metering valves - Ham-Let

advertisement

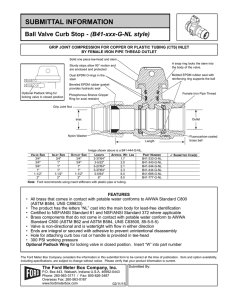

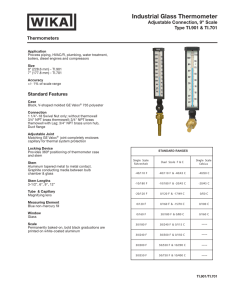

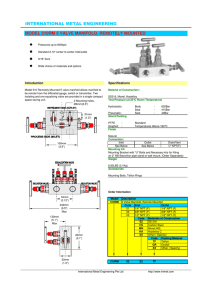

METERING VALVES H-1300 & MBV SERIES MBV Series: Pat. Pending No. 61/376,682 H, HF & HXF-1300 SERIES FEATURES GENERAL Forged-body 316 St.St.or Brass Construction n Straight and Angle Patterns and Panel Mounting n MAWP 2000 psig - (138 bar) For HXF n MAWP 1000 psig - (69 bar) For H, HF n MAWT 400°F (204°C) n Flow coefficients (Cv) from 0.004 to 0.15 n Round & Slotted Handles with Screwdriver Slots n HAM-LET LET-LOK® Ends, Male & Female NPT, HTC® Face Seal Bead End Connections n 1°, 3° and 5° Stem Taper for required flow control n Stem with Stopper Shoulder for maximum life The H-1300 Series is a moderate-pressure instrumentation flow-regulating needle valve. It is generally used for instrumentation panels, sampling systems and accurate applications. The valves are compact in size and structure and offer reliable low and moderate flow regulation with long service life. n HXF-1300 MATERIALS OF CONSTRUCTION A Item No. 1 2 3 4 5 B 6 7 8 9 10 C 11 12 Components Valve Body Material Qty 316 St.St. 1 Brass Handle Set Screw Flow Fixing Screw 1 18-8 Stainless Steel 1 18-8 Stainless Steel Handle Panel Nut 1 St.St. ASTM A-276 Brass ASTM B-16 1 St.St. ASTM A-276 Brass ASTM B-16 Safety Bonnet Sleeve Bonnet 1 St.St. ASTM A-276 Brass ASTM B-16 1 St.St. ASTM A-276 Brass ASTM B-16 Stem Stem Ring 1 1 Glass-filled TFE O-ring Guide Ring 1 Viton® (fluorocarbon) 1 Glass-filled TFE Orifice Body 1 St.St. ASTM A-276 1 St.St. ASTM A-182 Brass ASTM B-283 2 4 3 St.St. 174PH/A564 5 Brass ASTM B-16 Safety Bonnet Sleeve prevents bonnet release from body. 6 HXF SERIES STRAIGHT VALVE D 7 Lock Set Screw helps determine required flow (slotted handles) E Safety Bonnet Sleeve F Stem Upper Shoulder (for safe full opening) prevents locking between stem and bonnet Guide Ring keeps the stem concentric to the orifice 8 9 10 11 G H 236 Tapered Stem Tip controls accurate gas and liquid flow rate METERING VALVES H-1300 SERIES 12 CLEANING & PACKAGING HAM-LET H-1300 Metering Valve is treated with HAM-LET Passivation Cleaning and Packaging (Procedure 8075). HAM-LET H-1300 Ball valves with face-seal end connections are treated with Oxygen Cleaning and Packaging (Procedure 8075). 