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

1.2

1.3

2.2

Festo P.BE-CPX-FB36-EN en 1309NH English

III

Contents and general instructions

2.3

Notes on commissioning the CPX-FB36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1

Requirements for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2

Switching on the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3

Normal operating status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Participants in the network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1

Participant properties (EDS file) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-11

2-11

2-12

2-12

2-16

2-16

3.

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3.1

3-3

3-4

3-10

3-15

3-19

3-20

3-21

3-22

3-25

3-26

3-26

3-26

3.3

3.4

3.5

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1

Configuration with EDS file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2

Configuration with Generic Ethernet Module . . . . . . . . . . . . . . . . . .

3.1.3

Configuration with CPX-FMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4

Configuration in the Remote Controller operating mode . . . . . . . .

3.1.5

Setting up a listen-only connection . . . . . . . . . . . . . . . . . . . . . . . . .

Parameterisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1

Parameterisation when switching on (system start) . . . . . . . . . . . .

3.2.2

Methods of parameterisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3

Parameterisation via configuration data . . . . . . . . . . . . . . . . . . . . .

3.2.4

Parameterisation with the operator unit CPX-MMI . . . . . . . . . . . . .

3.2.5

Parameterisation in the PLC user program . . . . . . . . . . . . . . . . . . .

3.2.6

Parameterisation using CPX-FMT and system start with saved

parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reaction of the outputs in the Fail safe or Idle mode . . . . . . . . . . . . . . . . . . .

Web server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checklist for commissioning a CPX terminal . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1

4.1

4.2

Summary of diagnostics options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Diagnostics via LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.2.1

CPX-specific LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.2.2

Network-specific LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

4.2.3

Protocol-specific LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Diagnostics via status bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Diagnostics via I/O diagnostic interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

2.4

3.2

4.3

4.4

IV

3-27

3-28

3-29

3-30

Festo P.BE-CPX-FB36-EN en 1309NH English

Contents and general instructions

4.5

4.6

4.7

Diagnostics via EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Diagnostics via Modbus TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Error handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

A.

Technical appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-1

A.1

Technical data, bus node CPX-FB36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A-3

B.

Address assignment of the CPX terminal . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1

B.1

B.2

B.3

Address assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Address assignment after extension/conversion . . . . . . . . . . . . . . . . . . . . . . B-22

C.

EtherNet/IP Objects of the CPX-FB36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-1

C.1

C.2

Overview of Ethernet/IP objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objects for network settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.1

Device Level Ring Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.2

QoS Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.3

TCP/IP Interface Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.2.4

Ethernet Link Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objects for the I/O connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.3.1

Assembly Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objects for system data and diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.1

Identity Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.2

Global System Object (for operating mode Remote I/O) . . . . . . . .

C.4.3

Status and Diagnostics Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.4

Diagnostics Trace Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.5

Diagnostics Trace Status Object . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.6

General Module Parameter Object . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.7

Force parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.8

Fail Safe and Idle parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.9

Configuration Array Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.4.10 Slave Size Object (for operating mode Remote Controller) . . . . . .

C-3

C-8

C-8

C-9

C-10

C-12

C-13

C-13

C-18

C-18

C-20

C-23

C-24

C-26

C-28

C-31

C-36

C-42

C-42

C.3

C.4

Festo P.BE-CPX-FB36-EN en 1309NH English

V

Contents and general instructions

C.5

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-43

C.5.1

Forcing inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-43

C.5.2

Parameterisation with the general Module Parameter Object . . . . C-45

D.

Modbus/TCP Objects of the CPX-FB36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D-1

D.1

D.2

D.3

D.4

Overview of Modbus/TCP objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Commands and addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPX status information (group A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Processing data (groups B and D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4.1 Module CPX-FB36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4.2 Electric modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4.3 Pneumatic modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4.4 Technology module CP interface . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.4.5 Composition of diagnostic data (diagnostic word) . . . . . . . . . . . . .

D.4.6 Composition of the data of the I/O diagnostic interface . . . . . . . . .

Diagnostic memory (groups C and E) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus/TCP Objects (group F) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.6.1 Addressing examples for ModbusTCP . . . . . . . . . . . . . . . . . . . . . . .

D-3

D-3

D-4

D-5

D-5

D-6

D-9

D-14

D-18

D-18

D-20

D-22

D-23

E.

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E-1

E.1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E-3

D.5

D.6

VI

Festo P.BE-CPX-FB36-EN en 1309NH English

Contents and general instructions

Intended use

The bus node CPX-FB36 documented in this description is

exclusively intended for use as a participant in networks with

EtherNet/IP or Modbus TCP protocols.

The CPX terminal must only be used as follows:

–

As intended in industrial environments;

outside of industrial environments, e.g. in commercial and

mixed-residential areas, actions to suppress interference

may have to be taken.

–

in original status without unauthorised modifications.

Only the conversions or modifications described in the

documentation supplied with the product are permitted.

–

in perfect technical condition.

The limit values specified for pressures, temperatures, electrical data, torques etc. must be observed.

If standard ancillary components, such as sensors and actuators, are connected, the specified limits for pressures, temperatures, electrical data, torques, etc. must be complied with.

•

Festo P.BE-CPX-FB36-EN en 1309NH English

Observe the regulations of the trade associations, German Technical Control Board (TÜV), VDE stipulations or

corresponding national laws and regulations.

VII

Contents and general instructions

Target group

This description is intended exclusively for technicians

trained in control and automation technology, who have experience in installing, commissioning, programming and diagnosing participants in networks with EtherNet/IP or Modbus TCP protocols.

Service

Please consult your local Festo Service agent if you have any

technical problems.

VIII

Festo P.BE-CPX-FB36-EN en 1309NH English

Contents and general instructions

Information regarding this description

Further information regarding EtherNet/IP can be found here:

www.odva.org

General basic information about the mode of operation, assembly, installation and commissioning of CPX terminals can

be found in the CPX system description P.BE.CPX-SYS.

An overview of the structure of the user documentation for

the CPX terminal can be found in the CPX system description

P.BE.CPX-SYS.

Festo P.BE-CPX-FB36-EN en 1309NH English

IX

Contents and general instructions

Important user information

Danger categories

This description includes instructions on the possible dangers

which can occur if the product is used incorrectly. These instructions are marked with a signal word (Warning, Caution,

etc.), printed on a shaded background and marked additionally with a pictogram. A distinction is made between the following danger warnings:

Warning

... means that failure to observe this instruction may result

in serious personal injury or material damage.

Caution

... means that failure to observe this instruction may result

in personal injury or material damage.

Note

... means that failure to observe this instruction may result

in material damage.

In addition, the following pictogram marks passages in the

text which describe activities with electrostatically sensitive

devices:

Electrostatically sensitive devices: Incorrect handling may

cause damage to devices.

X

Festo P.BE-CPX-FB36-EN en 1309NH English

Contents and general instructions

Marking of special information

The following pictograms mark passages in the text which

contain special information.

