Flicker Analysis and Case Studies

advertisement

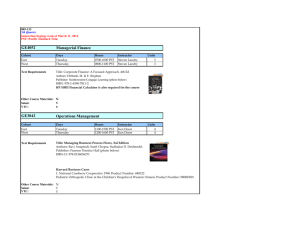

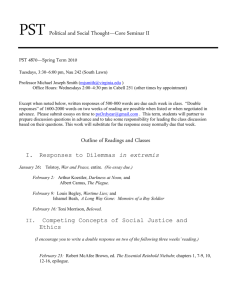

Flicker Analysis and Case Studies Jim Rossman, P.E. Senior Manager of Power Quality Gerald Johns, P.E. Senior Power Utilization Engineer TVA August 2008 1 Voltage Drop Creating Visible Light Flicker Voltage Flicker Is: Voltage Drop as Seen by Others Visible With Incandescent lights and some CFLs Complaints Normally From Residential Customers Much lower in magnitude than a fault related voltage sag – usually only a few volts on 120V system Noticeable at low levels and downright annoying at higher levels 2 Voltage Flicker Does Not: Normally does not cause equipment downtime Does not damage other folks equipment Flicker is Perceived Voltage Drop Voltage Drop is Graphically Shown Below Drawing Copied from IEEE 141 Vdrop ≅ IR cos Φ + IX sin Φ 3 Per Unit Approach to Calculating Flicker Vdrop ≅ IR cos Φ + IX sin Φ Hand calculations often work best in percent on an MVA base TVA uses 100-MVA as our base so the following is the same approach but written on a percent basis: %Vdrop ≅ MWswing (% R1) + MVARswing (% X 1) 100 Example: Large motor draws 25-MW and 40-MVAR on startup. With a system Thevenin equivalent Of Z= 0.988% +j 7.170% (100-MVA base), What is the expected voltage swing on startup? Vdrop ≅ 4 25MW (0.988%) + 40 MVAR (7.170%) = 3 .1 % 100 Perceived Voltage Drop in Lights GE Flicker Curves Copied From IEEE 141 5 TVA Flicker Curve 6 Flicker Curves IEEE 141 and TVA TVA Curve In Red 7 Three Key Flicker Components Recipe for Complaints: 1. Start with - Varying load/generation equipment 2. Serve from a - High System Impedance 3. Repeat variations until annoying 8 Component 1: Equipment with Load Swings Leading to Possible Flicker Issues • Motors and Compressors – – – – • • • • • 9 Rock Crushers Saw Mills Large Motors (Car Shredders, pumping systems) HVAC systems Welders Process ARC Furnaces Process Induction Furnaces Wind Generators Others Mitigation Systems Reducing Load Swings Dynamic Var Systems – – – – Static Var Compensators Dstatcom Intellivar Thyristor-Controlled Capacitor Systems Motor Impact Reduction – Reduced Voltage Starters – Wound Rotor Motor Resistors – DC Motor Systems Sequencing Multiple Welder Systems Arc Furnace Reactors 10 Component 2: Impedance Issues Important to Flicker Critical Point of Common Coupling (PCC) for Flicker Studies 60_MVA 2 AC1 + 1 RL + + PI2 RL 161kVRMSLL /_0 20_MVA 1 2 PI1 3 161/69/13 ZZ_1 + RL1 69/13.2 .28 7Ohm Transmission Sub-transmission Distribution Distribution Level Circuit Level Bus Level Circuit Level My PCC Definition: Closest Interconnection Location Where Another Customer Can See The Voltage Drop From The Disturbing Load 11 Component 2: Series Impedance to PCC – Shown in Percent (100-MVA Base) + AC2 161kVRMSLL /_0 + + RL3 RL + + RL4 + RL2 RL PI3 PI4 A B C D % Series Circuit Impedance 100-MVA base Possible PCC Interconnection Transmission – 161-kV A (0.70+j4.82)% – total to A Sub-transmission – 69-kV B (1.08+j12.6)% – total to B Distribution Bus – 13-kV C (1.75+32.6)% – total to C Distribution Circuit – 13-kV D (30.47+j138.9)% – total to D Hopkinsville, KY Facility - Services Went From 13-kV to 161-kV 12 Mitigation Approaches With Impedance Reductions Historical Solution to Flicker Problems – Reduce Impedance and percent voltage drop by Moving PCC upstream: – General Distribution to Dedicated Distribution Feed – Dedicated Distribution Feed to Sub-transmission Feed – Sub-transmission Feed to Transmission Feed Add Series Capacitors In Line 13 Component 3: Frequency of Voltage Variation Swings • Startup Related (once per season, month, week, day) – Pump Motors – Process Systems – Energizing Transformers • Low Frequency Process cyclic (multiple times per day or hour) – Air compressors – Refrigeration Compressors • High Frequency Process cyclic (many times per hour of second) – – – – 14 Rock crusher cycling Shredders Welders Arc Furnaces GE Flicker Curves Copied From IEEE 519 15 Drawbacks of IEEE 141/519 Curve 126 125 290.0 124 287.5 285.0 122 Volts