Work Practices Program - University of Northern Iowa

advertisement

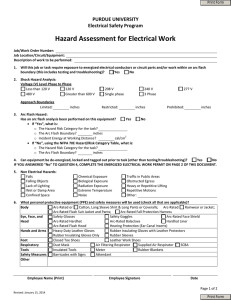

Electrical Safety – Work Practices Program (OSHA & NFPA 70E) Updated: June 2015 TABLE OF CONTENTS 1. Purpose & Responsibilities ...................................................................................................................................... 3 2. Training Requirements ............................................................................................................................................. 3 3. Test Instruments & Equipment ................................................................................................................................ 4 4. Visual Inspections .................................................................................................................................................... 4 5. Job Briefing ........................................................................................................................................................... 4-5 6. Hazard / Risk Evaulation ......................................................................................................................................... 5 7. Working On or Near Electrical Conductors or Circuit Parts .................................................................................... 5 8. Working On or Near Energized Parts (Justified for Energized Work)..................................................................... 5 9. Energerized Electrical Work Permit ........................................................................................................................ 5 10. Approach Boundaries to Live Parts ........................................................................................................................ 6 11. Preparation for Approach, Unqualified Person(s) ................................................................................................... 6 12. Arc Flash Risk Assessment ..................................................................................................................................... 7 13. Guarding Exposed Energized Electrical Circuit Parts............................................................................................. 7 14. Buried or Concealed Electrical Hazards ................................................................................................................. 7 15. Personal Protective Equipment Requirements ........................................................................................................ 7 16. Personal Protective Equipment - Specific ............................................................................................................ 7-8 17. Rubber Insulated Equipment Voltage Requirements (OSHA Table) ...................................................................... 8 18. Other Protective Equipment .................................................................................................................................... 9 APPENDIX “A” Job Briefing and Job Planning Check Sheet ................................................................................... 10 APPENDIX “B” Risk Assessment Procedure............................................................................................................. 11 APPENDIX “C” Physical Plant Energized Electrical Work Permit ...................................................................... 12-13 APPENDIX “D” Arch Flash Field Label Example..................................................................................................... 14 APPENDIX “E” PPE Reference Card ........................................................................................................................ 15 APPENDIX “F” Approach Boundaries AC Voltage .................................................................................................. 16 APPENDIX “G” Approach Boundaries DC Voltage .................................................................................................. 17 APPENDIX “H” Safety Acknowledgement Sheet ..................................................................................................... 18 APPENDIX “I” Tracking PPE and Equipment Inspections........................................................................................ 19 APPENDIX J Arch Flash Hazard Identification table…………………….. ......................................................... 20-22 APPENDIX “K” Arch Flash Hazard Identification AC Voltage .............................................................................. 23 APPENDIX “L” Arch Flash Hazard Identification DC Voltage ................................................................................ 24 APPENDIX “M” Protective Clothing and Personal Protective Equipment (PPE) ................................................ 