02024 Components Specifier`s Guide

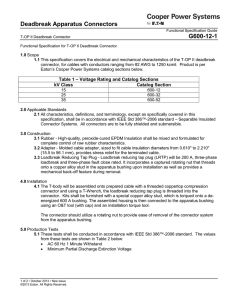

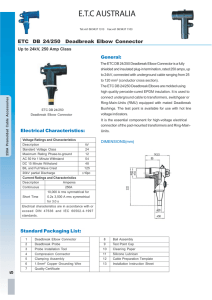

advertisement