INDENT NO:9346603

advertisement

INDENT NO:9346603

ITEM

MESC

UNIT

QTY

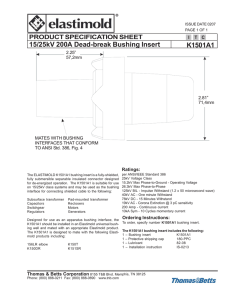

DESCRIPTION

PARTS FOR"ALSTOM: ELEC.MOTOR 3748 HP

6000V , 2800KW , 2973 RPM , 309 , 6A , 3PH

TYPE: N3HXC560-20H , Cos 0.90

01

6634970013

NO

10

BUSHING

(IN-AIR LONG SHANK BUSHING W/SUD 600A) , TYPE: K600TBC

NO ALSTOM ELEC. MOTOR,(CM-7301A/E)

MFG: "ELASTIMOLD"

EQUIPMENT BUSHINGS

Elastimold manufactures a complete line of 200 Amp deepwell and 600 Series apparatus bushings for use on transformers, switchgear and other equipment applications. The

bushings incorporate IEEE 386 standard interfaces (shown

on page 3) and are constructed of molded epoxy with

stainless steel flanges for mounting by welding or gasketed

clamp. K1601PCC series bushings are provided with a

Illustration

(not to scale)

Description

Voltage

Class

ELASTIMOLD

Part Number

Short Shank Well with bail tabs

and non-replaceable well stud

15/25kV

35kV

K1601PC-S1

L1601PC-S1

N1,9

N1,9

Short Shank Well with bail tabs

and with replaceable well stud

15/25kV

35kV

K1601PC-S1-R

L1601PC-S1-R

N1,7,9

N1,7,9

Short Shank Well without bail tabs

and non-replaceable well stud

15/25kV

35kV

K1601PC-S2

L1601PC-S2

N1,7,9

N1,9

Short Shank Well without bail tabs

and with replaceable well stud

15/25kV

35kV

K1601PC-S2-R

L1601PC-S2-R

N1,7,9

N1,7,9

Long Shank Well with bail tabs

and non-replaceable well stud

15/25kV

35kV

K1601PC-T1

L1601PC-T1

N2,9

N2,9

Long Shank Well with bail tabs

and with replaceable well stud

15/25kV

35kV

K1601PC-T1-R

L1601PC-T1-R

N2,7,9

N2,7,9

Long Shank Well without bail tabs

and non-replaceable well stud

15/25kV

35kV

K1601PC-T2

L1601PC-T2

N2,9

N2,9

Long Shank Well without bail tabs

and with replaceable well stud

15/25kV

35kV

K1601PC-T2-R

L1601PC-T2-R

N2,7,9

N2,7,9

Epoxy Flange Well

Epoxy Flange Well with replaceable well stud

15/25kV

15/25kV

K1601PCC

K1601PCC-R

N1,7,9

N1,7,9

15kV

25kV

1601CABA4R

2701CABA4R

N1,9

N1,9

Well w/Insert (K1601PCC-R & 1601A4)

Well w/Insert (K1601PCC-R & 2701A4)

N1.

N2.

N3.

N4.

N5.

N6.

N7.

N8.

N9.

N10.

N11.

N12.

Notes

200 A Deadbreak Integral Bushing

200 A Deadbreak Integral Bushing

15/25kV

15/25kV

K180T4

K180C4

N3,9

N2,9

600 A Short Shank Bushing w/stud

600 A Short Shank Bushing w.o./stud

600 A Short Shank Bushing w.o./stud

600 A Cu Short Shank Bushing w.o./stud

15/25kV

15/25kV

35kV

15/25kV

K600S1

K650S1

750S1

K675S1

N4,8,10

N4,8,11

N4,8,11

N4,9,11

600 A Long Shank Bushing w/stud

600 A Long Shank Bushing w.o./stud

600 A Cu Long Shank Bushing w.o./stud

600 A 12” Long Shank Bushing w/stud

15/25kV

15/25kV

15/25kV

15/25kV

K600T1

K650T1

K675T1

K600L12

N5,8,10

N5,8,11

N5,9,11

N6,8,10

600 A In-Air Long Shank Bushing w/stud

600 A Cu In-Air Long Shank Bush. w/stud

Boot & Collars for K600T1 to use in air

15/25kV

15/25kV

15/25kV

K600TBC

K675TBC

600BC

N5,8,10,12

N5,9,10,12

N12

Bushing shank length = 2 - 3/4 inches.