25-26 University of Northern Iowa Electrical Safety - Work Practices Program 2 1. Purpose: The purpose of this program is to establish safe work practices and procedures for University of Northern Iowa (UNI) Physical Plant (PHP) employees exposed to electrical hazards in the workplace. a. Objective: To safeguard our employees by providing an electrical safety management guide for compliance. b. Employees Responsibility for Safety: Before proceeding with any type of electrical work, all employees shall assure themselves that they can perform the work without injury. If they are assigned work they are not qualified to they shall call this to their Supervisor’s attention. c. Relationships with PHP and other Contractors: When outside contractor personnel are engaged in electrical work at UNI facilities for Physical Plant, the PHP Maintenance or project Supervisor in charge shall conduct a meeting with the contractors and inform them of the following: • Known hazards that are covered by NFPA 70E 2015 that are related to their work and that might not be recognized by their employees. • Information about UNI’s installation will be made available. Any assessment relating to electrical hazards, and any existing electrical hazards from our Arc Flash Hazard Analysis, if one was conducted. This coordination meeting will be documented using the Physical Plant’s Safety Acknowledgement Sheet APPENDIX “H” Page 20 of this program. d. Physical Plant Responsibilities: Physical Plant shall be responsible for the implementation of specific procedures and practices that meet or exceed those contained within this program, OSHA, and NFPA 70E 2015. 2. Training Requirements: The training requirements contained in this section shall apply to all UNI employees who face a risk of electrical hazard that is not reduced to a safe level required by the National Electrical Code installation requirements. Such employees will be trained to identify and understand the relationship between electrical hazards and possible injury. a. Type of Training: The training required shall be classroom, on the job, or a combination of the two. The degree of training provided shall be determined by the employee’s risks. b. Emergency Training: Employees working on or near the approach boundaries as found in NFPA 70E 2015 edition, who are exposed to energized electrical conductors or circuit parts shall as a minimum: • Fully understand the emergency procedures for the facility at which work is being performed. • Be trained in methods of release of victims from contact with exposed energized conductors or circuit parts. • Employees shall be regularly (as required by American Red Cross) instructed in methods of first aid and emergency procedures, such as approved methods of resuscitation, including cardiopulmonary resuscitation (CPR) and the use of A.E.D.’s. Employees shall be certified by the employer every two years as required by the certifying agency. c. Employee Job Safety Training: Qualified Persons shall be trained and knowledgeable of the construction and operation of equipment or specific work method, and be trained to recognize and avoid the electrical hazards that might be present with respect to that equipment or work method. Such persons shall also be familiar with the proper use of special precautionary techniques, Personal Protective Equipment, insulating and shielding materials, insulated tools and test equipment. A person can be considered qualified with respect to certain equipment and methods, but still be unqualified for others. Such persons permitted to work within limited approach of exposed energized conductors and circuit parts shall, at a minimum, be additionally trained in all of the following: University of Northern Iowa Electrical Safety - Work Practices Program 3 • • • • • • The skills and techniques necessary to distinguish exposed energized electrical conductors and circuit parts from other parts of electric equipment. The skills and techniques necessary to determine the nominal voltage of exposed energized electrical conductors and circuit parts. The distances specified in the NFPA 70E 2015 Approach Boundaries to Live Parts for Shock Protection Table 130.4(D)(a) APPENDIX “F” Page 18 and (Table 130.4(D)(b) APPENDIX “G” Page 19 of this document. The decision making process necessary to determine the appropriate Personal Protective Equipment (PPE) and job planning necessary to perform the task safely. Unqualified persons shall be trained in and familiar with any of the electrical safe work practices. Training shall include safety related work practices contained in 1926.416 and 1926.417 for construction. 1920.331 – 1910.335 in general industry standards and information contained in the NFPA 70E 2015 Standard for Electrical Safety in the Workplace. 3. Test Instruments and Equipment/Accessories: The training requirements contained in this section shall apply to all UNI employees who face a risk of electrical hazard that is not reduced to a safe level required by the National Electrical Code installation requirements. Such employees will be trained to identify and understand the relationship between electrical hazards and possible injury. a. Shall be rated for the voltage and equipment to which they will be connected. b. Shall be rated for the voltage and equipment to which they will be connected, designed for the environment to which they will be exposed, and for the manner in which they will be used. c. Shall be visually inspected for external defects and/or damage before the equipment is used on any shift d. Calibrate per manufacturer’s requirements. e. When test instruments are used to determine the absence of voltage on conductors or circuit parts operating at 50 volts or more, the operation of the test instrument shall be verified before and after an absence of voltage test is performed. f. Test instruments, equipment or accessories found to be defective, damaged or out of Calibration, shall be removed from service and tagged “Danger Unsafe Do Not Use”. 