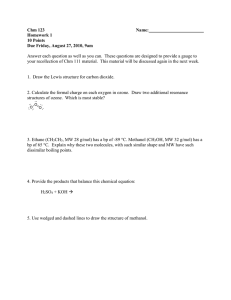

Methanol based System for Transportation Fuels

advertisement

Status and Outlook of Wood-based Biofuels Production A Finish solution for traffic fuels VTT 2G 2020 Biofuels Seminar VTT Espoo May 26, 2015 Ingvar Landälv Senior Project Manager LTU 1 ”Status and Outlook of Wood-based Biofuels Production” in the context of the Conference Agenda Questions which need an answer Presentation 26th May What climate targets will govern developments? Climate targets for EU …. What is the impact of emissions from traffic? Need to reduce emissions from traffic and driving …. Can engines be made more energy efficient? Alternative solutions in road transport: 10-20 year timeframe Can biofuels be integrated in the bioeconomy? Integration of biofuels and new products ….. Where does gasification fits best? Integration of gasification concepts to …. Can Pyrolysis oil be further upgraded to Development of pyrolysis automotive fuels? techniques towards … Will biofuels play a role in Europe 2030? 2 Scenarios biofuels: … Biofuels market - Policy • Very sensitive to global and regional policy Challenge with respect to societal acceptance • Current investments are risky due to RED revision uncertainties – – ILUC and the capping of 1st generation Sub-target for advanced biofuels lack of post 2020 strategies – • • 3 No specific target for the transport sector Member state ambitions Different EU Member States need time to react and develop national strategies for the deployment of advanced biofuels Long term regulations Investment in biofuels projects, including serving debt over 10-12 years and equity over 20 years is not possible without guarantees of regulatory stability of similar tenor Source: Biofuels production - Outlook • Long term strategy for biofuels is needed • The risk is big that developers and their financiers leave the green fuels business for an indefinite time period • built up knowledge disappears or picked up else where (US, China …) • key individuals change work focus • In the long run biofuels needs to be competitive against other alternative transport options. Special attention needs to be give to • infrastructure • engine adjustments • GHG emissions 4 Source: DIRECTIVE 2014/94/EU OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 22 October 2014 on the deployment of alternative fuels infrastructure Article 2 Definitions For the purpose of this Directive, the following definitions apply: (1) ‘alternative fuels’ means fuels or power sources which serve, at least partly, as a substitute for fossil oil sources in the energy supply to transport and which have the potential to contribute to its decarbonisation and enhance the environmental performance of the transport sector. They include, inter alia: — electricity, — hydrogen, — biofuels* as defined in point (i) of Article 2 of Directive 2009/28/EC — synthetic and paraffinic fuels, — natural gas, including biomethane, in gaseous form (compressed natural gas (CNG)) and liquefied form (liquefied natural gas (LNG)) — liquefied petroleum gas (LPG) 5 * ‘biofuels’ means liquid or gaseous fuel for transport produced from biomass; Hydrocarbon based energy system Crude Oil Biomass SOEC* Gasification of biomass Gasification HC upgrading Nutrients Biomass Pyrolysis Liquefact. CO2, H2O, electr. Biomass Wastes Gasification Pulp mill HC upgrading HC upgrading HC upgrading Renewable HC products Fossil HC products gasoline karosene Naphtha etc Ports Energy Use 1 2 n nn diesel B u n k e r Cars & buses Chemical industry Marine sector 6 Heavy transports Preem view: From Forest to Tank 1. Raw Material from the forest Tall Oil, Lignin or other forest based residues 2. Upgrading of raw material to a suitable refinery feed. 3. Co-processing, upgrading to high quality diesel and gasoline. 4. The future fuel – in todays vehicle fleet. 