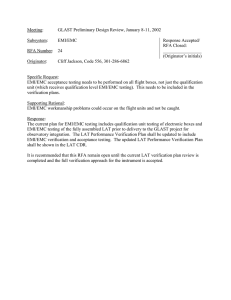

Overview of techniques and measures related to EMC and

advertisement