4. Visual Inspection of Portable Cord and Plug Connected Equipment and Flexible Cord Sets: Before each use and at the time of any shift change, portable cord and plug-connected equipment shall be visually inspected by the employee for external defects (such as loose parts, deformed and missing pins) and for evidence of possible internal damage. (such as, pinched or crushed outer jackets). Any portable cord and plug-connected equipment or flexible cord sets found to be defective or damaged shall be removed from service and tagged, “Danger Unsafe Do Not Use”. 5. Job Briefing: a. The Job Briefing for routine work will require only a brief discussion if the employee, by virtue of training and experience, can reasonably be expected to recognize and avoid the hazards in the job. b. A Job Briefing for non-routine job/tasks, will be conducted by the employee in charge, and shall include the following: • Hazards associated with the job. • Work procedures involved. • Special precautions. • Energy source controls. • Personal Protective Equipment requirements. Reference: APPENDIX “A” page 12 in this document, the Job Briefing and Planning Check Sheet. c. Follow the Hazard/Risk Procedure if either of the following applies: • The work is complicated or particularly hazardous. University of Northern Iowa Electrical Safety - Work Practices Program 4 • The employee cannot be expected to recognize and avoid the hazards involved in the job. 6. Hazard/Risk Evaluation Procedure: Before work is started on, or near live parts operating at 50 volts or more, each employee shall conduct a Hazard/Risk or Shock Hazard Analysis evaluation using Risk Assessment Procedure in APPENDIX “B” page 13 of this document. 7. Working on or Near Electrical Conductors or Circuit Parts: Prior to working on or near exposed electrical conductors and circuit parts operating at 50 volts or more, lockout/tagout devices shall be applied in accordance with the University’s Energy Control Program (lockout/tagout). 8. Working on or Near Energized Parts (Justification for Energized Work): Energized electrical conductors and circuit parts, to which an employee might be exposed, shall be put into an electrically safe work condition before an employee works within Limited Approach Boundary of those conductors or parts. 1. Greater Hazard. Energized work shall be permitted where it can demonstrated that de-energizing introduces additional or increased hazards. Examples of increased or additional hazards include, but are not limited to interruption of life support equipment, deactivation of emergency alarm systems, and shutdown of hazardous location ventilation equipment. 2. Infeasibility. Energized work shall be permitted where it can be demonstrated that the task to be performed is infeasible in a de-energized state due to equipment design or operational limitations. Examples include performing diagnostic and testing (e.g.start-up or troubleshooting) of electric circuits that form an integral part of a continuous process. 3. Less Than 50 Volts. Energized electrical conductors and circuit parts that operate at less than 50 volts to ground shall not be required to be de-energized. 4. Normal Operation. Normal operation of electric equipment shall be permitted where all of the following conditions are satisfied: • The equipment is properly installed. • The equipment is properly maintained. • The equipment doors are closed and secured. • All equipment covers are in place and secured. • There is no evidence of impending failure. • An example of normal operation includes, but is not limited to operating a switch rated breaker to turn lights on and off. 9. Energized Electrical Work Permit: a) Working on energized electrical conductors or circuit parts that are not placed in an electrically safe work condition (as indicated above in 8,1 or 8,2), the work performed shall be considered Energized Electrical Work and shall be permitted by completing the University’s Energized Electrical Work Permit APPENDIX “C” Page 14-15 in this document. b) Exemption. An energized electrical permit shall not be required if a qualified person is provided with and uses appropriate PPE and safe workplace practices in accordance with OSHA and NFPA 70E, Chapter 1 under any of the following conditions: • Testing, troubleshooting, voltage measuring. • Thermography and visual inspection if the restricted approach boundary is not crossed. • Access to and egress from as area with energized electrical equipment if no electrical work is performed and the restricted approach boundary is not crossed. • General housekeeping and miscellaneous non-electrical tasks are performed if the limited approach boundary is not crossed. University of Northern Iowa Electrical Safety - Work Practices Program 5 