Copper Ground Bus Wall Mount

Copper Ground Bus Wall Mount

DXE-GBWM

DXE-GBWM-INS Rev 0

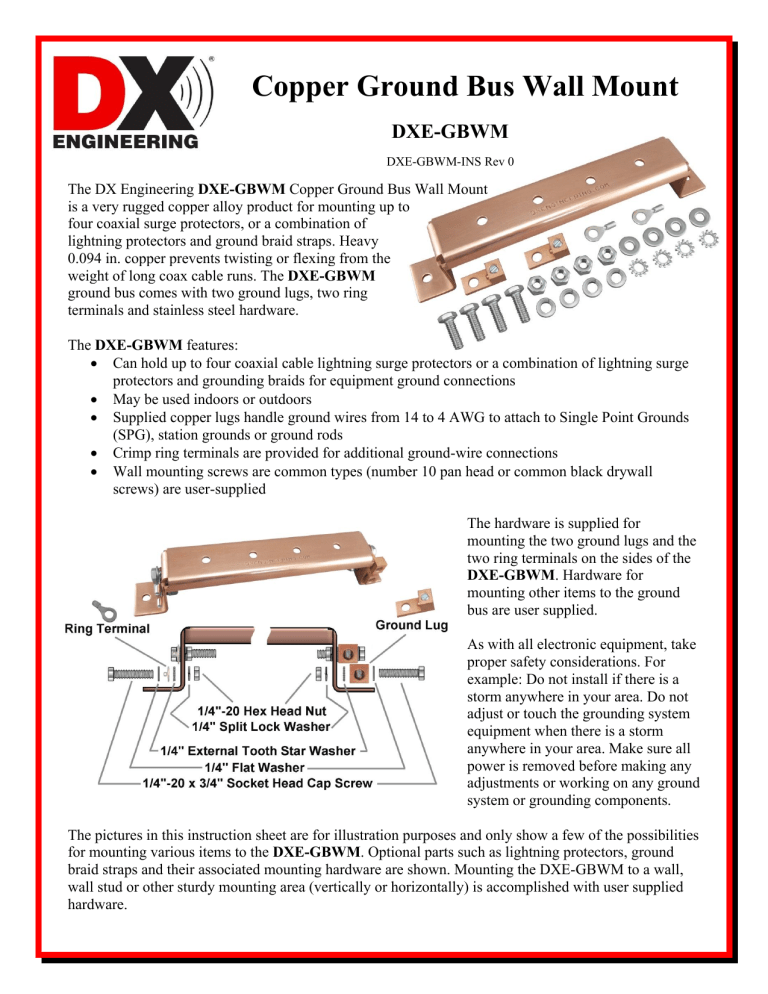

The DX Engineering DXE-GBWM Copper Ground Bus Wall Mount is a very rugged copper alloy product for mounting up to four coaxial surge protectors, or a combination of lightning protectors and ground braid straps. Heavy

0.094 in. copper prevents twisting or flexing from the weight of long coax cable runs. The DXE-GBWM ground bus comes with two ground lugs, two ring terminals and stainless steel hardware.

The DXE-GBWM features:

Can hold up to four coaxial cable lightning surge protectors or a combination of lightning surge protectors and grounding braids for equipment ground connections

May be used indoors or outdoors

Supplied copper lugs handle ground wires from 14 to 4 AWG to attach to Single Point Grounds

(SPG), station grounds or ground rods

Crimp ring terminals are provided for additional ground-wire connections

Wall mounting screws are common types (number 10 pan head or common black drywall screws) are user-supplied

The hardware is supplied for mounting the two ground lugs and the two ring terminals on the sides of the

DXE-GBWM . Hardware for mounting other items to the ground bus are user supplied.

As with all electronic equipment, take proper safety considerations. For example: Do not install if there is a storm anywhere in your area. Do not adjust or touch the grounding system equipment when there is a storm anywhere in your area. Make sure all power is removed before making any adjustments or working on any ground system or grounding components.

The pictures in this instruction sheet are for illustration purposes and only show a few of the possibilities for mounting various items to the DXE-GBWM . Optional parts such as lightning protectors, ground braid straps and their associated mounting hardware are shown. Mounting the DXE-GBWM to a wall, wall stud or other sturdy mounting area (vertically or horizontally) is accomplished with user supplied hardware.

