Chapter 8 Project Scheduling - eBooks

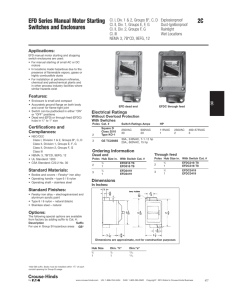

advertisement