Pictograms

Information:

Recommendations, tips and references to other information

sources.

Accessories:

Specifications on necessary or useful accessories for the

Festo product.

Environment:

Information on the environmentally friendly use of Festo

products.

Text designations

•

Bullets denote activities that may be carried out in any

desired order.

1. Numerals denote activities that must be carried out in the

sequence specified.

–

Festo P.BE-CPX-FB36-EN en 1309NH English

Arrowheads indicate general lists.

XI

Contents and general instructions

The following product-specific terms and abbreviations are

used in this description:

Term/abbreviation

Significance

160d

Decimal numbers are marked in part by a low-set “d”.

A0h

Hexadecimal numbers are marked by a low-set “h”.

AA, AO

Analogue output

AE, AI

Analogue input

BOOTP

Dynamic protocol for automatic assignment of IP addresses (Boot

protocol, predecessor of DHCP).

Bus nodes

A bus node connects the CPX terminal to the fieldbus or network; it

transmits control signals to the connected CPX and pneumatic modules

and monitors their operational capability.

C

Output

CEC

Codesys controller, e.g. CPX-CEC, applicable for control, configuration

and commissioning of CPX terminals.

CODESYS

Controller Development System

CP

Compact Performance

CP module

Collective term for the various modules which can be incorporated in

the CP system (decentralised installation system).

CPX-CP interface

Interface for connecting decentrally arranged CP modules to a CPX

terminal.

CPX-FMT

Festo Maintenance Tool for configuration and parameterisation of CPX

terminals.

CPX-MMI

Operator unit for commissioning and service purposes.

Tab. 0/1:

XII

CPX-specific terms and abbreviations – part 1

Festo P.BE-CPX-FB36-EN en 1309NH English

Contents and general instructions

Term/abbreviation

Significance

CPX modules

Collective term for electric modules which can be incorporated into a

CPX terminal: bus nodes, I/O modules and function modules

(technology modules).

CPX modules provide, among other things, electrical inputs and

outputs for connecting sensors and actuators.

CPX modules form the electrical side of the CPX terminal.

CPX terminal

Complete system consisting of various CPX modules with or without

pneumatics modules.

DHCP

Dynamic protocol for automatic assignment of IP addresses (Dynamic

Host Configuration Protocol).

DI

Digital input (or “Discrete input”)

DIL switches

Miniature switches; dual-in-line switches usually consist of several

switch elements which can be used to implement settings.

DO

Digital output (or “Discrete output”)

EtherNet/IP

Communication protocol for connecting various devices in a network.

FEC

Front End Controller, e.g. CPX-FEC, can be used as:

– stand-alone system controller (PLC, stand alone operating mode)

– system controller (PLC, remote controller operating mode)

– fieldbus slave (remote I/O operating mode)

Function module

Collective term for modules with additional functions, e.g.

CPX-CP-interface, Front End Controller (CPX-FEC) and CODESYS

controller (CPX-CEC); function modules are also known as technology

modules.

I

Input

I/O diagnostics interface

Bus-independent, bi-directional diagnostic interface at I/O level;

enables access to the internal data of the CPX terminal.

I/O module

Collective term for CPX modules that provide analogue or digital inputs

and outputs.

I/Os

Analogue or digital inputs and outputs.

Tab. 0/2:

CPX-specific terms and abbreviations – part 2

Festo P.BE-CPX-FB36-EN en 1309NH English

XIII

Contents and general instructions

Term/abbreviation

Significance

I/O signal

Input/output signal of an I/O module; also referred to as a process

signal.

Modbus TCP

Communication protocol via TCP/IP in automation technology.

Pneumatics interface

Interface between CPX modules and pneumatics modules within a CPX

terminal.

The pneumatics interface is used functionally for the electrical side of

the CPX terminal.

Pneumatic modules

Collective term for the pneumatics modules which can be integrated

into a CPX terminal.

Pneumatics modules provide, among other things, outputs (working

ports) for connecting actuators, e.g. cylinders.

Pneumatics modules form the pneumatic side of the CPX- terminal.

Status bits

CPX-internal status information (common diagnostic messages) which

are provided as input signals on the fieldbus of the control system

(optional function)

Technology module

Function module

Tab. 0/3:

XIV

CPX-specific terms and abbreviations – part 3

Festo P.BE-CPX-FB36-EN en 1309NH English

Contents and general instructions

Data type

Quantity

Range of values

Description

ARRAY

—1)

—

Structure with identical

data types

BOOL

1 bit

0 “False” and 1 “True”

Logical data type

BYTE

8 bit

00h … FFh

Bit field

DWORD

32 bit

00000000h … FFFFFFFFh

Bit field

DINT

32 bit

-2147483648 …

2147483647

Signed Double Integer

INT

16 bit

-32.768 … 32.767

Signed Integer

Padded EPATH

Max. 12 bytes

SINT

8 bit

-128 … 127

Signed Short Integer

STRING

8 bit/characters

—

String

SHORT_STRING

8 bit/characters +

8 bit length

specification

—

String with max. 255

characters

STRUCT

—1)

—

Structure of any data

types

UDINT

32 bit

0 … 4294967296

Unsigned Double Integer

UINT

16 bit

0 … 65.536

Unsigned Integer

USINT

8 bit

0 … 256

Unsigned Short Integer

WORD

16 bit

0000h … FFFFh

Bit field

Logical segments of a

path specification

1) Dependent on the data types used.

Tab. 0/4:

Data types used

Festo P.BE-CPX-FB36-EN en 1309NH English

XV

Contents and general instructions

XVI

Festo P.BE-CPX-FB36-EN en 1309NH English

Installation

Chapter 1

Installation

Festo P.BE-CPX-FB36-EN en 1309NH English

1-1

1. Installation

Table of contents

1.

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1.1

Installation instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1

Electrical connection and display elements . . . . . . . . . . . . . . . . . . .

1.1.2

Dismantling and mounting of the bus node . . . . . . . . . . . . . . . . . . .

Setting the DIL switches on the bus node . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1

Setting the operating mode and protocol . . . . . . . . . . . . . . . . . . . .

1.2.2

Setting the diagnostics mode for Remote I/O . . . . . . . . . . . . . . . . .

1.2.3

Setting the data field size for Remote Controller . . . . . . . . . . . . . . .

1.2.4

Setting IP addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting to the network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1

General information about networks . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2

Overview of connections, network connectors and cables . . . . . . .

1.3.3

Network connections of the CPX-FB36 . . . . . . . . . . . . . . . . . . . . . . .

1.3.4

Setting the IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.5

Advanced network settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ensuring protection classIP65/IP67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3

1-4

1-5

1-7

1-9

1-10

1-11

1-12

1-13

1-13

1-14

1-17

1-18

1-22

1-23

1-24

1.2

1.3

1.4

1.5

1-2

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

1.1

Installation instructions

Warning

Switch off the following components before undertaking

installation and/or maintenance work:

– Compressed air supply

– Operating voltage supply for electronics/sensors

– Load voltage supply for outputs/valves

In this way, you can avoid:

–

sudden uncontrolled movements of loose tubing

–

unexpected movements of the connected actuators

–

undefined switching states of the electronics

Caution

The CPX bus node contains electrostatically sensitive

devices.