RMS Volts 123 282.5 121 280.0 120 119 277.5 118 275.0 117 272.5 A Vrms (val) 116 280 300 320 340 seconds 360 16:04:02 03/13/2008 Thursday 380 16:04:04 16:04:06 16:04:08 16:04:10 288 120.01 286 284 282 RMS Volts RMS volts 120.005 120 280 278 276 119.995 274 272 119.99 270 230 16 230.5 231 231.5 seconds 232 232.5 2530.5 2531 2531.5 2532 2532.5 2533 seconds 2533.5 2534 2534.5 IEEE 1453 • Based on IEC 61000-4-15 (adopts the IEC standard). • Provides specifications for the measurement of flicker based on IEC 61000-4-15. • Provides recommended flicker limits on medium-voltage, high-voltage, and extra-high voltage systems based on IEC 61000-3-7. 17 Advantages of using IEEE 1453 over IEEE 141/519 curves • Measurement that directly represents flicker level in terms of human perception. • Provides a way of measuring flicker when voltage fluctuation is anything but a rectangular change. • Impact of modulations caused by modern solid-state converters (interharmonics) on voltage fluctuations taken into account. • Can be incorporated into simulation models to provide future flicker estimates and the effectiveness of various flicker mitigation options. 18 UIE/IEC Flickermeter First 4 blocks produce a signal that collectively represent: • Response of a lamp to a supply voltage variation. • Perception ability of the human eye • Memory tendency of the human brain. Block 5 is a statistical calculation that emulates human irritability to the flicker level. Figure Source: J.C. Gomez, M.M. Morcos, “Flicker Measurement and Light Effect”, Power Engineering Review, Nov. 2002. 19 IEEE 1453 Definitions • Pst – “A measure (statistical) of short-term perception of flicker obtained for a ten-minute interval. “ • Plt – “A measure (statistical) of long-term perception of flicker obtained for a two-hour period. This value is made up of 12 consecutive Pst values per the following formula.” - Necessary when duty cycle varies or multiple loads operating simultaneously. Plt = 3 1 N × ∑ Pst 3j N j=1 where N = The nunber of Pst readings. N should be based on the duty cycle of the fluctuating load. If exact duty cycle is unknown, assume N=12 to represent 2 hours. 20 IEC Flickermeter • Pst of 1.0 represents a magnitude and frequency of voltage fluctuation that is generally considered to be objectionable. • Measurement based on luminous fluctuation associated with 60-watt, 60-Hz 120-VAC or 50Hz 240-VAC incandescent lamps. 21 Comparison of IEEE 141 and IEC Flickermeter Curves *1 dip = 2 changes 22 IEEE 1453 Recommended Flicker Levels However, levels that are not objectionable may still be perceivable. 23 Represents the levels below which complaints are not generally received. 1453 Statistical Guidelines • As a general guideline, when designing, Pst and Plt should not exceed the planning levels more than 1% of the time (99% probability level), with a minimum assessment period of one week. • IEEE 1453 recommends that Pst and Plt not exceed 1.0 pu 5% of the time in existing low voltage and medium voltage systems (95% probability level. 24 Other Points To Note About Flicker • People most sensitive to fluctuation frequency of 2 to 10 Hz with flicker visible up to 35 Hz. • Any change in voltage 6.0 % or greater results in objectionable flicker, regardless of frequency. [1] • Lower-wattage incandescent bulbs produce more flicker for a given change in voltage. At the same rated wattage, a 230-volt bulb will flicker more than a 120-volt bulb for a given change in voltage. • Dimmers can exacerbate the flicker problem because flicker becomes more perceptible as baseline lumen levels are reduced. • Fluorescent lamps typically flicker less for a given voltage input [2]. [1] R.Dugan, et al., Electrical Power Systems Quality, 2nd Ed., 2002. [2]T.A. Short, Electric Power Distribution, 2005. 25 EPRI Studies of Compact Fluorescent Lamp Gain Factors The gain factor is defined as the ratio of relative light changes to relative voltage changes. 