Nov. 4 Distribution Automatic Transfer Switches and

Agenda Item:

A

GENDA

I

TEM

E

XECUTIVE

S

UMMARY

Consider Draft Resolution Authorizing Accepting the Bid for

Distribution Automatic Transfer Switches and Controls for the

Waste Water Treatment Plant

Presenter & Title: Michael J. Buffington, Superintendent of Electrical Services

Date: October 22, 2013

Please Check Appropriate Box:

X Committee of the Whole Meeting Special Committee of the Whole Meeting

X City Council Meeting

Public Hearing

Special City Council Meeting

Other -

Estimated Cost: $113,000

Budgeted?

If NO , please explain how the item will be funded:

X YES

NO

Executive Summary:

Bids were opened on October 3, 2013 for the purchase of Distribution Automatic Transfer

Switches and Controls for the Waste Water Treatment Plant . Three bid packages were received. This bid is under budget and will be expensed under line item 620.90.95.95-

815.25 in amount of $72,530.00. This distribution automation is to upgrade the reliability of electric service to the wastewater treatment plant during outage situations.

Attachments:

(please list)

Resolution

Memo

Recommendation / Suggested Action:

(briefly explain)

Award of the Distribution Automatic Transfer Switches and Controls to the lowest bidder

Resco in the amount of $72,530.00

.

RESOLUTION NO. 2013-119

RESOLUTION AUTHORIZING AWARDING

BID FOR DISTRIBUTION AUTOMATIC TRANSFER SWITCHES AND CONTROLS FOR

THE WASTE WATER TREATMENT PLANT

BE IT RESOLVED BY THE CITY COUNCIL OF THE CITY OF GENEVA, KANE

COUNTY, ILLINOIS

, as follows:

SECTION 1

: That the City Administrator is hereby authorized to award, on behalf of the

City of Geneva, bid for Distribution Automatic Transfer Switches and Controls for the Waste Water

Treatment Plant, as recommended by Staff, relating to the construction and maintenance of the electric distribution system.

SECTION 2:

This Resolution shall become effective from and after its passage as in accordance with law.

PASSED

by the City Council of the City of Geneva, Kane County, Illinois, this 4

th

day of

November, 2013

AYES: __ NAYS: __ ABSENT: __ ABSTAINING: __ HOLDING OFFICE: __

Approved by me this 4

th

day of November, 2013.

ATTEST:

City Administrator

PUBLIC WORKS DEPARTMENT

MEMORANDUM

October 7, 2013

Memo To: Mayor Burns and Committee of the Whole

Michael Buffington, Superintendent of Electric From:

Re: Recommendation for the purchase of Distribution Automatic

Transfer Switches & Controls

Bids were opened on Thursday, October 3, 2013 for the purchase of Distribution

Automatic Transfer Switches and Controls for the Waste Water Treatment Plant.

Participating vendors and their quotes are as follows:

Vendor Total Cost

Resco $72,530.00

HD Supply

G & W Electric Company

Staff Recommendation:

$73,718.00

$80,782.00

After careful and thorough review of the bids, it is the staff

’s recommendation to

COW, that COW approves and recommends to City Council to award the purchase of these items to the lowest bidder Resco in the amount of

$72,530.00.

Cc: Mary McKittrick, City Administrator

Dan Dinges, Director of Public Works

Hal Wright, Manager of Electric Operations

Jennifer Hilkemann, Manager of Distribution construction & Maintenance

Kirk Landberg, Purchasing & Inventory Coordinator

Distribution Switch Recommendation Page 1 10/7/2013

PUBLIC WORKS DEPARTMENT

MEMORANDUM

October 7, 2013

Memo To: Mayor Burns and Committee of the Whole

From: Michael Buffington, Superintendent of Electric

Re: Recommendation for the purchase of Distribution Automatic

Transfer Switches & Controls

Bids were opened on Thursday, October 3, 2013 for the purchase of Distribution

Automatic Transfer Switches and Controls for the Waste Water Treatment Plant.

Participating vendors and their quotes are as follows:

Vendor

Res co

Total Cost

$70,450.00

HD Supply

G & W Electric Company

Staff Recommendation:

$71,718.00

$78,482.00

After careful and thorough review of the bids, it is the staff's recommendation to

COW, that COW approves and recommends to City Council to award the purchase of these items to the lowest bidder Resco in the amount of

$70,450.00. Purchases for these items will be expensed under FY 2013-14 budget line item number

in

the of

_ _ _ _ _

Cc : Mary McKittrick, City Administrator

Dan Dinges, Director of Public Works

Hal Wright, Manager of Electric Operations

Jennifer Hilkemann, Manager of Distribution construction & Maintenance

Kirk Landberg, Purchasing & Inventory Coordinator

Distribution Switch Recommendation Page 1 10/7/2013

I

I

• _, , ., .... , '"''...,.

,,. , .. ,._,,,.Hu11r

LLl\lll,...l/Ui'I~ nr<u ....... 1..v1n.:."'.-.r''-'"'""°'"cr-rHJv1'31un.;>vr

1n'"'""''"''-"""'""'''"'"''' .... '"'""'"'-'-'--• ....... ' "' "'• ·- .... --···_-_·-_ _ -- - -

FU CHASE ORDER

CI Y

OF GENE

V.L

18 00 SOUTH STREET

GENE VA , ILLINOIS 60134

PHONE (630) 232-1503

N

o

~1soss

DELIVER TO SAME AS .

'JJDRESS A BOVE UNLESS NOTED BELOW. y

E

N

0

0

R

DJ!: , !::1 116/2013

Res co

2250 Pinehurst Dr.

Middleton, WI 53562-0000

D E PT.

For inquiry call

D

E

GENEVA ELECTRIC UTILITY

~

TO 1800 SOUTH STREET v

E GENEVA, IL 60134-2547

R

@ (630) 232-1503

T81 MS:

QUANTITY DESCR iPT!

O N

@ 70,450.000000

GU S/N Trans switch Automatic Distribution Transfer Switch

Per Bid 13-3

ForWWTP

TOTAL COST: v P S

/Sfo_oo

C, ~ ~l S lo;J!w

(>\ flo.66

~P P ll.t

\} fD fu y

(_J) u 1J C.,t

-------

L~ 7 ~1 s ~ tJ /J D

70,450.00

70,450.00

AMOUNT c

.PU

RCHASE SUB.JE

CH O: DO NOT' ADO Sil.LES TAX - - - - - CITI" IS EXEMPT

ORIG I NAL B I LL OF LADING MUST .4iCCOMPANY I NVOICE.

Mark all invoices, packages, etc., with our order number.

Wrltta n :icimowledgment of this order and date of shipment must b e made by return m ail.

Tnls o rder' is n o t to b e filled at prices higher than ihose last charged or quoted without o ur wr i tten c o ns e nt

W e !'6$l:!l"Ja th e right to cancel lhis order in whoie or in part if not filled according to

, sp9cil!

ca !!on

s.

N o rarurned goods t o be r ep l aced wiU1out farma! purchase ~rd.er.

No material i n e xcess of specifications will be accepted . it your terms are other ihan stated in this order please advise.

By ali:C!'lptin g this orde r yo u agree to d ef e n d , pro te ct a n d sa ve harmless lhe City of Ge n eva, . H lln o i s , its o u ccessors, assi g ns, and c us tom e rs an d the users of

~ro duots agai n st a ll s _ in law . or rts lh equ i ty , and fro m a ll da m a_q e cl ai m s and

;fi;marii:!s for actu al r :i ft eg ed f n frl n ge m enls or the U n ited Stat es , o r fore ign letters lat e nt, by reason o f the use of articles hereby or\'te _ .

REQUISmONER

CITY OF GENEVA ELECTRIC DEPARTMENT

1800 SOUTH STREET

GENEVA, IL 60134

SPECIFICATIONS AND CONTRACT DOCUMENTS 13-3 for

DISTRIBUTION AUTOMATIC TRANSFER

SWITCHES & CONTROLS

Bid Opening: 11:00 A.M.

Bid Deposit: NOT REQUIRED

Performance Bond: NOT REQUIRED

Specifications:

Return Bids To:

Attached

City Administrator

City of Geneva

22 South First Street

Geneva, IL 60134

THURSDAY, OCTOBER 3, 2013

Please Mark the Return Envelope and specify the:

1. Bid Opening Date & Time

2. Title of Job

For Additional Information regarding bid, contact:

Kirk Landberg

Purchasing & Inventory Coordinator

City of Geneva Electric Department

1800 South Street

Geneva, IL 60134

630-232-1503

Please submit entire document in duplicate intact.

CITY OF GENEY A

BID 13-3

DISTRIBUTION AUTOMATIC TRANSFER

SWITCHES & CONTROLS

Bidding Documents

ADDENDUM NO. 1

September 27, 2013

1. Scope . This Addendum No. I consists of pages AD 1-1, AD 1-2, AD 1-3 and AD 1-4

2. ADl-2: Questions asked in blue, Answers in red

.

3. ADl-3 and ADl-4: Information on Network Transceiver

4. Acknowledgement by B i dde r. Each Bidder is requested to acknowledge receipt of this Addendum No. 1 in the space provided below. Include in bid package.