7 Source: Battelle Project: Upgrading of Biomass Fast Pyrolysis Oil (Bio-oil) Biofuel Production Process Product Process Biomass Focus of the Current Project Conventional or Catalytic Pyrolysis Bio Oil State of the Art of Bio Oil upgrading at the Beginning of the Project Bio Oil Bio Oil Stabilization Hydrogenation & hydrocracking Zone I Zone II H/C Product 8 4 Bio-Oil Upgrading Battelle – PNNL Bio Oil Upgrading Process Solves Technical Challenges Bio Oil Technical challenges: • Coke deposition • Bed plugging • Deactivation • TOS ~100 hrs. to 200 hrs. Hydrocarbon Product Bio Oil clean-up Clean-up Zone I New catalyst & process Zone II Commercial sulfided catalyst Accomplishments: • Re-generable catalyst system • TOS > 1,000hrs. • Minimal plugging & deactivation H/C Product Battelle: Technical accomplishments Upgrading of Biomass Fast Pyrolysis Oil (Bio-oil) • Identified novel non-carbon supported metal catalysts with low coke formation rates • These catalysts can be regenerated to remove coke and recover activity • Achieved ~ 200 hrs. TOS while maintaining high activity 9 9 Comments to: Hydrocarbon based energy system (+): Complete macro and micro distribution system exists (+): Renewable fuels will be true drop-in fuels if they meet specification requirements BUT (-): Production of hydro carbons from renewables comes with high costs and low efficiencies. 10 LNG / CNG based Energy System Various renewable Wastes CO2, H2O, electr. Biomass Pyrolysis Digestion Biomass Natural gas (NG) Biomass SOEC* Gasification Liquefact. LNG Plants Gasification of biomass Gasification Nutrients Pulp mill BioSNG Biogas BioSNG BioSNG BioSNG NG/SNG /BioSNG BioSNG LNG/BioLNG Ports 1 2 n nn Cars & busses L N G Energy usage Distribution Chemical industry Marine sector 11 Heavy transports CNG core pipeline and LNG terminal network in Europe [Eurogas] 12 Comments to: LNG / CNG based Energy System (+): Large macro and micro distribution system exists in many countries for CNG for energy purposes. CNG for cars available in some countries to a certain extent. (+): Renewable methane, BioSNG, will be a true drop-in fuels if it meets specification requirements (+): Major LNG terminals exists at strategic harbors and connects to the CNG network BUT (-): Micro distribution for NG as motor fuel does not exist to any large extent for CNG and barely at all for LNG. (-): LNG distribution comes with very high distribution costs (-): Vehicle adaption for LNG is a technical challenge (-): Risk for methane leakage need to be considered 13 Methanol based System for Transportation Fuels Natural gas Methanol plants Fossil MeOH Via Ports Chemical industry 14 Methanol based System for Transportation Fuels A natural move 1970-1980 during first oil crises Natural gas Methanol plants Fossil MeOH Via Ports Distribution Ports 1 2 n nn Cars Chemical industry 15 Swedish Methanol tests in the 1980-ies • During 1980-82 a large M15 fuel testing project was done with 1000 vehicles at 19 fuel stations and 11 car makes with 20 million km of driving. As neat fuel M100 were tested 1984-86 by SAAB-Scania and Volvo with 20 vehicles. • Main results were same or better than for petrol in terms of engine performance, fuel handling and distribution. However, when oil prices fell 1986, investment in required infrastructure became less attractive. 16 Nynäshamnskombinatet 1984, 1500 MWth plant Project developed during 1982-84 by a Swedish team and with involvement of international contractors and process licensors. Engineering efforts of this and following NEX projects totaled €30 million Acquired technology knowledge have contributed to today’s status in development No methanol plant built but two IGCC plants in Italy and spinoff into black liquor methanol in Piteå by the team 17 Project size: 700 000 t/y of MeOH Methanol based System for Transportation Fuels An unexpected ban in the 1990-ies and onward Natural gas A corrosive, poisonous fuel Methanol plants Fossil MeOH Via Ports Distribution Ports 1 2 n nn Cars Chemical industry 18 Methanol based System for Transportation Fuels A surprising move “today” – methanol as bunker fuel Natural gas Methanol vs. LNG “In ECAs, methanol is widely regarded as a better alternative to HFO than LNG. It is easier to handle, because it is a liquid at ambient temperature and pressure, and so, unlike LNG, does not have to be cooled down to -163°. In the end, the price and availability of the fuel will determine the extent of its success.” Dirk Schroeder, Lloyd’s Register Methanol plants Fossil MeOH Via Ports 1 Ports M e t h 2 a n n nn o l Chemical industry Marine sector 19 Stena Germaica started to operate on methanol at one of its 4 engines in April 2015. Remaining 3 engines will follow later in 2015. Fuel: 25 000 tons of MeOH / year Source: Stena 20 Methanex: 7 Tankers to be Powered by Methanol on order. Another two are planned. 