26 EPRI Studies of Linear T8 Fluorescent Lamp Gain Factors 27 How About a Break! Lets Keep It to 15 Minutes – The Best is Yet to Come! 28 Case #1 Sawmill on Rural Feeder 7.2/12.47 kV distribution source @ mill Primary Z = 12.94 + j10.45 ohms 9.47 miles of 14.4/24.9 kV 3.76 miles of 7.2/12.47 kV Flicker caused by load fluctuations as well as motor starts. 29 Case #1 - Head-Saw Load Up – 9.6% Vdrop @ Mill Secondary and 6.6 % Vdrop On Primary Amps 1500 500 -500 -1500 Volts AI 280 275 270 265 260 255 BI CI Significant voltage reduction due to reactive power draw. A V rms ( val) B V rms (val) C V rms (val) 500 kW 400 300 200 kVAR 100 800 700 600 500 400 300 Real power draw starts to increase due to increase load torque (large log), but then declines because of reduced speed. TOT P( kW) (val) TOT Q(kV A R) 14:49:30.0 12/17/2007 Monday 14:49:30.5 14:49:31.0 14:49:31.5 Event #1 – 150-hp head saw abruptly loaded up – data collected at utility metering point 30 14:49:32.0 14:49:32.5 Reactive power draw increases substantially due to extreme speed reduction. Case #1 – 200 hp Chipper Startup w/softstart 7.5 % instantaneous Vdrop at Sawmill and app. 5 % corresponding drop at residence 1100 Amps 900 700 500 Volts 300 A Irms (val) B Irms (val) C Irms (val) A Vrms (val) B Vrms (val) C Vrms (val) 285 280 275 270 265 260 300 kW 250 200 150 100 TOT P(kW) (val) 800 kVAR 700 600 500 400 300 TOT Q(kVAR) 12:22:50 12/17/2007 Monday 12:22:52 Softstart programmed to start motor @ 330 % FLA 31 12:22:54 12:22:56 Initial 1-Week Pst Profile 32 Initial Goals • Reduce flicker Pst on utility system to < 1.0. • Reduction in voltage sags caused by sawmill operations on utility system to no more than 2.0 percent. • Mitigation mechanisms must not cause greater than 2.0 percent voltage rise on utility system. 33 Examples of Products Providing Fast Reactive Power Compensation S & C’s AVC (Adaptive Var Compensator) 34 ABB’s DynaComp (Dynamic-Var Compensator More Examples of Products Providing Fast Reactive Power Compensation Square-D Hybrid-Var Compensator Square-D Active Filter Eaton-CH Active Filter 35 Case Study #1 – Examples of Motor Starts with AutoXFMR starters 290 285 Volts 280 275 270 265 Headsaw (150hp) w/67% tap 260 1000 A Vrms (val) B Vrms (val) C Vrms (val) A Irms (val) B Irms (val) C Irms (val) Amps 750 Edger (150hp) w/50 & 67% taps 500 250 12:17:55 12/17/2007 Monday 36 12:18:00 12:18:05 12:18:10 Starter Modifications Set all taps to 50% on all autotransformer starters. Programmed 200hp softstart to start at 250 % of FLA. After starter modifications, Max starting Vdrop on primary ~3% 37 Findings of Additional Recording at the Sawmill Dran-View 6.5.00 OEM Site License Tennessee Valley Authority kW 600 400 200 kVAR 0 TOT P(kW) (val) 800 600 400 200 0 TOT Q(kVAR) 5 4 3 2 1 0 B VPst 12:00 05/12/2008 Monday 00:00 05/13/2008 Tuesday 12:00 00:00 05/14/2008 Wednesday 12:00 Fluctuations were more frequent and of higher magnitude overall due to type of wood being sawed. 38 00:00 05/15/2008 Thursday 12:00 00:00 05/16/2008 Friday Case Study #1 – Sawmill on Rural Feeder Worst-case primary fluctuation = 8% 39 Calculations - Converting 3.9 miles to 14.4/24.9 kV New worstcase primary fluctuation = 2.8% 40 Pst Calculations and Estimated Pst with Voltage Conversion Residence 1.75 1.50 Sawmill 1.25 1.00 0.75 0.50 0.25 B VPst 06:00 05/13/2008 Tuesday 08:00 10:00 12:00 14:00 Created with DranView 6.5.0 41 16:00 18:00 20:00 Estimating Future Pst After Voltage Conversion • Max Pst at residence for day shown = 1.34 • Corresponding Pst at PstMax @ residence 1.34 = = 0.77 sawmill secondary PstCorresponding @ sawmill 1.74 metering point = 1.74 • Typical ratio “every other interval” ~ 0.7-0.75 ZTo _ XFMR _ Sawmill _ Primary 0.1070 = = 0.7 • Impedance Ratio = ZTo _ XFMR _ Sawmill _ Secondary • By converting last 3.76 miles to 14.4/24.9 kV 0.1535 ZTo _ XFMR _ Sawmill _ Primary ZTo _ XFMR _ Sawmill _ Secondary With Impedance Ratio = 0.48 PstMax @ Residence Due to Sawmill Load = 0.84 42 = 0.0448 = 0.48 0.0933 Case Study #2a & #2b – Residential Air-Conditioning Starting • Customer complaints at their worst have resulted in service drop/lateral changeout or possibly even transformer upsizing • HVAC technicians often install “hard start” kits • On average, electric consumers understand that flicker is simply going to occur when their A/C starts. • Members sharing secondary conductors and sometimes transformer may result in one member seeing another member’s A/C startup. 