Signed by:

BIDDER: Resco

~~~~~~~~~~~~~~~~

BY:

Gary Toboyek

Inside Sales

10/1/13

ADl-1

CERTffICA TION OF COMPLIANCE

1 .

2 .

The undersigned hereby certifies as follows:

That he has the authority and consent to make this certification on behalf of the bidder,

R

E'SCC)

(Rc...v-,._/

1~lec..fr1c:_ s "'-f ely e.. .. p .

)

(Name of Co mp a ny)

That he has knowledge of the City of Geneva Codes pertaining to the disqualification of certain bidders.

3 .

4.

That he knows that the bidder listed above is not disqualified from bidding under the aforementioned sections.

That he has knowledge of the City of Geneva ordinances relating to Fair Employment

Practices and knows and understands the contents thereof; he certifies hereby that it is the policy of the bidder to recruit, hire, train, upgrade, promote, and discipline its employees without regard to race, creed, color, religion, age, sex, or physical or mental impairment.

5 .

6 .

7 .

8.

That said bidder is not barred from bidding on the aforementioned contract as a result of a violation of Sections 33E-3 or 33E-4 of Chapter 720, Illinois Compiled Statutes, [720

ILCS 5/33E-3 and 33E-4 (2009)].

That pursuant to Chapter 65, Section 11-42.1-1 [65ILCS 5111-42.1-1] of the Illinois

Revised Statutes, the bidder is not delinquent in the payment of any taxes administered by the Department of Revenue.

That the contractor (either as an individual or company agrees to provide a drug free workplace as provided for by the "30 ILCS 580/1 et. seq."

That all work under this contract shall comply with the Occupational Safety and Health

Act (OSHA) of 1975 as amended, and all other Federal, State, or Local statutes, rules, or regulations including all City of Geneva Safety Procedures affecting the work done under the contract.

9 . That all work done under this contract shall comply with the Prevailing Wage Rate Act of the State of Illinois [820 ILCS 130/1 et. seq.] County of Kane, Illinois in effect at the time the work is performed. l 0. Contractor acknowledges that th e Free dorn o f lnfo mmlio n Act , 5 ILCS 140/1 et seq. (the

"ACT") places an obligation on the City of Geneva to produce certain records that may

be in possession of the Contractor. Contractor shall comply with the record retention and documentation requirements of the Local Records Retention Act, 50 ILCS 205/1 et seq. and the Act and shall maintain all records relating to this Agreement in compliance with the Local Records Retention Act (complying in all respects as if the Contractor was, in fact, the City). Upon notice from the City, Contractor shall review its records promptly and produce to the City within two business days of said notice from the City the required documents which are responsive to a request under the Act. If additional time is necessary to comply with the request, the Contractor may request the City to extend the time to do so, and the City will, if time and a basis for extension under the Act permits, consider such extensions. In the event Contractor fails to produce the requested records or fails to produce the requested records within the time period required above and the City is assessed a fine, fee or penalty for failure to timely comply with Act do to Contractor's actions, Contractor shall reimburse City for all fines, fee or penalties, including reasonable attorney's fees, paid by the City.

By submission of this bid, I certify that the bid has been arrived at independently and has been submitted without collusion between or among any vendor of materials, supplies, equipment, or services.

f?GS.Co

Name of Corporation, Partnership, or

Proprietor

Address

City State Zip

Telephone

f,.w.P, s.._/"-'

Auth;.;ze(lignature/Title

SUBSCRIBED AND SWORN to before me hi; day of

·

ICC tori k .

20 I ;\

~!,\_

Notary Public

My commission expires:

L\ll'\I'

V\ d8 , JO

l

~

-

Commun

.

ication Architecture

Operations/SCADA

Existing Fiber Optic

Single-Mode Cable {Serial)

Existing H&L

Fiber Transceiver

NewNEMA

3R Cabinet

New Serial Cable from H&L to RTU

Existing RTU

I

New Serial Cable from RTAC to RTU

New SEL 3530 RTAC

DNP3/IP via New

Seri~I

Cable from

651Rl to RTAC

I

City

o

f

Geneva,

111111

IL

Mid-Point (Normally Open}

Existing Viper ST with SEL651Rl control (never hooked up to rtu)

Hardwired Cable

Notes:

• Multimode Fiber Optic cable from each

651R2 to the SEL 3530 RTAC. Cable to be provided and installed by others.

• All fiber will terminate in splice trays and be spliced to Pigtail jumpers/patch panels.

• 651R2 program to include provisions for hardwired trip/close (3ph), ATC on/off commands and open/close (3ph) and ATC on/off status.

• Hardwired 1/0 to be connected from each of the 651R relays to the RTU. Cable to be provided and installed by others.

• DNP communication from each recloser to be concentrated and converted to serial by the

SEL 3530 RTAC. A single DNP serial connection will be made between the RTU and RTAC.

• Existing RTU and H&L Transceiver. Serial cable from the RTU to the H&L provided and installed by others

• New NEMA 3R cabinet to be adequately sized to install the equipment shown and all associated hardware.

Hardwired Cable

Hardwired Cable

IEC61850 GOOSE messaging and DNP3/IP via

New Multimode Fiber Optic

Ethernet Cable

East Source (Normally Closed)

New Viper ST with SEL651R2 control w/ multimode fiber optic port

West Source (Normally Open)

New Viper ST with SEL651R2 control w/ multimode fiber optic port

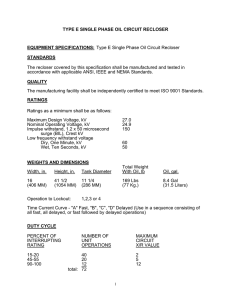

SECTION 26 13 **

OVERHEAD, DISTRIBUTED AUTOMATIC TRANSFER

PART1-GENERAL

1 .

01 .

1 SCOPE

A. This specification covers the design , manufacture, factory production testing and possible field service assistance during installation and commissioning of a two recloser, pre-configured automatic transfer system with a voltage rating of 15.5 kV.

1.02 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division 1 Specification Sect i ons , apply to this Section.

1.03 SUBMITTALS

A. Submit shop drawings and product information in the quantities listed according to the Conditions of the Contract. All transmittals shall be identified by purchaser name, purchaser location and purchaser's order number.

B . Approval documents shall include:

1. Three-line diagrams

2. Schematics

3. Electrical bill of material

4. Transfer function description

C. Final documents shall include:

1 . Documents listed in 1 .

3 . B above

2 . Wiring diagrams

3 . Recommended spare parts l i st for start-up support

4 . Instruction manual

D. Product data : Include features , characteristics and ratings of individual reclosers and other components.

E. Shop drawings : Detail equipment assemblies and indicate dimensions, weights, method of field assembly, components and location and size of each field connection . Include the following:

1. Short-t i me and short-circuit ratings of recloser assembly

2. Detailed wiring diagrams showing wiring for power, signal and control systems including differentiation between manufacturer-installed and field-installed wiring

3. Factory acceptance test report if applicable .

4 . Detailed description of functionality describing the application , communication, and settings of the programmed relays.

1.04 QUALITY ASSURANCE

A. Manufacturer Qualifications: The chosen manufacturer shall have at least 5 years experience in manufacturing solid dielectric type reclosers. The manufacturer of the switches shall be completely and solely responsible for the performance of the automated system.

B . The manufacturer shall furnish certification of ratings of the reclosers upon request.

C . The switch shall comply with requirements of the latest revisions of applicable industry standards, including :

September 18, 2013

OVERHEAD DISTRIBUTED ATC, TWO RECLOSER

26 13 **-1

City of Geneva, 11

1 . IEEE C37 .

60, IEEE C37 .

74, ANSI/IEEE 386 , IEC 60265-1

D . The switch manufacturer shall be ISO 9001:2000 and ISO 14001 : 2004 certified .

1 .

05 DELIVERY, STORAGE, AND HANDLING

A. Reclosers and controls shall be shipped preassembled at the factory . No field assembly shall be required .

B. The contractor, if applicable, shall handle, transfer and move the switches in accordance with manufacturer's recommendations.

PART 2- PRODUCTS AND FUNCTION

2.01 MANUFACTURERS

A. The medium-voltage, overhead, preprogrammed automatic transfer shall use two reclosers manufactured by G&W Electric or pre-approved equal. Approved manufacturers are as follows:

1 .

2 .

G&W Electric

2 .

02 RECLOSER CONSTRUCTION

A. Enclosure - Recloser enclosure shall be dead tank design. The magnetic actuator and corresponding linkage assemb l y shall be housed within a high impact , UV stable, air insulated , poly-carbonate enclosure . A contact position indicator and air vent shall be provided . Lifting provisions shall be provided.

B. Operating Mechanism - The recloser shall be capable of interrupt i ng faults on each phase individually (single option) or all three phases simultaneously (triple option) . Interruption of a fault or load current shall be accomplished with vacuum interrupters located inside a solid dielectric insulation . The operating mechanism shall utilize a magnetic actuator for opening and closing of the vacuum interrupters . The manual trip and lockout handle shall be made of stainless steel for maximum corrosion resistance. Vacuum interrupter contact position indication shall be accomplished using green (open) and red (closed) indicators located on the bottom of each mechan i sm enclosure and through LEDs inside the control.

