Nuaire Catalogue - Air Handling Units - Ecosmart BOXER

advertisement

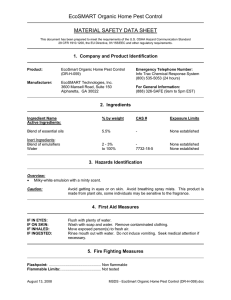

Nuaire AHU_Layout 1 12/08/2011 10:29 Page 98 E CO SM A RT B OX E R A HU STANDARD CONFIGURATIONS COMPLETE PACKAGED AIR HANDLING UNITS WITH ALL THE NECESSARY CONTROLS. 98 029 2085 8200 Nuaire AHU_Layout 1 12/08/2011 10:29 Page 99 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMART B OXER TEC H NI C A L I NF O R MATI O N B E NE F I T S VERY QUIET PART L AND ENERGY EFFICIENT COIL OPTIONS 25mm double skinned panels provide better acoustic and thermal properties over conventional AHU’s. Fan impellers are selected for optimum efficiency and noise characteristics. Motors are IE2 to BS 5000 direct drive and high efficiency belt drive. DX & chilled water coils are available, call Nuaire for further details. Note: Undressed coils are also available. REDUCE INSTALLATION TIME IMPROVED LIFE CYCLE/NO SYSTEM OVERLOADS WARRANTY All components are pre-assembled, wired and tested at the Nuaire manufacturing facility. Units are delivered conveniently in sections for easy site assembly. Ecosmart Boxer has a 5 year warranty. Ecosmart is pre-programmed to automatically give a soft start function which prevents electrical overloading and minimises mechanical wear. SIMPLE PRECISE COMMISSIONING LONG LASTING Minimum and maximum ventilation rates precisely set and limited at AHU requiring no throttling dampers. Each section is manufactured from a highly rigid pentapost framework with heavy gauge AluzincY, corrosion resistant steel panels. ENERGY EFFICIENT CONSTANT PRESSURE CONTROL AVAILABLE All models have Ecosmart controls built in, which provide the most energy efficient and cost effective solution. For further information contact Nuaire. ANCILLARIES & COMPONENT OPTIONS: Weather terminals. Silencers. Dampers. Vertical and horizontal heat exchangers. Base frames. DX Coils. Monometrer. Filter sizes 1 & 2 = G4 panel, sizes 3 - 7 = G4 bag or G4 bag & F7 bag. nuaire.co.uk 99 Nuaire AHU_Layout 1 12/08/2011 10:29 Page 100 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMA RT B OXER TEC H NI C A L I NF O R MATI O N PERFORMANCE - ECOSMART BOXER SIZES 1 and 2 Casing Ecosmart Boxer supply unit filter and heating coil 600 Tested in duct 500 ISO 5801 2007 Fan Static Pressure (Pa) V 400 1H 2H 300 200 2 1 Ecosmart Boxer sizes 1 and 2. 100 0 0 0.5 1.0 1.5 Air volume flow rate (m3/s) ESBH S - 2 - LC | | | | Ecosmart Boxer supply Unit filter and heating and cooling coil 1 600 Tested in duct V Fan Static Pressure (Pa) 500 ISO 5801 2007 400 1H 2H 300 200 2 1 100 0 0 0.5 1.0 1.5 Air volume flow rate (m3/s) Ecosmart Boxer fan unit only 600 V Fan Static Pressure (Pa) ISO 5801 2007 400 1H 2H 300 200 2 1 100 0 0 0.5 1.0 Air volume flow rate (m /s) 3 100 029 2085 8200 2 3 4 1. Ecosmart Boxer range 2. S = Supply EX = Extract 3. Size 1 - 2 4. L = Low Pressure hot water heater battery LC = Low Pressure hot water heater battery and CHCW chilled water cooling coil LD = Low Pressure hot water heater battery and DX cooling coil ED = Electric heater battery and DX = Direct expansion (refrigerant type coil) Note: If no Ecosmart control is required example code would be: BHS2NC-LC. If fan control only is required (undressed coils) example code would be: BHS2FC-LC. Tested in duct 500 Code descriptions 1.5 AIR HANDLING UNITS (AHU’S) ECOSMART BOXER TECHNIC AL INFORMATION PERFORMANCE - ECOSMART BOXER SIZES 1 and 2 ELECTRIC AL & SOUND Curve Motor Rating (kW) Electric Coil Data (kW) Fan Input Power (watts) Type Ducted sound power levels dB re 1pW Data 125 250 500 1K 2K RPM 1 1.28 18 1110 1272 1H 1.13 18 1620 2 1.6 24 2H 1.6 24 4K 8K I inlet O outlet 73 77 67 75 57 77 59 78 59 78 54 73 45 67 25 1480 I inlet O outlet 72 77 66 74 62 75 58 76 58 76 52 72 42 64 24 1620 960 I inlet O outlet 72 77 66 74 62 75 58 76 58 76 52 72 42 64 24 1600 1065 I inlet O outlet 79 81 74 81 69 76 69 76 65 72 60 69 54 63 33 EXTRACT Curve Breakout dBA@ 3m SUPPLY WITH ELECTRIC HEATER Code Phase FLC (amps) SC (amps) Curve Code Phase Total FLC (amps) Total SC (amps) 1 ESBHEX1 1 4.84 4.84 1 ESBHS1-E 3 29.9 4.9 1H ESBHEX1H 1 7.3 7.3 1H ESBHS1H-E 3 32.2 7.22 2 ESBHEX2 1 6.4 6.4 2 ESBHS2-E 3 40.7 7.32 2H ESBHEX2H 1 9.4 9.4 2H ESBHS2H-E 3 42.8 9.4 SUPPLY WITH ELECTRIC HEATER & COOLING COIL Curve Code Phase FLC (amps) SUPPLY WITH ELECTRIC HEATER & DX COOLING COIL SC (amps) Curve Code FLC (amps) Phase SC (amps) 1 ESBHS1-EC 3 29.5 4.8 1 ESBHS1-ED 3 29.5 4.84 1H ESBHS1H-EC 3 32.2 7.2 1H ESBHS1H-ED 3 32.2 7.22 2H ESBHS2H-EC 3 42.4 9.0 2 ESBHS2-ED 3 40.7 7.32 2H ESBHS2H-ED 3 42.8 9.4 SUPPLY WITH LPHW HEATER Curve Code Phase Flow valve setting FLC (amps) SC (amps) 1 ESBHS1-L 1 4.84 4.84 1H ESBHS1H-L 1 7.2 7.2 2 ESBHS2-L 1 6.4 6.4 2H ESBHS2H-L 1 9.0 9.0 SUPPLY WITH LPHW HEATER & DX COOLING COIL Curve Code Phase FLC (amps) SC (amps) 1 ESBHS1-LD 1 0.0 0.0 1H ESBHS1H-LD 1 5.2 5.2 2 ESBHS2-LD 1 0.0 0.0 2H ESBHS2H-LD 1 9.4 9.4 SUPPLY WITH LPHW HEATER & COOLING COIL Curve Code Phase FLC (amps) SC (amps) 1 ESBHS1-LC 3 4.84 4.84 1H ESBHS1H-LC 3 5.2 5.2 2 ESBHS2-LC 3 6.4 6.4 2H ESBHS2H-LC 3 9.0 9.0 Download specification from www.nuaire.co.uk/specifications DX COIL DATA Unit Size Max Air kW Evap. Flow Rating temp m3/s R407C deg C PD Conn through size Coil KPa 1 0.4 8 5 10 2x12&16od 2 0.7 13.5 5 16 2x12&22od Unit Size Frost Coils In Out Cooling Coils In Out Heating Coils In Out 1 0.75BSP 0.75BSP 1 BSP 1 BSP 1.25BSP 1.25BSP 2 0.75BSP 0.75BSP 1.25BSP 1.25BSP 1.25BSP 1.25BSP For wiring diagrams refer to pages 110. nuaire.co.uk 101 Nuaire AHU_Layout 1 12/08/2011 10:29 Page 102 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMA RT B OXER TEC H NI C A L I NF O R MATI O N DIMENSIONS AND CONFIGURATIONS Length Ecosmart BOXER sizes 1 and 2 B DI ME N S I ON S ( m m ) & W E I GH T S ( K G) ESBHEX* ESBHS*L/E Size L W L W ESBHS* LC/LD, ED/EC Heating & Cooling L W B C 1 700 84 1000 132 1600 170 954 530 400 342 2 1000 117 1130 185 1730 264 954 670 500 342 D dia D1 NB: Units are handed left hand side as standard. (L=Length, W=Weight). Right hand side is available on request. C D dia For component ‘Z’ factors please refer to page 109. D1 Airflow Airflow Model shown: size 1 and 2 (right hand extract). Model shown: size 1 and 2 (left hand extract). Model shown: size 1 and 2 (right hand LPHW supply). Model shown: size 1 and 2 (left hand LPHW supply). Model shown: size 1 and 2 (right hand electric supply). Model shown: size 1 and 2 (left hand electric supply). 