Bushing shank length = 9 -1/4 inches

Bushing shank length = 7 - 11/32 inches.

Bushing shank length = 2 - 5/16 inches.

Bushing shank length = 8 - 37/64 inches.

Bushing shank length = 12 inches.

Replacement stud available separately. Specify 1601RS.

Equipped with standard aluminum conductor rod.

Equipped with copper conductor rod.

Includes 5/8-11 threaded stud at elbow end.

Includes 5/8-11 threaded hole at elbow end.

Provides increased creep and strike.

ELASTIMOLD

molded epoxy flange for gasketed clamp mounting only.

Bushings are available for use on AIR, OIL or SF6 insulated

equipment . Units are rated for submersible, padmount, indoor, outdoor and other applications. Options include holddown bail tabs and replaceable studs for 200 Amp

deepwell bushings.

CABLE JOINTS, CABLE TERMINATIONS, CABLE GLANDS, CABLE CLEATS

FEEDER PILLARS, FUSE LINKS, ARC FLASH, CABLE ROLLERS, CUT-OUTS

11KV 33KV CABLE JOINTS & CABLE TERMINATIONS

FURSE EARTHING

www.cablejoints.co.uk

Thorne and Derrick UK

Tel 0044 191 490 1547 Fax 0044 191 477 5371

CATALOG 2001 Page 36 ID:

Tel 0044 117 977 4647 Fax 0044 117 9775582

0198

•

72202.0 T

0872

P2

550-12

i

I

i

""

I

U23

rOI:'

I,

.7!lO

~0lA

I

1132 A

118 A. TYP

2,860

G'OAl

.- .----r-

L.'••• :...-J

~

".

OIA, 3.080~

UPPER

~.

!=O

Jl2

3/32.

"--"

@)

•

.312

'''''

LUo?J

!

.1500

(,-i-\,

""

.""

L'35'

01". 3-080

'~;",,/

,

OIA,

'.

COLLAR

!..OWER COLLAR

f,=~,= __

800T

~

~

600-TI

UPPER COt,LAR

lown,

COlJ..,l,A:

,J1.

800T

ORDERING INSTRUCTIONS

1. For 15-kv use, order 8 BOOTBe.

2. For 25-kv use. order 8 KGOOTBC.

NOTE: An order for a 600TBC or K600TBC includes a

one boot-all in one package.

NOTE: For detailed product

Information.

re.'r

Goon

or K600T1 bushing, plus two collars and

to the catalog sheet lor the

Goon

in this section,

72202.0T

0872

Elastimold~

550-12

Pl

'-

"""