E. The operating temperature range shall be -60 to +65 degrees C .

F . Vacuum interrupter contact posit i on indication shall be accomplished using green (open) and red

(closed) indicators located at the bottom of each interrupter.

G . Interruption of the fault or load current shall be accomplished through vacuum interrupters molded in to Bisphenol-A epoxy or equivalent dielectric mater i al .

H. Sensing - Voltage sensing shall be an integral part of the each interrupter module on both line and load sides of the interrupters calibrated in the factory to less than 1 % error . Current transformers shall be dual ratio ( 1000 : 1 and 500: 1) and integrally molded into the solid dielectric insulation .

I. Reclosers shall be pole mounted unless otherwise specified .

2 .

03 DESIGN RATINGS

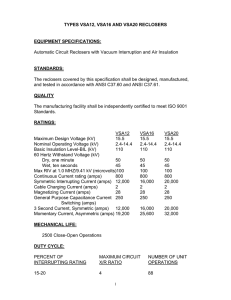

The recloser shall be rated :

-

SELECTION OF RATINGS IEEE/IEC

15.5

Maximum Design Voltage, kV

110 Impulse Level (BIL) Voltage, kV

September 18, 2013

OVERHEAD DISTRIBUTED ATC, TWO RECLOSER

26 13 **-2

City

of

Geneva

,

11

Continuous Current, Amperes

Load break Current, Amperes

8 Hour Overload, A, RMS

800

800

960

One Minute (dry)

Ten Second (wet)

Interrupting Current, kA, RMS SYM

Making Current, kA, ASYM RMS

Making Current, kA, ASYM Peak

Short Circuit Current, kA, SYM, 3 Second

Mechanical Endurance, Minimum Operations

50

45

12.5

20

32

12 .

5

10000

-

2.04 BUSHINGS

Bushings shall be 600 amp Apparatus bushing with elastomeric sheds installed over the bushing.

2.05 OPERATION

Monitoring of the circuit shall be accomplished using internal , multi-ratio current transformers.

The unit shall be powered by a customer supplied external 120 VAC source . Dead-line operation feature shall permit limited time operation using the control batteries if AC power is lost. A remote status feature shall provide the capability to remotely monitor the status of the power supply.

Recloser sequencing, tripping and overcurrent sensing shall be an automatic function of the electronic control. If a fault current is sensed on any phase, the recloser will trip all three phases.

Manual open and lockout shall be provided by an external, hook stick operable handle.

Operation of the manual open handle shall disable any local or remote closing operation until the handle is reset. An operations counter viewable through an opening at the bottom of the mechanism enclosure shall be provided.

2.06 MOUNTING

Lifting provisions shall be provided . Mounting provisions shall be supplied as a galvanized, mild steel pole mounting bracket permitting arrester mounting on both the load and line side bushings; a galvanized, mild steel substation frame as indicated.

2.07 ELECTRONIC CONTROLS

The recloser shall be controlled using the Schweitzer® model SEL-651 R2 control. Control cable and connections shall permit easy field retrofit from other style reclosers to the Viper. The controls shall be user programmable .

A. The microprocessor-based recloser control shall provide a combination of functions including protection, monitoring, control, fault locating, and automation. Recloser control self-checking functions shall be included . Specific operational and functional requirements are as follows .

1 . Autoreclosing Control - The recloser control shall incorporate a four-shot control. It shall include four independently set open time intervals, an independently set reset time from reclose cycle, and an independently set reset time from lockout.

City of Geneva, 11 September 18, 2013

OVERHEAD DISTRIBUTED ATC, TWO RECLOSER

26 13 **-3

2. Coordination With Downstream Reclosers - The recloser control shall include 38 standard recloser time-overcurrent curves and sequence coordination logic for secure and dependable operation.

3. Phase Fault Overcurrent Protection - The recloser control shall incorporate phase and negative-sequence overcurrent elements for detection of phase faults. For added security , the recloser control shall provide directional elements, load- encroachment logic, and torque-control capability (internal and external).

4 . Ground Fault Overcurrent Protection - The recloser control shall incorporate residual ground and neutral ground overcurrent elements for detection of ground faults . For added security , the recloser control shall provide directional e l ements and torque-control capability ( i nternal and external) .

5. Phase Under- and Overvoltage Elements - The recloser control shall incorporate under voltage and overvoltage elements for creating protection and control schemes, including but not limited to the following : voltage checks (e.g., hot bus/dead line) for reclosing; blown transformer high-side fuse- detection logic; control schemes for capacitor banks .

6. Sequence Voltage Elements - The recloser control shall incorporate positive-, negative-, and zero-sequence voltage elements that can be logically configured for either under- or overvoltage applications.

7 . Under- and Over frequency Protection - The recloser control shall incorporate four levels of under-lover frequency elements for detection of power system frequency disturbances .

Each setting level shall use an independently set timer for load- shedding or generatortripping schemes .

8 . Synchronism Check - The recloser control shall include two synchronism-check elements with separate maximum angle settings (e.g., one for autoreclosing and one for manual closing). The synchronism-check function shall compensate for close time and constant phase angle differences between the two voltage sources used for synchronism check

(phase-angle differences settable in 30-degree increments) .

9 . IED Communications - The recloser control shall include the capability for communication of internal logic values to a remote relay or recloser control via serial communications .

These values shall be available for use in control logic .

10 . Secure Communications - The recloser shall include an optional accessory for converting an EIA-232 serial port to encrYpted and authenticated IEEE 802.11 b w i reless communication. Software shall be provided with this accessory for access to the wireless port using a personal computer (PC) or personal data assistant (PDA).

11 . Operator Controls - The recloser control shall include 1 O operator controls on the recloser control front panel; these functions shall also be accessible in the recloser control logic.

The operator control panel shall include pushbuttons and LEDs with programmable functions and indications.

12 . Event Reporting and Sequential Events Recorder (SER) - The recloser control shall be capable of automatically recording disturbance events of 15 or 30 cycles with settable pre-fault duration and user-defined triggering . Events shall be stored in nonvolatile memory . The recloser control shall include an SER that stores the latest 512 entries.

13 . Status and Trip Target LEDs - The recloser control shall include 16 status and trip target

LEDs .

14. Overload and Unbalance Alarms - The recloser control shall include user-settable demand current thresholds for phase, negative-sequence, neutral , and residual demand measurements.

15. Recloser Wear Monitor - The recloser control shall include a recloser wear monitor with user-definable wear curves, operation counter, and accumulated interrupted currents by phase .

16 . Battery Monitor - The recloser control shall measure and report the battery level. Two user-selectable threshold parameters shall be provided for alarm and control purposes .

City of Geneva, Il September 18, 2013

OVERHEAD DISTRIBUTED ATC, TWO RECLOSER

26 13 **-4

17 . Fa ult Locator - The recloser control shall include a fault-locating algorithm to provide an accurate estimate of fault location without communications channels, special instrument transformers, or pre-fault information.

18 . Automation - The recloser control shall include 16 local control elements, 16 remote control logic points, 16 latching logic points, and 16 display messages in conjunction with a local display panel included in the recloser control. The recloser control shall have the capability to display custom messages.

19 . Recloser Control Logic - The recloser control shall include programmable-logic functions for a wide range of user-configurable protection, monitoring, and control schemes.

20. Communication - The recloser control shall include two independent EIA-232 serial ports, one 1 OOBase-FX fiber optic port , one optional 1 OOBase-TX Ethernet port and one

EIA-485 serial port for external communications . DNP3 Level 2 protocol with bit-mapping shall be provided.

21 . IRIG-B - The recloser control shall include an interface port for a demodulated IRIG-B time synchronization input signal.

22 . PC Software - The recloser control shall include compatibility with a PC software program for use in programming control settings and logic functions, and retrieving event data .

The PC software shall be included, but not required, to use the recloser control.