43 A/C Starting Case Study #2a Volts 150 50 -50 -150 Volts AV 120.0 117.5 Before hard start installed 115.0 112.5 110.0 Amps 150 A Vrms 50 0 -100 -150 AI Volts 150 19:55:25.3 07/11/2007 Wednesday 19:55:25.4 19:55:25.5 19:55:25.6 19:55:25.7 50 -50 -150 AV Volts 120.0 117.5 115.0 112.5 110.0 Amps 150 100 After hard start installed 0 -50 -100 -150 20:09:57.3 07/11/2007 Wednesday 44 A Vrms (val) AI 20:09:57.4 20:09:57.5 CI 20:09:57.6 20:09:57.7 Results of Using Hard Start Devices • Hard start results in increased starting torque • Compressor accelerates to full speed more quickly, thereby reducing startup duration • Magnitude of initial inrush current and voltage drop still the same as before – capacitor provides phase shift but no voltage rise 45 Minimum Voltage Magnitude Profile and Corresponding Pst for A/C Startups Case Study 125.0 Volts 122.5 120.0 117.5 115.0 Flicker could be considered objectionable although Pst <1.0 A Vrms (min) 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 A VPst 20:00 06/15/2008 Sunday 46 22:00 02:00 00:00 06/16/2008 Monday AVrms AVPst Min 113.3 0.06869 Max 124.8 0.8114 95% N/A 0.7575 99% N/A 0.8114 04:00 06:00 A/C Startup Case Study #2b • Customer complained about flickering lights, number of interruptions occurring, and damaged electronics. • Distributor power-quality monitoring revealed nothing problematic. • Distributor changed 50 kVA to 75 kVA transformer and concerns were not resolved. • Relationship between customer and distributor was tense and customer wondered why the transformer had been changed out if no problem could be detected. • HVAC technician told customer that the A/C unit needed a “booster” (hard-start kit). 47 A/C Startup Case #2b Power Quality Monitoring A/C unit starting current 300 200 100 0 -100 -200 -300 -400 0 0.02 0.04 0.06 0.08 0.1 T ime (sec) Switchbounce associated with the mercurybulb thermostat resulted in multiple A/C starts 48 0.12 0.14 Case Study - Raw Water Pumping Station – Original Design • Original study began in 2004 – Design incorporated 1 pump driven by 1250 hp 4,160 V AC induction motor – Provision for additional pump installation – 4,160 VAC Electronic softstarter – 2,125 kVAr 2-stage capacitor bank switched simultaneously on with motor (electromechanical contactor-switched) – 1,800 kVAr switched off just as motor about to reach full speed 49 Original Design – Circuit Characteristics • Fed from 161/69/12.47 sub off of 12.47-kV system • App. 3.5 miles with 8 line sections of distribution line • 12.47 kV to 4,160 V 2,500 kVA padmount XFMR • 0.1 miles from riser pole to XFMR, but distributor wanted PCC to still be at primary terminals of XFMR 50 Original Objectives and Constraints • Determine if original design with both electronic softstart and simultaneously-switched cap bank: – Result in less than 2.0 % voltage drop at PCC during motor start? • Use softstart manufacturer’s stated inrush current values for calculations • Perform calculations by hand and/or using steady-state type analysis program 51 Original Calculations from 2004-2005 2.0 % limit exceeded but distributor willing to go to 3.0 % with understanding that pump not started more than once per week 52 2006 Design Changes • Latest starter mfr/consultant analysis indicated voltage drop will exceed 4.0 percent at PCC during startup. • New design called for 2 pumps operating simultaneously • Increased runtime/# of startups • Customer contemplating generator because distributor does not want to allow more than 3% fluctuation under any circumstances 53 s c o pe C a d iz Su b Vo lta g e Pr ima r y _ C u r r e n t_ C rms s c o pe out tr _ 8 in out s c o pe tr _ 7 out i(t) + out p3 in S f(u) Fm6 ?v 1 s c p10 s c o pe Pr im a r y Vo lta g e a tTr a n s fo r me r s c ope p4 v(t) out tr _ 1 2 ASM 1 ?i ?m PF 4 .1 6 0 k V s c ope 1250hp Fm 7 SW 1 7 |1 E1 5 |0 1 2 .4 7 /4 .1 6 ia Se c Vo ltD r o p a tTr a n s fo r me r s c o pe AS M S + + ?v 1 6 1 k VR M SL L /_ 0 Tm Sp e e d Yg Yg _ n p 2 1 2 AC 1 s c p3 s c op e rms in ?v P 1 Q 2 BU S2 rms in tr _ 4 f(u) s c o pe Mo to r N o 2 R MSC u r r e n t Fm4 s c ope Se c o n d a r y Vo lta tTr a n s fo r m e r v(t) s c o pe s c p8 rms Fm 2 in in tr _ 2 out tr _ 1 + scope sc p4 sc p6 scope c SW 2 + C2 276uF rms sc p5 scope + C1 ?i + 276uF Mo to r N o 2 Sp e e d out rms c b a BU S2 c SW 1 + f(u) s c ope Fm 3 f(u) f(u) 1 s c op e s c p9 p1 Fm 1 out f(u) a Fm BU S1 1 ? + 1 YgYgD_np1 161/12.47/69 T s c ope 3 2 3 2 out tr _ 1 1 D EV4 Pr im a r y Vo ltD r o p a tTr a n s fo r me r 1 out tr _ 9 rms ?v 1 s c ope f(u) Pe r c e n tVd r o p a tC a d iz Su b s ta tio n rms tr _ 1 0 in ? s c ope s c p17 rms in s c o pe tr _ 6 + •Analysis of across-theline start with and without simultaneous cap switching Pr ima r y _ C u r r e n t_ A rms in YgYgD_np2 161/12.47/69 •EMTP used to simulate motor start using dedicated feed from substation Fm5 1 p2 Pr ima r y _ C u r r e n t_ B rms s c ope s c p18 v(t) in in out tr _ 3 c SW 3 ?i + BU S2 276uF Fm9 C3 + ?i f(u) 4 5 .9 8 u F + c SW 4 + C4 4 5 .9 8 u F ?i + c SW 6 + C5 ?i c SW 5 C8 ASM2 Tm_ 1 4 5 .9 8 u F 54 C6 ?i 10000 Sp e e d 2 s c ope Sp e e d c ia S Mo to r N o 1 R MSC u r r e n t AS M + 4 5 .9 8 u F C7 ?i + rms ?m 4 .1 6 0 k V 1250hp in s c o pe out tr _ 5 With Cap Bank Switched - Results Max 1.4 % drop during start at substation with caps 55 Without 1,800 kVAr Cap Bank Switched - Results Max 1.7 % drop during start at substation without caps 56 Case Study #4 – Automotive Component Manufacturer with Welders (Reactive Power) Estimated 400-kVAr swings per phase based on 1-minute max/avg/min data 57 Case Study #4 – Automotive Component Manufacturer with Welders (Real Power) Estimated 200-kW swings per phase based on 1-minute max/avg/min data 58 Case Study #4 – Automotive Component Manufacturer with Welders (Voltage) 3 to 4.7-volt swings based on 1-minute max/avg/min data 59 Case Study #4 – Corresponding Pst on Bus Feeding Welders (Dirty Feed) Due to voltage sag 60 Generally, Max Pst ~ 1.5 Case Study #4 – Corresponding Pst on Bus Fed By Separate Transformer Bank (Clean Feed) Generally, Max Pst ~ 0.5 61 Vdrop Calculation and Comparison of Welder Bus Pst to That of Separately Fed Bus • • • • • Max Pst on welding bus = 1.5 Max Pst on separately fed bus = 0.5 Utility-supplied SCC = 4,127 A @ 7.2/12.47 kV Welding bus XFMR %Z = 6 % Assume X/R of utility circuit = 7 and X/R of XFMR = 12 7200 × (cos(tan −1 (7)) + j sin(tan −1 (7))) = 0.25 + 1.73 ohms 4127 0.25 + j1.73 On 100 MVA base, Zsource = = 16 + j111.3 percent 12470 2 108 Transformer Z (on 100 - MVA base) = 20 + j239 percent 0.6 × (16 + 20) + 1.2 × (111.3 + 239) = 4.4% 100 Separately Fed Bus Pst 0.5 = = 0 .3 Welding Bus Pst 1.5 Expected %Voltage Drop = 16 + j111.3 111 Common Source Z = ≈ ≈ 0.32 Total Z to Welding Bus 36 + j350 350 62 Case 5 – Wind Generation 63 Buffalo Mountain Wind Farm Generation Flicker Case TVA originally contacted for three small windmills to be fed from a local distributor’s 13-kV system. Occasionally during windmill startup, the distributor received flicker complaints. When the 151.8-MW units went in service, it was decided to serve the new load at 161-kV. 64 Aggregate Load Swings for 15-1.8-MW Wind Generators Voltage MW MVAR 65 Case 6 – Large Motor System Evaluate Possibility of Serving a 3000-hp Wound Rotor Motor Metal Shredder At Two Possible Locations – – 66 XXX 69-kV: Z1 = 23.989 + j 52.618% YYY 161-kV: Z1 = 1.559 + j 9.048% Characteristics of Shredder Provided by Vendor 3 times per minute Shred Load Cycling 3.1-MVA swings at 78%p.f. 2.4-MW swing 1.9-MVAR swing 67 Hand Calculation Used for Approximation and EMTP Model Used for More Exact Solution Site XXX Hand Calculation: Z1 = 23.99 + j 56.6 % (100-MVA base) MVA swing = 2.4 + j1.9 %VDrop ≅ 2.4-MW (23.99)/100 + 1.9-MVAR (56.6)/100 = 1.65% sum1 v(t) + + in p3 1 Percent_V scope f(u) Use EMTP Modeling For More Exact Solution DYg_1 AC1 + Fm1 DEV6 out TACS type-66 rms meter - + RL1 1 69kVRMSLL /_0 2 69/4.16 3/7 C4 tmr1 c Timer 2 C2 1 0.25 1.0 select ?s Sel1 scope IArms_Uncorrected DEV5 out C3 TACS type-66 rms meter in c IArms_Corrected DEV3 out c in 2 scope TACS type-66 rms meter Tm Teg Speed ASM1 SW1 + 500ms| 1E15| 0 i(t) DEV1 p1 s3 i(t) s4 Gain2 p2 S ASM R N MW_MVAR_MW_METER 9.549297 4.16kV 3000hp + + 184uF 2.5 C1 + 0.0e+0m 68 Torque scope R2 R1 RPM scope EMTP Simulation Results Voltage Drops As Shredder Cycles YYY – 161-kV 0.3% XXX 69-kV 1.75% 69 Applying Results to TVA Flicker Curve Shows YYY is OK and XXX is Not Recommended TVA XXX 69-kV – Above Curve – Ruled Out YYY 161- Below Curve - OK 70 Case 7 My Town Needs a Steel Rolling Mill What do we need to do to allow us to run this mill? Remote Community Fed at 46-Kv – Impedance to Substation - Z1 = 74.9 +j113.5% At 26-kV Substation Transformer Secondary (PCC) - Z1=76.3 +j169.0% 71 Company Choose IntelliVar as Mitigation System Not actual Installation But Shows All Major Components Transformers Valves Filters Controls 72 IntelliVAR System at 1500-KVAR Controls Not Working Properly 1.8 1.6 26kV - Pst A 26kV - P Total from 06/13/2007 to 06/15/2007 from 06/13/2007 to 06/15/2007 PST(95) – 1.47 5000 Min[P Total] (kW) Avg[P Total] (kW) Max[P Total] (kW) 4500 1.4 4000 1.2 3500 3000 0.8 2500 Pst A 1.0 2000 0.6 1500 0.4 1000 0.2 0.0 13 Wed Jun 2007 EPRI/Electrotek 1.8 1.6 500 14 Thu Time 46kV - Pst A 15 Fri 0 13 Wed Jun 2007 PQView® EPRI/Electrotek 14 Thu Time 15 Fri PQView® 26kV - Q Fund All from 06/13/2007 to 06/15/2007 from 06/13/2007 to 06/15/2007 PST(95) – 1.17 1.4 4000 Min[Q Fund All] (kvar) Avg[Q Fund All] (kvar) Max[Q Fund All] (kvar) 3500 3000 1.2 2500 2000 0.8 1500 Pst A 1.0 1000 0.6 500 0.4 0 0.2 0.0 13 Wed Jun 2007 EPRI/Electrotek 73 -500 -1000 14 Thu Time 13 Wed Jun 2007 PQView® EPRI/Electrotek 15 Fri 14 Thu Time 15 Fri PQView® IntelliVAR Sizing Doubled to 3000-KVAR Control System Finally Tuned 26kV - P Total 26kV - Pst A 1.8 1.6 from 04/24/2008 to 04/26/2008 from 04/24/2008 to 04/26/2008 5000 26-kV - PST(95) - 1.18 Min[P Total] (kW) Avg[P Total] (kW) Max[P Total] (kW) 4500 1.4 4000 1.2 3500 3000 0.8 2500 Pst A 1.0 2000 0.6 1500 0.4 1000 0.2 0.0 24 Thu Apr 2008 EPRI/Electrotek 500 25 Fri Time 26 Sat 0 24 Thu Apr 2008 PQView® EPRI/Electrotek 46kV - Pst A 1.8 1.6 1.4 25 Fri Time 26 Sat PQView® 26kV - Q Fund All from 04/24/2008 to 04/26/2008 from 04/24/2008 to 04/26/2008 1000 46-kV - PST(95) – 0.82 Min[Q Fund All] (kvar) Avg[Q Fund All] (kvar) Max[Q Fund All] (kvar) 500 0 1.2 -500 -1000 0.8 -1500 Pst A 1.0 -2000 0.6 -2500 0.4 -3000 0.2 0.0 24 Thu Apr 2008 EPRI/Electrotek 74 -3500 25 Fri Time 26 Sat -4000 24 Thu Apr 2008 PQView® EPRI/Electrotek 25 Fri Time 26 Sat PQView® Before and After Intellivar Changes Kosciusko - Attala Steel 26kV Kosciusko - V RMS A Kosciusko - Attala Steel 26kV Kosciusko - V RMS A from 06/13/2007 to 06/15/2007 Min[V RMS A] (V) Avg[V RMS A] (V) from 04/24/2008 to 04/26/2008 Max[V RMS A] (V) 15400 15200 15200 15000 15000 14800 14800 14600 14600 14400 14400 14200 14200 14000 14000 13800 13800 13600 13 Wed Jun 2007 EPRI/Electrotek 1.8 26kV - Pst A 15 Fri 24 Thu Apr 2008 PQView® EPRI/Electrotek 25 Fri Time 26 Sat PQView® from 06/13/2007 to 06/15/2007 from 04/24/2008 to 04/26/2008 1.8 1.4 1.4 1.2 1.2 1.0 1.0 PST(95) - 1.18 – Not Under 1.0 But No Routine Complaints Pst A Pst A 1.6 0.8 0.6 0.6 0.4 0.4 0.2 0.2 13 Wed Jun 2007 EPRI/Electrotek Max[V RMS A] (V) 26kV - Pst A 1.6 0.0 Avg[V RMS A] (V) 13600 14 Thu Time 0.8 75 Min[V RMS A] (V) 15400 14 Thu Time 15 Fri PQView® 0.0 24 Thu Apr 2008 EPRI/Electrotek 25 Fri Time 26 Sat PQView® Case 8 My Largest Industry Has Us in a Bad Situation Due to Flicker, What Are Our Options? 