a

=

~~~

er

Distribution

Apparatus

Bushings

(For in~alr application)

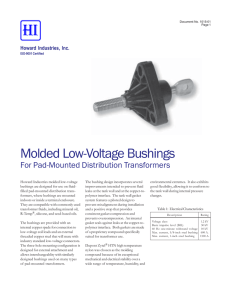

APPLICATION

The ELASTIMOLD

BooTSe and

K600TBC power distribution ap.paratus bushings will universally

accept ELASTIMOlO 650lA and

K650lA elbow connectors

and

600BE and K600BE bushing extensions. The bushings are deSigned to be directly mounted In

electrical apparatus on 600-amp.

15-kv and 25-kv systems.

Typical applicalions

•

•

•

•

Above-grade

Below-grade

Switchgear

Motors

would be in:

translormers

transformers

DESIGN

The600TBC and KGOOTBCare de.

signed lor m.air application. The

increased creep distance required

is provided by the non.tracklng

rubber boot and cOllars supplied

These are slipped on the epoxy

bushing shank after it has been

installed in the apparatus housing

ELECTRICAL RATINGS

25-'" CLASS

15-kv ClASS

Vott.

R.urogt

FOfUNon 15-llvCll"

IqUlpmen1

.r use on 25-kll

(tQ •••:~I.

BIL&5kv.l.2 .•.50_

-'L: :25 •••••1.2 II 50

ElASTIMOlD

42 kl/, 60 Hl. 1 minute

f'JC. 15 mlnutK

55 kl/. DC, 15 mlnUII!!&

Coron. 11 kVlulincUon

C"'u"u:

Currllfll

Continuous: 600 amps. RMS

l.:onlinuous:

R111!nga

&-Hour Overload:

&-Hour QviI,load: 9OOampll, RMS

900 amps. RM$

40,000 Imps, AMS. asym.

27.000 aml)a, Rt.4S. sym,"

PfodUC1lon

COron&

Tnls

Impulse:i5 k••.Bll

11 kll eldl1IC1'O!1

ELASTIMOLD ]

Route 24, HacI<St1St:lWf1. New Jersey 07840 USA

A Unit 01 EIJ9Ie 1nd1lS1IIeS. Inc.

19 kv •.•.tinction

12 cycles

SK:S.

and

600 amps. AMS

Momentary:

Momentary

GOOTBC

K600TBC bushings are molded

01 epoxy with molded rubber collars and boot and have a stamless

steeillange for welding or clamping to the apparatus.

¥I' •••••

.nsl.nd.

W,thtl;and:

35 kll, 60 Hz. 1 minute

~[

clan

40.000 Imps, RMS. uym, 12 cycles

21.000 Imps.

AMS. Sri'll, 4 MCS.

Corona: 19 kv •• tlrlchon

Impulse: 12$ k" BtL

INSTAllATION

Installa1l0n

of the bushings

Is

normally done by the apparatus

manufacturer_

- ,.

(,

• "

r.o'

-l

t,,.

/'

,

>

;..-1

I-

.

,~. .

.,

.

"

ElaSllmoid manufactures a complete line of 200 Amp deepwell and 600 series apparatus bushings for use on trans.

formers. swilChgear and other equipment applications. The

bushings Incorporate IEEE 386 standard interfaces (shown

on page J) and are conslructed

of molded epoxy with

stainless steel flanges for mounting by welding or gaskelcd

clamp. K1601PCC series bushings are provided with a

iltll'>tl811QJ1

~

1

-'"

m ..

I

,'"

I--@

, I

I

V(

L

,

I'll

N2

/113

Not

~:-p

~-

K1601pc.Sl

L 160IPC.Sl

Nl.9

Short S/lallk WeI with baMliIbs

lind WIthropIaceabic Y«?' ~ud

1!>l2SkV

35kV

Kltj()lPC.Sl.R

ll601PC.Sl.R

Nl.7.9

Nl.l.9

Short Shank wei WIhouI r ••.

end ~

WIllI iL.J

ISl2SkV

)SkV

Kl601pc.S2

ll&OIPC.S2

Nl.7,9

Nl.9

Short Shank 'MlI W'IlIlOiA

lMlItabs

lind ••••11ft'PI&Ceablc wotIscud

1S12~V

3SkV

K 1601pc.52.R

ll60IPC-51-R

N1.1.9

N1.7.9

long S/1<Inkwea wilh lJlloillabs

lInO nOll'fcp/llceahlc wolI stud

l!>J2SkV

35kV

Klf.01PC.Tl

l1601PC.Tl

N2.9

N2.9

L.oog S/1<InkWIll with baillilbs

lind WIth repliltBabioc wotISlud

1!l125kV

K1601pc.Tl.R

ll601PC.Tl.R

NV.9

N2.1,9

Long :>hank wei 'IIIlhotA blIIllllbs

on<!llOfWePla<:CIlblcwei )Iud

l!>l25kV

Kl60lpc.T2

ll601pc.T2

H2.9

N2.9

Long Shank WelIMlllotJ. balIlilbs

end with replacellbk> ~ $Iud

lSl25kV

35kV

K1601PC.T2.R

ll601pc.T2.R

N2.7.9

NV,9

15J25kV

l~5kV

K1601PCC

K1601PCC.R

Nl.7,9

Nl,7,9

1601CABA4R

2101CABMR

Nl.9

Nl.9

)SkV

""

"'"

..

.•••••a stud

t

l5kV

25kV

',f).

-

N~,~shIlnk~

KI80H

K18OC4

Nl,8

H2.9

600

600

600

600

A Short Shank Bll~h::

A Shon Shank BuoJ'Ml'!j;, ",>tuO

A Sl'lofl 5hi1nk BlIshing wo /51UO

