International Journal of Advance Engineering and Research Development (IJAERD)

ETCEE-2014 Issue, March 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

Modelling of Reactive Power & Unity Power Factor

Control of Inductive Load

Nirvisha V. Vyas1, Nitin H. Adroja2, Ashish Doorwar3

1

PG student, 2,3Asst. Professor, Electrical Engineering Department,

Atmiya Institute of Technology & Science, Rajkot

1

nirvisha.vyas@gmail.com

2

nhadroja@aits.edu.in

3

ashish.doorwar@gmail.com

Abstract— TSC-TCR (SVC) is applied to control power factor of

system at unity & effectively regulate load voltage. Unity power

factor controller uses SVC technique, whose output is adjusted

to exchange capacitive or inductive current so as to maintain or

control specific power factor. In this proposed scheme simple

circuit model of thyristor switched capacitor & thyristor

controlled reactor is modeled. The number of capacitors to be

turned-on is decided according to the reactive power

requirement of load. The current delivered by the capacitor

depends on the reactive power requirement.

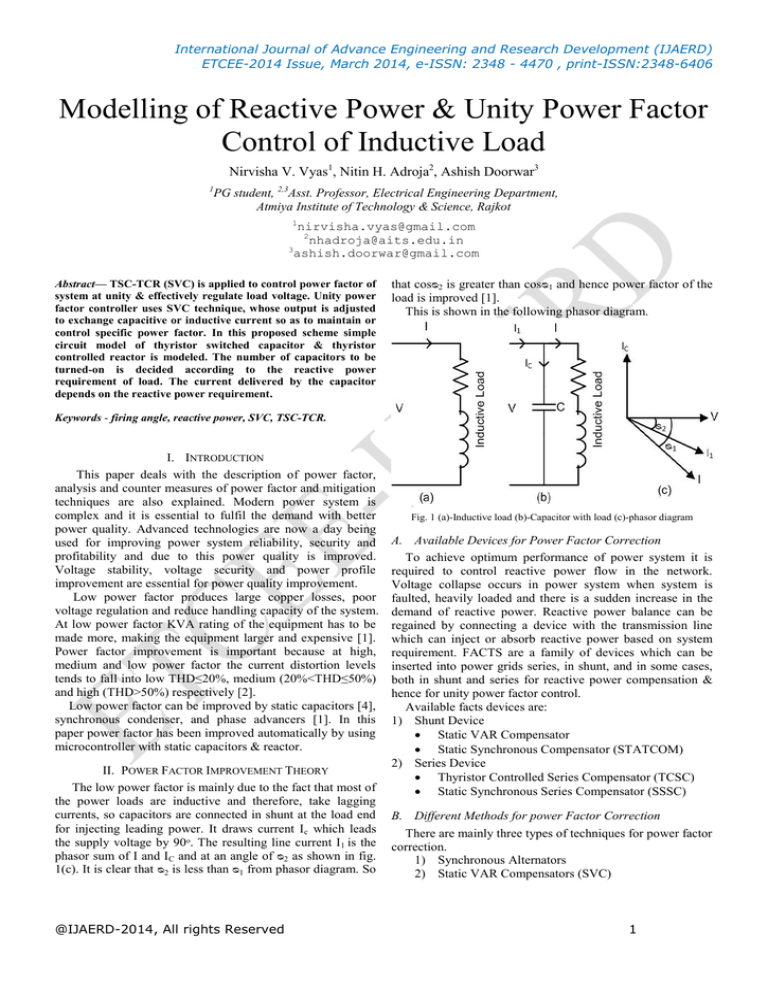

that cosᴓ2 is greater than cosᴓ1 and hence power factor of the

load is improved [1].

This is shown in the following phasor diagram.

Keywords - firing angle, reactive power, SVC, TSC-TCR.

I. INTRODUCTION

This paper deals with the description of power factor,

analysis and counter measures of power factor and mitigation

techniques are also explained. Modern power system is

complex and it is essential to fulfil the demand with better

power quality. Advanced technologies are now a day being

used for improving power system reliability, security and

profitability and due to this power quality is improved.

Voltage stability, voltage security and power profile

improvement are essential for power quality improvement.

Low power factor produces large copper losses, poor

voltage regulation and reduce handling capacity of the system.

At low power factor KVA rating of the equipment has to be

made more, making the equipment larger and expensive [1].

Power factor improvement is important because at high,

medium and low power factor the current distortion levels

tends to fall into low THD≤20%, medium (20%<THD≤50%)

and high (THD>50%) respectively [2].

Low power factor can be improved by static capacitors [4],

synchronous condenser, and phase advancers [1]. In this

paper power factor has been improved automatically by using

microcontroller with static capacitors & reactor.

II. POWER FACTOR IMPROVEMENT THEORY

The low power factor is mainly due to the fact that most of

the power loads are inductive and therefore, take lagging

currents, so capacitors are connected in shunt at the load end

for injecting leading power. It draws current I c which leads

the supply voltage by 90ᵒ. The resulting line current I1 is the

phasor sum of I and IC and at an angle of ᴓ2 as shown in fig.

