Lecture 02 Resistance and Resistors Full

advertisement

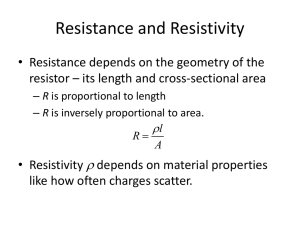

1E6 Electrical Engineering DC Circuit Analysis Lecture 2: Resistance and Resistors 2.1 Introduction Fig. 1 again shows the overlap of the conduction and valence bands of conductors. In pure metals, such as Copper, Iron, Silver or Gold and in metal alloys such as Steel or Brass, there is a large degree of overlap in the bands and a plentiful supply of free energy levels for charge to move between with ease. Consequently, these materials conduct electric current readily and a small electric field placed along them will result in a very high degree of conduction and high values of current. Hence, interconnecting wires and cables are made of such metals where they are intended to offer the least possible impediment to the flow of current. They are used only to provide a path for current to flow in an electric circuit and to connect points together electrically where the potential or emf is intended to be the same. However, practical electric circuits must consist of conducting elements other than interconnecting wires or there would be little point to their existence. The real motivation of the electric circuit is to transfer energy from its electric form into some other form such as thermal or mechanical energy in order to do work. In an electric kettle for example the electrical energy drawn from the mains supply is converted into thermal energy to heat water, while in an electric motor it is converted into mechanical energy to drive a physical load such as the drum of a washing machine. Fig. 1 Energy Bands in Solid Materials 1 2.2 Resistivity In electric circuits, and in particular in electronic circuits, it is generally required to control the voltages and currents present at various points in the circuit to defined values for given purposes, like the biasing of the semiconductor devices in a hi-fi amplifier, for example. In this case it is not just a matter of using wires to create circuits for current to flow in but rather one of limiting the currents and defining the potentials at specific values at particular locations within a circuit. In this case materials are used to create elements which provide specific degrees of impediment or resistance to the flow of current through them. Conductors which are not pure metals have a much lower number of free energy levels in their conduction bands and hence do not conduct current as easily as pure metals. In these materials a much larger emf or potential drop is required across them to enable the flow of current and the magnitudes of the resulting currents are much lower than in pure metals. Materials like Carbon, Cobalt and Ferrite compounds as well as some metal oxides are popular for this purpose. Conducting materials possess the property of resistivity. Resistivity is a measure of how strongly a material opposes the flow of electric current through it when subjected to the influence of an electric field or emf. A low value of resistivity means the material readily allows the movement of charge through it while a high value of resistivity means a high degree of opposition to the movement of charge. The resistivity, also known as the specific resistance, of a material depends on its particular atomic structure and is given the symbol ρ and has units of Ohm-metres. 2.3 Resistance The resistance of a piece of conducting material is essentially the combined effect of its resistivity established for the piece of material as a whole. It depends on the resistivity of the material as an element or compound and the physical dimensions of the piece of the material in question as well as the way in which the emf is applied to it. Fig. 2 A Piece of Resistive Material which Electrical Contacts on Both Ends 2 Fig. 2 shows a piece of resistive material having resistivity, ρ, uniform cross-sectional area, A and length, l. Electrical contacts are made uniformly over the cross-sectional area at both ends. This allows the uniform flow of charge through the material when an electric field is applied along its length. The total resistance, R, of this piece of material as a whole is given as: R=ρ l A Ohms (Ω ) Resistance has units of Ohms and uses the Greek letter Omega, Ω, as the symbol of this unit, which is named after the German physicist Georg Ohm (1789 1854) who first formally described the property. 2.4 Case Study 1 A piece of material having a resistivity of 2.5 x 10-5 Ωm has a cylindrical shape with a diameter of 6mm and a length of 12cm and has electrical connections made across its area at both ends. Determine the total resistance of the piece of material. Area A = πr2 = 3.14 x (3x10-3)2 = 3.14 x 9 x 10-6 = 28.8 x 10-6 m2 Length l = 12 cm = 0.12 m Resistivity ρ = 2.5 x 10-5 Ωm Then: R=ρ l 0.12 3 = 2.5 × 10 −5 × = = 0 .1 Ω A 28.8 × 10 − 6 28.8 This value is seen to be very low in absolute terms. Interconnecting wires in an electrical circuit will have values much lower than this but circuit components will require values which are much higher. The resistance can be increased by increasing the resistivity of the material used but there is a limit to what can be achieved here. It can also be increased by either increasing the length or reducing the conducting surface area of the piece of material. The latter is the more practical option in today’s manufacturing environment. 