Pyrophoric Chemicals Guide - the Department of Environmental

advertisement

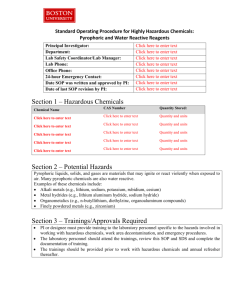

Pyrophoric Chemicals Guide Contents 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Intro What is a pyrophoric material (properties, examples) Engineering Controls (Glovebox, Fumehood, ..etc) Administrative Prerequisites (Prior to, Conditions of, use) PPE (Eye, Skin protection) Safe Work Practices (Storage , Handling, Transfers) Preventative Maintenance (Quenching, Disposal) Emergency Preparation (Spills, Exposure) Hazard Correction (Near miss and accident investigation and corrections) Appendices List of Pyrophoric Materials Videos Common Manufacturer Seals & Containers 11. References Disclaimer: In order to use pyrophoric chemicals, potential users must: • • • read and fully understood these safe operating procedures receive hands-on training from an experienced user familiar with department standards of use. New users of pyrophoric reagents must work under the close supervision of an experienced user. For a period of___ University of Minnesota- Pyrophoric Chemicals Guide Page 1 1. Introduction Pyrophoric chemicals are liquids and solids that have the potential to spontaneously ignite in air at temperatures of 130oF (54oC) or below. They often also have corrosive, water reactive, and peroxide forming properties. Improper use of these materials has resulted in research labs being shut-down to deal with the after effects of fires, damage to lab equipment, injury and even death. The increased level of risk these properties present, calls for additional safety standards to ensure appropriate utilization of these materials. The purpose of this guidance document is to be a resource for labs to utilize while performing the risk analysis of their processes required for writing their lab specific standard operating procedures. It is also intended to raise awareness to prevent further incidents with these materials and to reduce the severity of damage caused when they are released. 2. What is a pyrophoric material Pyrophoric [pahy-ruh-fawr-ik] [from Greek purophoros , “fire-bearing”, from pur “fire” + pherein to “bear”] A material with the ability to spontaneously ignite, without the influence of heat or fire, in air at temperatures of 130oF (54oC) or below can be in the solid, liquid or gas phase. Pyrophoric gases, pyrophoric liquids and pyrophoric solids all share the property of spontaneous ignition. Pyrophoric gases, such as silanes which are a nonmetallic hydride, can ignite immediately upon exposure to air. Pyrophoric gases are stored in compressed gas cylinders. Pyrophoric liquids such as tert-butyllithium are often metal- (alkyls, aryls, vinyls, carbonyls or hydrides). Pyrophoric liquids are often sold and stored in flammable hydrocarbon solvents, such as ethyl ether, tetrahydrofuran(THF), pentane or heptane. Pyrophoric solids such as lithium are often alkali metals and stored under kerosene or oil. Please see Appendix – List of Pyrophoric Materials for a more comprehensive list of pyrophoric materials. 3. Engineering Controls (Glovebox, Fumehood, ..etc) Image source Brandeis University Glove (dry) box • Required for solids • Flushed with inert gas i.e. nitrogen, argon • Strongly Recommended for liquids and gases, particularly transfers. • Excellent control device when inert or dry atmospheres are required University of Minnesota- Pyrophoric Chemicals Guide Page 2 Glove bags • Inexpensive inert atmosphere glove bags, are available for purchase, if you do not have access to a glove box http:/www.sigmaaldrich.com/labware/products/aldrich-atmosbag.html Fume Hood • Required minimum when glove box is not suitable • sash pulled down as low as possible • used to control vapors from o noxious or flammable gases released by pyrophoric chemicals o kerosene (or other flammable solvent) used to store over the pyrophorics. Fire Extinguishers • required Contact DEHS for advice selecting extinguishers or to receive training. • Class A, B, C (dry chemical) o For pyrophoric liquids and supporting flammable solvents o Must be located within 10 seconds travel time • Class D (recommended for certain materials) o For reactive metals Do NOT use Extinguishers containing or developing water, carbon dioxide or halons. They are not suitable for firefighting organolithium compounds as they react violently. o Know the location of the nearest Container of Powdered lime (CaO, calcium oxide), Soda Ash (Na2CO3) or Sand (SiO2) required • Container must be within arm’s length when working with pyrophoric materials. • Useful to extinguish any small fire that occurs at the syringe tip (aka pilot light) as a result from any last drops of reagent from the