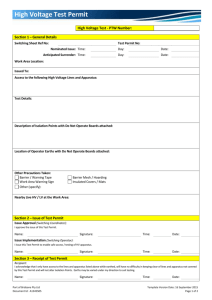

Employees Safety Code

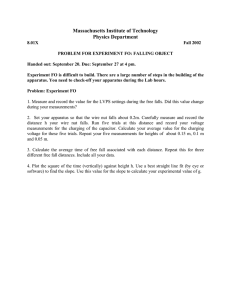

advertisement