Bulletin 15″ (DOE 2016) - MGM Transformer Company

advertisement

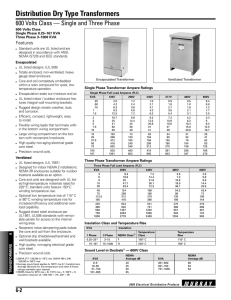

T R A N S F O R M E R C O M PA N Y Custom Custom 600V 600V Class, Class, DryType DryType DOE 2016 COMPLIANT General General Purpose Purpose DistributionTransformers DistributionTransformers Custom 600 V Class, Dry Type General Purpose Distribution Transformers Other Other Products Products Dry Dry Dry Substation Substation Substation (Bulletin (Bulletin (Bulletin30) 30) 30) Liquid Liquid Liquid Substation Substation Substation (Bulletin (Bulletin (Bulletin40) 40) 40) 600V 600V 600V Dry Dry DryType Type Type (Bulletin (Bulletin (Bulletin10) 10) 10) BULLETIN 15 TTRRAAN NSSFFO ORRM MEERR CCO OM MPPAAN NYY D Lo gen cur sol job C * Pu Not Dist ENCLOSURES TENV - NEMA 4 & 4X GENERAL INFORMATION K-FACTOR AUTOTRANSFORMER CORE & COIL COIL MARINE MARINEDUTY DUT The basic purpose of a transformer is voltage transformation as near as practically possible to the load for economy and distribution of power.Typical loads for dry type distribution transformers include lighting, heating, air conditioners, fans, and machine tools. Such loads are found in commercial, institutional, industrial, and residential structures. Open pen core and coil assemblies are typically used by panel builders and equipment OEM EM customers who incorporate the entire transformer into their structures. MGM M M Transformer’s Transformer s single-phase and three-phase marine-duty transformers have been developed utilizing over 80 years of commercial and military experience in magnetic transformer design.This ABS (American Bureau of Shipping) Approved product been Ships) TypeType Approved product lineline has has been engineered to meet the unique requirements of marine applications including commercial and pleasure ships, offshore oil rigs, tankers, near shore and other harsh marine environments. All of MGM’s M M s facilities are ISO9001 S 001 certified and have modern testing equipment to meet all the requirements of ABS,ANSI, ABS,ANS , CSA, NEMA and UL. L. Below are just a few of the enhanced design features of MGM M M marine duty transformers. Core Design – Cores are manufactured from the highest quality non-aging, cold rolled, grain oriented silicon steel laminations using stacked, step core construction and designed to minimize voltage harmonics.All cores are protected in a vacuum pressure impregnated resin. Steel Components – All steel parts (frames, base channels, brackets, rods, etc.), are either coated or plated to meet meetsUL50 L50salt saltspray sprayrequirements.All requirements.Allhardware hardware (bolts, nuts, washers, etc.), are fully protected in stainless steel or equivalent finish. Insulation 220°C nsulation – 220 C insulation systems are fully vacuum impregnated and protected. SCR & DRIVES DRIVESISOLATION ISOLATION ELECTROSTATIC ELECTROSTATICSHIELD SHIELD Drive isolation transformers are specifically designed for use with AC and DC adjustable speed drives.Two winding isolation or threedrive winding drive transformers provide: provide: isolation transformers Electrostatically (faraday) shielded transformers are designed to protect sensitive electrical and electronic devices and systems from high frequency voltages (electrical noise) or transients that occur due to switching and loading on distribution lines. Electrical noise and transients are classified two ways: Normal Mode - noise which appears between the hot & neutral conductors. Common Mode - noise which appears between the ground wire and hot and neutral conductors. Common mode noise is more prevalent and should be the key criterion for any noise suppression device. • Electrical isolation between the incoming line and the drive circuitry. • Voltage conversion of input line to standard drive input voltages. • Minimized line disturbances caused by SCR (silicon controlled rectifiers) firing. • Reduced short circuit currents and voltage line transients. Drive isolation transformers are specifically sized to the drive kVA requirements and are braced to withstand the mechanical stresses of current reversals