23 . The relay must allow the recloser be opened within 24 hours on loss of AC power from the recloser control or SCADA command.

2.8 LABELING

A. Hazard Alerting Signs

1. The exterior of the enclosure (if furnished) shall be provided with "Warning--Keep Out--

Hazardous Voltage lnside--Can Shock, Burn, or Cause Death" signs.

2. Each unit of switchgear shall be provided with a "Danger--Hazardous Voltage--Failure to

Follow These Instructions Will Likely Cause Shock, Burns, or Death" sign . The text shall further indicate that operating personnel must know and obey the employer's work rules, know the hazards involved, and use proper protective equipment and tools to work on this equipment.

3 . Each unit of switchgear shall be provided with a "Danger-Keep Away--Hazardous

Voltage--Will Shock, Burn, or Cause Death" sign.

B . Nameplates, Ratings Labels, and Connection Diagrams

1 . Each unit of switchgear shall be provided with a nameplate indicating the manufacturer's name, catalog number, model number, date of manufacture, and serial number.

2. Each unit of switchgear shall be provided with a ratings label indicating the following : voltage rating; main bus continuous rating; short-circuit rating; fault interrupter ratings including interrupting and duty-cycle fault-closing; and load break switch ratings including duty-cycle fault-closing and short-time .

2 .

9 COMMUNICATION AND TRANSFER

A. Communication

The method of communication between the two (2) new recloser controls and the SEL 3530

RTAC shall be IEC 61850 MMS GOOSE and DNP3/IP communication protocol . The medium for communication shall be a provided, ADSS, pre-terminated, multimode fiber optic cable of the required length. The communication between the third existing recloser control and the SEL 3530

RTAC shall be DNP3/IP via a serial cable. The new NEMA 3R control cabinet is designated as the data collector and shall incorporate the collocated communications and hardware including a new SEL 3530 RTAC with (4) four electrical ports and (2) two fiber-optic ports, and the existing

H&L fiber optic transceiver and RTU . DNP communication from each recloser to be concentrated and converted to serial by the SEL 3530 RTAC. The medium for communication medium between the RTAC, RTU and transceiver shall be serial cable . In addition (3) three hardwired

September 18, 2013

OVERHEAD DISTRIBUTED ATC, TWO RECLOSER

26 13 **-5

City of Geneva, Il

communication cable(s) will connect each of the (3) three SEL 651 R controls to the existing RTU.

This will be used to enable remote monitoring and control of the devices. Each device shall include provisions for hardwired trip/close (3Ph), ATC on/off commands, and open/close (3Ph) and ATC on/off status. See attached communication architecture diagram.

B.

1 . The communications between the SEL 3530 RTAC and the SEL 651R2 controls shall be high speed, relay-to-relay communications technology that sends internal logic status, encoded in a digital message, from one device to another.

2 . The received bits of one relay shall follow the status of the respective transmit bits sent from the other relay. Each of the relays in the scheme shall repeatedly send and receive the digital logic message while continually monitoring and checking the received message integrity. An internal monitoring point shall assert when a good signal is received and de-asserts immediately upon detection of a bad message.

3. The communication channel shall record a performance log of data which includes the following : Total failures, last error, relay disabled yes/no, data error, longest failure, resync required, under run, unavailability, overrun, parity errors, framing error, loop-back, and if a bad re-sync occurred . In addition to the communications log, a separate communications sequence of events shall be available. This report shall contain time tags for the assertion and de-assertion of any of the reported communications failures.

Automatic Transfer

1. The automatic transfer scheme shall activate on loss of source voltage. The (2) two new

Reclosers shall be designated as either Primary Source or Alternate Source. Primary

Source denotes the preferred supply for normal operation. Alternate Source denotes the back up supply when the Primary Source experiences a loss of voltage. The existing third recloser located between the two independent sources is the normally open point for the two independent sources and will be used as a remote SCADA operable switch. It will not be part of the automatic source transfer scheme. a. When Primary Source voltage drops to below XX% of nominal voltage (XX kV) for more than 60 seconds, the Primary Source recloser will first verify that the Alternate

Source has voltage, the Primary Source then opens, the Alternate Source will then verify that the loss of voltage on the Primary Source was not due to a downstream fault, if this is true the Alternate Source recloser closes to restore power (openbefore-close operation). b. The Alternate Source will continue to supply power until the Primary source voltage remains above XX%i of nominal voltage (XX kV) for 30 minutes. After 30 minutes) above XX% of nominal voltage, Primary Source recloser will close and Alternate

Source recloser will open maintaining power to loads (close-before-open operation) .

Synchronism Check functionality will be incorporated into this scheme to verify frequency , voltage, and phase control are synchronized before the close-before-open operation takes place . c. Operation shall be verified by performing a factory acceptance test. A complete report of the test shall be supplied with the equipment. d. Front panel settings required (Primary Source and Alternate Source recloser relays)

Aux 1 - select I de-select Primary Source

Aux 2 - activate I disable transfer scheme

2. Device programming software shall be SEL AcSELerator Quickset® relay programming tool with the following features: a . Create, edit, store, and transfer SEL device settings . b. Develop programmable logic equations offline with easy-to-use configuration tools . c . Test and commission installations with display of live device measurements and status information.

September 18, 2013

OVERHEAD DISTRIBUTED ATC, TWO RECLOSER

26 13 **-6

City of Geneva, 11

d . Use the configurable Human Machine Interface to obtain pertinent device data locally or from a remote location . e. Use the built-in waveform viewer to quickly analyze fault records and device element response. f. Obtain full integration with ACSELERATOR QuickSet Designer® templates for creating custom views of settings to simplify commissioning of multiple SEL devices. g. Retrieve updates delivered to your computer on a schedule that you choose through use of SEL Compass software . h. AcSELerator Quicksel® design templates and settings shall be supplied with products.

September 18, 2013

OVERHEAD DISTRIBUTED ATC, TWO RECLOSER

26 13 **-7

City of Geneva, Il

PART 3- EXECUTION

3.1 INSTALLATION

A. General: electrical contractor shall install reclosers in accordance with manufacturer's written instructions and the following specifications.

3.2 ADJUSTMENTS AND CLEANING

A Protective-relay settings: Set relays in accordance with the purchaser's coordination study (not part of this Contract).

3.3 TESTING - RECLOSERS (Generic)

A Each individual recloser shall undergo a series of mechanical operations verifying contact closing/opening velocity, travel profile, timing and phase synchronicity.

B. The recloser shall be AC hi-pot tested one minute phase-to-phase, phase-to-ground and across the open contacts.

C. Circuit resistance shall be checked on all ways.

D. Timing tests shall be conducted to verify TCC performance.

E. Each recloser and relay I controller shall be tested as a system.

3.4 FACTORY ACCEPTANCE TESTING OF AUTOMATION PACKAGE

A Time from loss of primary source to time of appearance of voltage on secondary is per City of

Geneva, IL standards.

B. Time from reappearance of voltage on primary source to the time of return transfer is per City of

Geneva, IL standards.

3.5 WARRANTY

A Equipment manufacturer shall warrant that all goods supplied are free of non-conformities in workmanship and materials for three years from date of purchase.

B. Equipment manufacturer shall warrant the DA solution for 3 years, including parts and performance. Does not include labor (in & out charges).

3.6 DEMONSTRATION

A Switchgear manufacturer shall include the following as part of the total cost:

1. Field service person on-site for the start-up of the ATC.

2. Training on controls and ATC set-up to maintenance, operations, or engineering personnel.

END OF SECTION

September 18, 2013

OVERHEAD DISTRIBUTED ATC, TWO RECLOSER

26 13 **-8

City of Geneva, II

1. The new NEMA 3R enclosure will house the SEL 3530 RTAC, H&L Fiber Transceiver, and Existing RTU. Is this enclosure provided by the City of Geneva? If not, is a specific cabinet sized desired. What are the dimensions for the H&l Fiber Transceiver, and Existing RTU? What provisions are required/needed for mounting. What are the electrical requirements (voltage and current). Who will install these existing devices? a. The enclosure is to be provided by the bidder. A size has not be specified. It should be equipped for both pole or pad mounting . The data sheet for the H&l is attached. The existing RTU is 12 inches square and also requires an additional 6 inches on each side (12 inches total) for mounting remote power supplies, communication modules, supply fuses, etc .. A back plt:1te or board are required for mounting the H&L and