Shown with optional items

Suggested Optional Items

PolyPhaser Coaxial Lightning Protectors

PolyPhaser Coaxial Lightning Protectors are designed for general, single-transmitter use in the 1.5 to 700 MHz frequency range. "Flange Mount" protectors anchor to a grounding panel with both connectors parallel to that flat surface. PolyPhaser

Coaxial Lightning Protectors use a DC blocked specially configured gas tube design that has no DC continuity between the two center pins. PolyPhaser's multi-strike products are designed to pass RF frequencies and block all DC. These protectors appear as a DC open between surge and protected ports and offer the best protection in the industry.

Part Number Description

PPR-IS-50UX-C0 Coaxial Lightning Protector, Flange Mount, 1.5-700MHz, HF 2kW, VHF 375W, DC Block, UHF Female, 50 ohms

PPR-IS-50NX-C0 Coaxial Lightning Protector, Flange Mount, 1.5-700MHz, HF 2kW, VHF 375W, DC Block, N Female, 50 ohms

Alpha Delta Coaxial Lightning Protectors

Alpha Delta UHF Connector Coaxial Cable Surge Protectors have SO-239 connectors and are rated for 200 or 2,000 watts at frequencies up to 500 MHz. They are not DC-blocked, so they will pass control voltages in applications requiring the coaxial cable to carry both RF and DC voltage. They can be easily mounted for the most effective grounding with their 1/4-20 in. stud in a single hole or as a bulkhead through the grounding panel. Through the careful design of the Alpha Delta Arc-Plug

® gas tube module and precision, constant impedance through-line allowing proper firing characteristics, these devices are designed to provide effective protection throughout this entire spectrum.

Part Number Description

ALF-ATT3G50UHP Surge Protector, Coaxial, DC pass, UHF Female, SO-239, 2,000 W Power Rating

ALF-ATT3G50U Surge Protector, Coaxial, DC pass, UHF Female, SO-239, 200 W Power Rating

DX Engineering Ground Braid Assemblies

Quality tinned copper braid in 5 widths for grounding applications. Preassembled with lugs in selected widths and lengths - for both #10 and 1/4" bolt sizes. Contact Customer Service for special lengths or terminations. Sold per foot to accommodate almost any project. Very long per-foot lengths may not be continuous. Contact Customer Service to discuss your length needs if continuous length is required. A major use of the Grounding Straps for amateur radio operators would be to ground one's rig, amp, etc. to a copper strip running behind the desk which acts as the central ground point for the equipment. This central point equipment ground would then be routed away with heavy copper strap to join any other similarly protected branches for

SPG single point grounding.

DXE Part Number Description

DXE-TCB-100 Braid Tinned Copper 1" wide Sold per ft

DXE-TCB-075 Braid Tinned Copper 3/4" wide Sold per ft

DXE-TCB-063 Braid Tinned Copper 5/8" wide Sold per ft

DXE-TCB-050 Braid Tinned Copper 1/2" wide Sold per ft

DXE-TCB-038 Braid Tinned Copper 3/8" wide Sold per ft

DXE-TCB05-RT01 Braid Tinned Copper 1/2" wide #10 ring terminals 1 ft

DXE-TCB05-RT03 Braid Tinned Copper 1/2" wide #10 ring terminals 3 ft

DXE-TCB05-RT05 Braid Tinned Copper 1/2" wide #10 ring terminals 5 ft

DXE-TCB05-RT10 Braid Tinned Copper 1/2" wide #10 ring terminals 10 ft

DXE-TCB05-RT18I Braid Tinned Copper 1/2" wide 1/4" ring terminals 18"

DXE-TCB05-RT24I Braid Tinned Copper 1/2" wide 1/4" ring terminals 24"

DXE-TCB05-RT36I Braid Tinned Copper 1/2" wide 1/4" ring terminals 36"

DXE-TCB075-RT18I Braid Tinned Copper 3/4" wide 1/4" ring terminals 18"

DXE-TCB075-RT24I Braid Tinned Copper 3/4" wide 1/4" ring terminals 24"

DXE-TCB075-RT03 Braid Tinned Copper 3/4" wide 1/4" ring terminals 3 ft

DXE-TCB10-RT01 Braid Tinned Copper 1" wide 1/4" ring terminals 1 ft

DXE-TCB10-RT18I Braid Tinned Copper 1" wide 1/4" ring terminals 18"