syringe. Eye wash o Required o Must be located within 10 seconds travel time o Bottle type station are not acceptable Safety Shower o Required University of Minnesota- Pyrophoric Chemicals Guide Page 3 o Must be located within 10 seconds travel time UCLA Gas Cabinets Required for pyrophoric gases o o Outside each gas cabinet, devices for Remote manual shutdown of pyrophoric gas flow should be provided. o Automatic shutdown devices for pyrophoric gas flow activated by interlocks tied into fire protection and/or detection should be protected. o Pyrophoric gas flow, purge, and exhaust systems should have redundant controls that prevent pyrophoric gas from igniting or exploding. o These controls include: excess flow valves, flow orifices, mass flow controller sizing, process bypass line control, and automatic gas shutdown. o Emergency back-up power should be provided for all electrical controls, alarms and safeguards associated with the storage and process systems. Mechanical or natural ventilation at a minimum of .00047 cubic meters per .09 square meters of storage and dispensing area should be provided. Vacuum protection o Conduct in fume hood o Protect with cold traps and filter to prevent particulate release o Exhaust must vent into a fume hood. o Take precautions to prevent implosion of glassware and limit potential damage caused by flying glass and splattered chemicals. 4. Administrative Prerequisites (Prior to, Conditions of, use) Reduce quantities and hazards o Whenever possible, purchase chemicals stored in heptane, since it is less hazardous than the other solvents. o Only order, store and keep what is needed o Choose other less hazardous reagents whenever possible (See AkzoNobel Pyrophoricity of metal Alkyls) N-butyl lithium instead of t-butyllithium Use lower concentrations instead of higher In general for metal alkyls: University of Minnesota- Pyrophoric Chemicals Guide Page 4 Metal Content ↑ Pyrophoricity ↑ Oxygen content ↑ Pyrophoricity ↓ Halogen Content ↑ Pyrophoricity ↓ Solvent vapor pressure Pyrophoricity ↑ ↑(or boiling point ↓) Temperature ↑ Pyrophoricity ↑ (Source: AkzoNobel Pyrophoricity of Metal Alkyls) Prior to beginning work in the laboratory Researchers must: • • • • • have taken Laboratory Safety Training (http://www.dehs.umn.edu/training_newlabsafety.htm) receive procedure-specific training o given by a qualified, experienced supervisor. Must include • Hazard analysis • location of: eyewash, shower, fire extinguishers, alarm pulls, emergency exits • what to do in emergency review o standard operating procedures (SOPs) o Safety Data Sheet (SDSs) practice o techniques with non-hazardous chemicals prior to working with the “real thing.” Be supervised o the first few times they conduct any work with pyrophoric chemicals. Conditions for use: • • • 5. there must be at least 2 people present in the laboratory o all people in the space must be aware that it is being used The use of pyrophoric chemicals is forbidden outside of normal business hours. (7 AM -5 PM) Each time before beginning work, verify the accessibility of the intended: eyewash, safety shower, fire extinguishers and exits. PPE (Eye, Skin protection) Eye Protection University of Minnesota- Pyrophoric Chemicals Guide Page 5 o Safety glasses (Required minimum) ANSI Z.87.1 1989 standard Prescription glasses ONLY if they also meet the ANSI standard if not safety glasses must be worn over them. o Safety goggles Required when: potential for splash Skin Protection o o o o Face Shield Required when: Risk of explosion, large splash, or highly exothermic reaction Dress Skin must be covered. • No open toe shoes (covered meta-tarsal) • Skin not protected by PPE must be covered by clothing. Mobile ignition sources • Hair must be tied back • No loose fabric Material • Not synthetic (melts and embeds into skin causing severe burns) • Prefer natural fibers such as silk, wool, or cotton. Gloves Nitrile use for: (Required minimum) • Inner layer • small quantities, low splash risk • NOTE: they ARE combustible! Heavy duty chemical-resistant gloves • Large quantities • High splash risk • Examples (4H, Silver shield) Nomex® flight/aviator (recommended) • Flame protection Lab coat Material • General lab (Required minimum) o 100% Cotton o Acceptable for work inside glove box without transfers. • Flame-resistant o Recommended for pyrophoric work in fume hood • Flame-proof University of Minnesota- Pyrophoric Chemicals Guide Page 6 o o 6. o Recommended for all. o Required for work outside a fume hood. Appropriate size Cleaned or discarded when contaminated Apron Chemical resistant Required for large quantities (> 1 L) Portable Shield Protects all occupants provides an excellent protection