and short circuits associated with SCR drives. SERIES SERIES MULTIPLE MULTIPLEWINDINGS WINDINGS (RECONNECTABLE) (RECONNECTABLE) To To make make the the basic basic single-phase single-phase transformer transformer more versatile, both the primary and secondary windings can be made in two equal parts.The two parts can be reconnected either in a series or in parallel.This provides added versatility as the primary winding can be connected for either 480 volts or 240 volts and the secondary winding can likewise be divided into two equal parts providing either 120 or 240 volts. (Note: there will be four leads per winding brought out to the terminal compartment rather than two). Either arrangement will not affect the capacity of the transformer. Secondary windings are rated with a slant such as 120/240 and can be connected in a series for 240V or in a parallel for 120V or 240/120V (for 3-wire operation). Primary windings rated with an “X” such as 240X480 can operate in series or parallel but are not designed for 3-wire operation.A transformer rated 240X480V primary, 120/240V secondary could be operated in 6 different voltage combinations. LOW SOUND SOUND LEVEL LEVEL Low sound transformers are designed to have average sound levels 3 dB below NEMA ST-20 standards. Depending on kVA rating and KV class, we may be able to reduce sound level up to 7 dB below NEMA ST-20 standard. Note: Sound levels are measured in a sound room, not at the installation. These quieter transformers are ideal for noise sensitive installations such as schools, hospitals, libraries, and offices. Proper installation procedures should be used to achieve maximum benefit. • Available in single-phase ratings 10 – 500 kVA • Available in three-phase ratings 15 – 1000 kVA V G C 1 2 T T N 3 4 5 S 6 10 11 B Example: Certi i ations 12 13 N UL Listed, CSA, 220º C Insulation System ase Single Phase, rated max. 500 kVA Three Phase, rated max. 1500 kVA As called out in numerals. , 10, 15, 25, 30, 3 , 45, 50, 5, 100, 112 , 150, 225, 300, 500, or 1000. (Other numbers between and 1000 may be used. Construction same as next larger number.) & ri ar e on ar oltage ingle ase 4 0 B 120 240 20 230 460 110 220 230 ree ase 4 0D B 20 120 20 D 230D 3 0D N 5 5D 240 13 440D 450D B 440 254 D 240 4 0 220 12 550D 2 0D 240 20 20 D 230D a s D 240 2 B 440 120 600 230 115 115 C 240D 460D 230 133 220D C 415D 416 240 360D 2 160 D 4 0 2 240 120 4W 400 231 500D 120D 600D 240 13 3 0 220 320 1 5 No Taps 2 - 21 2% FCAN and 4 - 21 2% FC N 1 - 5% FCAN and 1 - 5% FC N 2 - 21 2% FCAN and 1 - 21 2% FC N in ing aterial Copper other numbers between K2 and K re uen e el N N N n losure 460 266 160 3 4 0D N 2 - 21 2% FCAN and 2 - 21 2% FC N 4 - 21 2% FC N 2 - 5% FC N 1 - 5% FCAN and 2 - 5% FC N Aluminum e ial eatures Electrostatic Shield e erature C ise 150˚C (Standard) a tor K01 (Standard) K20 oun C 240 x 4 0 460 450 None Blan No Shield B 115˚C K04 K30 0˚C K06 K0 may by used 060 Hertz (Standard) NEMA ST-20 (Standard) 3 d elow NEMA d elow NEMA e NEMA 1 (Indoor) NEMA 3R (Outdoor) NEMA 4 (TENV) CC Core & Coil only 050 Hertz 400 Hertz N N 1d 5d elow NEMA elow NEMA NEMA (Indoor - SS) NEMA 3R (Outdoor - SS) NEMA 4 (TENV - SS) * We can build units that fall outside of this cataloging scheme. Please contact us for details. K13 115D 130 5 Department of Energy 2016 Efficiency Standards Low Distribution Transformers epartment Department ofVoltage Energy Department of2016 Energy Efficiency of2016 Energy Efficiency Standards 2016 Efficiency Standards Standards ow VoltageLow Distribution Voltage Low Distribution Transformers Voltage Distribution Transformers Transformers A distribution transformer provides the final voltage transformation in the electric power distribution system A distributionA transformer distributionA provides transformer distribution the final provides transformer voltage the provides final voltage the finalbyvoltage the transformation high voltage current a power to a by system by transformationreducing in the electric power distribution inpower the from electric system by powerline distribution transformation in