• Therefore, do not touch any components.

• Observe the handling specifications for electrostatically

sensitive devices.

They will help you avoid damage to the electronics.

Note

Use protective caps or blanking plugs to seal unused connections. You will then comply with protection class

IP65/IP67 ( section 1.4).

Information about mounting the CPX terminal can be found in

the CPX system description ( P.BE-CPX-SYS).

Festo P.BE-CPX-FB36-EN en 1309NH English

1-3

1. Installation

1.1.1

Electrical connection and display elements

The following connection, setting and display components

can be found on the CPX bus node CPX-FB36:

1

4

3

2

1 Protocol and CPX-specific LEDs

3 DIL switch with transparent cover

2 Network connections X1 and X2

4 Service interface for operator unit

(one 4-pin M12 socket each, D-coded)

(CPX-MMI; V24 interface) und USB

adapter (for CPX-FMT)

Fig. 1/1: Connection, setting and display components on the bus node CPX-FB36

1-4

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

1.1.2

Dismantling and mounting of the bus node

The bus node is mounted in an interlinking block of the CPX

terminal.

1 Bus node

CPX-FB36

3

2 Interlinking block

with contact rails

1

3 Torx T10 screws

2

Fig. 1/2: Dismantling / mounting the bus node

Note

• Check the start behaviour of the CPX terminal before

replacing the bus node.

If the Modify LED (M) illuminates or flashes permanently

after the system start, “System start with saved parametrisation and saved CPX expansion” is set or “Force” is active. In this case parameterisation is not created automatically by the higher-order system when replacing the bus

node or CPX terminal during servicing.

• Therefore, verify which settings are required before re-

placement and restore these settings after replacement.

Festo P.BE-CPX-FB36-EN en 1309NH English

1-5

1. Installation

Dismantling the bus node 1. Loosen the four screws of the bus node with a Torx

screwdriver size T10.

2. Pull the bus node carefully and without tilting away from

the contact rails of the interlinking block.

Note

• Always use the correct screws for the interlinking block,

which depend on whether the block is made of metal or

plastic:

– for plastic interlinking blocks:

self-tapping screws

– for metal interlinking blocks:

screws with metric thread.

Both types of screws are enclosed respectively when ordering

the bus node as a single part.

Mounting the bus node

1. Check the seal and the sealing surfaces between the bus

node and interlinking block.

2. Place the bus node in the interlinking block without

tilting. Make sure that the corresponding slots with the

contacting terminals on the bottom of the bus node are

above the contact rails.

3. Push the bus node carefully and without tilting as far as

possible into the interlinking block.

4. Set the screws so that the self-cutting threads can be

used.

5. Tighten the screws alternately in diagonally opposite

sequence with a Torx screwdriver (size T10). Tightening

torque:0.9…1.1 Nm.

1-6

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

1.2

Setting the DIL switches on the bus node

The DIL switches on the bus node are used to change the

following settings.

1 DIL switch

group 1:

Operating mode

and protocol

1

2

2 DIL switch

3

group 2:

Diagnostics mode

for remote I/O or

number of I/O

bytes for Remote

Controller

3 DIL switch

group 3:

IP addressing

Fig. 1/3: DIL switches on the bus node

Changes to the DIL switches only take effect when the bus

node is restarted.

The DIL switch cover must be removed to change the settings.

Caution

The CPX bus node contains electrostatically sensitive

devices.

• Do not therefore touch any contacts.

• Observe the handling specifications for electrostatically

sensitive devices.

This will help you avoid damage to the bus node electronics.

Festo P.BE-CPX-FB36-EN en 1309NH English

1-7

1. Installation

Procedure

1. Switch off the power supply.

2. Remove the DIL switch cover.

3. Change the DIL switch settings ( section1.2.1 ff.).

4. Mount the cover.

Remove the DIL switch cover

1. Unscrew the two mounting screws in the switch cover.

2. Lift off the cover.

Mounting the DIL switch cover

1. Place the cover carefully on the bus node.

Note

• Make sure that the seal is seated correctly.

2. Tighten the two mounting screws at first by hand and

then with a max. tightening torque of 0.4 Nm.

1-8

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

1.2.1

Setting the operating mode and protocol

•

Use DIL switch group 1 ( Fig. 1/1 1).

Operating mode and protocol

Setting of DIL switch group 1

Remote I/O operating mode

All functions of the CPX terminal are controlled

directly via EtherNet/IP or Modbus TCP.

A CPX-FEC or CPX-CEC that may be integrated

into the CPX terminal works as a passive function

module without controller.

DIL 1.1: OFF

(factory setting)

Operating mode Remote Controller

A CPX-FEC or CPX-CEC integrated into the CPX

terminal takes over I/O control.

DIL 1.1: ON

EtherNet/IP protocol

The CPX terminal uses the EtherNet/IP protocol.

DIL 1.2: OFF

(factory setting)

Modbus TCP protocol

The CPX terminal uses the Modbus/TCP

protocol.

DIL 1.2: ON

Tab. 1/1:

Setting the operating mode and protocol

Setting the diagnostics mode is required for the Remote I/O

operating mode ( chapter1.2.2).

Setting the data field size is required for the Remote Controller operating mode ( chapter1.2.3).

Festo P.BE-CPX-FB36-EN en 1309NH English

1-9

1. Installation

1.2.2

Setting the diagnostics mode for Remote I/O

•

Use DIL switch group 2 ( Fig. 1/1 2).

The functions of these DIL switches depend on the set operating mode of the CPX terminal ( Tab. 1/1).

Diagnostics mode for the Remote I/O operating

mode

Setting of DIL switch group 2

The I/O diagnostic interface and the status bits are

switched off

(+ 0 I/O bits)

2.1: OFF

2.2: OFF

(factory setting)

Status bits are switched on

(+ +16 E-bits (8 used))

2.1: OFF

2.2: ON

The I/O diagnostic interface is switched on 1)

(+ 16 I/O bits)

2.1: ON

2.2: OFF

Reserved

2.1: ON

2.2: ON

1) The I/O diagnostic interface occupies an additional 16 I/O bits.

Tab. 1/2:

Setting of the diagnostics mode for the Remote I/O operating mode

During subsequent activation of the diagnostics module

(status bits or I/O diagnostics interface), the CPX-internal I/O

image can be displaced.

The system controller carries out this adjustment automatically. Manual manipulation, e.g. reconfiguration of the CPX

terminal or manual adaptation of the hardware and network

configuration are not required.

1-10

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

1.2.3

Setting the data field size for Remote Controller

•

Use DIL switch group 2 ( Fig. 1/1 2).