A Cu Shoo Shank Bushing wo/5Wd

1Sl25kV

1!l/25kV

35kV

lSl25kV

K6OO51

K65051

15051

K61551

N4.8,10

/114.8,"

Not.8,n

Not.9,11

600

600

600

600

A LDng ShIlnk Busting wfSlud

1Sl25kV

15125kV

1Sl25kV

1tl/25kV

K600Tl

K650Tl

K615Tl

K600112

N5.11,1O

N5.8,11

N5.9,11

N6,8,lO

2 3Iot'roches

9.114 "lCl1eS

1. 11/32 inCheS.

1. 5116lOCtm..

••

Nl.9

1Sl25kY

1Sl25kV

~it j,pf\g~hilnij B.l!.$rJg wl.swd

600 A CII Ir>-Alllong Shank Bush wl~d

Boo! & C~!of

K600Tl to ~I':' 8If

8u!Jllng shenk lengtn •

Iko~ WInk lengU> •

~

shank IengIh BusIWlg!ohanll ~

-

N~n

200 A Deadbteak ~

8W1ng

200 A Dcacbeak 1nt.,9"'.!.BW*iO _

A Long Shank Bushing w.oJslud

A Cu Long Shaok aw.ng w 0 hlud

A 12' Long Shank BusrIlog w/!Itud

in.

studs lor 200 Amp

15aSkV

6o!l,A.

I ~

J.,

•I

rtJfiU5

--yo

down bail tabs and replaceable

dccpwell bushings.

Shun Sliank WeI WllhlJ.81\lib!.

lind IlOM'Cplaceablf' well ~

WollI w.-'Imerl fKl601PCC.1t f

j••

padmounl.

[LASTlMOLO

Pilll Number

W!lI ••••

llno;erl (l{1601PCCR

C.

Units are rated lor submersible

door, outdoor and other applications. Options include hold.

"""'9'

C~'5.!>

~.

Epoxy Flange lJ-A,ll

Epoxy nallqe Wei WIthrepl&c"

;to

,;.i

equipment.

Oesc;rip!ion

lrtOl !O K&IoII

P

molded epoxy flange for gasketed clamp mounting only.

Bushings are available lor use on AIR, OIL or SF6 insulated

~~,

15125kV

15125ltV

*'

~600TBC

K675TBC

600BC

~..> N5J1,lO. 1i

N5.9, 10,\2

N"

001,.

,t%1, .4.

.:.37lt4'iiJ2

NO. Ilushll'lgs/wlklcngth

_111rlChcs

';.u'

N1. R?corrl6lll!>lud

llVanable~r-a("I)'~1Iy ~601RS,

.~cjiJIppe4_wilh.s;JnOard olnrr,lnum ~

nil

N9 [9..,Ulppe(I WIII1copper conduclof roo

Nl~~5iil:nlJieoded

'~LJd

i1I ei60w 009

Nl1

hOleltl elboW end

IroctuQu-s

518.11J1Y~

N', P,

.

:,,!8i'Jclliii)l;'Kf~il

ELASTIMOLD

"~.

..

CABLE./Ol"TS. CoUll.l'TE_TlOf'CS.1;.AkI

CllNID5. CA&-l'(u .•.

rs

~l'EOE" Pll.UJl5 F\ISf UHKS,AIlCFl.AS><CAlkl' AOUl'IIS, ClJT-OtIfI,

~.

11 i<V ))I(V

-_.

CABLE JOINTS •• CIoBLE 1'£R/oIll'jA ~

FURSE EARTHI"'K>

n-no __

lIl<.

To! 00..- 191 .$l,I1!104f F•• oo..-"I.n

5311

To! OOU 117'17 oM' Fa'OOU '17 077-:'

w

15-0186

March 2010

Page 201 2

STEP 2

STEP 3

Slide the thin-waned upper bushing collar over the lower

end of the bushing until the collar butts against the bottom

of the mounting cover. Note: the collar must be positioned

such that the taper on the inside diameter of the coliar

matches the taper on the bushing.

Slide the lower (thick-walled)

collar over the lower end of

the bushing until it butts up against the upper collar. Match

tapers as outlined in Step 2. The distance from the flat

portion of the bushing contact to the bottom of the second

collar must be 5-1/16" or greater.

-

l \I

l \-12'6

~

Minimum

~

STEP 4

STEP 5

Slide boot over bushing as shown. Make certain that the

boot is all the wayan and that it overlaps lower collar.

For 25kV (125kV BtL Operation) make connection to the

stud as shown. Any connection which lies between the

double broken line and single broken line must be insulated. No connections should be above the double broken

line zone, regardless of insulation. Insulation should consist of appropriate self-amalgamating

high-voltage tape

and be double wrapped overlapped.

g"

600TBC

Bushing

Insulation

Region

= =:#

'ilJ\

-_J'

Bare RegiOn------

~

, 0"

~l

'"

Thomas&Betts

~

8155 T&B Boulevard, MemphIs, Tennessee 36125

(BOO)888-0211 Fax: (800) 888-0690

.'

~

15-0186

IS-600 Be

1'.elastimold"

•

CONTENTS: I-Boo',

Match 2010

Page 1 012

Installation Instructions

GOOBC

Boot and Collars

2-Collars,

The 600BC Is designed for in-air

1-lnstallation

applications

Instructions