21 Methanol based System for Transportation Fuels 2015: Methanol as bunker fuel => methanol in cars, busses and HD trucks Natural gas Still a corrosive, poisonous fuel or … Methanol plants Fossil MeOH Via Ports Distribution 1 Ports 2 n nn Cars & buses M e t h a n o l Chemical industry Marine sector 22 Heavy transports Fuel blending in China – Provincial Standards • Provincial Standards have been supporting strong demand growth for methanol fuel blending in China M15, M30 M15, M30 M15 Heilongjiang M15 M5, M15, M85 & M100 Jilin M15 Liaoning M15, M25 Inner Mongolia Xinjiang M15 Beijing Hebei Tianjin Gansu Shandong Shanxi Ningxia Qinghai Tibet M45 Henan Shaanxi Jiangsu Hubei Sichuan Shanghai Anhui Zhejiang M10 Chongqing Hunan Jiangxi Fujian Guizhou Example: “M15”=15% methanol, 85% gasoline Guangxi M15 23 Source: Methanol Institute Guangdong Yunnan Hong Kong Macau Hainan 23 M15, M30 & M50 Methanol based System for Transportation Fuels Parts included in the ForeMeOH Horizon2020 application Methanol plants Nutrients Gasification MeOH Fossil MeOH Pulp mill MeOH 1 2 n Via Ports nn DME M e t h a DME n o Cars & buses l Distribution Marine sector 24 MeOH Renewable MeOH Distribution Ports SOEC* Gasification of biomass Gasification MeOH Biomass Pyrolysis Liquefact. CO2, H2O, electr. Biomass Wastes Biomass Natural gas Chemical industry Heavy transports ForeMeOH - Demonstration of Sustainable conversion of Forest industry and Agricultural Residues to BioMethanol including its use in vehicles and ships (An Horizon 2020 Application from May 2015) FIVE DEMONSTRATIONS: 1. Demonstration of biomethanol as fuel for large marine 4 stroke engine system 2. Demonstration of biomethanol as fuel for small to medium size marine 4 stroke engine system 3. Use of raw biomethanol in a two stroke marine engine 4. Demonstration of biomethanol in a HD diesel engine including an ignition improver 5. Demonstration of GEM fuel on a fleet of used E85 passenger cars where the methanol component is biomethanol, not in compliance with chemical grade methanol 25 Methanol based System for Transportation Fuels DME identified as an excellent diesel fuel for HD vehicles Natural gas Methanol plants Fossil MeOH Via Ports Distribution 1 Ports 2 n nn DME M e t h a DME n o Cars & buses l Distribution Marine sector 26 Chemical industry Heavy transports More than 700 tons of BioDME has been produced since start in Nov 2011 LTU BioDME project 27 Biosyngas Program to May 2016 Goals achieved for the Volvo field tests 8 trucks, 2013-01-01 to 2014-06-30 Km / Mile Total mileage 1 truck Status Target 2014-08-31 June 2014 1 485 000 / 933 000 1 400 000 / 870 000 296 000 / 184 000 250 000 / 155 000 Extended field test 28 Comments to: Methanol based System for Transportation Fuels (+): Macro distribution system exists in many countries for methanol as a chemical commodity. The system can cost effectively be extended. (+): Renewable methanol can be blended with fossil methanol, it can be used as low blend component and it can be a green component in production of FAME and MTBE. Place for 5 milj tons within EU. (+): Methanol is one of, or maybe the simplest renewable fuel to produce from in principle all renewable feedstocks and has also comparably high energy conversion efficiency (+): Methanol is a very efficient motor fuel (+): Methanol is an efficient fuel for fuel cells. BUT (-): It is recognized as a less desirable fuel due to its toxicity. (-): Risk for corrosion needs to be carefully addressed 29 Gasification of Biomass in Liquid Form Methanol plants Nutrients Gasification MeOH Fossil MeOH Pulp mill MeOH 1 2 n Via Ports nn DME M e t h a DME n o Cars & buses l Distribution Marine sector 30 MeOH Renewable MeOH Distribution Ports SOEC* Gasification of biomass Gasification MeOH Biomass Pyrolysis Liquefact. CO2, H2O, electr. Biomass Wastes Biomass Natural gas Chemical industry Heavy transports Today’s commercial Forrest Industry has two main legs TODAY Forest Logs Pulp Wood Saw mill Wood Products Pulp Mill Recovery Boiler Pulp Mill Pulp 31 BLG is a transformative technology converting pulp mills to biorefineries making efficient use of the third fraction from the forest TOMORROW Forest Logs Pulp Wood Saw mill Wood Products Forest Residual H&P Boiler Combined Recovery Recovery Boiler And Fuel Generation Pulp Mill Pulp Mill Pulp 32 Fuel Pulp Mill Biorefinery Economics (l.g.e. : liter gasoline equivalents) Plant Financials Renewable energy price Renewable Energy price as currently under (Ethanol l.g.e.) discussion in Sweden Fossil energy price (gasoline) Biofuels price EUR / l.g.e. 1.3 0.9 0.6 Revenues, MEUR 232 164 109 Opex, MEUR (64) (64) (64) EBITDA , MEUR 168 100 45 Gross Payback, years Net payback, years 2.9 1.4 4.9 2.4 10.9 5.3 * Mill