102 029 2085 8200 Nuaire AHU_Layout 1 12/08/2011 10:29 Page 103 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMART B OXER TEC H NI C A L I NF O R MATI O N PERFORMANCE - ECOSMART BOXER SIZES 3 - 7 Casing Ecosmart Boxer supply unit filter and heating coil 1200 Tested in duct V Fan Static Pressure (Pa) 1000 ISO 5801 2007 800 7 600 6 4 400 5 3 Ecosmart Boxer sizes 3 - 7 200 0 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 Air volume flow rate (m3/s) ESBH S - 3 - LC | | | | Ecosmart Boxer Supply unit filter and heating and cooling coil 1200 Tested in duct 1000 ISO 5801 2007 Code descriptions 1 2 3 4 Fan Static Pressure (Pa) V 800 7 600 6 400 5 4 3 200 0 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 Air volume flow rate (m3/s) Ecosmart Boxer fan unit only 1200 Note: If no Ecosmart control is required example code would be: BHS3NC-LC. If fan control only is required (undressed coils) example code would be: BHS3FC-LC. Tested in duct V Fan Static Pressure (Pa) 1000 ISO 5801 2007 800 6 600 5 1. Ecosmart Boxer range 2. S = Supply EX = Extract 3. Size 3 - 7 4. L = Low Pressure hot water heater battery LC = Low Pressure hot water heater battery and CHCW chilled water cooling coil LD = Low Pressure hot water heater battery and DX cooling coil ED = Electric heater battery and DX = Direct expansion (refrigerant type coil) Please note: Sizes 3 - 7 do not have filters included as standard. 7 4 400 3 200 0 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 Air volume flow rate (m /s) 3 N.B. Unit air volume flowrates are calculated by component velocity. Download specification from www.nuaire.co.uk/specifications nuaire.co.uk 103 Nuaire AHU_Layout 1 12/08/2011 10:30 Page 104 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMA RT B OXER TEC H NI C A L I NF O R MATI O N PERFORMANCE - ECOSMART BOXER SIZES 3 - 7 E L E C T R I C A L & S OU N D Curve Motor Rating (kW) Electric Coil Data (kW) Fan Input Power (watts) RPM Type Ducted sound power levels dB re 1pW Data 125 250 500 1K 2K Pole Phase 3 2.2 27 1.584 1920 4 3 4 3 36 2.407 2160 2 5 4 54 3.132 2340 6 4 54 4.035 7 5.5 54 5.177 Breakout dBA@ 3m 4K 8K I inlet O outlet 84 87 81 82 82 81 76 75 73 71 67 66 62 62 40 3 I inlet O outlet 87 90 84 85 85 84 79 78 76 74 70 69 65 65 43 2 3 I inlet O outlet 89 92 86 87 87 86 81 80 78 76 72 71 67 67 45 1780 4 3 I inlet O outlet 84 84 86 84 83 84 80 85 77 80 72 74 65 66 43 1630 4 3 I inlet O outlet 86 87 91 90 85 87 81 86 79 82 74 75 69 70 45 C ODI N G Supply with LPHW Heater & Cooling Coil Code Supply with LPHW Heater & DX Cooling Coil Code FLC (amps) SC (amps) Curve Extract Code Supply with LPHW Heater Code 3 ESBHEX3 ESBHS3-L ESBHS3-LC ESBHS3-LD 5 5 4 ESBHEX4 ESBHS4-L ESBHS4-LC ESBHS4-LD 7 7 5 ESBHEX5 ESBHS5-L ESBHS5-LC ESBHS5-LD 8 8 6 ESBHEX6 ESBHS6-L ESBHS6-LC ESBHS6-LD 8.5 8.5 7 ESBHEX7 ESBHS7-L ESBHS7-LC ESBHS7-LD 11 11 Flow valve setting. C ODI N G DX COIL DATA Curve Supply with Electric Heater & DX Cooling Coil Code Supply with Electric Heater Code Supply with Electric Heater & Cooling Coil FLC Code (amps) SC (amps) Unit Size Max Air kW Evap. PD Conn Flow Rating temp through size m3/s R407C deg C Coil KPa 3 4 ESBHS3-ED ESBHS3-E ESBHS3-EC 5 27 3 1.0 19 5 18 2x12&22od ESBHS4-ED ESBHS4-E ESBHS4-EC 57 7 4 1.4 27 5 15 2x12&28od 5 ESBHS5-ED ESBHS5-E ESBHS5-EC 83 8 5 1.9 37 5 13 2x22&35od 6 ESBHS6-ED ESBHS6-E ESBHS6-EC 83.5 8.5 6 2.5 48 5 11 2x22&35od 7 ESBHS7-ED ESBHS7-E ESBHS7-EC 86 11 7 3.5 68 5 11 2x22&42od Z FAC TOR S FOR A N C I L L A R I E S Casing Module 1 2 3 4 5 6 7 Unit Size Frost Coils In Out Cooling Coils