3M™ Scotch-Weld™ Structural Adhesives

advertisement

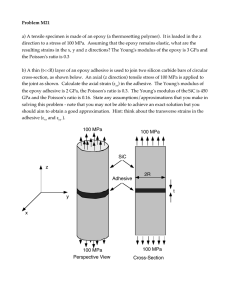

3M™ Scotch-Weld™ Structural Adhesives Load-bearing formulations for metals, rubber, glass and more. 6 As an alternative to mechanical or fusion fastening, the reasons for Scotch-Weld Adhesives are many: greater design latitude, cleaner lines, material substitution, less machining, lighter weight, more durability, and often less cost. To meet application and end-use requirements you can select from one-part heat-curing epoxies, and two-part roomtemperature curing epoxies, acrylics and urethanes. There are formulations for bonding steel, aluminum, copper, low surface energy plastics, rubber, glass, wood, masonry and more. 7 Whatever properties you need– durable adhesion, flexibility, creep resistance, heat and environmental resistance, void-filling—you’ll likely find a Scotch-Weld product to meet your requirements and expectations. 8 9 3M has long been recognized as a pioneer in structural strength adhesives. But to meet end use performance requirements doesn’t just mean providing the right chemical formula. Which is why 3M also develops dispensing systems to facilitate production in low and high volume assembly. Many two-part 3M formulations are available in Duo-Pak cartridges for dispensing with a manual or pneumatic 3M ™ EPX™ Applicator. 10 13 Aircraft entry steps – Brush-applied 2-part 3M ™ Scotch-Weld™ Adhesive 2216 B/A provides a tough, flexible bond between honeycomb and the framework in entry step panels of commuter aircraft. 12 11 Refrigerant coil – 3M ™ Scotch-Weld™ Epoxy Adhesive 2214 bonds and seals coils with overlap shear strength of 4500 psi. One part eliminates metering and mixing. Porch railing – 3M™ Scotch-Weld™ Structural Plastic Adhesive DP- 8005 bonds unique thermoplastic composite in assembly of hollow railings that are stiffer than wood. Retail store display columns – To maintain the quality wood-like appearance, 3M ™ Scotch-Weld ™ Structural Plastic Adhesive DP-8005 eliminates screws, nails, and related surface finishing in assembly of plastic composite components. 14 Bicycle frame assembly – 3M ™ Scotch-Weld™ Epoxy Adhesive DP-420 bonds steel couplings into aluminum tubing of the frame. Couplings are threaded for easy assembly and disassembly. The toughened epoxy bonds for the long run in high stress areas. 15 Bonding magnets to steel rotor – Bonds made with 2-part 3M ™ Scotch-Weld™ Epoxy Adhesive DP-460 cure at room temperature and reach 4500 psi in overlap shear strength. Void-filling properties secure loose fitting surfaces. Product Information: 3M™ Scotch-Weld™Adhesives in Duo-Pak Cartridges Product(1) (Color) Features DP-100 Clear • Fast cure adhesive • Rigid epoxy • 15-20 min. handling strength • Machinable product Approximate Viscosity 75°F (24°C) (CPS) 1:1 13,000 (2) (5) Approximate Worklife At 75°F (24°C) Average (4) T-Peel At 75°F (24°C) PIW -67°F (-55°C) 4 Min. 2 900 (3) Overlap Shear Strength PSI 75°F (24°C) 1500 180°F (82°C) 300 250°F (121°C) 200 7 DP-100Plus • Water clear • Fast cure rigid epoxy Clear • Good peel and shear strength 1:1 8,500 4 Min. 13 3000 3500 200 150 DP-100NS • 25-30 min. handling strength Translucent • Translucent low flow version of DP-100 Adhesive 1:1 95,000 6 Min. 2 900 1500 300 200 DP-100 FR • 25-30 min. handling strength • Meets White UL94V-0 rating • Self-extinguishing version of DP-100 Adhesive 1:1 50,000 6 Min. 2 