The functions of these DIL switches depend on the set operating mode of the CPX terminal ( Tab. 1/1).

Number of I/O bytes for the Remote Controller

operating mode

Setting of DIL switch group 2

8 byte I/8 byte O for communication of the bus node

with the CPX-FEC or CPX-CEC.

2.1: OFF

2.2: OFF

(factory setting)

Reserved

2.1: ON

2.2: OFF

16 byte I/16 byte O for communication of the bus node

with the CPX-FEC or CPX-CEC.

2.1: OFF

2.2: ON

Reserved

2.1: ON

2.2: ON

Tab. 1/3:

Setting the number of I/O bytes for the Remote Controller operating mode

The assignment of the I/O addresses and diagnostics addresses can be changed as needed by using the configuration

and programming software (e.g. Rockwell RSLogix).

Festo P.BE-CPX-FB36-EN en 1309NH English

1-11

1. Installation

1.2.4

Setting IP addressing

•

Use DIL switch group 3 ( Fig. 1/1 3).

By using DIL switch group 3 you can set the type of addressing or the IP address of the bus node.

•

Set all slide switches to “OFF”, so that when the bus node

is switched on it receives a dynamic or saved IP address

( section1.3.4).

•

Use DIL switches 1 ... 8 to define a binary number other

than 0 and 255.

This number is used as part of the IP address when turning on the bus node.

Tab. 1/4:

8

7

6

Setting:

Host ID of

the IP address

2

3

4

5

Setting:

All switches OFF

(factory setting)

Fixed addressing

1

1

2

3

4

5

6

7

8

Dynamic/saved addressing

Settings for addressing type or IP address

Dynamic addressing is set via DHCP/BOOTP by default.

If all of the switches in DIL switch group 3 are set to “ON”

when switching on the bus node, all IP parameters will be

reset to the factory setting.

•

1-12

Note the detailed information on addressing in section 1.3.4.

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

1.3

1.3.1

Connecting to the network

General information about networks

Note

Sub-assemblies with Ethernet interfaces should only be

operated in networks if all connected network components

are supplied by PELV power supplies or integrated power

supplies with equivalent protection.

Installation guidelines

The installation guidelines can be obtained via the ODVA user

organisation:

Internet: http://www.odva.org

Observe the instructions in these documents.

Use of switches and routers

The switch integrated in the bus node permits division of the

network into several segments.

With use of additional switches and routers, the network can

be divided into additional segments. Thus, it is possible to

structure the network and realise greater network expansions.

Independent of the network structure, the expansion of a

network segment must not exceed certain connection

lengths.

–

Festo P.BE-CPX-FB36-EN en 1309NH English

Copper connecting cable:

(Ethernet twisted pair cable, 22 AWG):

max. 100 m between network participants

1-13

1. Installation

Switches and routers for Industrial Ethernet are available on

the market from various companies. There are many IP20,

IP65 or IP67 components.

1.3.2

–

Unmanaged Switches:

for small network solutions with a low network load or

minimal requirements for deterministics

–

Managed Switches:

for comprehensive network solutions, with diagnostics

and monitoring functions

Overview of connections, network connectors and cables

Note

Faulty installation and high transmission rates may cause

data transmission errors as a result of signal reflections

and attenuations.

Transmission errors can be caused by:

– faulty screened connection

– branches

– transmission over distances which are too long

– inappropriate cables

Observe the cable specification!

Bus nodes

Connection technology

Network connectors

CPX-FB36

2 x M12 socket, D-coded, female, 4-pin,

corresponding to IEC 61076-2

Festo connector,

type NECU-M-S-D12G4-C2-ET

Internet: www.festo.com/catalogue/

Tab. 1/5:

1-14

Overview of connection technology and network plugs

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

RJ45 to M12 converter

For EtherNet/IP installations, it may be necessary to change

between RJ45- and M12 connection technology.

Example:

Connections between devices in the control cabinet with RJ45

connection and IP65/IP67 devices with M12 connection.

Cable specification

Use shielded Industrial Ethernet lines of category

Cat 5/Cat 5e or higher ( Tab. 1/6).

Crossover detection

The CPX bus node supports the “Crossover detection” function (Auto-MDI/MDI-X). Patch cables or crossover cables can

be optionally used for connecting the bus node to your network or a PC. The CPX-FB36 automatically adapts the protective circuit of network connections X1 and X2.

Note

If the “QuickConnect” function has been activated ( section 2.1.2 ), the crossover detection function is not available.

In this case the CPX-FB36 sets the pin allocation of network

connection X2 to “Crossover”.

•

Festo P.BE-CPX-FB36-EN en 1309NH English

Use suitable cables when the crossover detection function

is deactivated:

–

Crossover cable with the same port assignment as the

connected equipment

–

Patch cable with a different port assignment to the

connected equipment

1-15

1. Installation

CPX-FB36 + ...D12G4...

Cable specification1)

Cable type

Ethernet twisted pair cable, shielded (Shielded Twisted Pair, STP)

Transmission class

Category Cat 5/Cat 5e (link class)

Cable diameter

6 ... 8 mm

Wire cross section

0.14 ... 0.75 mm2; 22 AWG2)

Connection length

max. 100 m

1) Length corresponding to specification for EtherNet/IP networks (EtherNet/IP Installation Guide),

based on ISO/IEC 11801, ANSI/TIA/EIA-568 ( section 1.3.1)

Internet: www.odva.org

2) Required for max. connection length between network participants

Tab. 1/6:

Cable specification overview

Note

When mounting the CPX terminal on a moving part of a

machine:

• Make sure that the network cables are provided with

strain relief.

• Comply with the corresponding regulations set out in

EN 60204 part 1.

1-16

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

1.3.3

Network connections of the CPX-FB36

There are two 4-pin, D-coded M12 sockets on the bus node

for the network connection.

The sockets are compatible with SPEEDCON® plugs.

Network connection X1

Connect the CPX-FB36 via connection X1.

•

M12 socket

EtherNet/IP

Tab. 1/7:

Pin allocation

Signal

Pin equivalent with

RJ45 plug

1. TX+

2. RX+

3. TX–

4. RX–

Housing

Transmitted data+

Received data+

Transmitted data–

Received data–

Screening, FE

1

3

2

6

Pin allocation of network connection X1 on the CPX-FB36 (M12 4-pin)

Network connection X2

Connect the CPX-FB36 to the next device via connection X2.

•

M12 socket

EtherNet/IP

Tab. 1/8:

Pin allocation

Signal

Pin equivalent with

RJ45 plug

1. RX+

2. TX+

3. RX–

4. TX–

Housing

Received data+

Transmitted data+

Received data–

Transmitted data–

Screening, FE

3

1

6

2

Pin allocation of network connection X2 on the CPX-FB36 (M12 4-pin)

Note

When crossover detection is activated, the bus node automatically exchanges the RX and TX connections.

