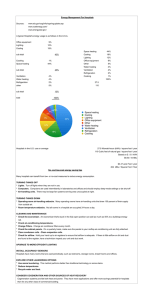

Air Handling Units

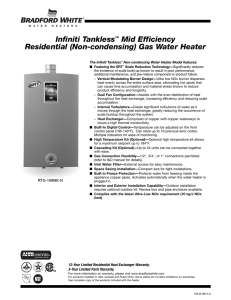

advertisement