Electrical - Beaumont Health System

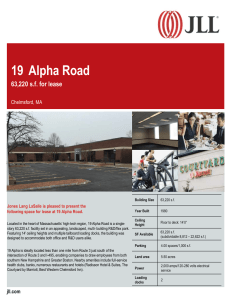

advertisement