EMI/EMC Test Facility

advertisement

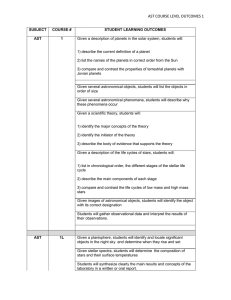

EPIC Electric Propulsion Competitiveness Workshop Brussels 25 -28 November 2014 Test Facilities and Advanced Diagnostics for EP Fabrizio Scortecci AEROSPAZIO Tecnologie s.r.l. - Rapolano Terme, Siena, Italy AST.1 EP Testing Centre Electric Propulsion test services • • • performance testing of plasma and ion thrusters endurance, lifetime and more in general qualification testing according to customers standards EP compatibility with spacecraft subsystems – backflow toward the spacecraft – erosion and sputtering of S/C surfaces Astrium RIT-22 Thales HEMPT Fakel SPT-100 Astrium RIT-XT AST.2 The Test Laboratory Electric Propulsion test services • • • • The present laboratory features 500 sq.m laboratory and 300 sq.m. offices Two Large Vacuum Test Facilities each with a volume >100 cu.m. are presently operated Additional Medium and Small vacuum facilities are available EMI/EMC test facility under commissioning AST.3 LVTF-1 Test Facility Characteristics: Heritage: - 3.8 m Ø x 11.4m L , 120 cu.m. Volume - Chevron beam target, Water/GN2 cooling, P>25kW - Graphite lining over the chevron target and the cylinder - Forevacuum system allowing p<1xE-2 mbar in less than 4h - High vacuum system allowing p<1xE-7 mbar in less than 12h - Chamber heat conditioning allow static vacuum p<3xE-8 mbar - Cryogenic pump speed on Xe >160.000 l/s over long duration test - Over 10kg of Xe cryocondensation before regeneration needs - Facility reliability >90% over long duration testing - over 500h testing of Astrium RIT-XT - over 5.000h testing of Astrium RIT-22 - over 5.200h testing of Thales HEMPT - over 300h testing of several Fakel SPT-100 models Ongoing programmes: - HEMP-TIS qualification programme AST.4 LVTF-1 (HEMP-TIS upgrade) Special test setup: - all the graphite protections have been fully removed from any part of the facility - new Aluminium panels have been installed in a concentric-cylindrical chevron shape - the accurate design was performed by the Max-Planck-Institut für Plasmaphysik - Greifswald under Thales supervision AST.5 LVTF-2 Test Facility Characteristics: Heritage: - 3.8 m Ø x 12.5m L , 140 cu.m. Volume - Chevron beam target, Water/GN2 cooling, P>25kW - Graphite lining over the chevron target and the cylinder - Dry pumping system at all stages - Mag-lev Turbomolecular pumps - Forevacuum system allowing p<1xE-2 mbar in less than 4h - High vacuum system allowing p<1xE-7 mbar in less than 12h - Chamber heat conditioning allow static vacuum p<3xE-8 mbar - Cryogenic pump speed on Xe >180.000 l/s over long duration test - Facility reliability >90% over long duration testing - Commissioned in 2011 - Performance testing of single and HET clusters - Performance testing of Helicon thrusters - Sputtering testing of HET plume over S/C surfaces - Thermal vacuum testing for ESA and ASI programmes Ongoing programmes: - High power EP thrusters testing - EMI/EMC testing AST.6 EMI/EMC Test Facility In-vacuum EMI/EMC test facility Shielded chamber internal dimensions before absorbers installation 6.0 x 5.2 x 3.3 m The EMI room is connected to the LVTF-2 test facility Shielding performance before the chamber upgrade Frequency Field Shielding (>) 10 KHz Magnetic 70 dB 100 KHz Magnetic 110 dB 1 MHz Magnetic 110 dB 100 MHz Electric 140 dB 500 MHz Plane Wave 110 dB 1 GHz Plane Wave 110 dB 10 GHz Microwave 100 dB 18 GHz Microwave 100 dB 40 GHz Microwave 90 dB AST.7 EMI/EMC Test Facility (2) 4.1 m ∅ 1m An optimal arrangement of different types absorbers has been designed to cover the walls, including: • Ferrite lining + hybrid absorbers • 24” and 30” absorbers Semi-anechoic room useful internal dimensions after absorber installation: 4.8 x 4.1 x 2.7 m 4.8 m AST.8 EMI/EMC Test Facility (3) Connection to LVTF-2 test facility LVTF-2 ∅ 3.8 m x L 12.5m Pump speed > 180.000 l/s on Xe ∅ 1m Gate Valve ∅ 1m x L 1.5m service chamber S2 glass + Epoxy Pyramidal beam dump AST.9 EMI/EMC Test Facility (4) New shielding test are actually ongoing to asses the new performance after the Gate Valve Installation AST.10 Ground Support Equipment EGSE & FGSE • Test Power Supplies for Hall Thrusters from 100 W to 10kW Power • Xenon Propellant Feeding System from 1 sccm to 200 sccm AST.11 Diagnostics Test Equipment Thrust Balance • Parallelogram with zero deflection type (null reading) • The stiffness of the hinges can be chosen so as thrusters of different weight and thrust can be accommodated. • Reconfigurable structure allowing different range of measurements (hundreds of mN, mN, and hundreds of uN ranges) • Typical accuracy in the range of +/- 0.5% over a single dedicated test, and +/- 2% over long duration testing Thrust balance installation in the MVTF-1 test facility