Guide Specification for BMS

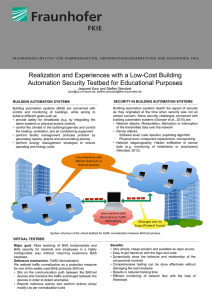

advertisement