Enhance MOSFET Cooling with Thermal Vias

advertisement

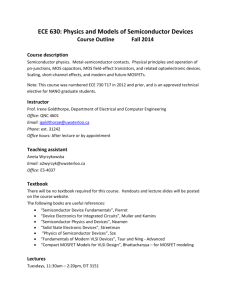

Enhance MOSFET Cooling with Thermal Vias Bottom-side cooling enables MOSFET heat transfer through the pc board to a heatsink. This decreases MOSFET junction temperatures while reducing the required area and thermal stress on the board. By Christopher Hill, Senior Applications Engineer, PowerMOS Product Line, and Norman Stapelberg, International Product Marketing Manager, PowerMOS Product Line, Philips Semiconductors, Hazel Grove, United Kingdom I n most modern power semiconductor applications there is a need to carefully manage heat. This is true in fields as diverse as mobile communications, PC motherboards, telecom power converters and industrial motor drives. Typically, the MOSFETs used as power switches in such applications are a significant source of heat, and the heat energy dissipated by these components must be carefully controlled if safe operating temperatures are to be maintained. To remove the heat from a power MOSFET, a thermally conductive pathway from the MOSFET to ambient is needed, which usually includes some form of heatsink. There are two conventional approaches to achieving this goal. The first approach is to use a MOSFET in a leaded package such as a TO-220. The package may be mounted on a heatsink or chassis, which allows for efficient removal of heat energy from the device. While this is an effective approach, there are some disadvantages. One disadvantage is that the assembly of the device and the associated insulating material or heatsink compound may be labor intensive. Another is that the increased lead and track lengths may create difficulties where a low-inductance design is required. The second approach is to use a MOSFET in a surface-mount package, Top copper such as D2PAK. A surface-mount package is soldered directly to the pc board, using it as a heatsink. This approach FR4 overcomes the two main disadvantages Bottom copper of the leaded-package approach: assemPower MOSFET in Electrical insulator bly is straightforward and devices may 2 D PAK package Aluminum plate be mounted close together to minimize stray inductances. Unfortunately, this approach also has disadvantages. One major problem is that a pc board will never be as effective at heat removal as a chassis or an aluminum heatsink. A closely related issue is that a temperature rise in one region of the pc board may Thermal vias region Printed circuit board have an adverse effect on other components mounted nearby. Furthermore, the pc board itself may suffer delamination Aluminum plate and other adverse effects if continuously operated at elevated temperatures. Topside cooling, an alternative to bottom-side cooling, involves mounting a Fig. 1. A D2PAK MOSFET mounted on a pc board employing bottom-side cooling transfers heat heatsink on the top of a device in order to to the aluminum plate heatsink through the thermal vias region. provide an improved thermal pathway to Power Electronics Technology February 2006 28 www.powerelectronics.com BOTTOM-SIDE COOLING are taken from Flomerics’ Flotherm thermal simulation software. The software uses computational fluid dynamics (CFD) techniques to analyze complex thermal scenarios involving coupled heat transfer by conduction, convection and radiation. Although the principles of CFD are generally applicable to many fields of engineering, Flomerics’ Flotherm package is specifically targeted at users in the field of electronic and electrical engineering. The following thermal analyses were carried out with Flotherm software. All the device and pc board models used in the simulations have been validated against real empirical data. Device silicon (heat source) Printed circuit board Aluminum plate Ambient Thermal Simulation For the purposes of this demonstration, we will consider the power stage of an H-bridge motor control circuit comprised of eight D2PAK MOSFETs (two parallel MOSFETs in each arm of the bridge). The circuit is constructed on a double-sided FR4 pc board with 2-oz copper on both layers. The topside of the circuit board is shown in Fig. 3. The pc board shown in Fig. 3 comprises the motor control power stage only. The power stage represents the area of greatest power dissipation and, therefore, is the focus of the thermal analysis. The upper copper layer (in green) is laid out in a way that represents the actual electrical connections that would be made in the real circuit. This is important because the upper copper layer plays a role not only in the electrical configuration of the circuit but also in its thermal behavior. Also note that areas of thermal vias have been incorporated beneath the tabs of each of the D2PAK packages, as represented in Fig. 2. Two simulations were initially carried out. The first used the pc board in Fig. 3 with the power dissipation per MOSFET set to a constant 1 W. Thermal vias were incorporated into the pc board, as stated previously. However, the aluminum plate was omitted so that bottom-side cooling did not apply Fig. 2. The primary heat path from device silicon to ambient for a D PAK MOSFET in a bottomside cooling scheme diverts the majority of heat directly to ambient via the pc board and heatsink. 