1 3 H&HF-1300 MATERIALS OF Item No. 1 2 3 4 5 6 7 8 9 10 Components 2 CONSTRUCTION Qty Valve Body Material 316 St.St. Brass St.St. ASTM A-276 Brass ASTM B-16 Handle Set Screw Flow Fixing Screw 1 Handle Panel Nut 1 1 St.St. ASTM A-276 Brass ASTM B-16 Safety Bonnet Sleeve Bonnet 1 St.St. ASTM A-276 Brass ASTM B-16 1 St.St. ASTM A-276 Brass ASTM B-16 Stem O-ring 1 St.St. 174PH/A564 1 Viton® (fluorocarbon) Guide Ring Body 1 1 1 4 A 18-8 Stainless Steel St.St. ASTM A-276 Glass-filled TFE St.St. ASTM A-182 Brass ASTM B-283 5 B 6 C HF SERIES ANGLE VALVE D Lock Set Screw helps determine required flow (slotted handles) Stem Upper Shoulder (for safe full opening) prevents locking between stem and bonnet 7 9 8 E Safety Bonnet Sleeve 10 Tapered Stem Tip controls accurate gas and liquid flow rate Guide Ring keeps the stem concentric to the orifice F G H HAM-LET ADVANCED CONTROL TECHNOLOGY 237 STANDARD CONFIGURATION DIMENSIONS A Basic Ordering Number Stem Taper Angle H-1300 Angle B C H-1300 Straight 50 H-1300 Angle 30 D HF-1300 Straight E HXF-1300 Angle F 10 HXF-1300 Straight G Orifice mm/in Cv Inlet 1/4'' LET-LOK® 6MM LET-LOK® 3.3mm 0.13 1/4'' LET-LOK® 0.13" Max 3/8'' LET-LOK® 6MM LET-LOK® 1/4'' Male NPT 1/8'' LET-LOK® 1/4'' LET-LOK® 3MM LET-LOK® 6MM LET-LOK® 1/8'' Male NPT 1/4'' Male NPT 1/8'' Male NPT 1/4'' Male NPT 1.4mm 0.03 1/8'' Female NPT 0.055" Max 1/8'' LET-LOK® 3MM LET-LOK® 6MM LET-LOK® 1/4" LET-LOK® 1/8'' Male NPT 1/4'' Male NPT 1/8'' Female NPT 1/4"' Male Face Seal 1/8'' LET-LOK® 1/4'' LET-LOK® 3MM LET-LOK® 1/8'' Male NPT 1/4'' Male NPT 1/8'' Male NPT 0.8 mm 0.004 1/4'' Male NPT 0.03'' Max 1/8'' LET-LOK® 1/4'' LET-LOK® 3MM LET-LOK® 6MM LET-LOK® 1/4'' Male NPT 1/4'' Male Face Seal Outlet 1/4'' LET-LOK® 6MM LET-LOK® 1/4'' LET-LOK® 3/8'' LET-LOK® 6MM LET-LOK® 1/4'' Male NPT 1/8'' LET-LOK® 1/4'' LET-LOK® 3MM LET-LOK® 6MM LET-LOK® 1/8'' Male NPT 1/4'' Male NPT 1/8'' LET-LOK® 1/4'' LET-LOK® 1/8'' Female NPT 1/8'' LET-LOK® 3MM LET-LOK® 6MM LET-LOK® 1/4" LET-LOK® 1/8'' Male NPT 1/4'' Male NPT 1/8'' Female NPT 1/4'' Male Face Seal 1/8'' LET-LOK® 1/4'' LET-LOK® 3MM LET-LOK® 1/8'' LET-LOK® 1/4'' LET-LOK® 1/8'' Male NPT 1/4'' Male NPT 1/8'' LET-LOK® 1/4'' LET-LOKv 3MM LET-LOK® 6MM LET-LOK® 1/4'' Male NPT 1/4'' Male Face Seal Dimensions are for reference only, and are subject to change. MAX PANEL THICKNESS H 238 “HXF” Series - 4.3 mm (0.17'') “H” and “HF” - 3.3 mm (0.13'') METERING VALVES H-1300 SERIES A-Open B C D E mm in mm in mm in mm in mm in 95.7 95.7 71.5 71.5 71.5 71.5 83.5 85.0 83.5 85.0 77.0 83.0 77.0 81.5 82.5 70.6 70.6 70.6 70.6 70.6 70.6 70.6 70.6 84.4 85.0 84.4 77.5 82 84.4 84.4 59.6 59.6 59.6 59.6 59.6 59.6 3.77 3.77 2.81 2.81 2.81 2.81 3.29 3.35 3.29 3.35 3.03 3.27 3.03 3.2 3.25 2.78 2.78 2.78 2.78 2.78 2.78 2.78 2.78 3.23 3.35 3.32 3.05 3.22 3.32 3.32 2.34 2.34 2.34 2.34 2.34 2.34 29.6 29.6 59.5 62.4 59.5 50.8 25.8 28.0 25.8 28.0 19.0 25.0 25.8 28.3 24.9 51.3 51.3 55.9 55.9 38.1 49.8 49.3 52.3 24.8 26.0 24.8 24.8 27.3 24.9 24.9 48.0 51.9 48.0 51.9 48.0 52.0 1.17 1.17 2.34 2.46 2.34 2.00 1.02 1.10 1.02 1.10 0.75 0.98 1.02 1.11 0.98 2.02 2.02 2.20 2.20 1.50 1.96 1.94 2.06 0.98 1.02 0.98 0.98 1.07 0.98 0.98 1.89 2.04 1.89 2.04 1.89 2.05 30.0 30.0 25.8 28.0 25.8 28.0 19.0 26.0 19.0 23.5 24.9 24.8 26.0 24.8 24.8 24.8 24.9 24.9 - 1.18 1.18 1.02 1.10 1.02 1.10 0.75 1.02 0.75 0.92 0.98 0.98 1.02 0.98 0.98 0.98 0.98 0.98 - 26.0 26.0 32.0 32.0 32.0 32.