RTU. Power requirement for the RTU and H&L are 120 volts AC and approx. 10 watts each.

, Geneva can install in the field or can provide the components to the successful bidder.

2. "The unit shall be powered by a customer supplied external 120VAC source. "Can we assume that the NEMA 3R enclosure will also be powered by a customer supplied external 120VAC source"? Will a power supply or battery back-up also be required/provided? a. Yes, a customer supplied 120VAC external source will be provided. The bidder will need to supply the required battery backup.

3. The SEL 3530 - 4 RTAC is to be mounted in the NEMA 3R enclosure. What mounting provisions are desired for the RTAC? Panel, Rack, Surface? a. Rack mount with front and rear access similar to the existing cabinet is desired.

4. How big are the hardwire cables going to each 651R2 and NEMA 3R enclosure. How big are the fiber optic cables? How big is the serial cable from the 651Rl? What size cable entrances are needed to be supplied into the 651R2 cabinet and NEMA 3R enclosure. a. These dimensions are not known at this time. Assume all cable dimensions to be J.-2 inch or less if knockouts are to be provided. Field modifications will be made as required.

5. Where is the splice tray/ patch panel located? Is it in the NEMA 3R enclosure or external? a. It will be in the enclosure. Allow 5 inches of rack space.

6. Are there any accessories/options that should be included in the 651R2 cabinets or NEMA 3R enclosure: Heater, auxiliary shelves, GFCI outlet, power supply, etc? a . A heater, battery backup, and GFCI outlet are needed.

7. "The unit (recloser) shall be powered by a customer supplied external 120VAC source". Should we include an alternate quote for PT's? Oil or Solid Dielectric? One each side? a. No. Voltage sensing for the relay control logic is all that needs to be provided.

8. I know we discussed it originally but would you consider locating the RTAC, H&L receiver, and RTU in one of the

651R2 recloser cabinets. It may be possible and might make a cleaner and easier installation? Let me know if this could be a consideration. a. This would certainly be considered and can be determined after the bid opening .

ADl-2

instruments

The Flberoptic

Communications

Specialists

If you want to increase the reliability and speed of your data communications system, then you need Fiberloop II with up to 1 6 virtual channels to perform multi-drop, radial, or loop serial RS-232 and RS-485 communications.

• Up to 16 virtual channels (A·P)

• 4 , 8 or 16 serial ports

• Up to 250 transceivers arranged

In a loop or radial bus topology

(scalable)

• Highly reliable, fault-tolerant, redundant, self-healing loop technology

• Variety of plug-in optical modules for varying distances between stations (up to 53 miles)

• Vastly superior noise Immunity and electrical Isolation

• Supports all byte protocols

(e.g. DNP, UCA)

• LED status indicators, non- volatile memory, and optical power meter

• 8 character alphanumeric LED display for diagnostics and port

Information

• Integrated Network Management

Software: HLPanel3

• Compatible with existing H&L

Model 560/562 Flberoptic

Transceivers

9200-5077

02/08/3112004

Overview

The Fiberloop 11 ·system incorporates H&L's field-tested fiberoptic transceiver technology, the Model 561, with

HLPanel3 ·, a Windows<B>-based network management software. You can add as many 561 transceivers as you need to connect Remote Terminal Units (RTUs) or other

Intelligent Electronic Devices (IEDs) to the SCADA masters at a Model 561 configured as the network controller.

Together they allow you to:

- Improve your ability to locate electric system faults.

- Ensure worker safety.

- Manage data in a single accessible system.

- Monitor and control switchgear remotely.

- Respond quickly to service outages and restore power.

Flexible and Self-Heating

The Model 561 transceiver is used on a pair of multidropped fiber for all remote devices, such as RTUs,

Programmable Logic Controllers (PLCs), IEDs, etc. You can arrange the transceivers in a loop or bus (radial) topology, which allows you the flexibility to greatly expand your system in the future.

The Model 561, used as a master unit, is the head end for the SCADA masters. All signals pass through the controller, which can automatically "self-heal" the system and re-route data in the event of fiber cuts or a transceiver failure anywhere in the system. The arrangement of transceivers in a loop configuration provides o highly reliable, fault-tolerant solution. Fiberloop II, in small systems, can provide a dedicated channel for each RTU.

Flberloop II at Work

In the Fiberloop II system, if a SCADA master needs to be at another location (e.g., a water plant master is typically in a different location than the electric department control center), then you can install serial port jumpers at the 561 network controller to bridge two virtual channels and remotely bridge that remote master on one virtual channel to another virtual channel that broadcasts to all units.

You can place Model 561 transceivers in the system as standby controllers at any location connected to a standby

SCADA master computer, which allows them to take over the Fiberloop II operation in case the primary controller fails. You con add as many as 250 additional Model 561 transceivers to the system and, depending on the model, you can connect up to 4, 8, or 16 RTUs or other IEDs to each one (32 devices can be multi-dropped on the optional

RS-485 port).

ADl-3

Integrated Network Management Software

Your purchase of Fiberloop II also includes HLPanel3 , extensive network management, configuration , and diagnostic software. Other fiberopt i c solutions only allow you to catch problems after there is a serious break in the system.

HLPanel3 helps you proactively maintain your system and streaml i ne your maintenance tasks.

This Microsoft " Windows-based application allows you to view the system at all times w i th graphical, easy-to-use window s and to access real-time information about its condition. The software supports remote connect i ons to the fiberoptic network via a standard modem. Additionally, through TCP/IP connect i vity, you c an monitor and configure the Fiberloop II system via your Intranet or the Internet . Up to four users can monitor an active session.

, ,_..,.,,, .... liTii..!..l~Jli.:!.Jllll.21..ttl...!lJ~

~ SW1D1 t•

SW1D2

SWHJJ

""'"'

·

~ ·~ r~~ r-....~ 1~ 0.11

FW: ~ ,

' 1 1 ,..1_

;.Nf1'ijt".... ..._~ p,,.

j~ :

~w__.

fliiiTi r" .!---~~ ,...k

.

~ ;

"""91 .... , llnlH-~ "" ~

&;

~~

.

..

. ,

::: , .,.,.

;J

....... _,,__ 1-

3

' " VrualOiamelMap

-

~o;,.&1Po1•

'"'"°""'"'""'·

SW1DIPl·M--SOIDlla

S\lllD311] Slwe{F'VllfRTU1)

J

0 S\¥1B4t1J-Sb<rv[P."llATU~I

Q.

9:WAJERSCADA

P";tt l ) ~i\ Tl

C$N91-MOCl.eit lM!l#Jl-Mdet !

~ .. S\ll'lm lll Mada IW.U S(.flOA Mala)

IG• Sr.ADA (SEL M..U.J

_:_

_____

a

'iW1D412' Sin-ol""'MRTIJZI .

~

....::::=======:=: •.!.I::

•

_J _.

A separate program, c alled SerialServer ™, connects a serial port on the remote PC t o a TCP/IP socket . You i nstall this program on the PC that is physically connected to a

Fib e rloop II 561 controller maintenance port. (A TCP/IP demonstration system is available at the H&L Instruments lab via the Internet.) A password provides additional security for

TCP/ I P connections . When companies secure the Ser i alServer port with a p a ssword , any connection request to that port must "know" the pass w ord i n order to connect.

After installing your H&L transceivers, you can use HLPanel3 to view a System Map of your entire set up. This Map represents the configuration and status of the fiberoptic network . The soflware also includes Unit Configuration tools to configure and monitor parame t ers within any unit, as well as Panel

Configuration capab i lities. The system records all network events in a log file and displays alarms .

If problems with the fibers occur, you can quickly identify and correct any issues . HLPanel3 helps you stay i nformed and eliminates the guesswork often found in fiberoptic maintenance, saving time and money . You no longer have to physically drive to individual units to record their status . From the conven i ence of your office, you can :

- Check fibers , locations, unit names, and ser i al numbers.

- Assign unit names and location tags.

- Configure your units.

- Designate channels and decide channel speed .

- Read optical signal strength .

- Turn off serial ports and re-route signals .

- Print reports on system activity, i ncluding diagnostic reports showing mis-wired fibers and malfunctioning units.

Serial Port:

600, 1200, 2400, 4800, 9600, l 9 .

2kb/s, 38.4kb/s full duplex RS-232 ports, 4 DB-9Fports standard,

8 ports (option), RS-485 opto-isolated (option)

Envlronmental/Mechanlcal:

Operat i ng Temperature : -40 ° C to + 85 ° C

5% to 95% RH

Net Weight: 3.251bs

9"L X 6"W X 3.3"H

Flberoptlc Connector Options:

ST

Optical Output Power:

LED > -18dBm @ 850nm multimode (62/125 fiber)

LED > - l 4dBm @ l 31 Onm multimode (62/125 fiber)

