NEMA Motor Control - A116 North American IC Catalog

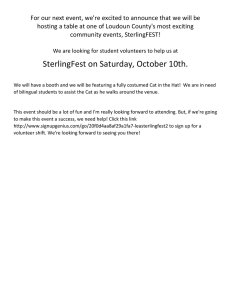

advertisement