800 1400 400 200 DP-105 Clear • Water clear • Fast cure • Very flexible • Excellent peel strength 1:1 6,500 5 Min. 35 3500 2000 150 100 DP-110 Gray • Fast cure adhesive • Flexible epoxy • 30 min. handling strength 1:1 55,000 9 Min. 15 2000 2500 200 150 1:1 50,000 9 Min. 10 2000 2500 200 150 • Medium worklife • Good peel strength 1:1 52,500 25 Min. 35 3400 4300 400 200 DP-125 • Medium worklife Translucent • Good peel strength 1:1 15,000 25 Min. 35 4000 2500 150 100 1:1 80,000 90 Min. 20 1500 2500 400 300 1:1 10,000 90 Min. 30 3500 1700 160 100 DP-110 • 30 min. handling strength • Translucent Translucent version of DP-110 Gray Adhesive DP-125 Gray Adhesives in Duo-Pak Cartridges Mix Ratio (Volume) B:A DP-190 Gray • Long worklife adhesive • Flexible epoxy • 8-12 hrs. handling strength • Can bond metals, plastics and many other dissimilar materials DP-190 • Long worklife Translucent • Good peel strength DP-270 Black • Long worklife potting compound • 8-12 hrs. handling strength • Rigid epoxy 1:1 19,000 70 Min. 2 1200 2500 300 200 DP-270 Clear • Clear version of DP-270 Black • Many electronic applications 1:1 19,000 70 Min. 2 1200 2500 300 200 DP-420 Off-White • Medium worklife toughened epoxy • 1-2 hrs. handling strength • High performance 2:1 45,000 20 Min. 50 4500 4500 450 200 DP-420 Black • Black version of DP-420 Off-White • Tough, durable structural bonds 2:1 22,500 15 Min. 50 4500 4500 2980 570 • Long worklife toughened epoxy • 2-4 hrs. handling strength • Meets MIL-A-23941A 2:1 45,000 60 Min. 60 4500 4500 700 200 DP-460NS • Non-sag version of DP-460 Off-White • Heat curable • High-performance 2:1 125,000 60 Min. 60 4900 4650 2630 420 DP-4XL Off-White 2:1 22,500 5-6 Hours 60 2800 4880 1240 280 1:1 150,000 4 Min. 15 1000 1250 325 100 • Non-sag • Long worklife • Tough flexible bonds 1:1 25,000 40 Min. 25 2500 2000 300 150 DP-805 Lt. Yellow • High peel and shear strength • Bonds slightly oily material • High temperature performance • Excellent plastic adhesion 1:1 110,000 4 Min. 35 2500 3500 2200 200 DP-810 Tan • Bonds many metals and plastics without surface preparation • Extremely fast strength build up • Fully cured in 6 hours 1:1 20,000 8-10 Min. 30 1200 4200 500 300 DP-820 Yellow • High shear and peel strengths • Bonds slightly oily metals • Medium worklife 1:1 60,000 15-20 Min. 22 3100 3150 1900 1450 DP-460 Off-White • Extra long worklife toughened epoxy for large assemblies • Handling strength in 5 minutes at 250°F DP-605NS • Fast cure semi-rigid urethane Off-White • 15-20 min. handling strength • Gap filler • Non sag for wood and plastic DP-640 Brown Note: The technical information and data on these pages should be considered representative or typical only, and should not be used for specification purposes. (1) Color is mixed if two-part product. (2) Brookfield viscometer viscosity values are typical values for the mixed product. (3) The time during which an adhesive will adequately wet-out on a substrate. (4) 180° peel tested on .030" aluminum per ASTM D 1876-61T. (5) Tested per ASTM D 1002-64. (6) Tested at 200°F (93°C). (6) (6) (6) Duo-Pak Cartridges Product Information: 3M™ Scotch-Weld™Adhesives in Duo-Pak Cartridges (cont.) Features DP-8005 • Structurally bonds polyolefins without Off-White, surface preparation • Excellent Black environmental resistance • 2-3 hour handling strength 10:1 Approximate Viscosity 75°F (24°C) (CPS) (2) 27,500 Approximate Worklife At 