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 27.0 23.4 23.4 23.4 23.4 23.4 23.4 23.4 24.4 24.4 24.4 24.4 24.4 24.4 1.02 1.02 1.26 1.26 1.26 1.26 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 1.06 0.92 0.92 0.92 0.92 0.92 0.92 0.92 0.96 0.96 0.96 0.96 0.96 0.96 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 14.8 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 0.58 F 29 mm 1.14'' 12.5 mm 0.5'' 12.5 mm 0.5'' 12.5 mm 0.5'' FLOW SETTING TESTING H-1300 series metering valve is tested for bubble tight shutoff at 100 psig (6.8 bar) differential pressure. HF-1300 series metering valve handle dead stop is set at 4 to 10 std cm3/min with 5 psig (0.34 bar) inlet pressure. HXF-1300 series metering valve handle dead stop is set at 4 to 10 std cm3/min with 15 psig (1.0 bar) inlet pressure. The H, HF and HXF Series metering valve designs have been tested for Proof and Burst. Every H,HF & HXF-1300 metering valve is factory tested for proper assembly, using leak detection. FLOW DATA AT 70ºF (20ºC) H-1300 METERING VALVE 5° STEM HF-1300 METERING VALVE 3° STEM A 0.03 0.025 0.12 Flow Coefficient (Cv) Flow Coefficient (Cv) 0.15 0.14 0.1 0.08 0.06 0.04 0.02 0 2 4 6 8 10 11 0.02 0.015 B 0.01 0.005 0 3 6 11 Handle Turns Handle Turns Maximum Flow Coefficient (Cv) 0.15 9 Pressure Drop to Atmosphere psi (bar) Water Flow U.S gal/min (L/min) Air flow stb ft3 / min (stb L / min) 10 (0.68) 0.47 (1.7) 1.6 (45.3) 50 (3.4) 1.0 (3.7) 4.5 (127) 100 (6.8) 1.5 (5.6) 7.9 (223) Pressure Drop to Atmosphere psi (bar) Maximum Flow Coefficient (Cv) 0.03 C Water Flow U.S gal/min (L/min) Air flow stb ft3 / min (stb L / min) 10 (0.68) 0.09 (0.34) 0.33 (9.3) 50 (3.4) 0.21 (0.79) 0.9 (25.4) 100 (6.8) 0.3 (1.1) 1.5 (42.4) D HXF-1300 METERING VALVE 1° STEM 0.83” (Ø 21.0) 0.004 E 0.003 0.0025 0.002 1.82”(46) Open Flow Coefficient (Cv) 0.0035 0.0015 0.001 0.0005 0 2 4 6 8 10 11 Handle Turns G Pressure Drop to Atmosphere psi (bar) Water Flow U.S gal/min (L/min) Air flow stb ft3 / min (stb L / min) 10 (0.68) 0.01 (0.03) 0.04 (1.1) 50 (3.4) 0.02 (0.07) 0.1 (2.8) 100 (6.8) 0.04 (0.15) 0.2 (5.5) HAM-LET ADVANCED CONTROL TECHNOLOGY Panel Thickness Maximum Flow Coefficient (Cv) 0.004 F H 239 TECHNICAL DATA A Series *O-ring Material Pressure - Temperature Ratings Temperature Rating °F (°C) Buna N -10 to 300 (-23 to 149) Ethylene Propylene -10 to 300 (-23 to 149) HF Viton® (Fluorocarbon) -15 