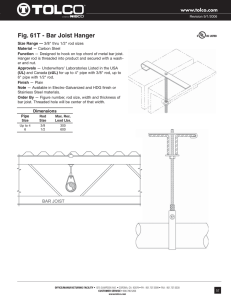

Standard Clevis - S3 amazonaws com

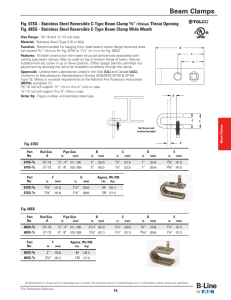

advertisement