LED > 24dBm @ l 31 Onm singlemode

Laser > -3dBm @ 131 Onm multimode (62/125 fiber)

Laser > -8dBm @ 131 Onm singlemode

Optical Receiver Sensitivity:

> -38dBm multimode

> -42dBm singlemode @ 131 Onm [1 X 10-9 BER]

Optical Budget:

20dB multimode LED @ 850nm (62 / 125 fiber)

28dB multimode LED@ 131 Onm (62/125 fiber) l 8dB singlemode LED@ 131 Onm

39dB multimode Laser@ 1310nm (62/l25fiber)

34dB singlemode Laser@ 131 Onm (62/125 fiber)

Power Options (10.4 watts max):

12Vdc , 24Vd c, 4 8 Vdc , l 25V dc!l 20Vac

50 6 0 Hz, 250 V dc/ 230Vac 50 ~ 6 0 Hz

Alarm Outpull

1 A (N .

O.) opto-isolated solid state re l ay

System Requirements for HLPanel3:

Microsoft ® Windows 98/2000/NT /XP

Fiberloop II and HLPanal3 are trademarks of H&L Instruments All other products are trademarks or registered trademarks of !hair respective owners. In our effort to continuously Improve functionality, specincations am subject to change.

-

!' i ~

= ;;...__-

~

instruments

www .

hlin s t ru m e nt s .

co m

PO Box 580

34 Post Road

North Hampton,

New Hampshire 03862

USA

Tel : 603.964.1818

Fax: 603.964.8881

9200-5077

02/08/31 /2004 ADl-4

Name of Bidder

Address of Bidder

RES CO

FORM OF PROPOSAL

2250 Pinehurst Dr. Middleton WI 53562

800-356-9370

To: City Administrator

City of Geneva

22 South First Street

Geneva, IL 60134

The undersigned bidder, having examined the specifications of the following proposal, hereby proposes to provide the required labor, services, and materials described in this Form of

Proposal, the Instruction to Bidders, and Specifications for the sum or sums stated hereinafter:

I. DISTRIBUTION AUTOMATIC TRANSFER SWITCHES & CONTROLS

Distribution Automated Transfer Switch & Controls

AS SPECFIED FOR THE SUM OF: $70450.00

IN

TO BE DELIVERED ON :

(DOLLARS)

- - - - -

Prices contained herein are firm through 30 da from time of bid as well as 60 da s aftex . e 1e

eneva

rec~tves

e

approv

awtngs

The undersigned bidder states that this proposal is made in conformity with the specifications and agrees that, in the event of any discrepancies between any conditions of this proposal and the specifications prepared by the City of Geneva, the provisions of the latter shall prevail.

The undersigned bidder certifies that this proposal is made in good faith, without collusion or connection with any other person or persons bidding for these services, labor and materials.

Signed by:

BIDDER: RESCO

--~~~ ------

BY: GaryToboyek

TITLE : Inside Sales

10/1/13

DATE:

NOTICE : SUBMIT PROPOSALS ON PROPOSAL FORM ONLY

G&W Electric Company

305 West Crossroads Pkwy

Bolingbrook, IL 60440 USA

Phone : 708.388

.

5010 www.gwelec

.

com

ISO 9001 : 2008 Certified

ISO 14001 : 2004 Certified

L

Distribution Automatic Transfer Switches &

Controls

(Loss of Voltage Source Transfer Package)

City of Geneva, Illinois

September

30th, 2013

~

valent

Technology

Engi.1eered to ordet Built to last

2

SECTION 1 - PROPOSAL

Loss of Voltage Source Transfer Package Proposal

High speed automatic source transfer switching with overcurrent protection for the load. Based on two (2) new Viper ST reclosers incorporating Loss of Voltage Source Transfer scheme.

Communication Network

Communication will be utilizing IEC 61850 Goose Messaging and DNP3/IP communication via a Fiber communication path between the recloser controls and the SEL RTAC controller. Fiber-Optic cable will be Multimode Fiber Optic cable provided and installed by others.

Control Power

Customer to provide 120 vac control power for all reclosers and the NEMA 3R enclosure.

System Description and Functionality:

Backup

Source

Preferred

Source

Existing Mid Point

Recloser {NO}

1-------------

t... n

...... __________ .,.

New

Recloser {NO)

0

0)

New

Recloser (NC)

Basic System Diagram

Communication Diagram :

Operations/SCADA

Existing Fiber Optic

Single-Mode Cable (Serial)

Existing H&L

Fiber Transceiver

NewNEMA

3RCabinet

New Ser i al Cable from H&L to RTU

Existing RTU

New Ser i al Cable from RTAC to RTU

New SEL 3530 RTAC

DNP3 Serial via New Serial Cable fron'I

651R1 to RTAC

Mid-Point (Normally Open)

Existing Viper ST with SEL651R1 control (never hooked up to rtu)

•••

Notes:

• Multimode Fiber Optic cable from each 651R2 to theSEL 3530 RTAC. Cable to be provided and installed by others. Fiber Optic cable to inccorporate LC connectors.

• Alf fiber will terminate in splice trays and be spliced to Pigtail jumpers/patch panels. Provided and installed by others.

·Hardwired 1/0 to be connected from each of the

651R relays to the RTU. Cable to be provided and installed by others.

• DNP communication from each recloser to be concentrated and converted to serial by the SEL

3530 RTAC. A single DNP serial connection will be made between the RTU and RTAC . Provided and

Installed by others.

• Existing RTU and H&L Transceiver. Serial cable from the RTU to the H&L provided and installed by others. RTU and H&L Transceiver provided and installed by others.

• New NEMA 3R cabinet to be adequately sized to install the equipment shown and all associated hardware.

3

Hardwired Cable

Hardwired Cable

IEC61850 GOOSE messaging and DNP3/IP via

New Multimode Fiber Optic

Ethernet Cable

Eut Source (Normally CloHd)

New Viper ST with SEL651R2 control w/ multlmode fiber optic port

West Sourc:e (Normally Open)

New Viper ST with SEL651R2 control w/ multi mode fiber optic port

1 . System will include three V i per ST reclosers : Two new with SEL 651R2 relays, and one existing with SEL651Rl relay . The new reclosers built to City of Geneva standards, pre-programmed to communicate and perform a loss of voltage transfer. One recloser will be designated as Preferred (Source 1), one as Backup (Source 2), and one existing as the Midpoint.

2. Communication will be using IEC 61850 GOOSE messaging protocol over a fi ber connection from the SEL 651R2 relays to the SEL

RTAC. See communication diagram above.

3. Sequence of operation will be the following: a) The automatic transfer scheme shall activate on loss of source voltage. The (2) two new Reclosers shall be designated as either Preferred Source or Backup Source . Preferred Source denotes the preferred supply for normal operation . Backup

Source denotes the backup supply when the Preferred Source experiences a loss of voltage. The existing third recloser located between the two independent sources is a normally open point for the two independent sources and will be used as a remote SCADA operable switch. It will not be part of the automatic source transfer scheme. i) When Preferred Source voltage drops to below XX% of nominal voltage (XX kV) for more than 60 seconds, the

Preferred Source recloser will first verify that the Backup Source has voltage, the Preferred Source then opens, the

Backup Source will then verify that the loss of voltage on the Preferred Source was not due to a downstream fault, if this is true the Backup Source recloser closes to restore power (open-before-close operation). ii) The Backup Source will continue to supply power until the Preferred source voltage remains above XX% of nomina l voltage (XX kV) for 30 minutes. After 30 minutes) above XX% of nominal voltage, Preferred Source recloser will close

4 and Backup Source recloser will open maintaining power to loads (close-before-open operation) . Synchronism Check functionality will be incorporated into this scheme to verify frequency, voltage, and phase control are synchronized before the close-before-open operation takes place.

4 .

. Setting information required to complete transfer programming : a . _ _ b . _ _

I cycles) Time delay to initiate transfer (i.e. 2 seconds) c. _ _ d. _ _

I minutes) Time of stable line voltage to initiate transfer back to original configuration (i.e

. 10 minutes) e. _ _ f . _ _ I cycles) Time delay to initiate transfer (i.e

. 2 seconds) g . _ _ h . _ _ I minutes) Time of stable line voltage to initiate transfer back to original configuration (i.e. 10 minutes) i . Close before open on return to normal transfer. j. Communication means

1. Fiber (multimode) k. System response to loss of communication (i.e

. no transfer)

5 . Protective settings to be determined and entered by customer or consultant engineer using SEL AcSElerator programming tool available for no charge at www .

selinc .

com

5

SECTION 2 - DELIVERABLES

Item

1

Lazer Automiition

SOl~tlon

Oescrf pt Ion

G&W Electric Catalog No. VIP378ER-12-1-ST: 15kV, llOkV BIL, Three-Phase,

Electronically Controlled, Vacuum Interruption, Solid Dielectric Insulation,

Overhead Style, AC Automatic Recloser with Triple Option & Six Pole Sensing

• 800 amp continuous and loadbreak.

• 12.S kA sym. maximum interrupting rating.

• Epoxy insulated vacuum interrupters

• Six (6) 800 Amp interfaces with screw-on silicone insulators - NEMA 2, 4 hole pads or Clamp type #2-500, 250-750MCM included. Customer to choose at time of order.

• Switch ratings per ANSI C37.60-2003

• Three (3) single-phase vacuum interrupters with single-phase trip, singlephase lockout and three-phase trip, three-phase lockout.

• Lifting provisions

• Magnetic actuator operators

• Manual trip and lockout handles.

• Corrosion resistant external fittings and hardware.

• One (1) internal 1000/500:1 dual-ratio current transformer per interrupter

