New surface mount power components drive military power supply

advertisement

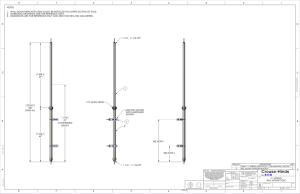

Power conversion New surface mount power components drive military power supply modules By Tracy Autry y l n O t n i r P e l g n i S r o F Hermetic surface mount packaging technology is replacing traditional hermetic through-hole technology in military power systems. These new hermetic surface mount packages have brought the advantages of better thermal dissipation, lighter weight, and smaller volume to the next generation of military power systems. While surface mount components have been in use in commercial power supply applications for many years, designers of the more demanding military power systems have been forced to continue to rely on a range of discrete hermetic through-hole components to implement their power solutions, since commercial surface mount components fail to survive in stringent military environments. Through-hole solutions, however, have poor thermal transfer characteristics, are heavy, always use wire bonds (including two terminal devices), and require significantly greater board space than surface mount devices. This is changing, however, with the emergence of a range of hermetically sealed surface-mount packages for power applications. These advanced packages include solutions for two-terminal devices such as rectifiers, Schottky diodes, and Transient Voltage Suppressors (TVSs), as well as three-terminal devices including MOSFETs, SCRs, and IGBTs. Together, they are rapidly transforming military power supply solutions, providing better thermal transfer characteristics, lighter weight, and smaller volume. Targeted for military applications, these packages are designed for life cycles that avoid obsolescence in these long-life programs. They can also be supplied in power module assemblies, providing a modular circuit solution with the advantages of surface mount components. Hermetic SMT packages Two-terminal packages can take one of two forms – a disk version often designated DO-217 for moderate-to-high power ratings, and a larger square configuration for higherpower applications. Both have an integral strap on the top to provide a contact lead to the surface of a printed circuit board. Figure 1a Figure1b Military Embedded Systems ©2007 OpenSystems Publishing. Not for Distribution. Figures 1a and 1b show the cross-sections of two-terminal packages having multiple and single die. These rugged components sandwich one or more silicon die between tungsten slugs that serve as anode and cathode. In multi-die applications, the silicon dice are thermally separated from each other using molybdenum discs. The package seal construction causes compressive forces between these disks and the silicon dice, improving overall heat transfer within the package. Their junction temperature (Tj) can be as high as 200 ˚C. Thermal resistance junction to case (ROjc) can be as low as 0.2 ˚C/W. The Coefficient of Thermal Expansion (CTE) is designed to match the silicon chip, which is 4.5 ppm/˚C. y l n O t n i r P e l g n i S r o F Figure 2 Since their double-plug construction has no internal wire bonds from the die or dice to external contacts in two-terminal devices, these packages are impervious to the effects of acceleration internally and exhibit lower inductance and higher surge capabilities than through-hole solutions. Even though wire bonds are employed here, this package exhibits low inductance due to the lack of ferrous materials. All wire bonds within the package are mono-metallic Al-to-Al bonds. This package is suited for integrating gate resistors and protection or zener diodes. Unlike commercial surface mount packaging that employs soft solder, these components use hard solder (Au/Sn or Au/Ge) throughout, eliminating solder creep and recrystallization problems that can be caused by power cycling and high-temperature operation in military applications. With hard solder, the thermal resistance junction to case (ROjc) doesn’t increase in operation, providing longer service life. Table 1 provides a comparison of three hermetic surface mount packages with standard through-hole packages like the DO-4 for two terminal devices or the TO-254 for three-terminal components. It can be seen that these surface mount devices provide a 6x improvement in weight, 3.5x in thermal resistance, and 2.5x in volume. Microsemi’s ThinKey package is representative of a higher power square implementation of this double-plug ceramic and metal construction. In this case, the silicon die is hard soldered to a molybdenum disk, and this assembly is then soldered between two square molybdenum pads that serve as the external terminal connections. A copper-clad strap brings the top terminal down to make contact on a circuit board. Typical applications are with Schottky die (Figure 2). Larger rectangular surface mount packages are designed for three-terminal devices. Here, the side of the die with the drain is soldered onto a copper/molybdenum pad to create one terminal, while the source and gate on the other side of the die are wirebonded across an insulating alumina bridge to pads that serve as the other two terminals – all within the hermetically sealed cavity. Power module assemblies In addition, these surface mount components can be used as building blocks for space-saving hermetic surface mount power modules, utilizing standard materials and processes to create application-specific power circuits of high reliability. This construction employs a five-step process designed to pass Quality Conformance Inspection (QCI) tests for Commercial, TX, TXV, and JANS equivalent screening levels: 1. Hermetic discrete devices are screened to the required level (for example, TX or S-level equivalent) so that only “known good” devices are used in the module’s construction. 2. Terminals are brazed to the substrate at 800 ˚C using Cu/Ag eutectic. 3. To prevent voiding, the substrate is bonded to its heatsink in a vacuum and is verified with 100 percent X-ray inspection. 4. Module is populated with the screened discrete devices at 215 ˚C. DO-4 TO-254 3-terminal SMT Schottky SMT Weight (grams) 10 9 1.5 1 Thermal resistance (C/W) 1.5 1.5 0.3 0.3 Volume (cubic inches) 0.25 0.125 0.05 0.02 Diode SMT 0.9 0.4 0.012 Package type Table 1 Military Embedded Systems ©2007 OpenSystems Publishing. Not for Distribution. Power conversion 5. Completed module is tested and screened to the appropriate level, including QCI samples. Since these hermetic power modules can be fabricated on ceramic (either metalized or direct bond copper) substrates and use aluminum composite or copper laminate heatsinks, their coefficients of thermal expansion will closely match that of the surface mount components. Integral contact terminations can be crafted easily from copper alloy or steel to provide an easy-toconnect final assembly. Employing these surface mount hermetic packages in military power modules greatly reduces complexity and cost, while simplifying testing and qualification. Up-front costs such as tooling and nonrecurring engineering charges are much less than for conventional hybrid, or multichip module designs. In addition, since the power module approach uses individual hermetic discrete devices, the modules can be reworked with relative ease and minimal costs. y l n O t n i r P e l g n i S r o F Prototype units can be built rapidly for in-circuit testing. If one or more of the discretes need to be changed to optimize circuit performance, the modules can be returned to install new discrete devices for additional testing. Military-grade reliability with surface mount performance In short, today’s hermetic power module technology can provide military applications with all the advantages of commercial surface mount assembly, but with military-grade reliability, faster prototype development, reduced costs, weight, and size compared with conventional through-hole hybrid solutions – the best of both worlds. Tracy Autry is a module development manager with Microsemi Corporation. He has 15 years of experience in electronic packaging development and 13 years of experience in designing and manufacturing high-reliability power modules for the military and aerospace markets. He received a BS in Ceramic Engineering from the University of Missouri-Rolla. Microsemi Corporation 11861 Western Avenue Garden Grove, CA 92841 714-372-8050 tautry@microsemi.com www.microsemi.com Military Embedded Systems ©2007 OpenSystems Publishing. Not for Distribution.