barrier Recommended, if available Safe Work Practices (Storage , Handling, Transfers) Storage Incompatibilities Containers of pyrophoric materials should be kept away from: • all other flammable and combustible materials (ex. paper, bench liners, and solvents.) • Heat and vibration sources (organolithium compounds must be kept at < 25 C°) • Corrosive materials which are capable of degrading the container. Pyrophoric materials themselves should be kept away from: • Air • Oxidizers • Water (if water reactive) • Protonating substances ( e.g. alcohols, amines, mercaptanes, and acids) • Specific: o Lithium alkyls from CO2 and fluorocarbons (exothermic) o Organolithiums from: (violent) Halogenated (e.g. chloroform) Multiple bonds (e.g. Ketone, nitriles) Oxidizing agents Containers • store minimum quantities • Organolithiums o should be kept in a flammable refridgerator o Mark date first opened on bottle Discard 1 month after opening • keep containers in inert atmosphere (if possible) University of Minnesota- Pyrophoric Chemicals Guide Page 7 o • • else provide secondary containment by storing in original manufacturer’s shipping container. See metal can below. Source: http://oregonstate.edu/ehs/sd0083 contact DEHS Hazardous Materials (4-8855) for a replacement if lost or damaged outer container (e.g.- metal can)should be labeled to indicate contents Always replace caps after use to protect the septa seal (prevent exposure to air) (see Appendix – Common Manufacturer Seals for examples) o outer prevents damage to inner container (tape, air-tight seal) o inner (prevents material getting out) liquids must have PTFE-lined septa Example Alrich Sureseal packaging system limit punctures to 16 per seal http://www.sigmaaldrich.com/chemistry/solvents/sureseal.html, http://www.sigmaaldrich.com/etc/medialib/docs/Aldrich/Bulletin/al_techbull__al195.P ar.0001.File.tmp/al_techbull__al195.pdf Repeated Dispensing o Use the The Sure/Seal septum-inlet transfer adapter o The adapter protects the contents of the bottles from air and moisture o Store the combined apparatus inside a can or other container to protect against accidental bumps • • • University of Minnesota- Pyrophoric Chemicals Guide Page 8 • Long-term storage o Use the solid plastic cap, or equip the bottle with an Oxford Sure/Seal valve cap, or transfer the reagent to a suitable storage vessel. o Consider storing inside the manufacturer provided metal can Materials • • • gases in gas cabinet (see below) liquids store under inert atmosphere solids store under kerosene (or other appropriate barrier). Special Note about Storing pyrophoric gases • The size and quantity of pyrophoric gas cylinders should be kept to a minimum. • The materials must be kept in approved gas cabinets University of Minnesota- Pyrophoric Chemicals Guide Page 9 • • • • • • • • Remote manual shutdown devices for pyrophoric gas flow should be provided outside each gas cabinet. Automatic shutdown devices for pyrophoric gas flow activated by interlocks tied into fire protection and/or detection should be protected. Pyrophoric gas flow, purge, and exhaust systems should have redundant controls that prevent pyrophoric gas from igniting or exploding. These controls include excess flow valves, flow orifices, mass flow controller sizing, process bypass line control, and automatic gas shutdown. Emergency back-up power should be provided for all electrical controls, alarms and safeguards associated with the storage and process systems. All process systems components and equipment should be purged with a dedicated inert gas cylinder. Pyrophoric storage and dispensing areas should be located on the exterior of the building, or in an approved shelter. Mechanical or natural ventilation at a minimum of .00047 cubic meters per .09 square meters of storage and dispensing area should be provided. Cylinder orifices with a 0.0006 inch diameter and not to exceed 0.010 inches. Handling Gather all necessary experimental equipment first to avoid prolonged exposure. • • Pyrophoric Solids Use in glove box flushed by inert gas (recommended) Mildly pyrophoric solids (such as lithium aluminum hydride and sodium hydride) may be handled in the air for brief periods of time, o Flush containers with inert gas before storage Pyrophoric Liquids By using proper needle and syringe techniques, these reagents can be handled safely in the laboratory. • Always transport using solid cap, buffer material between primary container and secondary container, secondary seal. Pyrophoric Gas Transportation of Cylinders o the cover cap should be screwed on hand tight to protect the valve, until the cylinder is in place and ready for actual use. o Cylinders should never be rolled or