pcs32 assembly and calibration manual

advertisement

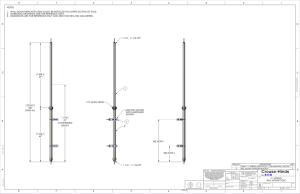

12 / 05 / 1997 PCS32 ASSEMBLY AND CALIBRATION MANUAL Special tools for testing and adjustment: • IBM compatible computer (486 or pentium) • Signal generator • Digital multimeter SEE MARKED TEXT FOR MODIFICATIONS 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 2 ASSEMBLY VERY IMPORTANT - MOUNT ALL COMPONENTS AGAINST THE PCB - MOUNT THE COMPONENTS IN THE ORDER INDICATED BELOW The oscilloscope consists of twe PCBs: 1 The small PCB PPCMK2PS, which, among others, supplies the negative voltage; the on/off switch, the fuse and the supply connector are also mounted on this PCB. 2 The base PCB P7103, which the rest of the circuit is mounted on 1) ASSEMBLY OF THE POWER SUPPLY PCB PPCMK2PS Mount the ¼W resistors R1... R4: 5K6 (green, blue, red, gold) (RA5K6) R5: 10K (brown, black, orange, gold) (RA10K0) R6: 47K (yellow, violet, orange, gold) (RA47K0) R7: 1K (brown, black, red, gold) (RA1K) R10: 330 ohm (orange, orange, brown) (RA330E0) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 3 Mount the 1% metall film resistors R8: 20K (red, black, black, red, gold) (MA20K0) R9: 1R5 (brown, green, black, silver; brown) (MA1E5) R11: 30 ohm (orange, black, black, gold, brown) (MA30E0) Mount the coils L1... L3: 220µH (red, red, brown) (220H0) Mount the diodes (watch the polarity!) D1: 1N4148 (1N4148) Mount the ic sockets IC1: 16P (16P) Mount the capacitors C1, C2: 2n2 (222) (C2N2) C3: 100nF (104, µ1) (C100N0) C4: 1µF (105) (C1M0) Mount the electrolytic capacitors (watch the polarity!) C5: 4,7µF (4µ7) (4J7J) Completely against PCB ! C6: 100µF (100J0D) Completele against PCB ! Mount the transistor T1: BC327 (BC327) T2: BC547 (BC547B) Mount the fuse holder (FUSE/H’LC) F1: Insert a 1A fuse in the fuse holder (FU1) Mount the DC connector J1: type (DJ-005) (SCREW02) Mount the screw connector J2 REMARK: FASTEN THE TWO SCREWS !!!!!!!!!!!!!!!!!!! Mount the 3mm LED (LED3RL) LD1 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 4 4mm Insert the IC Watch the position of the notch!IC1: CA3524 (CA3524) MOUNT C7: 220µF (220J0D) AT SOLDER SIDE ! Connect snap 9V (2x) (red= +) (SNAP9V) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 5 2) ASSEMBLY OF THE MAIN PCB P7103’3 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 6 Mount the ¼W resistors R1, R2, R42... R45, R49, R51... R58: 470R (yellow, violet, brown, gold) (RA470E0) R48, R50, R59... R61: 100R (brown, black, brown, gold) (RA100E0) R29, R30: 100K (brown, black, yellow, gold) (RA100K0) R3, R41: 47R (yellow, violet, black, gold) (RA47E0) R46: 1K (brown, black, red, gold) (RA1K0) R67, R68: 4K7 (yellow, violet, red, gold) (RA4K7) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 7 Mount the 1% metall film resistors R9, R24: 360R (orange, blue, black, black, brown) (MA360E0) R4, R14: 820R (grey, red, black, black, brown) (MA820E0) R15, R34... R39: 1R5 (brown, green, black, silver; brown) (MA1E5) R5, R16: 750ohm (purple, green, brown, gold) (MA750E0) R10, R20: 30R (orange, black, black, gold, brown) (MA30E0) R11, R21: 82R (grey, red, black, gold, brown) (MA82E0) R47: 110R (brown, brown, black, black, brown) (MA110E0) R7, R18, R31, R32: 200R (red, black, black, black, brown) (MA200E0) R8, R19, R25.. R28: 470R (yellow, violet, black, black, brown) (MA470E0) R13, R23: 10K (brown, black, black, red, brown) (MA10K0) R12, R22: 91K (white, brown, black, red, brown) (MA91K0) R6, R17: 910K (white, brown, black, orange, brown) (MA910K0) R33, R40: 3R3 (orange, orange, black, silver; brown) (MA3E3) Mount the diodes (watch the polarity!) D1... D9, D11, D23... D26: 1N4148 (1N4148) D13, D21: 1N4000... 