10. Approach Boundaries to Live Parts: a. Shock Risk Assessment: A shock risk assessment shall determine the voltage to which personnel will be exposed, boundary requirements, and Personal Protective Equipment necessary in order to minimize the possibility of electric shock to personnel. Refer to Approach Boundaries to Live Parts for Shock Protection Table 130.4D(a) for AC APPENDIX “F” page 18 or 130.4D(b) for DC APPENDIX “G” Page 19. b. Approach to Exposed Live Parts Operating at 50 Volts or More: No qualified person shall approach or take any conductive object closer to exposed live parts, operating at 50 volts or more, than the restricted approach boundary (as set forth in Table 130.4D(a) for AC APPENDIX “F” Page 18 or 130.4D(b) for DC APPENDIX “G” Page 19 unless the qualified person is insulated or guarded from the live parts operating at 50 volts or more (insulated gloves or insulating gloves and sleeves are considered insulation only with regard to the energized parts upon which work is performed), and no uninsulated part of the qualified person’s body can come in contact with exposed energized electrical conductors or circuit parts. c. Employees shall use properly rated insulated tools and/or handling equipment when working on exposed energized electrical conductors or circuit parts where tools or handling equipment might make accidental contact. d. NO EMPLOYEE IS AUTHORIZED TO WORK ON ENERGIZED CIRCUITS ABOVE 480 VOLTS NOMINAL UNLESS THEY RECEIVE PROPER CERTIFICATION. 11. Preparation for Approach, Unqualified Person(s): Observing a Safe Approach Distance for exposed energized electrical conductors or circuit parts is an effective means of maintaining electrical safety. As the distance between a person and exposed energized conductors or circuit parts decreases, the potential for an electrical accident increases. a. Unqualified Persons, Safe Approach Distance. No unqualified person is permitted to approach nearer than the Limited Approach Boundary of energized conductors or circuit parts unless permitted by section b) below. b. Unqualified Persons Entering the Limited Approach Boundary. Where there is a need for an unqualified person to cross the limited approach boundary, a qualified person shall advise him or her of the possible hazards, AND continuously escort the unqualified person while inside the limited approach boundary. Under no circumstance may an unqualified person cross the Restricted Approach Boundary Limits of Approach Graphic University of Northern Iowa Electrical Safety - Work Practices Program 6 12. Arc Flash Risk Assessment: Physical Plant employees shall refer to the existing “ARC Flash Hazard Analysis” assessment to determine if arc flash hazards exist. The results of this analysis are indicated by a “Field Label” affixed to the electrical equipment APPENDIX “D” Page 16. Physical Plant employees will utilize the facility “Arc Flash Hazard Analysis”. In absence of a recognized analysis, refer to NFPA 70E (2015) Arc-Flash Hazard Identification Table 130.7(C)(15)(A)(a) APPENDIX “J” Pages 22-24, Arc-Flash Hazard PPE Categories for Alternating Current, Table 130.7(C)(15)(A)(b) APPENDIX “K” Page 25, Arc-Flash Hazard PPE Categories for Direct Current, Table 130.7(C)(15)(B) APPENDIX “L” Page 26, Personal Protective Equipment (PPE), Table 130.7(C)(16) APPENDIX “M” Pages 27-28 in this document to determine the Arc-Flash Boundary, Arc-Flash PPE Category and the personnel protective equipment to be used. 13. Guarding Exposed Energized Electrical Circuit Parts: a. Barricades shall be used in conjunction with safety signs where it is necessary to prevent or limit employee access to work areas containing energized conductors or circuit parts. When needed, PHP employees shall place barriers of red “Danger” tape in conjunction with safety signs to prevent or limit unqualified persons access to the electrical hazard. Place the barriers no closer than the limited approach boundary given in 2015 NFPA 70E Table 130.4 (D)(a) APPENDIX “F” Page 18 and 130.4 (D)(b) APPENDIX “G” Page 19 in this document. b. If signs and barriers do not provide sufficient warning or students and faculty are at risk because of the location of energized conductors, an attendant shall be stationed to warn and protect persons. 14. Buried or Concealed Electrical Hazards: a. Before excavation starts where there exists a reasonable possibility of contacting electrical lines or equipment, the employer shall take the necessary steps to contact the appropriate owners or authorities to identify and mark the location of the electrical lines or equipment. When it has been determined that a reasonable possibility of contacting electrical lines or equipment exists, appropriate safe work practices and PPE shall be used during the excavation. b. Before cutting or drilling into equipment, floors, walls, or structural elements where a likelihood of contacting energized electrical lines or parts exists, the employer shall perform a risk assessment to: • Identify and mark the location of conductors, cables, raceways, or equipment • Create an electrically safe work condition • Identify safe work practices and PPE to be used 15. Personal Protective Equipment Requirements – General: a. General. Employees