Manual

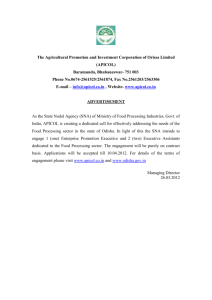

advertisement