• Six (6) capacitive voltage screens, one (1) on each bushing

• Open/ Close visual indicators, one per interrupter

• Standard Aluminum Pole mounting bracket with mounting hole provisions for Lightning arrester

• Deadline operation

~ 30' {32-pin) recloser control cable to be connected to from controller to recloser

I

"Q ty

2

Unlt

Prfce

Extend e d

Pr ic e

Included Included

Customer must supply 120vac if they aren't purchasing a PT for control power .

• SEL-651R Electronic controller with the following features:

Part Number :

0651 R221XGA8AF212314XX

Key :

Product: SEL-651R-2 c;;ate .

g ory

Firmware

.· Selection

Standard with Power Quality Monitoring, 8 Settings Group

Storage, SEL Fast SER and DNP3 Level 2 Outstation

Control Cable Interface

Enclosure ( 2

)

Secondary Input Voltage

G&W V i per®-ST or G&W Viper ® -L T

Dual Door (Side Mount) , Painted Steel

(6) 8 Vac Max LEA lnputs( 4

)

Secondary Input Current 1 Amp Phase , 0 .

2 Amp Neutral

Extra Inputs/Outputs

Communications Port

7 Inputs (12 Vdc)/8 Standard Outputs*

3 EIA-232 (Pin 1 = NC) , USB

Communications Interface (2)1 OOBase-FX , EIA-485"

*

6

2

3

4

Communications Protocol Standard plus IEC 61850*

Power Supply

Battery Option

User Interface

Installed Accessories(s)

120 Vac (Includes GFCI Outlet)

12 V, 40 Ahr *

Configurable Labels (

7 l and Tri-Colored LEDs*

1 OOW Cabinet Heater( 9 l*

Bundled Accessories None

NEMA 3R Cabinet and Associated Components

This includes a Dual-Door Pole mount Enclosure, (1) SEL 3530 RTAC (see description below), 400W, 24/48V de Power Supply with Battery Backup,

Convenience Outlet, Thermostat & Heater. The enclosure has a 19" Rack on both doors and will have ~15U (26.25") of space on one side and ~4u (7") on the other available for customer installed equipment.

Part Number:

3530AC2XX313XOXXXXXX

Product: SEL-3530 RTAC

Category

Mounting

Power Supply

. Selection

Horizontal Rack Mount

24/48 Vdc

, 1 U 111

Rear Ethernet Connections Two 100BASE-FX (Multimode)*

None 1/0 Board

Web Human Machine

Interface (HMI)

None

Client Protocols

Server Protocols

SEL, DNP3 , Modbus , C37 .

118 Synchrophasors , L&G

8979 , IEC 61 8 50 MMS*

SEL, DNP3, Modbus , L&G 897 9,

SES-92 , IEC 60870 · 5 -101/ · 104, C37.118 Synchrophasors

Peer-to-Peer Protocols

Rear Serial Ports

Conformal Coat

MIRRORED BITS.,

None

, IEC 61850 GOOSE

17 EIA-232/EIA-485 Serial Ports

*

I

I

1 Included Included

I I

I

•

Installation of the customer supplied RTU and H&L fiber optic transceiver to be installed and wired by others .

•

All fiber optic and hardwire cable to be provided and i nstalled by others .

•

Yi" knockout provisions have been provided for customer cables .

Lazer Loss of Voltage Source Transfer Automation Package

Programming, testing, templates and G&W program instruct i on manual for a two recloser loss of voltage transfer scheme as detailed above.

Script based programming utilizes a high level programming language which is designed to be used with customer specific LaZer solutions. It enables the definition and execution of programs which use database points as variables.

Script based programming will be used for calculations and source transfer switching sequences. The program will be written to provide the specific

Automatic Source Transfer functionality as detailed above .

Factory Acceptance Test (FAT) of system at G&W Bolingbrook, IL facility

•

Test to include verification of and complete test report detailing:

•

Time from loss of primary source to time off appearance of volta ge on secondary is per City of Geneva req u irements as

LA!ili

_ ,,.

, h_, .....

1 Included Included

I

1 Included Included

I

7 detailed above

• Time from reappearance of voltage on primary to the time of return transfer is per City of Geneva requirements as detailed above

I ii

City

of

G

_ L

OS5' of Voltage

Sa

rce

T

ta

nsf

e

r So ldl on

Tota1

(Equlpment

i P."

ogr

a

mm:

Jng,

an

llt f

AT)

-

Clarifications

!

!.

'

I

I

~0,450

• 2.05 Spec calls for recloser to have an operational counter. The above offering utilizes the control for an operation counter.

• 2.06 Spec calls for recloser to have a galvanized frame. Aluminum is the standard frame that G&W supplies with our Viper ST. The above offering is with an aluminum frame.

• Specification makes reference to the recloser being in both an overhead and substation application. The above offering is for a overhead application. A price adder is also included in the quotation for a substation frame.

• Connections beyond those mentioned in the quote above are to be provided by others.

I tern Li ter Aulomation Soltttion C o mmfs$joning (O pti on ~ !)

,.

1 Field Commissioning and Field Testing of System

•

1-day on site commissioning

• No expenses included

.

.

Rate sheet attached for reference .

2 Uninterruptible Power System

SOLA HD SOU Series, Din Rail AC UPS, 120 Vac

• sou

500:

0

Capacity (VA/W): 500/300

0 Typical Back-up Time (minutes)*: 4.5/18 minutes (At Full

Load/Half Load

"

Qty

1

1

Pn

i

t Extena

ed

Pri c e Rrice

$1550

$530

Notes:

1. Above price(s) include only those options listed . For other switchgear options , please refer to G & W Catalog SF-1-

VS1, SG2-PS98, GW20-CS57B and SG3-APOO or visit our web site at www.

gw elec .

co m. Please contact your local G

& W representative for prices.

2 . Any discrepancies between unit pricing and extended pricing , unit pricing will take precedence .

3 . Customer will have 60 days from receipt of approval drawings to return the drawings without a price review . If the drawings are returned past the 60 days , the order is subject to price review and a possible price escalation.

Commercial Terms and Conditions

FOB: Factory - Bolingbrook, IL USA

Freight: Prepaid and Allowed on a standard closed top over the road trailer .

Payment: Net 30 days

Payment terms are subject to G&W Finance Department approval.

L

8

Ex Fac tory Shlpm e 11 Ho r orders requiring approval of switch drawing : Drawings for approval l<!ke approxima te ly 4 wee_k s after rece ipt of order and c omplete Informa tio n at G & W Eleotric'Co . Shipment is approximately 1921 weeks after receipt of approved drawings . Pl ease note that ce rtain changes to the ap prov~I drawings may affec t the ship dat e o f the order. Quoted lead time may .

oha" nge based on Factory Load .

Warranty and all other terms and conditions are as per SM-F-1 rev 5 attached .

10

DELAY

Shippir1g dnte~ are i1pproxilu, t~

1111cl nre bn s ed upcm prompt receipr of all nec esSi'l r y info1lnarlo11 .T he ellel' s hall not be liable for delays in delivery or failme to manufacture or deliver due to acts of ' Goel war. riot emb i trgoes. acts o! civil or milira1y authorities. priori ties . all oca tio ns . fires. flood ~ . epidemics. accidents. quaranti11e restiictions. mill conditions, strikes. differences with workmen. delays in tra11spo1tation. sho1tage of cars. fuel. labor, manufactming facilities, components or materials. acts of the

Buyer, or any other cause beyond the reasonable control of the

Seller. In the event of any such delay, the date of delive1y shall be extended for a period equal to the tin1e lost by reason of the delay.

ORDER CANCELLATIOX

Non-Engineered Products

A. S11111dal'd catalogued items not yet through complete order entry. no chnrge .

B . taucl.'tl'd catalogued item s through order entry but not yet in pr o dll lion $250.

00 dome s tic: $500 intemntional.

Engineered Prnducts

A. Ordeis lb.rough OJ'Oer entry but not yet in enginee1ing process -

$250.00 dom es tic:$ 00 it\temarionnl

B. Ot<lers it\ eugiueeiiu~ process · 25% of order value plus t111y vendor cht111!e

-S le,ied agninst G&W for advanced ordered mate1ials.

C. Approval drawings ftmlished and materials advanced ordered •

35% of order value plus cost of materials ordered.

D. Order released for production - up to 100% of order value.

L

STORAGE

Equipment on which manufacttue or delive1y is delayed. -due to nily cause wit hin t he 'Buyer's control. n1n y be plnced in 101 ' a!?e b y

~lier. for Btty<!!"s acco1uu aml risk. nnd regular charge there fo r e aud expense in connecrion therewith s hell be paid by Bu yer. but if. in Seller'

5

~pill.ion. it is wiabte to obrain . or conil.nue with s \lch storage. Buyer will. on request, provide or ammge for suitable storage facilities and assume all costs and risks in connection therewith.

PAIT~TS

Seller \'\i ll defend ar it ow n expense any action brought agninst

Bu yer. t o tl i e e:·reor tl1ar ii i~ based

0 11 a cl ai m that the goods fnl)ti s hed by Seller i.uf)'ln ge n U.S. pment. aud Seller will pay tho s e co s r ~ 111 1<1 damages finally l\WMded at?ainsr Boye r in nny sucll ac rion w hich m~ arMbmabl .

e to a11y s uch claim , but s nch derense and paymeu ts are c on diti o ned on the following: (a) that Seller shall be notified promptly in writing by Buyer of any notice of such claim: and (b) that Seller shall have sole control of the defense of any action on such claim and all negotiations for its settlement or compromise: and (c) should the goods become or in Seller's opinion be likel y to become the subjecr of a clain1 of inft.ingeUlent of a U.S. pat~t. that Bu . er shall pem1it Seller at it s option nd expense either to pi·ocme for .Buy<!!· the 1i g hr to continue u si ng the