1(c). It is clear that ᴓ2 is less than ᴓ1 from phasor diagram. So

@IJAERD-2014, All rights Reserved

Fig. 1 (a)-Inductive load (b)-Capacitor with load (c)-phasor diagram

A. Available Devices for Power Factor Correction

To achieve optimum performance of power system it is

required to control reactive power flow in the network.

Voltage collapse occurs in power system when system is

faulted, heavily loaded and there is a sudden increase in the

demand of reactive power. Reactive power balance can be

regained by connecting a device with the transmission line

which can inject or absorb reactive power based on system

requirement. FACTS are a family of devices which can be

inserted into power grids series, in shunt, and in some cases,

both in shunt and series for reactive power compensation &

hence for unity power factor control.

Available facts devices are:

1) Shunt Device

Static VAR Compensator

Static Synchronous Compensator (STATCOM)

2) Series Device

Thyristor Controlled Series Compensator (TCSC)

Static Synchronous Series Compensator (SSSC)

B. Different Methods for power Factor Correction

There are mainly three types of techniques for power factor

correction.

1) Synchronous Alternators

2) Static VAR Compensators (SVC)

1

International Journal of Advance Engineering and Research Development (IJAERD)

ETCEE-2014 Issue, March 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

3) Banks of Static Capacitors

Distributed power factor correction

Group power factor correction

Automatic power factor correction

In TSC capacitor is connected in series with anti-parallel

connected thyristor. By controlling turning ON & turning

OFF of the thyristor control reactive power delivered. This is

shown in fig 3.

III. PROPOSED SCHEME

Zero crossing of voltage & current of the system is

measured & it is given to micro-controller to generate

appropriate gate pulses as shown in fig.2. According to the

generated gate pulses, number of capacitor is on. To provide

proper compensation reactor is on after turning on number of

capacitor so that power factor can be maintain at unity [5].

Fig. 3 Switching of capacitor

Fig. 2 Basic unity power factor system

A. Switched capacitor

1) Switching Technique:

To avoid transients at the moments of connecting

capacitors, their voltage as well as sign must be equal to that

of the line. Moreover, the slope of variations of line voltage

must be equal to zero; that is, dVL(t)/d(t) = ic(t)/c = o , where

VL (t) is the line voltage (the series low impedance inductor is

ignored) and c is the capacity of a TSC branch. To disconnect

a capacitor from the line, sending firing signals to the relevant

thyristor gate will stop. When the current value through a

capacitor passes by zero, the thyristor turns off and leaves the

capacitor charged to the line peak voltage. To avoid the

capacitor to discharge in long periods of time due to its own

and also its peripheral circuit leakage, firing pulses are

sometime employed to the thyristor gate around the voltage

peak time.

Fig. 4 Voltage & Current waveforms of switched capacitor

B. Firing of Reactor

Firing of thyristor can be done according to the load

requirement & reactive power absorbed by the capacitor.

Here reactor is connected in series with anti-parallel thyristor

as shown in fig. 5[6].

2) Change of Polarity:

Technically and also economically considering, the best

capacitors for use in switching are AC capacitors. However

such capacitors cannot tolerate large DC voltages for a long

period of time [2]. In a TSC system, those capacitors that are

not connected to the line have fixed voltages and having

changed their polarity periodically, and therefore, put them

under a low frequency AC voltage. To achieve this, as shown

in fig. 3, connect the capacitor to the AC voltage line for only

half a cycle. Here inductor is connected in series with

capacitor to control high inrush current.

@IJAERD-2014, All rights Reserved

Fig. 5 Firing of reactor

IV. CONTROL STRATEGY

Basic scheme for power factor correction is shown in fig.6.

Here AC supply of load is fed to the transformer; this will

step down the voltage. Zero crossing of voltage & current is

2

International Journal of Advance Engineering and Research Development (IJAERD)

ETCEE-2014 Issue, March 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

sensed by zero crossing voltage & current detector

respectively .This phase difference decide firing angle of

thyristor switched capacitor. This signal is generated by the

microcontroller. Reactor firing depends on the number of

capacitor to be on & reactive power required by the load.

Control scheme for generating switching signal &

maintaining power factor at unity.

Power

Supply

1) Simulation Results

Load

Voltage

Sensor

Current

Sensor

Control circuit

Zero Crossing

Detector

Micro Controller

Gate driver

Circuit

Capacitor

and

Inductor

Bank

Anti-parallel

Thyristor

Fig. 8 Waveforms of open loop system

The reactive power required to compensate the reactive

power & make power factor at unity can be calculated by

using the following equation [5].

Fig. 6 Control scheme for unity power factor

V. OPEN LOOP CONTROL

Inductive load is connected with power supply of 230

volt is shown in fig.7. Due to this inductive load power factor

of the system is 0.91 lagging and active power & reactive

power is 10000 watt & 4300 VAR.