2 ambient. Depending on the nature of the application, topside cooling can be highly effective. In certain other cases, it may make little difference or even make the thermal situation marginally worse. The bottom-side approach to cooling power MOSFETs retains the benefits of surface-mounted components while avoiding their main disadvantages. Typically, bottom-side cooling involves mounting one or more power MOSFETs on a pc board in the usual manner. A pattern of thermal vias is incorporated in the pc board under each power MOSFET, and the opposite side of the pc board is mounted on a chassis or heatsink. In this way, the pc board acts as a pathway for the heat energy to reach the main heatsink, rather than serving as the heatsink itself. This arrangement is illustrated in Fig. 1. The primary heat path in the bottom-side cooling scheme is shown in Fig. 2. Note that the images shown in Figs. 3 and 4, as well as Fig. 6, Fig. 4. Simulated temperature profiles for the H-bridge motor control power stage show how bottom-side cooling (omitted at left; enabled at right) can reduce device temperatures. Fig. 3. In this implementation of an H-bridge motor control power stage, the tab of each MOSFET is mounted over a group of thermal vias. Power Electronics Technology February 2006 30 www.powerelectronics.com BOTTOM-SIDE COOLING The bottom-side approach to cooling power MOSFETs retains the benefits of surface-mounted components while avoiding their main disadvantages. to this case. In the second simulation, all parameters were the same, but an aluminum plate was attached to the bottom of the pc board enabling bottom-side cooling. The device junction temperatures were recorded for these two simulation cases. For the case with no bottom-side cooling, an average device junction temperature of 105.6°C was recorded. For the second case, in which bottom-side cooling was enabled, the average device junction temperature was 68.8°C, a significant decrease. The temperature profiles for the two cases are shown in Fig. 4. In Fig. 4 it is clear the application of bottom-side cooling results not only in a large reduction in MOSFET temperatures but also in a significant reduction in pc board temperatures. This occurs mainly because the pc board is no longer being used as a heatsink, and hence, problems with pc board delamination and the heating of adjacent components are also greatly reduced. This fact also opens the possibility of further reducing the pc board space occupied by the power MOSFETs by using physically smaller devices and placing those devices closer together. To investigate this possibility, another simulation was carried out where each pair of D2PAK MOSFETs in the H-bridge circuit was replaced with three LFPAK devices. The LFPAK package is much smaller than the D2PAK, occupying the same pc board footprint as the familiar SO-8 package. However, unlike the SO-8, the LFPAK is a true power package that incorporates a bottom metal contact, which provides an effective heat path out of the device. There is an additional thermal pathway between the top of the device silicon and ambient through the top part of the encapsulation (Fig. 5). Although the LFPAK solution increases the total number of power packages used, the total board area occupied by this solution is significantly less than for the D2PAK case because the LFPAK package is much smaller than the D2PAK (Fig. 6). Note that the overall pc board size in Fig. 6 is the same as in Figs. 3 and 4, though the copper coverage in Fig. 6 is much less. The bare FR4 pc board surrounding the power devices in Fig. 6 does www.powerelectronics.com not play a significant role in cooling the power MOSFETs and therefore is available for mounting other components such as driver ICs. 31 Power Electronics Technology February 2006 BOTTOM-SIDE COOLING An Emerging Solution Bottom-side cooling is not a totally new concept. For several years it has developed as a suitable solution in dc-dc power supplies for telecom applications. However, the concept has not yet fully matured in the telecom industry and is still in its infancy in the industrial market segment. Industrial electronics forms a large part of the semiconductor industry, and dc motor control in turn forms a main portion of the industrial electronics market. These motor-control applications vary from stepper motor controllers the size of a matchbox (four to eight MOSFETs) to forklift motor controllers having between 80 and 300 MOSFETs per controller. According to a report by EA technology (Cheshire, United Kingdom), “Fuel Cells Niche