working in areas where electrical hazards are present shall use: • Protective equipment that is designed and constructed for the specific part of the body to be • Protected and for the work to be performed. See APENDIX “E” page 17 in this document for PPE Reference • Card. b. Care of Equipment. Protective equipment shall be maintained in a safe, reliable condition. • The protective equipment shall be visually inspected before each use. 16. Personal Protective Equipment – Specific: a. General: When an employee is working within the Arc Flash Boundary, he/she shall wear protective clothing and other personal protective equipment as required by our Arc Flash Hazard Analysis or in accordance with Table 130.7(C) (16) APPENDIX “M” Pages 27-28 in this document. b. Movement and Visibility. When flame-resistant (FR) clothing is worn to protect and employee, it shall allow for movement and visibility. Clothing made from flammable synthetic materials that melt, such as nylon, polyester polypropylene and spandex may not be use. University of Northern Iowa Electrical Safety - Work Practices Program 7 c. Head, Face, Neck and Chin Protection. Employees shall wear nonconductive head protection wherever there is a danger of head injury from electric shock or burns due to contact with live parts or from flying objects resulting from electrical explosion. Employees shall wear nonconductive protective equipment for the face, neck and chin whenever there is a danger of injury from exposure to electric arcs or flashes; or from flying objects resulting from electrical explosion. Hard hats shall meet current ANSI Z89.1, Class E & G. d. Balaclava. Where necessary, employees shall wear FR Balaclava. To eliminate potential transmission of cold and flu viruses, it is recommended that employees not share a balaclava. e. Eye Protection. Employees shall wear protective equipment for the eyes whenever there is a danger of injury from electric arcs, flashes, or from flying objects resulting from electrical explosion. Safety glasses shall meet current ANSI Z87 and have non-metallic frames. f. Body Protection. Employees shall wear FR clothing wherever there is possible exposure to an electric arc flash hazard. g. Care and Maintenance of FR Clothing and FR Flash Suits: • Inspection: FR apparel shall be inspected before each use. Work clothing or flash suits that are contaminated, or damaged to the extent their protective qualities are impaired shall not be used. Protective items that become contaminated with grease, oil, or flammable liquids or combustible materials shall not be used. • Care: All FR clothing shall be laundered per each manufacturer’s instructions. h. Hand and Arm Protection. Employees shall wear rubber gloves with leather protectors where there is a danger of hand and arm injury from electric shock due to contact with live parts. Hand and arm protection shall be worn where there is possible exposure to arc flash burn. • i. Insulating Gloves – Per Use/Periodic Testing: Per use testing of rubber insulated gloves shall be done by inflating them. All rubber insulating gloves shall be voltage tested by a qualified testing facility before they are first issued and every 6 months thereafter. PHP is responsible to determine a testing facility and establish a tracking system to ensure this requirement is met. A competent qualified person may be designated to track insulating glove inspections. Foot Protection. Footwear shall meet the current ASTM F2413 standard and shall have non-metallic composite toes and for electrical hazard. CFR 1910.137 University of Northern Iowa Electrical Safety - Work Practices Program 8 17. Other Protective Equipment: a. Insulated Tools and Equipment. Employees shall be issued and use electrically insulated tools and/or handling equipment when working inside the Limited Approach Boundary of exposed live parts where tools or handling equipment might make accidental contact. b. Requirements for Electrically Insulated Tools. The following requirements shall apply to insulated tools: • Insulated tools shall be rated for the voltage on which they are used. • Insulated tools shall be designed and constructed for the environment to which they are exposed and the manner in which they are used. c. Fuse Pulling Equipment. Fuse pullers shall be rated for the circuit voltage. NEVER REMOVE A FUSE UNDER LOAD! d. Ropes and Hand lines. Ropes and hand lines used near exposed live parts operating at 50 volts or more, or used where an electrical hazard exists, shall be nonconductive. e. Fiberglass-Reinforced Plastic Rods (hot stick). Fiberglass reinforced plastic rod and tube used for live-line tools shall meet the requirements of applicable portions of electrical codes and standards dealing with electrical insulation requirements. f. Portable Ladders. All portable ladders shall have nonconductive side rails if they are used where the employee or ladder could contract exposed live parts operating at 50 volts or more or where an electrical hazard exists. Nonconductive ladders shall meet the requirements of current ANSI standards for ladders. g. Periodic Testing. Insulating materials, hot sticks and tools (etc.) shall be periodically tested and/or inspected according to