dragged. o large cylinders should be strapped to a properly designed wheeled cart. University of Minnesota- Pyrophoric Chemicals Guide Page 10 o Only one cylinder should be handled at a time. https://web3.unt.edu/riskman/index.2.php?section=onlinetraining&group=pyrophoricsafety&module=5 #content Transfers • • • • Each time prior to transferring reagents, THINK “Triple A+” Safety o check for: (All-Access-Aware) All necessary PPE (e.g. chemical resistent gloves, eye protection, lab coat) Accessibility of intended eyewash, safety shower, exit and fire extinguisher. Make sure there is at least one other person in the lab and they are Aware of what you are about to do and emergency procedures + check your space • free of aqueous, combustible and oxidizing materials Location o Prefer an inert environment such as glovebox Solids are transferred in a glovebox o If not an inert atmosphere must use a fume hood Keep sash as low as possible Amount o Maximum transfer amount is 50 mL o If more than 50 mL is required, use canuula method. Divide the amount needed into several transfers of 50 mL or less. Methods o Cannula (aka double tipped needle) Use if transferring more than 50 ml When using the canuula method: Never transfer excess material back into an original container as minute impurities may cause an explosive reaction. o Syringe Use if transferring less than 10 ml Equipment Must use: • Containment • Mineral oil bubblers at all times in order to release the excess pressure from the reaction vessels o Note: balloons used for air-sensitive reagents are not suitable for pyrophorics • Needles o Must have a locking mechanism to prevent accidental disconnection and release of pyrophoric liquids. University of Minnesota- Pyrophoric Chemicals Guide Page 11 o o • • Should be 1-2 ft long and flexible to reach from the bottom to top of the bottle(~1 ft) and from the bottle top to the inverted syringe (~1 ft) Gauge must be smaller than 16 gauge (Note: the larger the gauge number the smaller the size) Small needles (> 16 gauge) have small diameter which has enough surface tension to resist dripping Bigger needles (< 16 gauge) have a larger diameter. When they penetrate the seal on the reagent bottle, the hole they form is too large for the Teflon septum to close around. Septum o Add a layer of silicone or hydrocarbon grease on the septum to help when inserting the needle through the hole in the metal cap and through the septum. o Upon withdrawal of the needle, the small hole that remains in the PTFE liner will not cause the reagent to deteriorate under normal circumstances. Syringe o Size Choose 2 X the largest volume transfer largest allowed is 100 mL (any larger is clumsy ~4” long syringe + ~4” plunger) • NOTE: For large volume syringes, use a corresponding larger gauge needle. o Material selection Glass syringes with Teflon-tipped plungers (gastight) syringes are best. • Simple glass syringes are more prone to causing gas bubbles. Disposable plastic syringes have a good seal on the plunger and work well. o MUST have needle-lock mechanism (Luer-Lok) to prevent separation of needle and syringe o o One time use! Plunger might freeze in the barrel as the tiny residual material in barrel forms a solid when exposed to air. This solid residue could cause the syringe to freeze during second transfer. • e.g. R-Li (tiny) + Air (excess H2O, O2, N2) LiOH s • Clean glass syringes via quenching before re-use. Solids • Weighing Alkali Metal o Using a knife, cut the metal while submerged under oil. University of Minnesota- Pyrophoric Chemicals Guide Page 12 o Transfer Use tweezers to transfer from oil covered reagent bottle to rinse flask to rinse off oil. • Rinse flask should contain toluene or heptane. • AVOID low boiling rinses such as ether and pentane that tend to condense water upon evaporation Use tweezers again to transfer from rinse flask to a weighed flask of toluene • measure weight to determine mass of metal Use tweezers again to transfer from the toluene to desired reaction flask. Recommendations for Working with Specific Pyrophoric Solid Reagents • Lithium Aluminum Hydride reacts violently with water and has a significant heat of solvation. o DO NOT add solvent to dry LiAlH4. o Instead, slowly add LiAlH4 to anhydrous solvent in the reaction flask. The initial small amount of LiAlH4 will react with any trace amounts of water. • Potassium metal is considerably more reactive than lithium or sodium. • Potassium metal oxidizes to potassium oxide (K2O), potassium peroxide (K2O2), and potassium superoxide (KO2). o The yellow peroxides are shock-sensitive and can explode when handled or cut. o if old or if significant amounts of yellow crust is visible DO NOT USE! Dispose