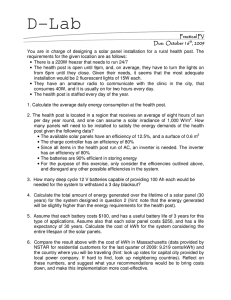

Available

advertisement