Volume II:Layout 1.qxd

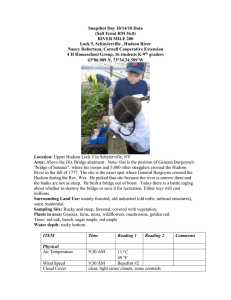

advertisement