DXE-TCB10-RT24I Braid Tinned Copper 1" wide 1/4" ring terminals 24"

DXE-TCB10-RT03 Braid Tinned Copper 1" wide 1/4" ring terminals 3 ft

DXE-TCB10-RT05 Braid Tinned Copper 1" wide 1/4" ring terminals 5 ft

DXE-TCB10-RT10 Braid Tinned Copper 1" wide 1/4" ring terminals 10 ft

DXE-CCK - DX Engineering Copper Cleaning Kits help you ensure a low-impedance bond. Properly cleaned and prepped copper ground connections are essential to maintaining the low-resistance properties of the strap connection. DX Engineering Copper Cleaning Kits have everything you need to establish the bond!

Cleaning kits include:

* Scotch-Brite abrasive scrub pad

* Loctite anti-seize copper anti-oxidant lubricant paste

* Finger towlettes for cleanup

* Instructions included

LCT-37533 - Loctite Copper Anti-Seize provides a shield against high-temperature seizing and galling.

Studs, bolts, flanges, and other mated parts can be easily removed in typical dry service temperatures up to

1,800 degrees F (982 degrees C). Copper anti-seize can be used on copper, brass, cast iron, all steel alloys including stainless steel, all plastics, and all non-metallic gasketing materials. Ideal when mating lightning protection items to copper grounding plates.

Technical Support

If you have questions about this product, or if you experience difficulties during the installation, contact

DX Engineering at (330) 572-3200. You can also e-mail us at:

DXEngineering@DXEngineering.com

For best service, please take a few minutes to review this instruction sheet before you call.

Warranty

All products manufactured by DX Engineering are warranted to be free from defects in material and workmanship for a period of one (1) year from date of shipment. DX Engineering’s sole obligation under these warranties shall be to issue credit, repair or replace any item or part thereof which is proved to be other than as warranted; no allowance shall be made for any labor charges of Buyer for replacement of parts, adjustment or repairs, or any other work, unless such charges are authorized in advance by DX Engineering. If DX Engineering’s products are claimed to be defective in material or workmanship, DX Engineering shall, upon prompt notice thereof, issue shipping instructions for return to DX Engineering (transportation-charges prepaid by Buyer). Every such claim for breach of these warranties shall be deemed to be waived by Buyer unless made in writing. The above warranties shall not extend to any products or parts thereof which have been subjected to any misuse or neglect, damaged by accident, rendered defective by reason of improper installation, damaged from severe weather including floods, or abnormal environmental conditions such as prolonged exposure to corrosives or power surges, or by the performance of repairs or alterations outside of our plant, and shall not apply to any goods or parts thereof furnished by Buyer or acquired from others at Buyer’s specifications. In addition, DX Engineering’s warranties do not extend to other equipment and parts manufactured by others except to the extent of the original manufacturer’s warranty to DX Engineering. The obligations under the foregoing warranties are limited to the precise terms thereof. These warranties provide exclusive remedies, expressly in lieu of all other remedies including claims for special or consequential damages. SELLER NEITHER MAKES NOR ASSUMES ANY OTHER WARRANTY

WHATSOEVER, WHETHER EXPRESS, STATUTORY, OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY

AND FITNESS, AND NO PERSON IS AUTHORIZED TO ASSUME FOR DX ENGINEERING ANY OBLIGATION OR LIABILITY

NOT STRICTLY IN ACCORDANCE WITH THE FOREGOING.

©DX Engineering 2014

DX Engineering

®

, DXE

®

, DX Engineering, Inc.

Mechanical

®

, EZ-BUILD

®

®

, Hot Rodz

®

, Maxi-Core

®

, DX Engineering THUNDERBOLT

®

, DX Engineering Yagi

, TELREX

®

and Gorilla Grip

®

Stainless Steel Boom Clamps, are trademarks of PDS Electronics, Inc. No license to use or reproduce any of these trademarks or other trademarks is given or implied. All other brands and product names are the trademarks of their respective owners.

Specifications subject to change without notice.

© DX Engineering 2014

1200 Southeast Ave. - Tallmadge, OH 44278

Phone: (800) 777-0703 ∙ Tech Support and International: (330) 572-3200

Fax: (330) 572-3279 ∙ E-mail: DXEngineering@DXEngineering.com