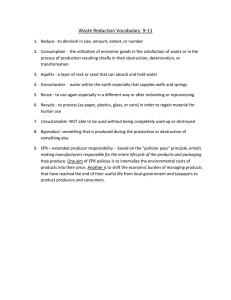

The Post-consumer Waste Problem and Extended Producer

advertisement