manufacturer’s requirements. The PHP Electrical Supervisor is responsible to determine testing facility and establish a Tracking System (See APPENDIX “I” Page 21) to ensure this requirement is met. A competent qualified person may be designated to track equipment inspections. University of Northern Iowa Electrical Safety - Work Practices Program 9 APPENDIX A Physical Plant Job Briefing and Job Planning Check Sheet Employee in Charge: ______________ Date: _______ Job Location: ______________Project: ____________ University of Northern Iowa Electrical Safety - Work Practices Program 10 APPENDIX B Risk Assessment Procedure University of Northern Iowa Electrical Safety - Work Practices Program 11 APPENDIX C Physical Plant Energized Electrical Work Permit This permit is required for any work in which a person or object will approach closer than the Restricted Approach Boundary to energized (live) parts operating at 50 volts or more. EXEMPT ACTIVITIES: PPE and electrically rated equipment is still required, however the following do not Require this permit to be completed. • Testing and troubleshooting, including voltage and current testing. • Breaker and switch operation with covers closed or safe. • Activities to lockout/tagout equipment. • Installation of barriers to make the job safe. • Tightening a 110 AC terminal screw. • Removing a cover to perform an IR scan. Before initiating this work….. Can this job be avoided? Yes ☐ No ☐ Is there a safer way to do this work? Yes ☐ No ☐ Can it be shut down? Locked/Tagged? Yes ☐ No ☐ Can it be delayed until such a time that it can be shut down? Yes ☐ No ☐ Can Voltage Rated Barriers be installed to eliminate the hazard? Yes ☐ No ☐ If one or more of these questions is “Yes”, then use this method and use a normal Job Briefing for this work. If all are “No” proceed with an Energized Electrical Permit. Why does it have to be done energized? (Check all that apply) ☐ It is part of a Continuous Process that can’t be shut down. ☐ Emergency System ☐ Hazardous Location Ventilating System? ☐ Creates additional hazards or infeasible due to equipment design or limitation? If none of these items are checked, Energized Electrical work is not allowed and the equipment should be shut down and locked out! Instructions to electrically Qualified Individual (Permit Issuer): Verify/Fill out permit daily All items on the permit must be checked or filed out Insure proper PPE Sign permit Review project plan and secure acknowledgement signatures Notify designated 1st Aid/CPR site Safety Coordinator Post permit at job site Note: Once work is completed, return this form to your supervisor Emergency information: Dial 911 for emergency response University of Northern Iowa Electrical Safety - Work Practices Program 12 Physical Plant Energized Electrical Work Permit Energized Electrical work being done by: 5. Means to keep unqualified people out: ____ Employee: __________________________ ______________________________________ Date: ______________________________ Permit expires: (time) _________________ 6. Additional Safety Work Practices Employed: Job/WO number: _____________________ ______________________________________ Job location: _________________________ ______________________________________ Flash Hazard Boundary______________ ______________________________________ Flash Hazard Category (Circle) and ______________________________________ Protection Required: __________________________or none ☐ 0 1 2 3 4 7. Other job hazards: _____________________ See page 16 for Personal Protection Equipment _______________________________________ required. _______________________________________ Description of circuit equipment: __________ __________________________or none ☐ _____________________________________ 8. Job briefing/planning checklist filled out _____________________________________ Yes ☐ No ☐ _____________________________________ 9. ERT/FRT and technical community been _____________________________________ notified Yes ☐ No ☐ _____________________________________ 10. >150V: identify observer if working alone on Description of work being done: __________ work or N/A ☐ : ________________________ _____________________________________ 11. Do you agree that this work can be _____________________________________ performed safely? _____________________________________ Signature (s) Note: See Arc Flash Label for some of the ____________________________Yes ☐ No ☐ Following information: Use Power Feed Label ____________________________Yes ☐ No ☐ In absence of local label: ____________________________Yes ☐ No ☐ MAXIMUM VOLTAGE EXPOSED: (CIRCLE) If “No”, stop work and report to your Supervisor. 150-300V, 300V to 750V, >750V specify: ____ ___________________________AC ☐ DC ☐ Voltage being worked on: (circle) 12. Do you acknowledge that you have reviewed <150V, 150-300V, 300V to 750V, >750V this job at the worksite with the electrically If >750V specify: ____________AC ☐ DC ☐ qualified worker? 