the electric distribution system lower voltage for use in building. Theto ofpower reducing thecurrent high voltage current from aDepartment line ato a reducing the high voltage reducing from theaahigh power voltage line current apowerfrom line to a Energy (DOE) hasuse regulated efficiency level of for in a building. Department of lower voltage lower for usevoltage in a building. lower voltage The Department forthe useenergy inThe a of building. The Department of dry-type distribution transformers since 2007. Energy (DOE) has energy regulated theregulated energy efficiency level of Energy (DOE)low-voltage has regulated Energy the (DOE) efficiency has level the of energy efficiency level of Beginning indry-type 2016, there will be newly amended, federally low-voltage distribution transformers since 2007. since 2007. low-voltage dry-type distribution low-voltage transformers dry-type since distribution 2007. transformers mandated, standards for distribution Beginning in 2016, thereinwill be there newly amended, federally Beginning in 2016, thereenergy will Beginning beefficiency newly amended, 2016, federally will be newly amended, federally transformers. MGM Transformer Company is at thefor distribution mandated, energy efficiency standards forstandards distribution mandated, energy efficiency mandated, standards energy for distribution efficiency of this newCompany standard and will the newis at the transformers. MGM Transformer Company is at the transformers. forefront MGM Transformer transformers. MGM is atTransformer the be offering Company efficiencies itsand products on 2016. forefront of on this new standard andstandard will benew offering the forefront of this new standard forefront will of this bestarting offering new theJanuary and 1, will be new offering the new ruling applies to on three phase voltage dry-type efficiencies on its products on January 1,on2016. efficiencies onThis its products efficiencies starting January on starting its products 1,low 2016. starting January 1, 2016. general purpose distribution transformersThis manufactured starting onapplies January 1,three 2016. Transformers the dry-type This ruling to phase low voltage dry-type ruling applies to three This phase ruling low voltage applies to dry-type three phasethat lowmeet voltage current efficiency requirements in the U.S. (NEMAonTP-1) that1,are physically in2016. the U.S. can continue to meet be legally general purpose distribution transformers manufactured starting on January 1,on Transformers that thethat meet the neral purpose distribution general transformers purposemanufactured distribution transformers starting January manufactured 2016. starting Transformers January that1, meet 2016. theTransformers sold requirements andefficiency installed after 1, This units stored at manufacturers’ warehouses, distributor stock,to be legally current requirements in 2016. the TP-1) U.S. (NEMA TP-1) that are physically the U.S. can continue to be legally rrent efficiency current in efficiency theJanuary U.S. (NEMA requirements that inincludes the areU.S. physically (NEMA inTP-1) the U.S. thatcan areincontinue physically to in bethe legally U.S. can continue job sites, etc.sold and sold and installed after January 1, 2016. This units stored at manufacturers’ warehouses, distributor stock, ld and installed after January 1, 2016. installed Thisafter includes January units 1,includes stored 2016. at This manufacturers’ includes units warehouses, stored at manufacturers’ distributor stock, warehouses, distributor stock, b sites, etc. job sites, etc.job sites, etc. Comparison of various efficiency standards: NEMA TP-1, NEMA PREMIUM CSL-3 & DOE 2016 Comparison Comparison of various Comparison of various standards: efficiency of various NEMA standards: efficiency TP-1, standards: TP-1, PREMIUM NEMA NEMACSL-3 TP-1, PREMIUM NEMA & DOE CSL-3 PREMIUM 2016 & DOE CSL-3 2016& DOE 2016 The tableefficiency below lists the minimum efficiencies ofNEMA low-voltage dry-type three phase distribution transformers required for their kVA rating. The standards for transformers manufactured