to 400 (-26 to 204) Perfluor -0 to 300 (-18 to 149) HXF Neoprene -10 to 250 (-23 to 121) H B Orifice Shutoff Service Angle 3.3 *Yes 5° 0.055 1.4 No 3° 0.03 0.8 No 1° Pressure psig (bar) inch mm 1000 (68.9) 0.13 1000 (68.9) 2000 (138) Viton® (Fluorocarbon) is a standard O-ring for H,HF,HXF-1300 C D *Shutoff Service: In Stainless Steel constructions only. H-1300 Series valves are not recommended for shutoff in vacuum or gas service or for repetitive shutoff in liquid service. HANDLE OPTIONS Vernier Handle Round Aluminum Handle* E Metal Slotted Handle Metal Slotted Handle F Optional for H, HF & HXF G Standard for H * Black is Standard. Colored Handles are available upon request, see "Ordering Information" H 240 METERING VALVES H-1300 SERIES Standard for HF Standard for HXF H-1300 ORDERING INFORMATION OPTIONAL H-13 - - 00 - SS - L - 1/4 S - - - A Valve Series End Connection O-ring Material - 5° stem taper H-13 HF-13 - 3° stem taper HXF-13 - 1° stem taper L N GL HL EP NE KZ BU - LET-LOK ® - Threaded NPT - Male Face Seal - ONE-LOK® - EPDM, - Neoprene - Perfluor - Buna-N B Viton® O-rings are standard Valve Type 00 10 80 95 Handle Options End Connection Size - LET-LOK® End 1/6 - Female End 1/8 3 MM - Male End 1/4 6 MM - Male to LET-LOK® End 3/8 VER RH YH GH BH - Vernier Handle - Red Aluminum Handle* C - Yellow Aluminum Handle* - Green Aluminum Handle* - Blue Aluminum Handle* * for H-1300 only Body and Ends Material Pattern Valve Type Treatment SS B S A 800 BLANK - Standard Cleaning & Passivation - Oxygen Clean OC - Lubricant Free LF - St.St. 316 - Brass - Straight Port Valve - Angle Port Valve - MBV Configuration SEAL KIT HANDLE KIT Seal Kit contains O-ring Z - 1300 - D E Handle Kit contains handle + set screw. SK - 1/4 - VI Z - 1300 - HK - 1/4- - Body Designator per end connection O-Ring material Handle Options Handle Options 1/4 VI EP NE KZ VITON® EPDM Neoprene Perfluor 1/4 BU Buna-N VER RH YH GH BH M for all end connections for all end connections VER - Vernier Handle - Red Aluminum Handle* F - Yellow Aluminum Handle* - Green Aluminum Handle* - Blue Aluminum Handle* - Metal slotted Handle** * for H-1300 only **for HF & HXF-1300 only G Warning! For your safety The system designer and user have the sole responsibility for selecting products suitable for their special application requirements, ensuring their safe and trouble-free installation, operation, and maintenance. Application details, material compatibility and product ratings should all be considered for each selected product. Improper selection, installation or use of products can cause property damage or personal injury. H Viton® - TM DuPont H-1300, Rev.07, July 2011 HAM-LET ADVANCED CONTROL TECHNOLOGY 243