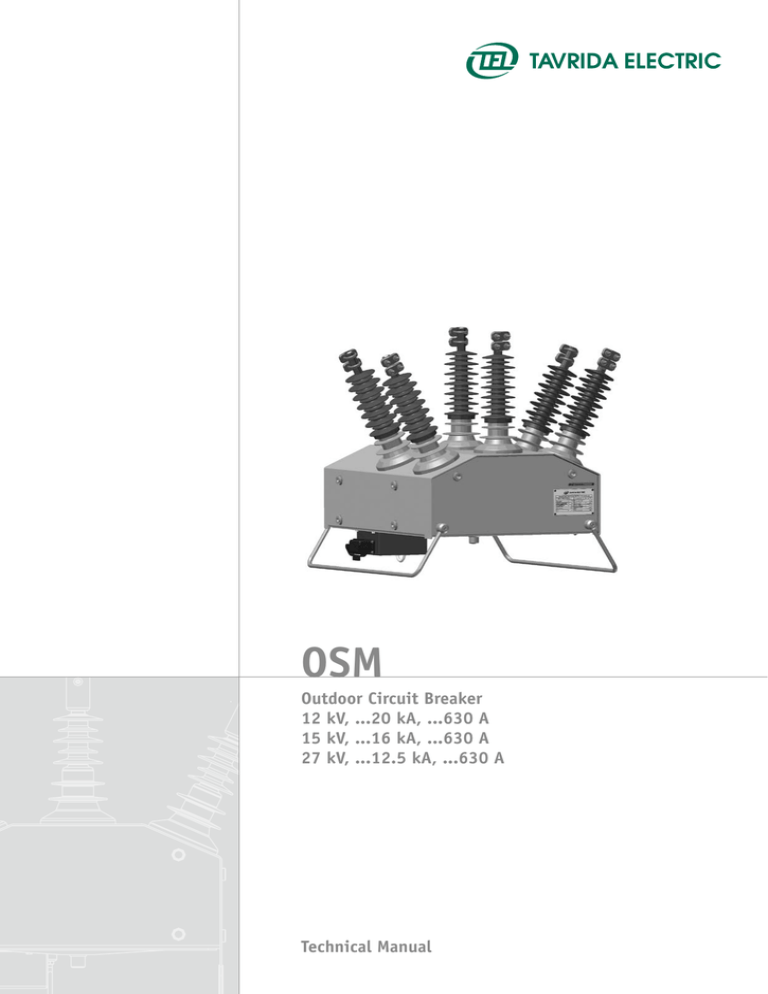

Manual

advertisement