Festo P.BE-CPX-FB36-EN en 1309NH English

1-17

1. Installation

Connection with plug from Festo

The CPX terminal is connected to the network with Festo

plugs, type NECU-M-S-D12G4-C2-ET.

The plugs are designed for network cables measuring

6...8 mm in diameter.

To comply with protection class IP65/IP67:

1.3.4

•

Use Festo plugs

•

Seal unused interfaces ( section1.4)

Setting the IP address

The IP address of bus node CPX-FB36 is alternatively set via:

–

Dynamic addressing via DHCP/BOOTP (factory setting)

–

Saved network settings

–

Addressing via DIL switch

Note

When changes are made to the network settings of the

CPX-FB36 via DIL switch, the Modify LED “M” flashes yellow.

• Perform a restart of the bus node so that the modified

network settings are applied.

1-18

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

Dynamic addressing via DHCP/BOOTP

•

Make sure that a DHCP/BOOTP server is located in the

network.

To set the dynamic addressing:

1. Set all switches of DIL switch group 3 to OFF

( Tab. 1/4).

2. Alternatively activate DHCP/BOOTP in the bus node via:

–

Operator unit CPX-MMI

–

Programme “Festo Maintenance Tool” (CPX-FMT)

–

Programme “BOOTP-DHCP Server” from Rockwell

Automation

Saved network settings

The CPX-FB36 offers the option to save the network settings

in a non-volatile memory of the bus node. DHCP/BOOTP is

thereby deactivated.

1. Set all switches of DIL switch group 3 to OFF

( Tab. 1/4).

2. Alternatively change the network settings via:

–

Operator unit CPX-MMI

–

Programme “Festo Maintenance Tool” (CPX-FMT)

–

Programme “BOOTP-DHCP Server” from Rockwell

Automation

Use this setting to activate the storage of network settings in

a non-volatile memory of the bus node.

Festo P.BE-CPX-FB36-EN en 1309NH English

1-19

1. Installation

Addressing via DIL switch

Tip

When addressing via DIL switch the bus node obtains a fixed

IP address.

This setting is recommended for test purposes during commissioning or for small networks.

The IP address of the bus node consists of 4 octets:

–

Octets 1 ... 3 (saved in the bus node)

–

Octet 4 through the setting of DIL switch group 3

( Tab. 1/9)

•

Use DIL switch group 3 to define a binary number

between 1 and 254. This number is then used as the 4th

octet of the IP address when turning on the bus node.

Tab. 1/9:

8

7

6

21 + 22 + 25 =

2 + 4 + 32 =

38

2

3

4

5

20 + 22 =

1+4=

5

Example with IP address:

192.168.001.038

1

1

2

3

4

5

6

7

8

Example with IP address:

192.168.001.005

Examples of fixed values for the 4th octet of the

IP address (binary coded)

If all of the switches in DIL switch group 3 are set to “ON”

when switching on the bus node, all IP parameters will be

reset to the factory setting.

1-20

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

Factory settings of the CPX-FB36

IP address - octet 1 ... 3

192.168.1

IP address - octet 4

01)

Network mask

255.255.255.0

Gateway

0.0.0.0

1) Dynamic addressing via DHCP/BOOTP

Tab. 1/10:

•

Factory settings of the CPX-FB36

Alternatively change the first 3 octets of the IP address

via:

–

Operator unit CPX-MMI

–

Festo Maintenance Tool CPX-FMT

–

Access to corresponding EtherNet/IP objects

The network mask and gateway are set by using the corresponding CPX parameters.

Festo P.BE-CPX-FB36-EN en 1309NH English

1-21

1. Installation

1.3.5

Advanced network settings

The following settings for the network connection can be implemented via Ethernet link objects ( appendixC.2.4).

Automatic setting

When set to the factory setting the CPX-FB36 automatically

detects the baud rate and duplex mode.

Baud rate

Setting via attribute 6 (Forced Interface Speed) of the Ethernet link object:

–

10 Mbit/s

–

100 Mbit/s

Duplex mode

Setting via attribute 6 (Control Bits, Bit 1) of the Ethernet link

object:

1-22

–

Half-Duplex

–

Full-Duplex

Festo P.BE-CPX-FB36-EN en 1309NH English

1. Installation

1.4

Ensuring protection classIP65/IP67.

In order to comply with protection class IP65/IP67, seal any

unused sockets with the appropriate plugs or cover caps.

Connection

Port IP65/IP67

Cover IP65/IP67 1)

X1, X2 (M12)

Festo connector,

type NECU-M-S-D12G4-C2-ET

Cover cap from Festo,

type ISK-M12

Service interface (M12) for

CPX-MMI + CPX-FMT

Connecting cable and plug

of the CPX-MMI or CPX-FMT

Cover cap from Festo,

type ISK-M12 2)

1) if connection is not used

2) included in scope of delivery, always cover unused connection

Tab. 1/11:

Connections and covers for protection class IP65/IP67

Festo P.BE-CPX-FB36-EN en 1309NH English

1-23

1. Installation

1.5

Power supply

Warning

Electric shock

Injury to people, damage to the machine and system

• For the electrical power supply, use only PELV circuits in

accordance with IEC 60204-1 (Protective Extra-Low

Voltage, PELV).

• Observe the general requirements in accordance with

IEC 60204-1 for PELV circuits.

• Use only voltage sources that guarantee a reliable elec-

tric disconnection of operating and load voltage in accordance with IEC 60204-1.

• Always connect all circuits for the operating and load

voltage supplies UEL/SEN, UVAL and UOUT.

The current consumption of a CPX terminal depends on the

number and type of integrated modules and components.

Observe the information on power supply ( electrical connection) as well as on the earthing measures to be carried out

( potential equalisation) contained in the CPX system description.

1-24

Festo P.BE-CPX-FB36-EN en 1309NH English

Preparing for commissioning

Chapter 2

Preparing for commissioning

Festo P.BE-CPX-FB36-EN en 1309NH English

2-1

2. Preparing for commissioning

Table of contents

2.

Preparing for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2.1

EtherNet/IP protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1

Multicast telegram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2

QuickConnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.3

Device Level Ring protocol (DLR) . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus/TCP protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes on commissioning the CPX-FB36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1

Requirements for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2

Switching on the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3

Normal operating status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Participants in the network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1

Participant properties (EDS file) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3

2-3

2-4

2-8

2-10

2-11

2-11

2-12

2-12

2-16

2-16

2.2

2.3

2.4

2-2

Festo P.BE-CPX-FB36-EN en 1309NH English

2. Preparing for commissioning

2.1

EtherNet/IP protocol

EtherNet/IP is an industrial Ethernet protocol, which is predominantly used in automation technology.

The EtherNet/IP protocol is activated with DIL

switch 1.2 = OFF. The bus node is then identified with the

designation: FB36 - EtherNet IP Remote-IO

After switching the protocol ( section 1.2.1) the following

unmodified parameters are available:

–

IP address

–

Diagnostics mode

–

System parameters

The DIL switch function remains unchanged.