75°F (24°C) Average (4) T-Peel At 75°F (24°C) PIW 2.5-3 Min. 16 (3) (5) Overlap Shear Strength PSI -67°F (-55°C) – 75°F (24°C) 180°F (82°C) 2000 340 250°F (121°C) – Product Information: 3M™ Scotch-Weld™ Two-Part Structural Adhesives -67°F (-55°C) 75°F (24°C) 180°F (82°C) 250°F (121°C) 700,000 45 Min. 4 1400 2000 500 300 4:5 400,000 60 Min. 4 1500 3000 500 300 6:5 250,000 60 Min. 5 1500 3000 500 300 1:1 10,000 60 Min. 5 2000 3000 400 200 • Long worklife adhesive • Rigid epoxy • 8-12 hrs. handling strength • Excellent void filler and machinable for many "Body Solder" applications 3:2 1838 B/A Green • Long worklife adhesive • Rigid epoxy • 8-12 hrs. handling strength • Meets MIL-A-23941A • Excellent Environmental Resistance 1838 B/A Tan • Long worklife adhesive • Rigid epoxy • 8-12 hrs. handling strength • Tan version of B/A 1838 Green Adhesive 1751 B/A Gray Two-Part Epoxy Adhesives Average (4) T-Peel At 75°F (24°C) PIW Approximate Viscosity 75°F (24°C) (CPS) Features 1838-L B/A • Long worklife adhesive • Rigid epoxy Translucent • 8-12 hrs. handling strength • Translucent, low viscosity version of 1838 B/A Green Adhesive (5) Approximate Worklife At 75°F (24°C) Mix Ratio (Volume) B:A Product(1) (Color) Two-Part Urethane Adhesives 8 Product(1) (Color) Mix Ratio (Volume) B:A (2) (3) Overlap Shear Strength PSI 2158 B/A Gray • Long worklife adhesive • Rigid epoxy • 8-12 hrs. handling strength • General purpose product 1:1 375,000 120 Min. 4 1700 2000 400 300 2216 B/A Gray • Long worklife adhesive• Flexible epoxy • 8-12 hrs. handling strength • Can bond plastic, metal and other dissimilar materials 2:3 80,000 90 Min. 25 2000 2500 400 200 2216 B/A Tan Non sag • Long worklife adhesive• Flexible epoxy • 8-12 hrs. handling strength • Tan version of 2216 B/A Gray Adhesive 2:3 350,000 90 Min. 25 2000 2500 400 200 2216 B/A • Long worklife adhesive• Flexible epoxy Translucent • 16-20 hrs. handling strength • Translucent version of 2216 B/A Gray Adhesive 1:1 10,000 120 Min. 25 3000 2000 200 100 3501 B/A Gray • Fast cure adhesive • Rigid epoxy • 20-30 minutes handling strength • Rapid room temperature curing material that can bond metal, wood, most plastics and masonry products 1:1 500,000 7 Min. 5 1500 2400 300 200 3532 B/A Brown • Fast cure adhesive • 20-30 min. handling strength • Semi-rigid urethane • Rapid cure for flexible bonds of many plastics, wood, and rubber 1:1 30,000 7 Min. 25 2500 2000 300 150 3535 B/A Off-White • Very fast cure adhesive • 15-20 min. handling strength • Semi-rigid urethane • Faster setting version of 3532 B/A Adhesive 1:1 30,000 3 Min. 25 2500 2000 300 150 3549 B/A Brown • Long worklife adhesive • 2-4 hrs. handling strength • Semi-rigid urethane • Longer worklife version of 3532 B/A Adhesive 1:1 30,000 60 Min. 25 2500 2000 300 150 Note: The technical information and data above should be considered representative or typical only, and should not be used for specification purposes. (1) Color is mixed if two-part product. (2) Brookfield viscometer viscosity values are typical values for the mixed product. (3) The time during which an adhesive will adequately wet-out on a substrate. (4) 180° peel tested on .030" aluminum per ASTM D 1876-61T. (5) Tested per ASTM D 1002-64. Product Information: 3M™ Scotch-Weld™ One-Part Epoxy Adhesives; Metal Primers (2) Optimum Cure Product (Color) One-Part Epoxy Adhesives Average T-Peel Pressure At 75°F (PSI) (24°C) Overlap Shear Strength PSI -67°F 75°F 180°F 250°F 350°F (-55°C) (24°C) (82°C) (121°C) (177°C) 1386 Cream A 350°F (177°C) curing epoxy for metal to metal bonding provides exceptionally high strength, impact resistant bonds. Meets requirements of MMM-A-134 Type III. 150,000 cps 60 350/177 10 10 (Alum.) 3000 5500 4500 2500 400 1469 Cream A 350°F (177°C) curing epoxy with excellent performance at elevated temperatures. Meets requirements of MMM-A-132 Type II, Class 3, Group 4. 