~oo ds or to repl n oui..nfiin~ing . Tli.: c or modify the same so that it bee-ome s foregoing mces the entire .liability of Seller with · respect to lllfi'illgl'tnem of paren by the goods or nuy pait lhel'eot ~ Buye1• ·· ht1U hold elle1 · hannless against an y expense. j n dgmen t o r l o o n ncc:o um of any ne:nml or olleged i11tiingemeut of any patents, copyrights or u·actemarks which result from Seller's compliauce with Buyer's desigus, specifications or instmctions.

RETUl."I\' OF MATERIAL

No mate1i~J mil be renun d without fa st lla vi n° s ecured approva l and te1ms for renu111. alOUtl with necess.11y rerumecl good fomis. from G&W El~tric Co. Finni acceptauce of amhodzed renuus will be made when the matedal is received at the factory.

CO'.\IPLIA."ICE WITH LAWS eller certifies that tile ~oorls old her e uuder were produced in colllplian.;e with all i1pplicable requilemeot~ of s ections 6. 7 and 12 of the Fair Labor Standards Act of 1938 amended and of re_gulatious and order s of the United States Depa1tmeut of Labor is 1ed tmder seccfon 14 t h ereo f.

GENER_U

A YC'llicl n~reeweur billding upon .

. eller w ill only came int o bein!? a s o f tile time a fonual writreu l\ckuowledgemenr of n purchase

O(dcl' . enT 10 Bn yer b eller . S uch 11greemenr i

JIGt ass ign !lb

le by Buyer without wdnen approvnJ of Seller. uch agreement \\ill be ~ovemed by 1he law . of the . rare of Illino is. Waive r by Seller ofn lire<1~ll of nuy of the Te rm s and Conditions of t h is or any ot her agreemen t with Buyer shall not be consti11ed as a waiver of any othe r brl?ach.

PATTER_"IS A.'-U TOOLS d:Uy partem s n nd tool hel'etofore or llereafter ncqnired s pecinUy to ptodtice goo<ts for Buyer shal l become the property of the Selle1· . If

Bu yer does not order ~oo · c produced with such prope1ty for a j )eriod of two years. Seller 11u1y dispo se of uch prop •my .

E:\'TIRE AGREE'.\IBNT

Tha~e Teruis and Conditions con stit ut e rhe entire agreement lh!1wee.n elle1· and Buyer . afld s uch n!l'eement ma y n.ot be modified or amended excep1 b y a wri ting ~x<?cuted after the dare heree f by ru.i authol'ized office r ofSeller . Seller h a ll not be bound by any tem1s of Buyer's pmchase order fonns or other documents which attempt to impose conditions at vmiance with Seller's Tenus and Conditions of Sale set forth herein rntless the same shall be specifically agreed to in w1iting by an authorized officer of Seller.

Seller· . failure to object to the provi · ios contailled in any of

Buyer' s fonu s hall not be deemed

(I wah·er of tbe provisiQns of t be s e Te1 ' 11lS and Condition$ wlticll. s hall cou titure the euri.re agreement between the parties.

INSTALLATIO:\', SERVICING OR ERECTION

Insulllntion, erection or servici.n~ of the equipment or upervlSlon rhereef by Seller. if specified or requested b y Buyer, is a\ · nilable.

Contact Factory for tenns and conditions.

11

DA Field Service and Consulting Rate Schedule

Domestic Rates

DA Programming Engineer

Straight Time

Hourly Rate

$200

Overtime

Weekdays

$300

Overtime

Weekends

$300

Overtime

Holidays

$400

Inte

r

nat

i

onal Rates

DA Programming Engineer

Straight Time

Daily Rate

$1600

Overtime

Weekdays

$2400

Overtime

Weekends

$2400

Overtime

Holidays

$3200

Business Class required for any flight over 4 hours.

Rates exclude travel and living expenses, special tools or instruments. Minimum billing for any day that service work is performed shall be four (4) hours for 1·4 hours worked; eight hours for 5-8 hours worked.

EXPLANATION OF RATES

STRAIGHT TIME is defined as time worked on a regular schedule of 8 hours between 7 AM and 6 PM, Monday through

Friday or for time worked on any other agreed upon schedule of 8 hours per day, Monday through Friday. Each hour of straight time shall be billed for at the straight time rate.

OVERTIME is defined as time worked in excess of 8 hours or at times other than the regular straight time schedule. Each hour of overtime shall be paid as noted; except that hours worked in excess of 16 hours per day, Monday through

Friday, or excess of 8 hours on Saturdav, , and hours worked on Sundays and Holidays shall be paid at "Overtime/Holidays

& OT" rate. A "Holiday" is any day observed as a US Nationally Observed Holiday

OT is defines as double time for additional billing to holiday and overtime rates.

STAND-BY-TIME is defined as time, up to 8 hours per day, Monday through Friday, during which the Representative during the course of this assignment is available for work, but is not working because of circumstances beyond G&W

Electric's control. Each hour of stand-by time will be paid for at the applicable rate.

TRAVEL TIME is defined as portal to portal. Paid at straight time .

TIME WORKED, TIME TRAVELLED AND STAND-BY TIME occurring on the same day will each be charged at the rates and within the limitations as aforesaid.

MEAL EXPENSES at $65 per diem unless quoted otherwise and excepting airfare. Public transportation, overnight accommodations, and miscellaneous expenses will be billed at cost plus 10%.

MATERIAL AND RENTAL EXPENSES will be billed at cost plus 10%

CANCELLATION CHARGE: If a job is delayed or canceled 3 days or less from the schedule services, we reserve the right to assess a mobilization fee, which is not to exceed 15% of the contract value.

9

SECTION 3 - TERMS & CONDITIONS

G&W Electric Company, Tenns and Conditions

For Use With Quotations

TER"IS OF PAYMEi'T

Domestic accounts - Net 30.

Intematioual accom1ts - Standard tem1s are au ill'evocable letter of credit. coufinnecl by a Prime U.S

. bank. for the full amO\mt of the courrac t. valid for at lea st 60 d ays b eyo nd the lnle$f q u o1ed hipping dar e. Oth er 1ert1.1 may be ~ra nted upon l'l:ceipt of a1i s foc to1y cr e di1 re fereuces and npprovnl by our Fi nnnce

Department. Letter of credit must be received prior to release of the order to manufacturing.

Late payment charge of 1

1

/1 % per month on all past due invoices and unpaid balances. Shipments and deliveries herem1der shall at all times be subject to the judgment of Seller that the fmancial conditio n of Buyer at all H m es j t lSfifies co 1\tlnuauc e of s hipme111 _ m i d l e .li

\'er i e J1<!rem1d~. If s lrnll fail to umke uy pnyu1eu~ i.u ncllordnnce with fue tenn nnd provision her eof. SeU-er. in addition to its tights and remedies. but not in limitation thereof. may at its option. defer shipments or deliveries herem1der. or tmder any o_t he r 0 1\1l'act with the B u y er. except upon receipt of satis fm:1ory ecurity o r of c ash b dore. sh ipment.

PRICE POLICY

It is G&W's policy to publish for sole use of om domestic representatives Confidential price lists of om· Standard Products.

Q1101ed pr i cas m · e fiun for 30 day ((i0 day s inremnlionnl) . Ordet pl aced .1ft

e r ~O tl<ly . 60 dny s i.!11:-ematlou.al

) nre · u bjec1 t o price In effecr lit time of ncceptnuce . P 1 · ke on ad:i1owled~ed orde Cll'e finn for 1he ng~eed upon delin~ry rime . Cu ro ute r req_ue t to exte ud olig.inn

ll y a -eed ro deli ·ery dale will be s ub ject r o price. estalation .

EXPORT PACKI~G

Export order for all material or deYices (except compom1d alone) add 5% to uet price of order. Expo1t orders for compound alone -add 50¢ per gallon.

TITLE Ai"-"D Th'SURA.i"'CE

Seller asstillles no responsibility for insuring shipments mtless spe~ ifkally re que .s

tc(I by Buyer and 1llen ooly at Bnyer 's expeuse and 'll hlllti o n . Re gal'd less of fi · eight p11ymeur . all risk of l oss haU pass to Buyer upon delive1y by Seller to canier ar F .O.B. point.

'"'ARRA."TY

EXCEPT AS OTHERWISE EXPRESSLY STATED HEREIN.

SELLER l\.IAKES NO REPRESENTATION OR WARRANTY

OF ANY KIND, EXPRESS OR IMPLIED . AS TO l\1ERCHA1'<'TABILITY, FITNESS FOR A PARTICULAR

PURPOSE , OR ANY OTHER l\.IATTER WITH RESPECT TO

THE GOOD SOLD HE REUl'IDER . Seller wanants aJl sold herem1der to be free from ~ef.!c in mat enn l go ods ancl workmanship und e r 11om1(ll n s e and e1Yice fo r n P.eriod of one ( 1 year from rhe dare o.f sllipmen1 by Seller . Sellen 01Jligatio 11 under this wnnilncy is llmhed to repn il · or 1 · •~p l acing. at its optio1L n u y good s, which upon lw p-.:ctiou. l>y ·~lier hnU disc lo e to . eller ·~ sat i .-;factio n to have b~n defecth·e i11 materfal o r worku1nUJ;bjv .

Buyer tut'lSf retn111 the ~oocts ro eller· fucro r y. slilppin~ c h a g pr~nid . with cowplete i n fo rmnrion as to nll ege d defect a n d tl1e installation , operation and service of the good;;.

TAXES

Any taxes which the Seller may be required to pay or collect. under any existing or future law. upon or with respect to the sale. pm d t nse. de l h-ery . tQrage. p1 ' o _ u , ~e or consumptio n o f any of the marerinl co\ · ered h .

ereby , iuc l11 ding ta x es up o n or mea U'ed by rh e receipl:S from t he sale l11e 1 · eof . h a ll be for b-.: ncco m1 r of the

Buyer. who shall promptly pay the amount thereof to the Seller upon demand.

FREIGHT TER"\IS

Te1ms as stated in the attached quotation.

;\-IThUU r ~ 1 ORDER CHARGE

Domestic destination· $250 Net

Iutemational destination - $500 Net

LL"IITS OF LL\BILITY

Seller ltnll 11 0 1 b e fiabl e fo r , and Bu yer s l u U indemnify 1 1ie Seller froUl liability nn~lng from inj w y or dn Ul<'l$--e lo property o r per so n s