Markets Applications Solution Average Junction Temperature (°C) 8x D2PAK 68.8 12x LFPAK 8x LFPAK 70.4 74.1 Table. Average device junction temperatures for various MOSFET thermal solutions. Note that the 8x LFPAK solution may be used in place of the 12x LFPAK if a slightly higher average junction temperature is acceptable. and Design Study,” the estimated 2005 demand for heavy industrial battery-powered vehicles is 260,000 and for light industrial/commercial vehicles is 250,000. At an average of 110 MOSFETs per vehicle, the total estimated market for these MOSFETs is 56 million pieces. In the case of heavy industrial vehicles, physical space is not always a constraint and TO-220 devices can thus be used for these applications. In light industrial and commercial applications, however, there is a push for better efficiency and higher power density. Furthermore, in heavy and light industrial applications, there is also a move toward lower-cost solutions, and this is where the mounting cost of TO-220 packages and their associated heatsinks become a burden. There also are several practical problems associated with using these packages in industrial motor controllers. The challenge of mounting 20 to 40 MOSFETs in parallel while ensuring that they are all aligned with the heatsink and the mounting holes in the heatsink is one example. Another example is the electrical challenge of driving several MOSFETs simultaneously when using packages with high inductance and resistance. The aim of using surface-mount packages is to reduce the pc board size, if not, more importantly, to simplify the electrical behavior of these MOSFETs in parallel. Mounting D2PAK devices on a pc board holds the promise of reduced pc board space, shorter track lengths and easier driving of the MOSFETs. In practice, however, this is not so easily achieved. In choosing D2PAK devices, sufficient Power Electronics Technology February 2006 32 www.powerelectronics.com BOTTOM-SIDE COOLING Encapsulation Upper die attach Top metal contact Silicon (die) Pins 1 – 4 ��������� �� ��� ������ Lower die attach (Printed circuit board) Solder Printed circuit board copper Drain tab Solder Fig. 5. The cross-section view of the LFPAK package shows the two thermal paths from the top and bottom of the device silicon. throug h the pc board, even when smaller power packages like the LFPAK are used in place of the D2PAK. The package onresistance and inductances for these smaller package Fig. 6. The overlaid temperature profile (right) of the LFPAK devices types are also sig(left) shows that the pc board area around the devices remains nificantly lower. relatively cool. The total losses in a system caused by these sources are copper space is required around each therefore reduced significantly, even MOSFET to act as a heatsink. Thus, with the additional devices needed additional components cannot be when using the smaller package types placed in the copper area and the pc in place of larger MOSFETS. board space is ultimately not decreased The greatest advantage when as much as desired. switching from D2PAK to LFPAK is The concept of bottom-side coolthe resulting reduction of board space ing may hold some of the answers to occupied by the MOSFETs, since pc these problems. Bottom-side cooling board top copper is not needed to radiallows the heat from MOSFETs to ate heat. The smaller MOSFETs can be flow more effectively into a heatsink placed closer together, and the previmounted on the opposite side of the ously occupied board space is made host pc board. The heatsink can quite available for other components. often be the chassis of the vehicle beIt is ideal for any module manuing driven, such as the cast-iron body facturer to do more with the same pc of a forklift. board space while reducing thermal In the last few years, there have and electrical losses, and system and been significant advances in the manufacturing costs. With bottompackaging of MOSFETs, including the side cooling and design optimization introduction of the power SO-8 packthrough thermal simulation, this goal age. Bottom-side cooling can now is one step closer. PETech be used successfully to transfer heat ��� ������������� ������������������������������ ���������������������������� ��������������� � ��������������������� ���������������� �� �� ���������������������������������� ������������������������������������� ��������������������������� �� ��������� ����������������������������� ����������������������������������� �� ��������������������������������� ���������������������������������� ���������� �� ��������������������������������� ��������������������������������� �� ������������������������������ �������������� �� ���������������������������� �� ��������������������������������� ��������������������� ������������ ������������������������ ���������������������� www.powerelectronics.com 33 Power Electronics Technology February 2006