1. Prohibited Approach Boundary: (Permit Requirements) Physical Plant Electrical Supervisor <300V – Avoid contact Name: __________________________________ 300 to 750V – One inch Signature: _______________________________ >750V – Seven inches (up to 15,000 volts) 2. Shock Protection Boundary (Restrictive Department/Maint./or Engineering Manager Approach Boundary) _______________ Name: __________________________________ 3. Shock Hazard PPE Required (Circle Signature: _______________________________ Required Elements) -Voltage Rated Gloves/Leathers Once the work is complete, forward this form Class Required (Circle): 00, 0, 1, 2, 3, 4 to Safety Department for review and -Voltage Rated Tools Yes ☐ No ☐ retention. 4. Limited Approach Boundary: (Unqualified People Entry Distance) _______________ University of Northern Iowa Electrical Safety - Work Practices Program 13 APPENDIX D Field Label University of Northern Iowa Electrical Safety - Work Practices Program 14 APPENDIX “E” Electrical PPE Reference Cards Electrical PPE Reference Card Recognize electrical hazards before beginning work on any electrical device. Take necessary precautions so hazards do not cause injury or death. Place devices in an Electrically Safe Condition whenever possible ACHIEVE AN ELECTRICALLY SAFE WORK CONDITION (ESWC) BY: 1. Disconnecting from energized parts. 2. Locking/Tagging per PHP Facility procedures 3. Testing to ensure the absence of voltage 4. Grounding if determined necessary Assure you are wearing the appropriate Personal Protective Equipment (PPE) before proceeding Cat Flash Hazard Cal/Cm2 PPE Rating Cal/Cm2 Flash PPE Required Head Protection Required Hand & Foot Protection Required 0 <1.2 >1.2 Long Sleeve Shirt with Long pants – Natural Fiber Safety Glasses, Hearing Protection Approriate Gloves Foot Protection 1 1.2-4 >4 Long Sleeve Shirt with Pants – (FR at 4cal/cm^2) Safety Glasses Hard Hat w/Arc Rated Face Shield, Hearing Protection Approriate Gloves, Foot Protection 2 4-8 >8 Long Sleeve Shirt with Pants – (FR at 8cal/cm^2) Safety Glasses Hard Hat w\Arc Rated Face Shield, Arc-Rated Balaclava, Hearing Protection Approriate Gloves, Foot Protection 3 8-25 >25 Flash Suit with Hood (FR at 25cal/cm^2), Safety Glasses, Hard Hat, Flash Suit Hood, Hearing Protection Approriate Gloves, Foot Protection 4 25-40 >40 Flash Suit with Hood (FR at 40cal/cm^2), Safety Glasses, Hard Hat, Flash Suit Hood, Hearing Protection Approriate Gloves, Foot Protection Card Issued: June 2010 > 40 Electrical PPE Reference Card Recognize electrical hazards before beginning work on any electrical device. Take necessary precautions so hazards do not cause injury or death. Place devices in an Electrically Safe Condition whenever possible ACHIEVE AN ELECTRICALLY SAFE WORK CONDITION (ESWC) BY: 1. Disconnecting from energized parts. 2. Locking/Tagging per PHP Facility procedures 3. Testing to ensure the absence of voltage 4. Grounding if determined necessary Assure you are wearing the appropriate Personal Protective Equipment (PPE) before proceeding Hazardous – No clothing available. DO NOT ACCESS unless all power feeding this equipment is verified as de-energized Cat Flash Hazard Cal/Cm2 PPE Rating Cal/Cm2 Flash PPE Required Head Protection Required Hand & Foot Protection Required 0 <1.2 >1.2 Long Sleeve Shirt with Long pants – Natural Fiber Safety Glasses, Hearing Protection Approriate Gloves Foot Protection 1 1.2-4 >4 Long Sleeve Shirt with Pants – (FR at 4cal/cm^2) Safety Glasses Hard Hat w/Arc Rated Face Shield, Hearing Protection Approriate Gloves, Foot Protection 2 4-8 >8 Long Sleeve Shirt with Pants – (FR at 8cal/cm^2) Safety Glasses Hard Hat w\Arc Rated Face Shield, Arc-Rated Balaclava, Hearing Protection Approriate Gloves, Foot Protection 3 8-25 >25 Flash Suit with Hood (FR at 25cal/cm^2), Safety Glasses, Hard Hat, Flash Suit Hood, Hearing Protection Approriate Gloves, Foot Protection 4 25-40 >40 Flash Suit with Hood (FR at 40cal/cm^2), Safety Glasses, Hard Hat, Flash Suit Hood, Hearing Protection Approriate Gloves, Foot Protection Card Issued: June 2010 > 40 Electrical PPE Reference Card Recognize electrical hazards before beginning work on any electrical device. Take necessary precautions so hazards do not cause injury or death. Place devices in an Electrically Safe Condition whenever possible ACHIEVE AN ELECTRICALLY SAFE WORK CONDITION (ESWC) BY: 1. Disconnecting from energized parts. 2. Locking/Tagging per PHP Facility procedures 3. Testing to ensure the absence of voltage 4. Grounding if determined necessary Assure you are wearing the appropriate Personal Protective Equipment (PPE) before proceeding Hazardous – No clothing available. DO NOT ACCESS unless all power feeding this equipment is verified as de-energized Cat Flash Hazard Cal/Cm2 PPE Rating Cal/Cm2 Flash PPE Required Head Protection Required Hand & Foot Protection Required 0 <1.2 >1.2 Long Sleeve Shirt with Long pants – Natural Fiber Safety Glasses, Hearing Protection Approriate Gloves Foot Protection 1 1.2-4 >4 Long Sleeve Shirt with Pants – (FR at 4cal/cm^2) Safety Glasses Hard Hat w/Arc Rated Face Shield, Hearing Protection Approriate Gloves, Foot Protection 2 4-8 >8 Long Sleeve Shirt with Pants – (FR at 8cal/cm^2) Safety Glasses Hard Hat w\Arc Rated Face Shield, Arc-Rated Balaclava, Hearing Protection Approriate Gloves, Foot Protection 3 8-25 >25 Flash Suit with Hood (FR at 25cal/cm^2), Safety Glasses, Hard Hat, Flash Suit Hood, Hearing Protection Approriate Gloves, Foot Protection 4 25-40 >40 Flash