4007 (1N4007) Mount the adjustable resistors RV1, RV4: 100ohm multiturn (E100TW or E100TY) RV3, RV6: 4K7 (5K) (K004SH) Mount the IC sockets IC15, IC22: 24P Mount the capacitors 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 8 C89, C90: 10P (C10) C86, C87: 100P (101) (C100) C3, C8: 100P (101) (C100) C14, C20: 150P (151) (C150) C17, C26: 1N5/400V! (152, 1500) (5MQ1.5) C15, C21: 2N2 (222) (C2N2) C4, C5, C9... C12, C41... C63, C28, C29, C32, C37: 47nF (473) (C47N0) C23, C38... C40, C64... C70: 220nF (224) (C220N0M) C25, C31: 47N/400V (K400) (1MK47) C35, C36, C75, C76, C91, C92: 100N (104) (C100N0) C18 & C27 : 10nF (C103) DO NOT MOUNT: C13, C19, C16 Mount the adjustable capacitors CV1, CV3: 22P (green) (TRIM22P) CV2, CV4: 50P (yellow) (TRIM65P) Mount the transistors T3, T5: 2N2907A (2N2907A) T1, T2,: U441 (U441) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 9 Mount the electrolytic capacitors (watch the polarity!) C1, C2, C6, C7, C33, C34: 4U7 (4J7J) or (4T7C) C22, C71: 100µF (100J0D) C30: 1000µF (1000J0D) Mount the crystal oscillator (X032) X1: 32.000mhz Position it carefully; the corner must coincide with the PCB marking! Mount the REED relays Attention: Two types of relay are used; in order to distinguish between them, the code number is completed with an “A” or a “C”. Also pay attention to the position of the notch. RY3, RY4, RY5, RY6: 1A (VR05R051’A ) RY1, RY2, RY7, RY8: 1C (VR05R051’C) Mount the sub D connector J7: 25-pole male connector (also solder the mount part) (SUBD25M) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 10 Mount the switches SW2, SW3: 2-pole cross, switch with 3 positions (300DP6R2) Now with plastic actuator! Correct the position of the switch at final assembly, for easy adjustment, then solder all the leads!! Mount the voltage regulators IC28: 78L05 IC17: 7806 This should be mounted horizontally; fix it using 6mm bolt, lock washer and nut, then solder the connections. ( UA7806 + BT30060 + MR3 + MR3K ) DO NOT MOUNT IC23 JET. Mount the potentiometers Cut the axes of both potmeters to a lenght of 6 - 7 mm HOLD THE AXIS WHILLE CUTTING! RV2, RV5: 1K LIN (K001AM) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 11 Insert the IC's into their sockets ! Watch the position of IC1, IC2 and IC3, because it differs from the position of the other IC’s Watch the position of the notch! IC6, IC7: TDA8703 (TDA8703) IC33, IC34: AD811 (AD811) IC19: 74HC00 (HC00) IC21: 74HC139 (HC139) IC1... IC3: 74F161 (74F161) IC12... IC14: 74HC161 MUST BE MOTOROLA OR HARRIS (HC161) IC8: 74HC162 MUST BE MOTOROLA !!!!!!! (74HC162) IC9... IC11: 74HC162 IC26, IC27: 74HC244 (HC244) IC16, IC24: 74HC273 (HC273) IC25: 74HC374 (HC374) IC18: 74HC74 (HC74) IC4, IC5: SRAM 8K X 8 (65764, 61C64, 7C185...) (6408) IC15: VK7103A (GAL22V10) (CK7103A) IC22: VK7103B (GAL22V10) (CK7103B) 3) ASSEMBLY OF THE COMPLETE UNIT • Mount the 3 (12 cm) supply wires : +9 .. +12 V (red), GND (black), -6V (yellow) (MOWR + MOWBK + MOWY) • Mount the spacers for the powersupply PCB BUS.8M 8mm spacer R/TO220 TO220 isolator BUS3FF05 5mm spacer 10mm bolt (BT3010) • Mount the main PCB spacers 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 12 BUS3FF20 BUS.8M BT30150 • Solder the supply leads on the supply board • Place the powersupply PCB on its spacers and fasten with two 6 mm bolts. (BT30060) • Connect testpoint J9 on the main PCB to the rightmost tab on the supplyboard. Use a 6 cm yellow wire. (MOWY) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 13 • Connect two 15 cm wires (yellow) to both tabs close to the led on the supply board. (MOWY) • Mount the ON-OFF indicator 5mm led on the main PCB. Bend its leads according to drawing. Make sure the it is soldered in the right way ( cathode ‘negative’ is the shortest lead ) (LED5RL) • Mount the leads for CH1 (J1) and CH2 (J3). Use 11 cm of yellow cable. (WOMY) • Use 5cm + 7cm of black cable to connect the ground of the PCB ( J2-J4 ) to potentiometers and to continue. (WOMBK) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 14 • Mount the rear panel. Fasten the SUB-D connector with its two own bolts. (CKRPCMK2) • Mount the clamp and IC23 voltage regulator 7805 . Use silicon compound to ensure cooling. Be carefull not to damage the regulator, use 10mm bolts, lock washers and nuts. Do NOT forget isolators. Solder regulator leads AFTER fixation. Nut M3 MR3 Washer RM3K Isolator R/TO220 Volt regulator UA7805 Isolating mica M/TO220 Bend