AST.12 Diagnostic Test Equipment (2) Probe set-up on the diagnostics boom • The diagnostics boom is moved by a stepper motor which is controlled by a PC based system • The boom can be rotated around the thruster axis. • Typical range of rotation depends from the mechanical constrains placed around the thruster (e.g. –100 to 100 deg with thrust balance installed). • 34 Faraday Probes placed at different angular positions on the arm (each 5 deg from β =-80 to +85 deg). It allow to measure the ion current 1 m from the thruster at different angles from the centerline. • additional probes are mounted on the boom for special measurements. • 2 RPA are available on the diagnostic boom. RPA Probe b Probe a AST.13 Beam Diagnostics Faraday probes current density plot for each Faraday probe current density 3D plot current density contour plot beam current beam divergency beam axis deviation test report generated automatically 10 Co nto ur m ap o f Curre nt De ns ity (inte rpo late d) FP11 (β = -0.54°) 1 80 60 40 0 0.5 1 2 7 4 10 5 -20 -1 2 6 3 1 2 3 0 3 5 6 4 β (°) 20 0.5 2 10 0 .5 Curre nt De ns ity (A/m ) • • • • • • • 1 0 .5 -40 -60 10 -2 -90 -80 -70 -60 -50 -40 -30 -20 -10 0 α (°) 10 20 30 40 50 60 70 80 90 -80 -80 -60 -40 -20 0 20 40 60 80 α (°) AST.14 Beam Diagnostics (2) The Retarding Potential Analyser (RPA) 1.8 x 10 -5 Origina l Da ta S moothing S pline 1.6 • • • • The RPA measure the energy of the ions emitted from the thruster at different angles from the centerline The first grid is electrically isolated from the probe The second grid is biased to a constant negative potential to repel all plasma electrons from the collector The third one is the ion retarding grid and is connected to a variable high voltage power supply The ion current to the collector is measured by using a Picoammeter 1.4 1.2 1 0.8 0.6 0.4 0.2 0 1000 9 x 10 1200 1400 1600 1800 2000 2200 2400 2000 2200 2400 Io n Vo ltag e Dis tributio n -8 8 7 6 5 dI/dV (A/V) • 4 3 2 1 0 -1 1000 1200 1400 1600 1800 Ene rgy / Cha rge (V) AST.15 Beam Diagnostics (3) Langmuir Probes • • • Plasma potential Electron energy distribution The probes can be mounted on the rotation boom to measure the far field or in a fast sweeping mechanism to investigate the near field Thruster Langmuir 1 20° Firing Direction Langmuir 2 Langmuir Movement System AST.16 Beam Diagnostics (4) Emission Spectroscopy • electron temperature • neutral Xe density • charged ions Xe density AST.17 Beam Diagnostics (5) Laser Induced Fluorescence (LIF) Collimator 2 • • • • • 3.5 Lock-in signal [V] 3.0 X=0 mm; Z=-48 mm; Y=0mm Y=+8.5mm Y=+17mm Y=-8.5mm Y=-17mm 4 Collimator 1 reference line at 834.745 nm LIF signal at 834.724 nm 3 Lock-in output [V] 4.0 neutral Xe velocity single charged Xe velocity axial and radial velocity components thruster mounted on a 3 axis displacement system for fast sweep spatial resolution 1x1x8 mm 2.5 2.0 1.5 2 1 1.0 0.5 0 0.0 -12 -10 -8 -6 -4 -2 0 2 4 6 8 10 12 14 Frequency [GHz] Radial velocity distribution as a function of the Y direction -30 -25 -20 -15 -10 -5 0 5 Frequency [GHz] Most probable axial velocity measurement at V=250 V and 0.7 mg/sec Xe flux (left) and an example of the LIF signal (right). AST.18 Beam Diagnostics (6) E x B Probe The diagnostics is under development in the frame of the ESA Program “Qualification of the AEPD System as a Standard On-ground Tool for Electric Propulsion Thrusters”, ESA Contract No. 4000107451/12/NL/RA • multiple charged species fractions • multiple charged species velocity Magnetic assembly analysis 30 AST.19 Additional Test Facilities • Small Vacuum Test Facilities • The SVTF-1 / 2 / 3 are mainly used for : • regular vacuum gauges verification comparing to calibrated gauges • Spectrometers check and verification • cathode testing • Medium Vacuum Test Facilities • The MVTF-1 is mainly used for low power thruster test • 1.3 m Ø x 3 m L , 4 cu.m. Volume • Graphite lining over the chevron target and the cylinder • High vacuum system allowing p<1xE-6 mbar (p<1xE-7 mbar after chamber heat conditioning static vacuum) • Cryogenic pump speed on Xe >10.000 l/s • Beam diagnostics • Thrust balance • Spectroscopic and LIF diagnostics AST.20 Engineering Activities Vacuum Test Services • • • • • Leak-check services Residual gas analysis Special flanges/adapter design/manuf. Vacuum harness design/manuf. Vacuum chambers design/manuf. Cryogenic systems developments • Cryostats design/manuf. • LN2 supply/lines design/manuf. • LN2 phase/separators design/manuf. Electronics and management of data • Data Acquisition & Control for complex systems • Networking & Communications in harsh environments • Specific HW and SW developments AST.21 AEROSPAZIO TECNOLOGIE s.r.l. Rapolano Terme, Siena, Italy www.aerospazio.com Thank You AST.22