capacity: 2500 ton dry solids per day Production and CAPEX Production, million l.g.e Gross CAPEX, MEUR Avoided cost for recovery boiler, MEUR Net CAPEX, MEUR 33 Source: Chemrec 182 (490) 250 (240) Extremely profitable at biofuels prices and avoided cost of recovery boiler Robust: Positive EBITDA even at fossil prices Biomass flow from the forest can be increased adding pyrolysis oil (PO) to the black liquor (BL) flow TOMORROW (2) Forest Logs Pulp Wood Saw mill Wood Products Forest Residual H&P Boiler Combined Recovery Recovery Boiler And Fuel Generation Pulp Mill Pulp Mill Pulp 34 Fuel PO Production Pilot plants in Piteå, Sweden (Host plant for the LTU Biosyngas Program) WP1 Pilot scale experiments Powder WP2 Catalytic gasification ETC EF gasifier WP3 Solid fuel gasification WP4 Novel syngas cleaning WP5 Catalytic conversion WP6 Containment materials WP7 Field tests Torrefied Mtrl Cleaning Pyrolysis oil Others BioMeOH WP2 Membranes Black Liquor 25-30 bar > 100 bar BioDME DP-1 Plant Active C Abs H2 O2 Amine Wash Future development The Renewable Syngas Highway MeOH Synth. CO, H2 Electrolysis Existing facilities 35 WG Shift DME Synth. Catalytic Process Development CO2 Fuel Cells H2O Distillation The catalytic gasification project - turning alkali to an advantage • Alkali metals often problematic in biomass combustion and gasification • But: – Alkali metals known to catalyze gasification reactions – Handling and recovery of alkali salts is well developed in the Chemrec gasification technology • So: Let’s use alkali metals to improve efficiency instead of considering them a problem 36 Black liquor char has a very high reactivity compared to chars of other origin ~300 times higher 903˚C 838˚C 780˚C 37 When BL and PO are mixed the char from the mix gets the reactivity of BL BL & BL/PO 80/20 & 70/30 ~300 times higher 30-40 times higher 903˚C 838˚C 780˚C 38 Co-gasification of BL and PO offers many potential advantages All calculations thus assume that BL/PO can be gasified at same temperature as BL is today. Syngas Capacity increases Energy efficiency for gasification about 100% by having about of added PO is 80-85% 27% PO to the BL/PO mix (by weight) 100% 95% 90% 400% ~27% 300% 80% CGE Production (syngas energy) 85% 85% 350% 250% 200% SF-LHV total 75% H2CO total 70% SF-LHV incr PO 65% H2+CO incr PO 60% 150% 55% 100% 50% 0% 50% 10% 20% 30% 40% 50% PO mix (part of total feed) 0% 0% 10% 20% 30% PO mix (part of total feed) 40% 50% Figure shows simulated increased production of final liquid biofuel product at fixed BL feed (i.e. for specific mill) 39 Figure shows simulated gasifier energy efficiency of total mixed feed (solid) and for added PO (dashed) Co-gasification of BL and PO offers many potential advantages All calculations thus assume that BL/PO can be gasified at same temperature as BL is today. Syngas Capacity increases Energy efficiency for gasification about 100% by having about of added PO is 80-85% 27% PO to the BL/PO mix (by weight) 100% 95% 90% 400% ~27% 300% 80% CGE Production (syngas energy) 85% 85% 350% 250% 200% SF-LHV total 75% H2CO total 70% SF-LHV incr PO 65% H2+CO incr PO 60% 150% 55% 100% 50% 0% 50% 10% 20% 30% 40% PO mix (part of total feed) 0% 0% 10% 20% 30% PO mix (part of total feed) 40% 50% Figure shows simulated increased production of final liquid biofuel product at fixed BL feed (i.e. for specific mill) 40 13% PO successfully mixed Into BL in trials March 2015. Week operations planned for autumn 2015. 50% Material and energy balances 0% PO 25% PO 50% PO PO: 0 MW, 122 MW, 365 MW Electricity 32 MW 45 MW 70 MW Fuel drying Boiler Turbine Electricity 15 MW 14 MW 13 MW Electricity 28 MW BFP Off-gases 7 MW 12 MW 23 MW Lime kiln fuel 16 MW 11 MW 0 MW 41 Bl Pulpwood 420 MW 18 0 M Bark 29 MW Electricity 20 MW 31 MW 55 MW W Biomass 96 MW 92 MW 86 MW Pulp mill Pulp 157 MW MeOH 97 MW 183 MW 353 MW Cash flow analysis shows that PO can be valued to ~90€/MWh to meet the same IRR as a pulp mill without any PO addition 35% Case BLG 30% Case 25 Case 50 IRR [%] 25% 20% 15% 10% 5% 0% 35 45 55 65 75 85 Pyrolysis oil cost [€/MWh] 42 95 105 115 “....but we need the stable long-term investment conditions......” 130 € / MWh 120 Cellulosic EtOH 0.70 €/l 110 100 100 €/MWh = ~4.4 USD/g.g.e. 90 80 70 60 50 Today’s cost for advanced biofuels In Europe Brazilian ethanol at 0.40 €/l Long term stable legislation is required to cope with the difference 40 30 20 10 2000 43 2010 2020 2030 Special thanks to research partners and sponsors 44