of 15 or 25 k'Vt-600/900 amp apparatus bushings.

DANGER

All apparatus must be de-energized during Installation

or removal of par1(s). For loadbreak products follow

operating Instructions. All deadbreak connectors must

be de-energized before operating. All 200A deadbreak

connectors must be mechanically secured with balls

when connected.

All apparatus must be Installed and operated In

accordance with Individual user, local, and national

work rules. These Instructions do not attempt to

provide for every possible contingency.

Do not touch or move energized products.

Excessdistortion of the assembledproduct may result

In Its failure.

Inspect parts for damage, rating and compatibility

mating parts.

with

This product should be Installed only by competent

personnel trained In good safety practices Involving

high voltage electrical equipment. These Instructions

are not Intended asa substitute for adequatetraining or

experience In such safety practices.

Failure to follow these Instructions will result In

damage to the product and serious or tatal injury.

If this product Is supplied with a protective shipping

cover(s), remove this shipping cover(s) and replace

with the appropriate HV Insulated cap(s) or

connector(s) before submerging or energizing Ihe

circuit.

FOR MORE INFORMATION ON PARTS, INSTALLATION RATINGS AND COMPATIBILITY, CALL THE NEAREST ELASTIMOLO OFFICE.

IMPORTANT

1. Check contents 01package to ensure they are complete

and undamaged.

2. Check all components to ensure proper fit with cable

and/or mating products.

•.. 3. Read entire installation Instructions before starting.

4. Have all required lools at hand and maintain cleanliness

throughout the procedure.

STEP 1

Wipe lower end 01bushing clean. Surface should be free of

aU grease, dirt or lubricants since the collars are kept in

place solely by friclion.

Clean

15-0186

15-600 Be

March 20\0

Made In U.S A

Thomas&Betts

as

81

T&6 Boulevard, MemphiS. Tennessee 36125

(800) 888-0211 Fax: (800)888-0690

IS-~'

March 2010

Page2012

HEAT SINKS

c.

To minimize heat tIow to the epoxy, the use of copper heat

sinks is required. The following suggestions Bre offered:

a.

d. Copper _

sinks are reqUred. Use 1hlrmaJy tor1dl.OMl

paste at face a __

i1 oonIaclwithllllr"9' and CXMlr.

Water Cooled (helical coil-top and bottom). Suggest

setting up three or four work stations In order to BIlow

enough time to utilize heat sink before removing work

piece.

b.

Recommended

Non-water cooled heat sinks must not be lett on too

long since heat will flow back Into bushing. Air cool

bushing atter removal of heat sink.

e.

Venting of heat sinks must be provided.

t.

Do not thread heat sink to bushing or bushing well

stud. Expansion due to heat may affect the Integrity of

these parts.

Configuration.

.c.

:"""

...

v

)v/

~

7-

0

ts.;>

, _./

¥

Bottom heat sink should

be of larger diameter than

lop to allow heat to be ab-

II

R!

I

II .Q, II

Ir

I

U

U

Heat line from

welding to be kept

to 1/8- maximum.

sorbed by bottom sink rather

than flow into the lank.

RECOMMENDED

~

a.

PROCEDURES

Keep heattoa minImum. Visible heat line shOuld not be

grealerthan 1/B from weld, 3/16- from 0.0. of flange.

d.

Handling techniques before and atter welding must

.minlmize forces applied to heated stud and flange.

e.

No torque is to be applied to epoxy when making any

bus bar connection.

r.

Temperatures at points indicated by curved arrows

must OoLaxceed--22£f. This must be determined by

the

use

of

thermocouple

detectors

during

development of the required heat sink.

M

b.

c.

All surfaces (tank. bushing and bushing well) must be