through Haz. Waste. • Potassium hydride or sodium hydride dispersions o rinse the mineral oil off using a light hydrocarbon solvent such as hexane. o This is easily accomplished in a glove box or can be done in a hood UNDER CAREFULLY CONTROLLED CONDITIONS o Weigh out desired amount of dispersion and seal in a flask under nitrogen o Add dry hexane via syringe, swirl, and let metal hydride settle o Slowly syringe off hexane carefully discard into a separate flask containing isopropanol o Repeat rinse procedure • Sodium amalgam, Na(Hg), (or potassium amalgam) o prepared by dissolving sodium into liquid mercury. o Must be performed in a hood under dry nitrogen gas. o highly exothermic process University of Minnesota- Pyrophoric Chemicals Guide Page 13 produces the intermetallic compound NaHg2 with enough heat to cause local boiling of the mercury. The grey solid produced has the reducing potential of sodium, but is more air stable o Liquids Set Up • Check PPE • Obtain supplies o Check Containment for both reagent and reaction vessels needle for blockages • Pass nitrogen through one end. The other ends in a liquid. Bubbles means the line is clear Glassware for defects and cracks • Use Poly-coated material • Do not use if in doubt syringe for leaks addition funnel for leaks • Use soup bubble test at valve joint o Oven dry all glassware o Flush inert gas through all vessels and transfer lines Use 3-5 psi to flush out vessels Use bubbler line to flush out the syringe o Clamp the reagent bottle and receiving vessel leaves both hands free. o Assemble bubbler Note: Methods vary depending on whether glass or plastic syringes are used • Glass syringe o Reagent vessel will be pressurized with an inert gas o Allow the inert gas to transfer the reagent to the syringe Use caution not to overpressurize! Use only 3-5 psi • There is a danger of blowing the plunger out of the syringe body and spilling out pyrophoric reagent. • Plastic syringe o Reagent vessel will be connected to a bubbler Use < 3 psi or neutral pressure University of Minnesota- Pyrophoric Chemicals Guide Page 14 o Manually pull the plunger to draw the reagent into the syringe. Syringe Method (only for 50 ml or less) Follow these steps in order: 1. Insert a needle from an inert gas source with a bubbler outlet into the reagent bottle a. Keep the needle tip above the liquid level 2. Flush dry syringe with inert gas, depress the plunger and insert the needle into the Sure/Seal bottle a. Keep Needle above liquid 3. Push needle beneath reagent liquid level 4. Gently pull the plunger to draw liquid into the syringe a. Note-Pulling too hard or too fast can cause air bubbles. b. Do NOT fill more than 50% full up to 50 ml max. 5. Slightly overfill the desired amount into the syringe 6. Pull needle above reagent liquid level but still within vessel. 7. Vent the pressure on the reagent bottle 8. Carefully force excess reagent and entrained bubbles back into the reagent bottle 9. Draw a “plug” of inert gas from the reagent vessel in the needle headspace. a. This step is especially important for highly pyrophoric materials such as tert-butyllithium and trimethylaluminum 10. Carefully withdraw needle 11. Quickly insert needle into inert reaction apparatus by puncturing the septum. 12. Dispense reagent a. There will be a pocket of liquid in the syringe tip 13. Pull a “Plug” of inert gas University of Minnesota- Pyrophoric Chemicals Guide Page 15 14. Immediately clean the syringe and needles a. This avoids clogging the needles and seizing the syringes. 15. Canuula Method (aka Double-Tipped Needle Safety) Do NOT overfill! Excess cannot be put back into reagent bottle Follow these steps in order: 1. Insert a needle from an inert gas source with a bubbler outlet into the reagent bottle a. Keep the needle tip above the liquid level 2. Quickly insert one end of the double-tipped needle (call this end “A”) in the pressurized reagent bottle by puncturing the septum. (inert gas should be flowing out the needle) a. Keep Needle above liquid 3. Insert other end of the double-tipped needle (call this end “B”) into inert reaction apparatus by puncturing the septum. 4. Vent the reaction apparatus. 5. Allow inert gas to flow into reagent bottle, through end A of the needle and out end B, into the reaction vessel and out. 6. Begin transfer by carefully lowering end A of the needle beneath reagent liquid level 7. Allow the inert gas pressure to force the reagent up through the needle into the reaction vessel. 8. When close to the desired volume pull end A of the needle up the liquid surface. 9. Then carefully “meter” the last amount to prevent overfilling. 10. Stop the transfer by pulling end A of the needle above reagent liquid level but still within vessel. 