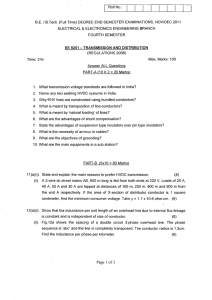

technical specification

advertisement