on or after January 1, 2007 are The table below The lists table thebelow minimum Thelists table efficiencies the below minimum lists of the low-voltage efficiencies minimumof dry-type efficiencies low-voltage three ofdry-type phase low-voltage distribution threedry-type phase transformers distribution three phasetransformers distribution transformers known as NEMA TP-1 (or Energy Star labeled). On May of 2010 The NEMA CSL-3 standards were introduced required for their required kVA rating. for their required The kVA standards for rating. their The for kVAtransformers standards rating. The formanufactured standards transformers for transformers manufactured on or after January manufactured on or1,after 2007January are on or after 1, 2007 January are 1, 2007 are with higher efficiency ratings than NEMA TP-1. The benefits of CSL-3 transformers are reduced electrical & known TP-1 Energy Star labeled). OnThe May of 2010 NEMA CSL-3 were introduced known as NEMA TP-1 as (orNEMA Energy known Star as(or labeled). NEMA TP-1 On(or May Energy of 2010 Star labeled). NEMA CSL-3 On The May standards of 2010 were The standards NEMA introduced CSL-3 standards were introduced heat losses, lower total cost of ownership (TCO), greater energy savings and green/LEED design. These with higher efficiency ratings thanThe NEMA TP-1. The benefits of transformers are reduced & electrical & with higher efficiency ratings with than higher NEMA efficiency TP-1. ratings benefits thanofNEMA CSL-3 TP-1. transformers TheCSL-3 benefits are reduced of CSL-3electrical transformers & electrical are reduced features are beneficial for data centers, healthcare installations, schools & colleges, green applications, LEED heat total losses,cost lower total cost of total ownership greater energy savings anddesign. green/LEED These heat losses, lower heat of losses, ownership lower (TCO), greater cost of(TCO), energy ownership savings (TCO), andgreater green/LEED energy savingsThese and design. green/LEED design. These buildings and government projects. The CSL-3 efficiency standard was never federally mandated. features for aredata beneficial forhealthcare data centers, healthcare installations, schools & colleges, green applications, features are beneficial features centers, are beneficial for installations, data centers, schools healthcare & colleges, installations, green applications, schools & colleges, LEED green LEED applications, LEED Transformers manufactured on or after January 1, 2016 are required to meet the minimum DOE 2016 standard efficiency was standard never efficiency federally wasstandard never mandated. federally was never mandated. federally mandated. andbuildings government projects. The CSL-3 buildings and buildings government projects. andThegovernment CSL-3 efficiency projects. The CSL-3 efficiencies listed below. These standards will be federally mandated. Transformers manufactured Transformers Transformers manufactured on or after manufactured January on or after 1, 2016 January onare or required after 1, 2016 January to aremeet required 1, 2016 the minimum are to meet required the DOEto minimum 2016 meet the DOE minimum 2016 DOE 2016 efficiencies listed efficiencies below. These listed efficiencies standards below. listed These willbelow. be standards federally These will mandated. standards be federally willmandated. be federally mandated. KVA NEMA TP-1 NEMA PREMIUM DOE 2016 (Three Phase) (Energy Star) CSL-3 * Standards KVA KVA NEMA KVA TP-1Federally NEMAMandated TP-1 NEMA NEMA PREMIUM TP-1 NEMA PREMIUM NEMA DOE PREMIUM 2016 Federally DOE Mandated 2016 DOE 2016 Not Federally Mandated (Three Phase) (Three Phase) (Energy (Three Phase) Star) (Energy Star) (Energy CSL-3 Star) * CSL-3 * Standards CSL-3 * Standards Standards 15 kVA 97.0 97.90 97.89 15 kVA 30 kVA 45 kVA 75 kVA 112.5 kVA 150 kVA 225 kVA 300 kVA 500 kVA 750 kVA 1000 kVA 30 kVA 15 kVA 45 kVA 30 kVA 75 kVA 45 kVA 112.5 kVA 75 kVA 150 kVA 112.5 kVA 225 kVA 150 kVA 300 kVA 225 kVA 500 kVA 300 kVA 750 kVA 500 kVA 1000 kVA 750 kVA 1000 kVA Federally Mandated Federally Mandated Not Federally Federally