Retentive bus-specific parameters are only active if the relevant protocol is selected ( section 1.2.1).

Parameterisation examples can be found in appendix C.5.

2.1.1

Multicast telegram

EtherNet/IP uses IP Multicast telegrams as standard for

transferring process data. An advantage of Multicast compared to Unicast is that a telegram can be received by multiple participants.

Simple switches, however, cannot distinguish to which participant a Multicast telegram is to be transferred. Therefore,

these switches send the Multicast telegrams to all devices in

the network.

This results in an EtherNet/IP participant receiving numerous

unnecessary telegrams, which must then be discarded from

the device. This can reduce the response times of the participants. The demand on the network bandwidth increases.

Festo P.BE-CPX-FB36-EN en 1309NH English

2-3

2. Preparing for commissioning

This does not pose a problem for smaller networks; the performance for larger networks, however, can be improved with

the following functions and/or protocols.

–

Use of switches with “IGMP snooping”

–

Segmentation of the network

Switches with “IGMP snooping”

By using an IGMP (Internet Group Management Protocol) the

switches are able to decide to which devices the various Multicast telegrams are transferred. This allows unnecessary

Multicast traffic to be avoided.

•

Activate this function in all switches/routers used.

•

Configure at least one switch so that cyclical IGMP queries are sent. The IGMP snooping function cannot work

properly without these IGMP queries.

Segmentation of the network

•

2.1.2

Split the machine into smaller network segments. This can

be realised without changing the network cabling, for

example, by using VLANs.

QuickConnect

The EtherNet/IP function QuickConnect (QC) enables a quicker initialisation of the CPX terminal and a fast connection setup to the EtherNet/IP master.

QuickConnect is commonly used for applications with a tool

change, for which the downtime should be minimised by the

disconnection and connection of devices.

2-4

Festo P.BE-CPX-FB36-EN en 1309NH English

2. Preparing for commissioning

Note

QuickConnect only works if this function is supported by

all participating devices.

• Make sure that intermediate switches and routers in

your network support this function.

Using QuickConnect:

•

•

Deactivate Auto-Negotiation in the bus node for both network connections X1 and X2.

–

Baud rate = 100 Mbit/s

–

Duplex mode = Full-Duplex

Attribute 6d of the Ethernet link object (Interface Control).

Deactivate Auto-Negotiation and crossover detection for

the corresponding network connection of the counterpart

station (e.g. switch connection).

–

Baud rate for connection of the counterpart station =

100 Mbit/s

–

Duplex mode = Full-Duplex

•

Activate QuickConnect via attribute 12 of the TCP/IP interface object. (The QuickConnect function in the bus node is

in a deactivated state when delivered.)

•

Activate QuickConnect in the PLC or in the control program.

Simplified configuration of QuickConnect on CPX-FB36:

•

Set the CPX parameter “IP configuration” to

“With saved parameters and QuickConnect”.

Selecting this setting activates QuickConnect and deactivates

Auto-Negotiation for both network connections.

Festo P.BE-CPX-FB36-EN en 1309NH English

2-5

2. Preparing for commissioning

Crossover detection is automatically deactivated in the bus

node when Auto-Negotiation is deactivated.

Network connection X1 runs in the MDI-mode here and network connection X2 runs in the MDI-X mode.

This allows a line topology to be constructed with patch

cables.

TP1

X2

X1

MDI MDIX

TP2

1

1 PLC or switch

2

X2

X1

MDI MDIX

X2

X1

MDI MDIX

3

3 I/O device (e.g.B. CPX-FB36)

2 Patch cable

Fig. 2/1: QuickConnect line topology with patch cables

The bus node corresponds to a Class A device of the EtherNet/IP specification. When switched on, the bus node requires less than 350 ms to accept a TCP connection.

Note

Due to the rapid establishment of the TCP connection, the

detection of already used IP addresses (IP Address Conflict Detection, ACD) is not executed completely. This can

lead to multiple assigned IP addresses only being detected

at a late stage. This can impair the function of the network.

2-6

Festo P.BE-CPX-FB36-EN en 1309NH English

2. Preparing for commissioning

QuickConnect is available for the following modules.

CPX modules

Type

Bus node CPX-FB36

CPX-FB36

Digital 4-off input module

CPX-4DE

Digital 8-off input module

CPX-8DE

Digital 8-off input module with

channel diagnostics

CPX-8DE-D

Digital 8-off input module, n-switching

CPX-8NDE

Digital 16-off input module

CPX-16DE

Digital 16-off input module with channel diagnostics

CPX-16DE-D

Digital 16-off input module

with terminal strip

CPX-L-16DE16-KL-3POL

Digital 4-off output module

CPX-4DA

Digital 8-off output module

CPX-8DA

Digital 8-off output module,

high-current variant

CPX-8DA-H

Digital 8-off input/output module

CPX-8DE-8DA

Digital 16-off input/output module with terminal

strip

CPX-L-8DE-8DA16-KL-3POL

Analogue 2-off input module

(voltage/current)

CPX-2AE-U-I

Analogue 2-off output module

(voltage/current)

CPX-2AA-U-I

Analogue 4-off input module (current)

CPX-4AE-I

Tab. 2/1:

Festo P.BE-CPX-FB36-EN en 1309NH English

CPX modules which support QuickConnect

2-7

2. Preparing for commissioning

QuickConnect is available for the following pneumatics interfaces and modules.

Pneumatic interfaces

Type

Pneumatics interface for VTSA or

VTSA-F pneumatics

VABA-10S6-x1

Pneumatics interface for MPA-S valves

VMPA-FB-EPL-...

Pneumatics interface for MPA-F valves

VMPAF-FB-EPL-...

Pneumatics interface for MPA-L valves

VMPAL-FB-EPL-...

VMPAL-EPL-CPX

Tab. 2/2:

Pneumatic modules

Type

MPA1 pneumatic module

VMPA1-FB-EM...-8

MPA2 pneumatics module

VMPA2-FB-EM...-4

MPA1 pneumatics module with diagnostic

function

VMPA1-FBEM...-D2-8

MPA2 pneumatics module with diagnostic

function

VMPA2-FBEM...-D2-8

Tab. 2/3:

2.1.3

Pneumatics interfaces which support

QuickConnect

Pneumatics modules which support

QuickConnect

Device Level Ring protocol (DLR)

The Device Level Ring protocol (DLR) allows multiple devices

to be operated in a ring topology.

Requirements

All DLR devices feature an integrated Ethernet switch with at

least 2 external ports and support the DLR Protocol.

2-8

Festo P.BE-CPX-FB36-EN en 1309NH English

2. Preparing for commissioning

Ring

Supervisor

Ring

Ring

Node 4

Node 1

Ring

Ring

Node 3

Node 2

Fig. 2/2: Device Level Ring topology, example

The availability of the network can be increased by using ring

topology as there are redundant communication paths

between two devices. A cable or communication fault

between two devices will therefore not result in communication failure. Only two faults in a ring will lead to a malfunction.