kept clean. Contamination such as paint, grease, etc.,

will extend wetdi"Q lime, thus raising the temperature

and will affect the Integrity of the bushing.

Minimize air currents in welding area which will disturb

the gas atmosphere.

-

-

INSTALLATION REQUIREMENTS

A.

B.

C.

D.

E.

Clearance between epoxy shank and maUling

hole must be 3/16- ::t 1/16-.

Enclosure

cover thickness

to be 1/4maximum. Consult the factory for enclosures

that exceed 1/4 - thick.

Clearances from the apparatus connection to

enclosure stiffeners and adjacent ground

planes are critical and must be observed during'

Installation. For more information regarding

spacing, please consult the manufacturer ..

Oil level covering the immersed stud connection

must be greater than 2 inches.

Certain equipment surface finishes require a

thermal bakIng to cure the finish. In such

cases, the bake sequence must not exceed

0

130 or 8 hours to prevent damage to critical

sealing aspects of the bushings. In addition,

114'

-

Remove AIl Burrs

and Finish with

1/16- Radius.

Ire bl.sting metaJic 0Clnlads should "'" be

mecI1anicaIyloaded i1letralIy '" extemaBydlri1g

this cue prccess 10prlMlnt epoxy distortion

ELASllMOLD BUSHING ARE NOT DESIGNED FOR USE IN AIR EXCEPT FOR THE 600Tl WITH

BOOTS AND COUARS.

••

~

1

•

/' • elastimold"

15-OOIt

IS-Wl (Rev D)

March 2010

Page 1 of 2

Suggested Welding Guide

Apparatus Bushings and Bushing Wells

DAN(;ER

,

All epp8mu. muat be de-energIzed durfng Installation

or removal 01partes).

AU apparatusmust be Installed and operated In

This Product should be Installed only by competent

personnel trained In good safety practices Involving

high voltageelectrlcaf~ulpment Th••• lnstruetJons

accordance with Individual user, local, and national

work rules. These Instructions

do not attempt to

are not Intended as • substitute tor 8dequate training or

experience In such safety practices.

providefor everypossiblecontingency.

Donot touchor moveenergIzedproducts.

Failure to follow these Instruction. will result In

damageto the productendserious or fatalInjury.

Excess distortion ot the assembled product may result

It this product I. supplied with • protective shipping

cover(s), remove this shipping cover(s) and replace

In Ita failure.

In8pectpartsfor damage,ratingand compatibilitywith

matingparts.

with the appropriate HV Insulated cap(8) or

connector(8) before 8ubmerglng or energizing the

circuIt.

FOR MORE INFORMATION ON PARTS, INSTAUATION

RATINGS AND COMPATIBIUTY, CAlL THE NEAREST ELASTIMOLO OFFICE.

IMPORTANT

1. Check contents 01 package to ensure they are complete

3. Read entire installation Instructions before starting.

2. Check 811 components to

and/or mating products.

~ Have all required tools at hand and maintain cleanliness

throughout the procedure.

and undamaged.

ernourltf ~Iuper frt

with cable -

WELDING

WELDING PROCESSES

The following data are suggested recommendations for

welding ELASTIMOLD apparatus bushings and bushing

wells. Because of the many variations in transformer

design, and the various welding techniques used, the

following is Intended as a guide only. The most important

factor during welding is that heat must be kepi at a

minimum. Excessive heating of the epoxy can affect the

Integrity of the bushing.

1. Inert-gas, tungsten-arc welding (TlG).

2. Short-arc welding (metal Inert-gas, MIG).

Both of the above processes are fast and. therefore. create

heat.

minimum

MATERIALS

No. 308 bare stainlesssteel wire Is used with either process.

IS-ooel

ThomasNletts

March 2010

Pri'ded In U$,A

8155 T&8 Bou!evIWd.MemphIs.T~

IS - W1 (Rev 0)

(800)888-0211 Fax: (800) 888.0690

>

38125