leads Bolt 10mm M3 BT30100 Use two 10 mm bolts, lock washer and nut to connect the clamp to the rear panel. Do not forget to use plenty of silicon compound ! • 22 / 04 / 1996 2x BT30100 + 2x RM3K + 2x MR3 PCS32i Assembly & Calibration Manual 15 Degrease the alu frontpanel with a non-aggresive solvent ( eg alcohol). Stick the frontpanel-foil carefull on the alu panel. Make sure it is perfectly centered. (FPCMK2 + FPPCMK2) Cut the excess border from the front sticker • Mount both BNC connectors on the front panel. Make sure they are mounted in upright position. now IN PLASTIC!! (BNCICHAS) • Fasten the switch onto the sub chassis as shown. Be sure to mount it neatly horizontal. REMOVE PROTECTIVE FILM FROM SUB CHASSIS IF PRESENT! (CHPCMK2 + BT20100 + BUS05 + MR3 + MR2 + RS-4) 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 16 Preparation of the screening foil: (CKSPCMK2) Isolate the edge of the foil by means of tape, first bendover the foil: Adhesive tape Coductive side Isolated side • Put the screen foil between potentiometer and subchassis . • Fasten the subchassis on both potmeters. Do not fasten bolt to tight, it will need adjustment later. 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 17 Connect BNC GND (black wire) and signal (yellow wire). • Guide both yellow switch leads trought the center hole and connect to the switch. Isolation, cover both contacts 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 18 Pre Testing Check the following voltages after supplying power supply. All voltages are measured with respect to ground (use test point J11 as ground). · Connect a voltage of 9 - 12VDC/700mA to the DC connector (check the polarity). · Measure around -6V on pin 4 of IC33. · Measure around 6V on pin 7 of IC33. · Measure around +5V on pin 16 of IC1. 6V IC33 & IC34 0 mV -6V IC1 5V Adjust the following offset voltages • Set input selector switch to GND of both channels • The voltages are measured with respect to ground, point J2. • Measure pin 3 of IC33 and adjust RV1 until the voltage is 0mV. • Measure pin 3 of IC34 and adjust RV4 until the voltage is 0mV. 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 19 Calibration: Install the software Connect unit with printer port LPT1 of computer. Start the PCS32.BAT program. This is an MSDOS program but can generally be run from Windows. Set the TIME/DIV switch to 1ms by using the mouse, (click on the figures). Press on RUN ON Press CH1 to ON. Press CH2 to OFF Press TRIG to OFF Set switch SW3 to the GND position. Adjust the Y POSITION potentiometer RV5 until the line can be seen. Set the VOLT/DIV switches to 1V and then 5V by using the mouse. After selecting these two positions the lines must not move vertically. If this is not the case, then adjust RV4 until the movement is minimal. Follow the same test and adjustment procedures for channel 2 : Press CH2 to ON Press CH1 to OFF Set switch SW2 to the GND position. Adjust the Y position potentiometer RV2 until the line can be seen. Set the VOLT/DIV switches to 1V and then 5V by using the mouse. After selecting these two positions the lines must not move vertically. If this is not the case, then adjust RV1 until the movement is minimal. Adjustment of the vertical amplifiers Set the TIME/DIV switches to 1mS. Set channel 1 ON and channel 2 OFF Set the VOLT/DIV switch to 1V. Set the line to the center of the screen. Connect an X1 probe or a direct connection to channel 1. Connect the channel 1 probe to a sinewave signal generator. Set the sinewave generator to 2.5Vrms output (check with true RMS voltmeter !) Set the switch on the device to the DC position. Adjust RV6 until the true RMS readout is 2.5Vrms For the 2nd channel: Same procedure as for channel 1, except for this: Set channel 2 ON and channel 1 OFF Adjust RV3 until the true RMS readout is 2.5Vrms 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 20 Transient response adjustment Set TIME/DIV to 0.1ms. Use an X1 probe. Use an insulated screwdriver (small metal tip is allowed). Channel 1: Set the VOLT/DIV switch to 1V. Connect the probe to test point J9. Adjust CV3 until the top of the square wave is as flat as possible. Set the VOLT/DIV switch to 0.1V. Connect the probe to test point J10. Adjust CV4 until the top of the square is as flat as possible. 