A ring always consists of at least one ring supervisor and any

number of ring nodes.

•

Only use DLR-compatible devices in a ring.

Otherwise, the time required for automatic elimination of

a fault may be adversely affected.

•

Operate the bus node as a ring node either in a beaconbased or announce-based configuration.

Operation as a ring supervisor is not possible. This function is normally executed by an EtherNet/IP scanner.

The DLR protocol is configured via the DLR object (class

code 47h).

Festo P.BE-CPX-FB36-EN en 1309NH English

2-9

2. Preparing for commissioning

2.2

Modbus/TCP protocol

Modbus is an open communication protocol based on the

master-slave architecture. This is a standard for communication via TCP/IP in automation technology.

The Modbus/TCP protocol is activated with DIL

switch 1.2 = ON. The bus node is then identified with the designation: FB36-MB - Modbus TCP Remote-IO

After switching the protocol ( section 1.2.1) the following

unmodified parameters are available:

–

IP address

–

Diagnostics mode

–

System parameters

The DIL switch function remains unchanged.

Retentive bus-specific parameters are only active if the relevant protocol is selected ( section 1.2.1).

The configuration options via Modbus TCP correspond to

those via EtherNet/IP.

Exception: EtherNet/IP objects cannot be accessed via Modbus TCP.

In order to configure the CPX terminal for Modbus/TCP, you

will require the Modbus addresses of the data and of the I/Os

of the CPX terminal ( appendix D).

Addressing examples can be found in appendix D.6.1.

2-10

Festo P.BE-CPX-FB36-EN en 1309NH English

2. Preparing for commissioning

2.3

Notes on commissioning the CPX-FB36

Configuration of the CPX terminal demands a very accurate

procedure, as different configuration specifications are sometimes necessary for each station in the network, due to the

modular structure.

Detailed instructions and further information can be found in

the documentation or online help for the controller or control

program.

Note

Bus node CPX-FB36 can be used on all EtherNet/IP or

Modbus/TCP controllers.

The following section describes the configuration and

commissioning procedure using the example of

Rockwell/Allen-Bradley controllers (PLC) via the Rockwell

RSLogix software platform.

2.3.1

Requirements for commissioning

–

Installation of the bus node is complete ( chapter 1)

–

The DIL switches of the bus node are set correctly.

–

All connecting cables are connected and checked.

Festo P.BE-CPX-FB36-EN en 1309NH English

2-11

2. Preparing for commissioning

2.3.2

Switching on the power supply

Warning

Before switching on:

• Make sure that the requirements for commissioning

have been met. Also observe section 3.1.2, especially

regarding the DIL switch setting.

During operation:

• Do not alter the DIL switch setting. This will prevent acci-

dental and uncontrolled movements of the connected

actuators and undefined switching states of the electronics.

Note

• Please observe the switching-on instructions in the

manual for your controller.

2.3.3

Normal operating status

When the CPX terminal is switched on the status LEDs

( Fig. 4/1) indicate the operating status and correct function of the bus node and of fieldbus communication as a function of the configuration.

–

Bus node not configured Tab. 2/4

–

Bus node configured and higher-order PLC is in stop

mode Tab. 2/5

–

Bus node configured and higher-order PLC is in run mode

Tab. 2/6

Information on diagnostics using the LED displays can be

found in section 4.2.

2-12

Festo P.BE-CPX-FB36-EN en 1309NH English

2. Preparing for commissioning

Bus node not configured

LED display

Status and significance

MS illuminates green:

– Device is ready to operate

PS illuminates green:

– Voltage supply (Power System, PS) is OK

– Operating voltage present

(in the approved range)

NS flashes green:

– Fieldbus communication present (“Online”

operating status), but not configured.

This is correct in this case because the bus node

is not configured.

PL illuminates green:

– Load voltage present (in the approved range) 1)

TP1/TP2 illuminates green:

– Device is correctly connected to the bus node

– Internal communication between bus node and

device 1 or device 2 is error free

– Operating and load voltage present (in the approved range) 1)

1) Display dependent on monitoring and signal from the connected

device.

Tab. 2/4:

Festo P.BE-CPX-FB36-EN en 1309NH English

Status LEDs after switching on –

bus node not configured

2-13

2. Preparing for commissioning

Bus node configured - PLC in stop mode

LED display

Status and significance

MS illuminates green:

– Module status (MS) is error free

PS illuminates green:

– Voltage supply (Power System, PS) is OK

– Operating voltage applied

(in the approved range)

NS illuminates green:

– Network status (NS) is error free (“Online”

operating status)

– Communication with the fieldbus and with the

PLC is OK

PL illuminates green:

– Load voltage present (in the approved range) 1)

TP1/TP2 illuminates green:

– Device is correctly connected to the bus node

– Internal communication between bus node and

device 1 or device 2 is error free

– Operating and load voltage present (in the

approved range) 1)

1) Display dependent on monitoring and signal from the connected

device.

Tab. 2/5:

2-14

Status LEDs after switch on – bus node

configured, PLC in stop mode

Festo P.BE-CPX-FB36-EN en 1309NH English

2. Preparing for commissioning

Bus node configured - PLC in run mode

LED display

Status and significance

MS illuminates green:

– Module status (MS) is error free

PS illuminates green:

– Voltage supply (Power System, PS) is OK

– Operating voltage applied

(in the approved range)

NS illuminates green:

– Network status (NS) is error free (“Online”

operating status)

– Communication with the fieldbus and with the

PLC is OK

PL illuminates green:

– Load voltage present (in the approved range) 1)

TP1/TP2 illuminates green:

– Device is correctly connected to the bus node

– Internal communication between bus node and

device 1 or device 2 is error free

– Operating and load voltage present (in the

approved range) 1)

1) Display dependent on monitoring and signal from the connected

device.

Tab. 2/6:

Festo P.BE-CPX-FB36-EN en 1309NH English

Status LEDs after switch on – bus node

configured, PLC in run mode

2-15

2. Preparing for commissioning

2.4

Participants in the network

When using the CPX terminal as a new network participant for

the first time, the configuration program is to be informed of

certain network properties.

These network properties are integrated into the participant

properties.

2.4.1

Participant properties (EDS file)

The participant properties are predominantly managed by the

configuration program in a list or library e. g. EDS library (EDS

for electronic data sheet).

The following options are available for expanding an EDS library:

–

Installing EDS files

–

Entering participant properties manually

–

Importing participant properties

When the CPX terminal has been registered as a potential

network participant, it can be added to a network.

2-16

Festo P.BE-CPX-FB36-EN en 1309NH English

Commissioning

Chapter 3

Commissioning

Festo P.BE-CPX-FB36-EN en 1309NH English

3-1

3. Commissioning

Table of contents

3.

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1

3.1

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1

Configuration with EDS file . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2

Configuration with Generic Ethernet Module . . . . . . . . . . . . . . . . . .

