military - Carling Technologies

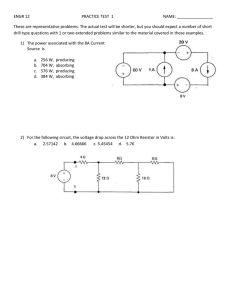

advertisement