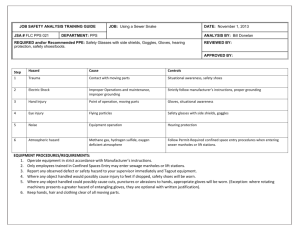

Job Hazard Analysis Manual

advertisement