3.1.3

Configuration with CPX-FMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4

Configuration in the Remote Controller operating mode . . . . . . . .

3.1.5

Setting up a listen-only connection . . . . . . . . . . . . . . . . . . . . . . . . .

Parameterisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.1

Parameterisation when switching on (system start) . . . . . . . . . . . .

3.2.2

Methods of parameterisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2.3

Parameterisation via configuration data . . . . . . . . . . . . . . . . . . . . .

3.2.4

Parameterisation with the operator unit CPX-MMI . . . . . . . . . . . . .

3.2.5

Parameterisation in the PLC user program . . . . . . . . . . . . . . . . . . .

3.2.6

Parameterisation using CPX-FMT and system start with saved

parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reaction of the outputs in the Fail safe or Idle mode . . . . . . . . . . . . . . . . . . .

Web server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checklist for commissioning a CPX terminal . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3

3-4

3-10

3-15

3-19

3-20

3-21

3-22

3-25

3-26

3-26

3-26

3.2

3.3

3.4

3.5

3-2

3-27

3-28

3-29

3-30

Festo P.BE-CPX-FB36-EN en 1309NH English

3. Commissioning

3.1

Configuration

A CPX terminal with bus node CPX-FB36 can be configured

using various methods.

Method

Description

Benefits

Disadvantages

Configuration with EDS

file

section 3.1.1

Installation of

participant properties

for the CPX terminal in

the “RSLogix 5000”

configuration program.

– With the exception

of the I/O data

length, the entire

configuration is

transferred from the

EDS file.

– Not available with all

EtherNet/IP

masters.

– Parameterisation is

saved locally in the

CPX terminal and is

lost if the terminal is

replaced.1)

Configuration with

Generic Ethernet

Module

section 3.1.2

Creation of a new

participant and manual

configuration in the

“RSLogix 5000”

configuration program.

– Works with all

versions of RSLogix.

– All settings must be

entered manually.

Configuration with

CPX-FMT

section 3.1.3

Export of the CPX

terminal settings by

CPX-FMT and import of

the settings to the

“RSLogix 5000”

configuration program.

– Transfer of the

existing

configuration of the

participant and

parameterisation of

the CPX Terminal.

Tab. 3/1:

Configuration methods

Festo P.BE-CPX-FB36-EN en 1309NH English

3-3

3. Commissioning

3.1.1

Configuration with EDS file

This section describes the commissioning procedure for

EtherNet/IP with an Allen-Bradley controller and the “RSLogix

5000” program from Rockwell.

The fundamental aspects of this description also apply for

other control systems.

Obtaining EDS files

•

Use the following EDS files for the CPX terminal with

CPX-FB36.

File type File name

Language

Description

EDS

English

Provides the communication adapter in the

configuration program.

File with information for the Remote Controller

operating mode.

–

Icon file for representing the CPX terminal or

mode in the configuration program.

cpx_FB36.eds

cpx_FB36RC.eds

ICO

Tab. 3/2:

EDS- files

cpx_FB36.ico

Configuration files for CPX-FB36

Source www.festo.com/sp

1. Enter “CPX-FB36” in the search field.

2. Select the “Firmware and drivers” tab.

3. Click “Device description file”.

4. Select a directory and save the ZIP file.

Icon files

3-4

Use icon files (included in the ZIP file) to assign icons to the

CPX terminal and CPX modules.

(Dependent on the configuration program used).

Festo P.BE-CPX-FB36-EN en 1309NH English

3. Commissioning

Registering the EDS file in RSLogix

1. Start the program RSLogix.

2. Launch the EDS wizard by selecting “EDS Hardware Installation Tool” from the “Tools” menu.

1

1 Menu command “EDS Hardware Installation Tool”

Fig. 3/1: Launching the EDS wizard

3. Select the option “Register an EDS-file(s)”.

Festo P.BE-CPX-FB36-EN en 1309NH English

3-5

3. Commissioning

Fig. 3/2: EDS wizard - Options

4. Click the “Next >” button.

Fig. 3/3: EDS wizard with selected EDS file

3-6

Festo P.BE-CPX-FB36-EN en 1309NH English

3. Commissioning

5. Select one of the following options:

–

Register a single file

–

Register a directory of EDS files

6. Click “Browse” to select the directory and name of the

EDS file.

7. Click the “Next >” button.

The procedure for registering the bus node in “RSLogix” is

complete.

Integrating participants in a project

The integration of the bus node in a new RSLogix project can

only be implemented if there is no online connection between

RSLogix and the controller ( “Communications” “Go

offline”).

1. In the “Controller Organizer” window of the “RSLogix

5000” program, right-click on “Ethernet” under the “I/O

Configuration” branch.

Fig. 3/4: Context menu in the “Controller Organizer”

window

Festo P.BE-CPX-FB36-EN en 1309NH English

3-7

3. Commissioning

2. Select the command “New Module...” from the context

menu.

This opens the dialogue window “Select Module Type”.

3. Select the “Catalog” tab and choose the module with the

description “CPX-FB36 Ethernet Module” from the bottom

table.

Fig. 3/5: Integrating bus node CPX-FB36

4. Confirm your selection by pressing “Create”.

Configuring a participant

1. In the “Controller Organizer” window right-click on the

newly integrated module and select the “Properties” command in the context menu.

This opens the dialogue window “Module Properties”.

2. Check and alter the IP address if necessary.

3. Click the “Change” button.

This opens the dialogue window “Module Definition”.

3-8

Festo P.BE-CPX-FB36-EN en 1309NH English

3. Commissioning

4. Enter the correct length of the CPX I/O data in the “Size”

field.

This value can either be calculated or retrieved using

CPX-FMT or a web server.

The basic configuration of the CPX terminal in the project is

now complete.

•

Festo P.BE-CPX-FB36-EN en 1309NH English

Parameterise the modules and valve terminals used in the

CPX terminal ( chapter 3.2).

3-9

3. Commissioning

3.1.2

Configuration with Generic Ethernet Module

This section describes the manual configuration process of a

participant via the “RSLogix” program using a “Generic Ethernet Module”.

Integrating participants in a project

The integration of the bus node in a new RSLogix project can

only be implemented if there is no online connection between

RSLogix and the controller ( “Communications” “Go

offline”).

1. In the “Controller Organizer” window of the “RSLogix”

program, right-click on “Ethernet” under the “I/O Configuration” branch ( Fig. 3/4).

2. Select the option “New Module” from the context menu.

This opens the dialogue window “Select Module Type”.

3. Select the “Catalog” tab and choose the module with the

description “Generic Ethernet Module” from the bottom

table.

Fig. 3/6: Integrating a bus node as a Generic Ethernet

Module

3-10

Festo P.BE-CPX-FB36-EN en 1309NH English

3. Commissioning

4. Confirm your selection by pressing “Create”.

Configuring a participant

1. In the “Controller Organizer” window right-click on the