60,000 cps 120 350/177 10 2 (Alum.) 3150 3700 3700 3600 1000 2086 Gray A 350°F (177°C) curing epoxy similar to 1386 Adhesive but filled to provide excellent flow control. Paste 60 350/177 10 5 (Alum.) 3000 5000 5000 2200 500 Aluminum filled heat curing (250°F, 121°C) structural adhesive of paste consistency. Can bond metals, glass and many plastics. Paste 60 250/121 10 5 (Alum.) 50 (Steel) 3000 4500 4500 1500 400 2214 Similar to 2214 regular adhesive but Hi-Density deaerated and formulated to provide Gray dense, void-free bond lines. Paste 60 250/121 10 5 (Alum.) 50 (Steel) 3000 4500 4500 1700 400 2214 Regular Gray 9 2214 Hi-Temp Original Gray Formulated to provide outstanding performance at elevated temperatures and excellent sag control. Paste 60 250/121 10 2 (Alum.) 5 (Steel) 2000 2000 3000 2500 900 2214 Hi-Temp New Formula Gray A version of 2214 Hi-Temp Adhesive with exceptional performance at elevated temperatures and excellent performance under high temperature and high humidity conditions. Resists attack by hot ethylene glycol. Paste 60 250/121 10 5 (Alum.) 5 (Steel) 2800 2800 2500 2000 1200 Similar to 2214 Regular Adhesive but deaerated and formulated to provide bonds featuring outstanding shock resistance. Paste 60 250/121 10 10 (Alum.) 65 (Steel) 2500 4000 2000 450 250 2214 NonMetallic Filled Cream A cream colored non-metallic version of 2214 Regular Adhesive suggested for electrical applications where insulating qualities are desired. Paste 60 250/121 10 7 (Alum.) 12 (Steel) 3000 4000 4500 1500 400 2290 Amber A 21% solids liquid epoxy. B-stageable. Can be used in laminating steel cores for motor stators and rotors. Excellent for many thin metal stack laminations such as those used in magnetic tape heads. 60 cps 30 350/177 50 10 (Alum.) 5000 5000 3500 1200 200 2214 Hi-Flex Gray Product Color Metal Primers Time Temp Viscosity (Min.) (°F/°C) Features (1) 3901 Red 1945 B/A Green Features Viscosity Comments • Adhesion promoter • Organo-silane base • Brush or spray application 5 CPS A primer for film and liquid adhesives in those applications where it is desired to obtain improved metal and glass adhesion or improved resistance to environmental exposure with epoxy and urethane adhesives. It can help simplify production scheduling by protecting the cleaned surfaces until the bonding operations can be completed and imparts improved corrosion protection to metal. • 1:1 mix ratio 2-part epoxy primer • 8 hour potlife • Brush, spray or dip application 500 CPS It is a two-part chemically curing, corrosion resistant primer to improve adhesion of urethanes and epoxies to many metals as well as offering increased corrosion protection. It cures at room temperature and has excellent adhesion to many metals. Note: The technical information and data on these pages should be considered representative or typical only, and should not be used for specification purposes. (1) Tested per ASTM D 1876-61T. (2) Tested per ASTM D 1002-64.