76 Distributor Not Routinely Serving Any Customer From 46-kV Winding Due to Flicker Complaints Other Customers Normally Fed From 46-kV System Distributor Removed Them Due to Flicker Complaints YgYgD_np1 2 1 3 161/46/13 + AC1 161kVRMSLL /_0 + + RL1 + + RL3 RL2 + RL4 PI1 T Equivalent DEV1 PCC Is Located Within Transformer At T Equivalent Tie Point 77 DEV2 DEV3 Arc Furnace Arc Furnace Arc Furnace Site Fed From Dedicated 13-kV Winding 161/46/13 Transformer PST Estimate – Traditional Hand Calculation 161-kV MVAsc at Sub – 1558 MVAsc or 3.85% at 60 MVA Base 161-kV:46-kV:13:kV Transformer Nameplate: Z161-46 = 9.7% at 60-MVA, Z161-13 = 5.8% at 21-MVA (16.57% at 60-MVA) Z46-13 = 2.1% at 21-MVA (6.0% at 60-MVA) Convert to T equivalent Z161 = ½ (9.7% +16.57%-6.0%) = 10.135% at 60 MVA Z46 = ½ (9.7% + 6.0% -16.57%) = -0.435% at 60 MVA Z13 = ½ (16.57%+6.0% -9.7%) = 6.435% at 60-MVA PCC Includes TVA plus 161-kV portion of winding to 46/13-kV T point PCC = 3.85% + 10.135% = 13.985% = 429-MVAsc Estimated AF Swing = 2 x 4-MW = 8-MVA Swing with 3 AF = 3 3 x 8-MVA = 11.54-MVAsc for 3 units operating 46-kV Short Circuit Voltage Depression (SCVD) = 11.54/429 = 0.0269 161-kV Short Circuit Voltage Depression (SCVD) = 11.54/1558 = 0.0074 46-kV PST Estimate = 0.0269 x KST = 0.0269 x 60 = 1.61 161-kV PST Estimate = 0.0074 x KST = 0.0074 x 60 = 0.44 78 PST Measurements of 46-kV and 161-kV Bus Confirm Hand Calculations - Target – PST Under 1.0 Moving to 161-kV Accomplishes This Objective Timeplot 2.00 PST Measurements at 161-kV 1.75 1.50 161-kV PST (a phase) 161-kV Flicker 0.44 per hand calc. 1.25 1.00 0.75 0.50 0.25 0.00 A FDPst 06/12/2007 2.00 06/14/2007 06/16/2007 46-kV Flicker 1.61 per hand calc. 06/18/2007 06/20/2007 06/22/2007 06/24/2007 06/26/2007 06/28/2007 Event #25 at 06/25/2007 08:10:30.067 AVrms RMS and Waveform PSTTimeplot Measurements at 46-kV - PCC 1.75 1.50 1.25 46-kV PST (a phase) 1.00 0.75 0.50 0.25 0.00 A FDPst 06/12/2007 06/14/2007 06/16/2007 06/18/2007 06/20/2007 Event #1 at 05/23/2007 14:04:48.349 AVrms RMS and Waveform 79 06/22/2007 06/24/2007 06/26/2007 06/28/2007 Option 1 – Add Transformer at Substation Use Existing 13-kV Feed to Plant Remove Plant Load From Existing 3-winding Transformer YgYgD_np1 2 1 3 161/46/13 + AC1 161kVRMSLL /_0 + + + RL1 + Other Customers Fed From 46-kV System RL3 RL2 + RL4 PI1 T Equivalent DEV1 New PCC At 161-kV 80 DEV2 DEV3 DYg_1 1 2 Arc Furnace Arc Furnace Arc Furnace 161/13 Dedicated 161:13-kV Existing 13-kV Line Transformer at Sub Move PCC Up to 161-kV Option 1 - Install Dedicated Transformer Option 1 Move PCC up to 161-kV System at Substation All cost below in $1000s Install Total 1a New 16-MVA Transformer, oil containment, foundations, bus $850 $150 $1,000 1b 161-kV SF-6 breaker w/ bay and relays $250 $150 $400 1c 13-kV Distribution Breaker with relays $50 $25 $75 1d Routing Existing 13-kV Wiring to New System $10 $10 $20 1e Two-Step - 4.5 (4.0 effective) -MVAR Harmonic Filter $100 $23 $123 Misc. cost not currently identified - 20% of cost (excluding transformer) Grand Total - New Transformer System 81 Equip. $124 $1,742 Option 2 Build 161-kV Line to Plant Site and Add Transformer at That Site Remove Plant Load From Existing 3-winding Transformer YgYgD_np1 2 1 3 161/46/13 + AC1 161kVRMSLL /_0 + + + RL1 + RL3 RL2 PI1 T Equivalent Other Customers Fed From 46-kV System DYg_1 1 2 161/13 DEV1 New PCC At 161-kV 82 DEV2 DEV3 + PI2 New 161-kV Line To Plant Site Arc Furnace Arc Furnace Arc Furnace Dedicated 161:13kV Transformer at Plant Move PCC to 161-kV Option 2 - Install Dedicated 161-13-kv Substation at Plant Site Option 2 Move PCC Up to 161-kV System at Plant All cost below in $1000s Install Total 2a New 16-MVA Transformer, oil containment, foundations, bus $850 $75 $925 2a Used 18-MVA Transformer, oil containment, foundations, bus $350 $75 $425 2b 161-kV SF-6 breaker w/ bay and relays $250 $75 $325 2c 161-kV Feed to Plant (existing row - big unknown ??) 2d 161-kV Circuit Switcher at Plant with relays 2e 13-kV Distribution Breaker at Plant with relays 2f Two-Step - 4.5 (4.0 effective) -MVAR Harmonic Filter Misc. cost not currently identified - 20% of cost (excluding transformer) 83 Equip. $400 $100 $25 $125 $50 $25 $75 $100 $23 $123 $210 Grand Total - New Transformer System $2,183 Grand Total - Used Transformer System $1,683 Option 3 - Install Quick, Dynamic VAR Correction and Harmonic Filter System at Plant Site Add Dynamic Var Correction at Plant Site 1x YgYgD_np1 + AC1 161kVRMSLL /_0 + + RL1 + + RL3 RL2 + SVC_1 2 3x 3 161/46/13 Other Customers Fed From 46kV System 1 2 1 RL4 PI1 T Equivalent DEV1 No Transmission or Distribution System Changes Needed! 