11. Blow the needle dry by allowing inert gas to continue to pass from the pressurized reagent vessel into the vented reaction vessel. 12. Carefully withdraw a. End B of the needle from the reaction vessel i. Remove vent University of Minnesota- Pyrophoric Chemicals Guide Page 16 13. b. Then end A of the needle from the reagent vessel. i. Turn off inert gas. Immediately clean the needles a. This avoids clogging the needles. Cleaning Pyrophoric Reagents from Needles and Syringes Syringes Beneath the inert gas “plug” a small amount of residual pyrophoric material will remain in the syringe. 1. Rinse the Syringe by inserting the needle end into an inert non-reacting solvent such as hexane into the syringe and then drawing the solvent into the syringe. 2. Pump and expel at least 3 times. 3. Perform second rinse in an alcohol such as isopropanol. 4. Again pump and expel at least 3 times 5. Syringe and needle are now safe to clean with water 6. Dispose of wash solvent with other hazardous waste solvents. 14. Preventative Maintenance (Quenching, Disposal) Preventative Maintenance Systems Quenching, cleaning CHEMICAL WASTE AND CLEAN-UP PROCEDURES Quenching of Pyrophoric Residue Small amounts of unused pyrophorics must be destroyed by quenching of the residue. The basic procedure for quenching is as follows: Transfer the residue to a reaction flask for neutralization. Dilute with copious amounts of a less hazardous solvent such as heptane or toluene. Place the flask in an ice bath, and slowly add isopropanol to quench pyrophoric residue. Next, slowly add methanol as a more reactive quenching agent to ensure completion. Finally, add water drop-wise to ensure that there are no pockets of reactive materials left. Dispose of as hazardous waste through the University’s Hazardous Waste Program (612) 624-1604. Do not leave containers with residues of pyrophoric materials open to the air, because this is a possible flash fire hazard. Liquid “Disposal of Pyrophoric Reagents • Small amounts of unused or unwanted pyrophoric materials must be destroyed by careful University of Minnesota- Pyrophoric Chemicals Guide Page 17 quenching of the residue. Transfer the materials to an appropriate reaction flask for hydrolysis and/or neutralization. Dilute significantly with an unreactive solvent such as heptane or toluene and place the flask in an ice water cooling bath. Slowly add isopropanol to quench pyrophoric materials. Upon completion, add methanol as a more reactive quenching agent to ensure completion. Finally, add water dropwise to make sure there are no pockets of reactive materials. Dispose of as hazardous waste. • Alternatively, reactive substances can be quenched by slowly adding the dilute solution to dry ice, then adding a mildly reactive quenching agent such as methanol. • AVOID low boiling diluents such as ether and pentane that tend to condense water upon evaporation. • Do not leave containers with residues of pyrophoric materials open to the atmosphere due to uncontrolled ignition.” Solid “Disposal of Pyrophoric Solid Reagents by Quenching • Small amounts of unused or unwanted pyrophoric materials must be destroyed by careful quenching of the residue. Transfer the materials to an appropriate reaction flask for hydrolysis and/or neutralization. Dilute significantly with an unreactive solvent such as heptane or toluene and place the flask in an ice water cooling bath. Slowly add isopropanol to quench pyrophoric materials. Upon completion, add methanol as a more reactive quenching agent to ensure completion. Finally, add water dropwise to make sure there are no pockets of reactive materials. Dispose of as hazardous waste. • Alternatively, reactive substances can be quenched by slowly adding the dilute solution to dry ice, then adding a mildly reactive quenching agent such as methanol. • AVOID low boiling diluents such as ether and pentane that tend to condense water upon evaporation. • Do not leave containers with residues of pyrophoric materials open to the atmosphere due to uncontrolled ignition.” UCLA Disposal of Pyrophoric Solids through the Hazardous Waste Program Larger quantities of pyrophoric solid chemicals can be disposed of as hazardous waste. Carefully package and label the wastes, according the University’s hazardous waste guidelines (http://www.dehs.umn.edu/hazwaste_chemwaste_umn_cwmgbk_sec2.htm). Contact DEHS at (612) 624-1604 and specifically state that you have pyrophoric hazardous waste that needs Larger quantities of pyrophoric chemicals can be disposed of as hazardous waste. • Carefully package and label the wastes. • Specifically Alert EH&S personnel at the collection location to the hazards