3 2.5 Case Study 2 A resistor is formed of a hollow cylinder of internal diameter 2mm and length 8mm. The Carbon material used has a resistivity of 3.5 x 10-5 Ωm. Determine the thickness of the cylinder required to manufacture a resistor of value 10 kΩ. r1 r2 tρ Fig. 3 A Resistor of Hollow Cylindrical Construction The area of the cylinder forming the resistor is the difference in the areas of the bases of cylinders having the radii r1 and r2 as indicated in Fig. 3. Then: A2 = πr22 = π (r1 + t ρ ) 2 A1 = πr12 A = A2 − A1 A = πr12 + 2πr1t ρ + πt ρ2 − πr12 = 2πr1t ρ + πt ρ2 If r1 >> tρ then this approximates to: A = 2πr1t ρ so that: R=ρ l l =ρ A 2πr1t ρ Rearranging gives: tρ = ρ l 2πr1 R Finally substituting gives: 8 × 10 −3 28 × 10 −9 t ρ = 3.5 × 10 × = = 4.45 × 10 −9 = 4.45nm −3 4 2 × π × 10 × 10 6.28 −5 4 2.6 Resistors Resistors are electrical circuit elements specifically manufactured to exploit their properties of resistivity. The resistors typically used as components in electronic circuits are manufactured using amorphous Carbon as the material. This is a form of Graphite having no consistent crystalline structure and providing a resistivity ranging from 1.5 – 4.5 x 10-5 Ωm, with a value of 3.5 x 10-5 Ωm being popular. Resistors are usually cylindrical in shape with electrical connections at both circular ends to wires which can be soldered into a circuit. This familiar form of resistor is shown in Fig. 4 below where the usual colour bands printed on the component are used as a numbering system to indicate the value of its resistance. Fig. 4 Typical Resistors for Electronic Circuits The resistor shown can be fabricated in the form of cylinder or rod of conductive carbon granules bound in a resin compound. The more modern method is to deposit a thin film of carbon onto a cylindrical base made of an insulating material such as glass or ceramic. In some cases the deposited layer of Carbon is cut into a spiral shape to allow higher values of resistance to be obtained. Metal oxides such as tin-oxide are sometimes used as an alternative to Carbon when other properties of the resistor such as a low temperature coefficient are important. Resistors are manufactured in ranges or series which have different degrees of refinement of the materials and control of the process. This produces resistors having different ranges of accuracy or manufacturing tolerance. The most common ranges of manufacturing tolerance today are ±5%, ±2%, ±1%, while the most common series of values are the E12 and E24. A colour-code printed onto the body of the resistor is used internationally to specify the value of a resistor. Using the colour code the value of resistance which may range over several decades can be determined for any individual resistor. The colour code is shown printed on the body of a typical resistor in Fig. 5. This code consists typically of four coloured bands. The three left hand 5 bands indicate the value of the resistance while the fourth band on the right hand side indicates the manufacturing tolerance. Fig. 5 The Resistor Colour Code Each of the left hand group of three bands represents one decimal digit in the value of resistance. The first and second digits are the numerical significant digits while the third is the multiplier digit which gives the numerical value of the power of ten which the two significant digits in the value are multiplied by. The decimal numbers associated with each colour in the resistor value are given in Table 1 while the value of the tolerance corresponding to the colour of the fourth band is given in Table 2. Table 1 Resistor Value Number Table 2 Manufacturing Tolerance Tolerance Colour Colour 0 Black ±1% brown 1 Brown ±2% red 2 Red ±5% gold 3 Orange ±10% silver 4 Yellow 5 Green 6 Blue 7 Violet 8 Grey 9 White 6 From this the value of the resistor in Fig. 5 is obtained as: Digit 1 Yellow = 4 Digit 2 Violet = 7 Digit 3 Multiplier Red = 2 Value is 47 x 102 = 47 x 100 = 4700 Ω = 4.7 kΩ. Digit 4 Gold Tolerance = ±5% The E12 series of resistors is so called because it has 12 values of resistance per decade. This means that Digits 1 and 2 in the code have 12 values. The E24 series has 24 values per decade. The values in each of these series are given in Table 3. Table 3. E12 series E12 and E24 Series of Resistors tol. ±5%, ±10% 10 E24 series 10 11 12 12 13 15 15 16 18 18 20 22 22 24 27 27 30 33 33 36 39 39 43 47 47 51 56 56 62 68 68 75 82 82 91 7 tol. ±5% Fixed resistors, having specific values in particular ranges, come in a number of different forms. The form shown in Fig. 2 is the most familiar in low-and medium power electronic circuits such as those implemented on printed circuit boards. However, for higher power ratings larger packages are used as shown in Fig. 6 and the resistors are often constructed of resistance wire wound on an insulated former. Fig. 6 A Range of Resistors of Various Power Ratings In modern low-power electronic circuits where long-term battery operation and miniaturisation of size is of importance other forms of packages are available such as pin-arrays and surface mounted resistors as shown in Fig. 7. Fig. 7 Miniaturised Resistor Packages 8 There is also a wide variety of variable resistors whose value can be altered to suit particular circumstances or to achieve a specific purpose in electric and electronic circuits. Small low-power trimmers are used to make incircuit adjustments to cancel out unwanted errors such as offset voltages in semiconductor devices. Examples of these are shown in Fig. 8. Fig. 8 Low-Power Trimmer Resistors Larger manually variable resistors, known as potentiometers, are used as volume controls, for example in radios of hi-fi systems. Examples of these are shown in Fig. 9. Fig. 9 Potentiometers Used as Volume and Tone Controls The conventional symbols used for fixed and variable resistors in schematic diagrams of electric circuits are shown in Fig. 10. fixed resistor variable resistor or potentiometer R RV Fig. 10 Schematic Symbols for Resistors 9