Suit with Hood (FR at 40cal/cm^2), Safety Glasses, Hard Hat, Flash Suit Hood, Hearing Protection Approriate Gloves, Foot Protection Card Issued: June 2010 > 40 PRINT CUT Hazardous – No clothing available. DO NOT ACCESS unless all power feeding this equipment is verified as de-energized FOLD LAMINATE University of Northern Iowa Electrical Safety - Work Practices Program 15 APPENDIX F Approach Boundaries AC Current University of Northern Iowa Electrical Safety - Work Practices Program 16 APPENDIX G Approach Boundaries DC Voltage University of Northern Iowa Electrical Safety - Work Practices Program 17 APPENDIX H Safety Acknowledgement Sheet This is to acknowledge that I have received a copy of Physical Plant’s Energy Control Procedure, Lockout/Tagout Program and a copy of UNI’s Physical Plant Electrical Safety Work Practices Program. These programs establish minimum safe work practices and procedures for workers exposed to electrical hazards in the workplace. This also acknowledges that I have been informed that the work practices and procedures of my employees exposed to electrical hazards in the course of their work under the contract with UNI will be equal to or more stringent that the work practices and procedures outlined in the programs above. Date: _____________________ Job Number (if applicable): ____________________ Project/Job Title: _________________________________________________________ Contract Employer: _______________________________________________________ Signature: ______________________________ Contract Employer Signature ___________________________________ Contract Employer, Print Signature: ______________________________ UNI Witness Signature __________________________________ UNI Witness, Print University of Northern Iowa Electrical Safety - Work Practices Program 18 Appendix I Tracking PPE Inspections UNI Physical Plant will inspect PPE and track this information at a minimum. Calibration Due Report Tool No Location As of: ____________________ Description Tool Type Date Out Serial No Condition Test Cal Date University of Northern Iowa Electrical Safety - Work Practices Program 19 Appendix J Arch Flash Hazard Identification Table University of Northern Iowa Electrical Safety - Work Practices Program 20 University of Northern Iowa Electrical Safety - Work Practices Program 21 University of Northern Iowa Electrical Safety - Work Practices Program 22 APPENDIX K Arch Flash Hazard Identification AC Voltage University of Northern Iowa Electrical Safety - Work Practices Program 23 APPENDIX L Arch Flash Hazard Identification DC Voltage University of Northern Iowa Electrical Safety - Work Practices Program 24 APPENDIX M Table 130.7 I (16) 2012 edition Protective Clothing and Personal Protective Equipment (PPE) Hazard/Risk Category 0 1 2 3 Protective Clothing Protective Clothing, Nonmelting or Untreated Natural Fiber (i.e., Untreated cotton, wool, rayon, or silk, or blends of these Materials) With a fabric weight of at least 4.5 oz/yd2 Shirt (long sleeve) Pants (long) Protective Equipment Safety glasses or safety goggles (SSR) Hearing protection (ear canal inserts) Heavy duty leather gloves (AN) (see Note 1) Arc-Rated Clothing, Minimum Arc Rating of 4 cal/cm2 (see Note 3) Arc-rated long-sleeve shirt and pants or arc-rated overall Arc-rated face shield (see Note2) or arc flash suit hood Arc-rated jacket, parka, rainwear, or hard hat liner (AN) Protective Equipment Hard hat Safety Glasses or safety goggles (SR) Hearing protection (ear canal inserts) Heavy duty leather gloves (See Note 1) Leather work shoes (AN) Arc-Rated Clothing, Minimum Arc Rating of 8 cal/cm2 (See Note 3) Arc-rated long-sleeve shir and pants or arc-rated overall Arc-rated flash suit hood or arc-rated face shield (See Note 2) and arc-rated balaclava Arc-rated jacket, parka, rainwear, or hard hat liner (AN) Protective Equipment Hard hat Safety glasses or safety goggles (SR) Hearing protection (ear canal inserts) Heavy duty leather gloves (See Note 1) Leather work shoes Arc-Rated Clothing Selected so That the System Arc Rating Meets the Required Minimum Arc Rating of 25 cal/cm2 (See Note 3) Arc-rated long-sleeve shirt (AR) Arc-rated pants (AR) Arc-rated coverall (AR) Arc-rated arc flash suit jacket (AR) Arc-rated arc flash suit pants (AR) Arc-rated gloves (See Note 1) Arc-rated jacket, parka, rainwear, or hard hat liner (AN) Protective Equipment Hard hat Safety glasses or safety goggles (SR) Hearing protection (ear canal inserts) Leather work shoes University of Northern Iowa Electrical Safety - Work Practices Program 25 Continued Hazard/Risk Category 4 DANGEROUS Protective Clothing Arc-Rated Clothing Selected so That the System Arc Rating Meets The Required Minimum Arc Rating of 40 cal/cm2 (See Note 3) Arc-rated long-sleeve shirt (AR) Arc-rated pants (AR) Arc-rated arc flash suit jacket (AR) Arc-rated arc flash suit pants (AR) Arc-rated arc flash suit hood Arc-rated gloves (See Note 1) Arc-rated jacket, parka, rainwear, or hard hat liner (AN) Protective Equipment Hard hat Safety glasses or safety goggles (SR) Hearing protection (ear canal inserts) Leather work shoes NO PPE EXISTS! DO NOT WORK ENERGIZED! University of Northern Iowa Electrical Safety - Work Practices Program 26