Mandated Mandated Not Federally Mandated Not Federally Federally Mandated Mandated Federally Mandated Federally Mandated 15 kVA97.0 30 kVA97.5 45 kVA97.7 75 kVA98.0 112.5 kVA 98.2 150 kVA 98.3 225 kVA 98.5 300 kVA 98.6 500 kVA 98.7 750 kVA 98.8 1000 kVA 98.9 97.5 97.0 97.7 97.5 98.0 97.7 98.2 98.0 98.3 98.2 98.5 98.3 98.6 98.5 98.7 98.6 98.8 98.7 98.9 98.8 98.9 97.90 97.0 98.25 97.5 98.39 97.7 98.60 98.0 98.74 98.2 98.81 98.3 98.95 98.5 99.02 98.6 99.09 98.7 99.16 98.8 99.23 98.9 98.25 97.90 98.39 98.25 98.60 98.39 98.74 98.60 98.81 98.74 98.95 98.81 99.02 98.95 99.09 99.02 99.16 99.09 99.23 99.16 99.23 97.89 97.90 98.23 98.25 98.40 98.39 98.60 98.74 98.83 98.81 98.94 98.95 99.02 99.14 99.09 99.23 99.16 99.28 99.23 98.23 97.89 98.40 98.23 98.60 98.40 98.74 98.60 98.83 98.74 98.94 98.83 99.02 98.94 99.14 99.02 99.23 99.14 99.28 99.23 99.28 97.89 98.23 98.40 98.60 98.74 98.83 98.94 99.02 99.14 99.23 99.28 * Published CSL-3 efficiency percentages may vary by manufacturers. Note: All efficiency values at by 35manufacturers. percent of nameplate-rated according to the DOE Test Method for Measuring the Energy Consumption of * Published CSL-3* efficiency percentages may vary by manufacturers. ublished CSL-3 efficiency percentages Published mayare vary CSL-3 efficiency percentages mayload, varydetermined by manufacturers. Distribution Transformers under Appendix A to Subpart K of 10 CFR part 431. Note: All values at 35 percent of determined according to thefor DOE Test Method for Measuring the for Energy Consumption of Consumption of e: All efficiency values areefficiency at 35 percent Note: All of are nameplate-rated efficiency values load, arenameplate-rated atdetermined 35 percentaccording ofload, nameplate-rated to the DOE load, Testdetermined Method according Measuring tothe theEnergy DOE Test Consumption Method ofMeasuring the Energy tribution Transformers underTransformers Appendix Distribution A tounder Subpart Transformers K of 10ACFR under part Appendix 431. A toCFR Subpart K of 10 CFR part 431. Distribution Appendix to Subpart K of 10 part 431. C BOTTOM H * J * J C * J G * J C B H ® G B MGM TRANSFORMER COMPANY 5701 SMITHWAY STREET A F E CITY OF COMMERCE, CA 90040 Phone: (800)423-4366, (323)726-0888 A Fax: (323)726-8224 www.mgmtransformer.com MGM TRANSFORMER COMPANY e-mail: sales@mgmtransformer.com 5701 SMITHWAY STREET F CITY OF COMMERCE, CA 90040 D E Phone: (800)423-4366, (323)726-0888 Submit your quote request at: Fax: (323)726-8224 www.mgmtransformer.com Website: www.mgmtransformer.com D Weather-shields Weather-shields (optional) (optional) Primary taps Primary taps e-mail: sales@mgmtransformer.com Wall K AVAILABLE ACCESSORIES bracket (optional) Bottom Mount Wall Bracket Side Mount Wall Bracket OSHPD Seismic Kits Rain Hoods/Weather Shield Kits Rodent/Bird Screen kVA 9 - 15 KVA A 9 - 15 28 30 - 45 32 25 - 50 75 38.5 75 112.5 40.5 112.5 150 40.5 150 225 - 300 51.5 225 - 300 500 66 500 A B 21 28 26.5 32 28.5 381/2 31.5 401/2 36.5 401/2 40.5 511/2 50.5 66 B C 14 K DIMENSIONS (Inches) DIMENSIONS (Inches) D E F G H C D E F G 18.5 14 17 23 261/2 17 20 28.5 281/2 20 213/4 28.5 311/2 213/4 213/4 33.5 361/2 213/4 261/2 37 401/2 261/2 32 47.5 501/2 32 21 11.5 181/2 14 23 17.5 281/2 19 281/2 19 331/2 21 37 24 471/2 111/2 14 171/2 19 - - - 17 22 26 26 31 19 10.5 35 101/2 21 11.75 44 113/4 24 Submit your quote request at: quotes@mgmtransformer.com 17 10 13 22 16.5 26 16.5 26 16.5 31 19 35 24 44 H 10 13 161/2 161/2 J - 161/2 4.63 19 4.63 24 Wall Weather Enclosure Wall Weather Bracket Shield K Enclosure Bracket Shield J K WB1 GPA GPA WB1/NWB † WB1 GPB GPB WB1/NWB † WB2 GPB+ GPB+ WB2/NWB † WB2 GPC GPC † GPC+ GPC+ † 5” RH5 GPD 45/8 GPD 5” RH5* 2-5” RH6 GPE 45/8 GPE 2-5” RH6* GPA, GPB, GPB+, GPC, & GPC+ - Dual Rated Indoor/Outdoor design. *GPD and GPE enclosures require weather shield kits for outdoor (NEMA 3R) installations. *Weather-shield kits are available for GPD and GPE enclosures only. † Dual rated enclosures suitable for indoor or outdoor installations. (NEMA 1, NEMA 3R) Bulletin 15, Printed in U.S.A. Bulletin 15, 3/2016 Printed in the U.S.A.