2nd channel: Set the VOLTS/DIV switch to 1V Connect the probe to test point J9 Adjust CV1 until the top of the square is as flat as possible. Set theVOLTS/DIV switch to 0.1V Connect the probe to test point J10. Adjust CV2 until the top of the square is as flat as possible. Not correct (overcompensated) Correct Not correct (undercompensated) NOTE: If an X10 probe is used then it must also be set to the X10 position. It can then be used in the same way as above but with the difference that the probe trimming capacitor has to be adjusted. IMPORTANT: Repeat the above check at least once. 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 21 Testing the battery charge circuit: • Connect battery holders and insert 2x4 AA rechargeable batteries • Connect a 12VDC / 800mA power supply adapter • The charge LED at the back of the unit must light up 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 22 Final Assembly • When the unit is carefully calibrated, you can continue the assembly. • Degrease the tape location in the plastic casing with a non-aggresive solvent ( eg alcohol ). Clean the bottom of the batteryholders with alcohol. • Stick the tape (2 x 12cm) onto the plastic chassis as indicated. (2x12cm TAPE4932) 6 cm // 2 x 12 cm // 6 cm • Put both batteryholders in place. Press firmly 5cm • Connect the snaps to the battery holders 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 23 Put the whole assembly in place, make sure everything fits snugly. CHECK THE FUNCTIONING OF THE 3 POSITION SWITCH !!! CHECK THE CENTER OF THE POTENTIOMETERS • Fasten the subchassis with two parkerscrews. • Fasten the potentiometers • Check the position of the LED, bust be behind display window Check the function of the powerswitch 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 24 • Put both grey knobs in place. Be sure the direction of the arrows is correct. (KN156G + DK15GWS) Left center right • Fasten 4 rubber feet with 10 mm bolts (4X BT30100 + 4X VOET) • Close the lid and fasten with the supplied bolts TEST THE FUNCTION OF ALL THE SWITCHES !! 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 25 Testing the time per division section: • Connect the oscilloscope to the computer • Turn the oscilloscope on (check power LED on front panel) • Start the test program TST.com (or TSTi for opto -box) Computer screen: TEST PROGRAM FOR OSCILLOSCOPES K7103 AND PCS32 SELECT THE TEST: 1 - Timer test 2 - IC22 test 3 - IC21A test 4 - Cable test 5 - Exit Select 1, timer test. The result must be: TIMER TEST FREQUENCY 32 MHz 16 MHz 8 MHz 3.2 MHz 1.6 MHz 800 kHz 320 kHz 160 kHz 80 kHz 32 kHz 16 kHz 8 kHz 3.2 kHz 1.6 kHz 22 / 04 / 1996 ESC=EXIT RESULT ok ok ok ok ok ok ok ok ok ok ok ok ok ok PCS32i Assembly & Calibration Manual 26 Testing the input section: • Connect the oscilloscope to the computer with optobox • Apply 1KHz input signal to the scope channel 1 SIGNAL GENARATOR • Turn the oscilloscope on • Start the program PCS32 (new SOFTWARE FOR OPTO BOX!!) • Set scope at 1mS 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 27 Set at 1ms Check different volt/div settings, for correct readout. • Repeat for channel 2 • Test input selection switch GND, AC, DC. (apply DC input voltage) • Test Y position potentiometer function 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 28 • Inspect the unit and wipe clean • Check all functions and make sure the unit functions properly Packing: Put unit in plastic bag (PZ25/35) Put Manual in plastic bag + DISK + NOTE + spare fuse (PLZ20x25 + DSKPCS32 + NOTA + FU1 Put unit and manual in box + CABLE (DPSCMK2 + PARCABLE) Put box in sleeve and apply shrink foil round box. 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 29 ONLY FOR THE VOLTCRAFT VERSION: Package includes opto - box 22 / 04 / 1996 PCS32i Assembly & Calibration Manual 30