of any wastes containing pyrophoric chemicals University of Minnesota- Pyrophoric Chemicals Guide Page 18 15. Emergency Preparation (Spills, Exposure) Emergency Preparation Spill Information: Large Spills Use extreme caution due to potential for spontaneous ignition. If anyone is exposed or on fire, rinse with copious amounts of water under the emergency shower. Call 911 and evacuate the spill area. Do NOT attempt to clean up the spill yourself. Cordon-off the spill area with tape and keep other people from entering. If possible, provide emergency responders with technical information on the chemicals involved. Contact DEHS immediately at (612) 626-6002. “Exert extreme caution due to potential spontaneous combustion. • Exert extreme caution due to potential ignition of flammable solvents or other materials.UCLA Chemistry & Biochemistry Procedures for Safe Use of Pyrophoric Solids, 2/2009 Page 4 of 4 • If anyone is exposed, or on fire, wash with copious amounts of water, ideally in the lab shower. • Call 911 for emergency assistance. • Evacuate the spill area. • Post someone or mark-off the hazardous area with tape and warning signs to keep other people from entering. • Provide emergency personnel with technical advice on the chemicals involved” UCLA Small Spills Use extreme caution due to potential for spontaneous ignition. If anyone is exposed, or on fire, rinse with copious amounts of water, or utilize the emergency safety shower. In the event of a flash fire, dial 911. If nobody is injured and nothing has ignited, first access a class C fire extinguisher and place it nearby the spill area prior to proceeding. Then, carefully remove any flammable materials that are near the spill area. Completely cover the spill with powdered lime (calcium oxide, CaO) or dry sand. Next, quench the spill by slowly adding isopropanol to the area. After quenching is completed, double bag spill residues and manifest through the University’s hazardous waste program. Call DEHS at (612) 626-6002 for assistance. “Exert extreme caution due to potential spontaneous combustion. • Exert extreme caution due to potential ignition of flammable solvents or other materials. • If anyone is exposed, or on fire, wash with copious amounts of water, ideally in the lab shower. • Call for a coworker to provide backup. • Place a fire extinguisher nearby. • Carefully remove nearby flammable materials. • Powdered lime (calcium oxide, CaO) or dry sand should be used to completely smother and University of Minnesota- Pyrophoric Chemicals Guide Page 19 cover any spill that occurs. • Carefully quench by slow addition of isopropanol. • After complete quench, double bag spill residues for hazardous waste pickup. • Call 911 for emergency assistance if necessary. UCLA Medical Programs HEALTH HAZARDS / TOXICITY Eyes: Can cause severe burns to the eyes. Skin: Can cause severe burns to the skin. Ingestion: May cause severe and permanent damage to the digestive tract. Can cause severe burns to the gastrointestinal tract. May cause central nervous system depression. Inhalation: Causes chemical burns to the respiratory tract. Exposure produces central nervous system depression. May cause drowsiness, unconsciousness, and central nervous system depression. Vapors may cause dizziness or suffocation. Chronic: Repeated exposure can cause nervous system abnormalities with muscle weakness and damage, motor incoordination, and sensation disturbances. EXPOSURE LIMITS See chemical specific MSDS. Emergency Information: Eyes: Flush eyes at the emergency eyewash station for 30 minutes. Seek medical attention immediately. Skin: Remove any contaminated clothing, in case of flash fire. Rinse skin with copious amounts of water for at least 15 minutes. If larger areas of skin are affected, rinse under the emergency safety shower for at least 15 minutes. If you experience any burning or irritation thereafter, seek medical attention. Ingestion: Do NOT induce vomiting. Seek medical attention immediately. Inhalation: Remove victim from exposure area to fresh air immediately. If not breathing, give artificial respiration. If breathing is difficult, give oxygen. Do NOT use mouth-to-mouth resuscitation. Seek immediate medical attention or Call 911 if not breathing. 16. Hazard Correction (Near miss and accident investigation and corrections) ADDITIONAL INFORMATION • For general information regarding the safe use of pyrophoric chemicals, please contact DEHS at (612) 626-6002. University of Minnesota- Pyrophoric Chemicals Guide Page 20 • If you have any concerns regarding the stability or testing of a chemical, contact the Hazardous Waste Program at (612) 624-1604. University of Minnesota- Pyrophoric Chemicals Guide Page 21