A. Without TSC-TCR

+ -i

Vac

Cu

Continuous

powergui

Voltage Measurement

P,Q pf

+v

-

Scope5

Subsystem

V

1

PQ

pf

I

Scope2

Active & Reactive

Power

.........................................(1)

Where, VAR = capacitor unit VAR rating

C = capacitor (farads)

f = frequency (cycles/second)

Vr = capacitor unit rated voltage

From this equation, calculate the reactive power of

capacitor to compensate the lagging power factor of inductive

load. According to the theory of power factor controller the

capacitor add leading current to the lagging current and

resultant current phase is less than the phase angle of previous

inductive current. As power factor is cosine of this angle,

power factor is also increases. To correct power factor at

unity, capacitor of appropriate reactive power is fed using in

eq. (1). By calculation the value of capacitor is 4280 VAR.

B. Power Factor Correction With TSC

Power factor correction by placing capacitor in shunt with

load is shown in fig. 9.

Scope4

Fig. 7 Open loop control of power factor controller

@IJAERD-2014, All rights Reserved

3

International Journal of Advance Engineering and Research Development (IJAERD)

ETCEE-2014 Issue, March 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

+ -i

+ -i

Cu2

Cu2

Scope1

Scope2

Scope2

V

V

PQ

PQ

Scope1

I

a

g

Sequence

Thy5

k

k

k

a

Active & Reactive

Power2

Thy4 Repeating

Thy3

g

k

Thy2

a

g

k

a

g

k

g

Vac

a

a

Thy1

Thy5

k

a

Thy3

g

Active & Reactive

Power2

a

g

Repeating

Thy4

Sequence

g

Thy2

k

a

g

Thy1

AC Voltage Source1

k

a

k

g

I

P,Q pf

P,Q pf

Scope4

Subsystem4

Scope4

Subsystem4

+v

-

+v

-

Voltage Measurement1

Voltage Measurement1

Continuous

C1

C1

powergui

Subsystem3

Continuous

Subsystem3

Logical

Operator1

Logical

Operator1

powergui

Fig. 9 Open loop system with capacitor

Fig. 11 Open loop system with capacitor & reactor

1) Simulation Results for Power Factor Corrector:

1)

Simulation Results for Power Factor Corrector &

Reactive Power Controller:

Fig.10 Waveform of close loop system

For variable load, reactive power requirement changes to

compensate the low power factor problem. So this circuit can

not be usefull for variable inductive load. For that continous

measurement & calculation of reactive power is required.

This is the limitation of this sheme. fig. 10 shows the

waveforms of corrected supply voltage and current & reactive

power when capacitor is connected in shunt with load.

C. Power factor & Reactive Power Correction With TSCTCR

@IJAERD-2014, All rights Reserved

Fig.12 Waveform of close loop system with reactive power

4

International Journal of Advance Engineering and Research Development (IJAERD)

ETCEE-2014 Issue, March 2014, e-ISSN: 2348 - 4470 , print-ISSN:2348-6406

VI. CLOSED LOOP CONTROL

For close loop system, continuous measurement of the

reactive power requirement of variable load is required. As

shown in fig. 12, power factor corrector that can supply

reactive power up to 6000 VAR is presented. Each capacitor

provides power of 2000 VAR

System is designed for variable load. According to the

requirement of the load number of capacitors is on. Here

working flow of the scheme is present for each capacitor

having capacity of providing 2000 VAR.

reactive power control shunt inductor is required. By using

TSC-TCR technique power factor & reactive power

consumption of load can be improved.

REFERENCES

[1].

[2].

[3].

[4].

[5].

[6].

V.K Metha and Rohit Mehata,“ Principles of power system”,S. Chand

& Company Ltd, Ramnagar, Newdelhi-110055,4th Edition,Chapter,6.

W.Mack Grady and Robert J. Gilleskie, “Harmonics and how they

relate to power factor”, Proc.Of the EPRI power quality issues &

opportunities conference (PQA’93), San Diego,CA,November 1993.

Coso, “Calculation of reactive power needed for the power factor of

given system.” a precise catalogue, published by khawaja electronics

pvt. ltd. manufacturing of fuji capacitors in lahore, pakistan, 1994.

Technical Application Paper No: 8, “Power FactorCorrection and

Harmonic Filtering in Electrical Plants”, ABB, Bangalore, 2010

Nader Barsoum,“Programming of pic microcontroller for power

factor correction.” School of Engineering, Curtin University of

Technology, Sarawak, Malaysia 2007

Md. Shohel Rana, Md. Naim Miah & Habibur Rahman, “Automatic

Power Factor Improvement by using Microcontroller” Double Blind

Peer Reviewed International Research Journal, Global Journals Inc.

(USA), Volume 13 Issue 6 Version 1.0 Year2013.

Fig. 13 Flow chart of proposed scheme

VII.

CONCLUSION

This paper shows an efficient & economic technique to

control power factor of the load. To improve power factor of

load, only shunt capacitor or static capacitor are used. But for

@IJAERD-2014, All rights Reserved

5