84 DEV2 DEV3 Arc Furnace Arc Furnace Arc Furnace Fix Flicker at Plant 13-kV Bus Option 3 - Install Quick, Dynamic VAR Correction and Harmonic Filter System at Plant Site Option 3 Install ABB Mincomp or S&C Purewave Dstatcom All cost below in $1000s Install Total $1,000 $100 $1,100 3a Install +10 /- 2-MVAR Var Compensator 3b Two Step - 6.6/6.3 (6.0 effective)-MVAR Harmonic Filter $120 $25 $145 3c 13-kV Switchgear Integrated Into Existing System $100 $25 $125 Misc. cost not currently identified - 10% of cost Grand Total 85 Equip. $125 $1,370 Economic Summary: Installing Dynamic Var Compensation is Best Choice Option # Power Factor Correction Savings (1000s) Electronic Equip. Savings (1000s) Production Profit Increase (1000s) Total Savings Total Cost (1000s) (1000s) Option 1 $32.8 $31.6 $0 $64.4 $1,742 27.0 Option 2 $32.8 $31.6 $0 $64.4 $2,183 33.9 Option 3 $32.8 $31.6 $415.0 $479.4 $1,370 2.9 Option 1 – Transformer Isolation at Substation, filter at Plant Option 2 – Transformer Isolation at Plant, filter at Plant Option 3 – Install Filter/Dynamic VAR Compensation at Plant 86 Simple Payback (years) Case 9 A Large Steel Mill Has an SVC, Why is it Creating More Flicker When On Compared to When its Off? DEV2 s3 Super_Voltmeter1 PCC + AC1 161kVRMSLL /_0 RL2 + 0.285,4.004Ohm RL1 + DY_1 1 DD_1 2 1 2 0.804,2.3585Ohm 161/33 33/0.7 DEV1 + FLICKERMETER_PCC IEC FLickermeter 87 10 R1 Arc Furnace Base Case Without SVC System Operating 2 Days Phase A Voltage (Max, Min, Avg) 161PCC - Pst A from 10/29/2004 to 10/31/2004 1.4 Flicker Summary PCC Monitor Site Without SVC/ Filters PST(95) = 0.93 1.2 Pst A 1.0 0.8 0.6 0.4 0.2 0.0 29 Fri Oct 2004 EPRI/Electrotek 88 30 Sat Time 31 Sun PQView® Base Case With SVC System Operating 2 Days Phase A Voltage (Max, Min, Avg) 161PCC - Pst A from 10/26/2004 to 10/28/2004 Flicker Summary PCC Monitor Site Without SVC/ Filters PST(95) = 1.22 1.4 1.2 Pst A 1.0 0.8 0.6 0.4 0.2 0.0 26 Tue Oct 2004 EPRI/Electrotek 89 27 Wed Time 28 Thu PQView® Flicker Reduced by Approximately 24% by Switching Off SVC/Filters What is the reason for lower flicker levels with the SVC out of service? Without SVC With SVC 161PCC - Pst A 161PCC - Pst A from 10/29/2004 to 10/31/2004 from 10/26/2004 to 10/28/2004 1.2 1.2 1.0 1.0 0.8 0.8 Pst A 1.4 Pst A 1.4 0.6 0.6 0.4 0.4 0.2 0.2 0.0 29 Fri Oct 2004 EPRI/Electrotek 30 Sat Time PST (95) – 0.93 90 31 Sun 0.0 26 Tue Oct 2004 PQView® EPRI/Electrotek 27 Wed Time 28 Thu PQView® PST (95) – 1.22 Base Case With SVC System Operating Weakened TVA System - 2 Days Complaints Ramped Up During This Period 161PCC - Pst A from 02/09/2008 to 02/11/2008 2.4 2.2 Flicker Summary PCC Monitor Site Without SVC/ Filters PST(95) = 1.86 2.0 1.8 1.6 Pst A 1.4 1.2 1.0 0.8 0.6 0.4 0.2 9 Sat Feb 2008 EPRI/Electrotek 91 10 Sun Time 11 Mon PQView® Comparison of Voltage Swings at PCC Both With and Without SVC Operation No SVC SVC Controls Overshoot – One Possibility For Flicker Swing 92 GE Flicker Curves Copied From IEEE 519 Voltage Swing Possible By TCR Overshoot = 1.1% 93 Case 10 A Large Steel Mill Has an SVC and DC Electric Arc Furnace, Here is The Way Things Should Operate! 94 EAF Operation with Great SVC Control Performance 161PCC- Pst A from 06/03/2008 to 06/04/2008 0.35 0.30 PST Pst A 0.25 0.20 0.15 0.10 0.05 3 Tue 3AM 6AM 9AM Jun 2008 EPRI/Electrotek 12PM Time 3PM 6PM 9PM 4 Wed 161PCC- V RMS A PQView® from 06/03/2008 to 06/04/2008 Min[V RMS A] (V) 97000 Avg[V RMS A] (V) Max[V RMS A] (V) 96500 96000 95500 VOLTAGE 95000 94500 94000 93500 93000 92500 92000 3 Tue 3AM 6AM 9AM Jun 2008 12PM Time 3PM 6PM 9PM 4 Wed 161PCC- Q Fund All EPRI/Electrotek PQView® from 06/03/2008 to 06/04/2008 Min[Q Fund All] (kvar) 30000 Avg[Q Fund All] (kvar) Max[Q Fund All] (kvar) 25000 20000 15000 10000 REACTIVE POWER 5000 0 -5000 -10000 -15000 -20000 -25000 -30000 Jun 2008 EPRI/Electrotek 95 3 Tue 3AM 6AM 9AM 12PM Time 3PM 6PM 9PM 4 Wed PQView® Questions/Comments If not, then lets eat!! 96