In Out Heating Coils In Out Silencer 102 41 20 11 8 3.1 2 3 1 BSP 1 BSP 1.25BSP 1.25BSP 1.25BSP Damper 61 25 12 6.8 4.8 1.9 1.2 4 1 BSP 1 BSP 1.25BSP 1.25BSP 1.5BSP 1.5BSP Frost coil LPHW 122 50 23 14 9.6 3.8 2.4 5 1.25BSP 1.25BSP 1.5BSP 1.5BSP 2 BSP 2 BSP Frost coil electric 122 50 23 14 9.6 3.8 2.4 6 1.25BSP 1.25BSP 2 BSP 2 BSP 2 BSP 2 BSP Weather cowl 61 25 12 6.8 4.8 1.9 1.2 7 1.5BSP 1.5BSP 2 BSP 2 BSP 2 BSP 2 BSP Plate heat exchanger 612 148 117 68 48 1.9 12 H or V For wiring diagrams refer to pages 110. 104 029 2085 8200 1.25BSP Nuaire AHU_Layout 1 12/08/2011 10:30 Page 105 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMART B OXER TEC H NI C A L I NF O R MATI O N DIMENSIONS AND CONFIGURATIONS B Length Ecosmart BOXER size 3 - 7 DI ME N S I ON S ( m m ) & W E I GH T S ( K G) ESBHEX* Size L W ESBHS*L/E ESBHS* Heating & Cooling L W L W B C E F G H 3 1200 199 2400 402 3000 529 800 800 373 403 600 350 4 1200 243 2400 442 3000 590 1000 800 373 535 600 450 5 1200 255 2400 490 3000 600 1000 1000 373 535 600 450 6 1500 390 2700 702 3300 858 1300 1000 557 479 600 500 7 1500 507 2700 913 3300 1115 1300 1300 638 638 600 500 F C E H NB: Units are handed left hand side as standard. (L=Length, W=Weight). Right hand side is available on request. Airflow Airflow Model shown: size 7 (right hand with cooling coil). Model shown: size 7 (left hand with cooling coil). Model shown: size 7 (right hand with DX cooling coil). Model shown: size 7 (left hand with DX cooling coil). Model shown: size 7 (right hand supply with electric heater). Model shown: size 7 (left hand supply with electric heater). Download specification from www.nuaire.co.uk/specifications G nuaire.co.uk 105 Nuaire AHU_Layout 1 12/08/2011 10:30 Page 106 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMA RT B OXER TEC H NI C A L I NF O R MATI O N ECOSMART BOXER SIZES 3 - 7 Model shown: size 7 (right hand supply with electric heater and cooling coil). Model shown: size 7 (left hand supply with electric heater and cooling coil). Model shown: size 7 (right hand supply with electric heater and DX coil). Model shown: size 7 (left hand supply with electric heater and DX coil). Model shown: size 7 (right hand supply with LPHW heater). Model shown: size 7 (left hand supply with LPHW heater). Model shown: size 7 (right hand supply with LPHW heater and cooling coil). Model shown: size 7 (left hand supply with LPHW heater and cooling coil).). 106 029 2085 8200 Nuaire AHU_Layout 1 12/08/2011 10:30 Page 107 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMART B OXER TEC H NI C A L I NF O R MATI O N ECOSMART BOXER SIZES 3 - 7 Model shown: size 7 (right hand supply with LPHW heater and DX cooling coil). Model shown: size 7 (left hand supply with LPHW heater and DX cooling coil). Model shown: size 7 (right hand with extract). Model shown: size 7 (left hand with extract). Please note: Sizes 3 - 7 do not have filters included as standard. Download specification from www.nuaire.co.uk/specifications nuaire.co.uk 107 Nuaire AHU_Layout 1 12/08/2011 10:30 Page 108 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMA RT B OXER C O I L S F O R L P H W ECOSMART BOXER Size 1 and 2 Air Volume Flow rate (m3/s) Water Heat Air Off on/off Air On Output C C C (kW) C -3 25 31 3 11.5 35 82/71 9 21 38 15 19.2 41 60/40 2 ROW 0.6 Water flow rate (l/s) 0.556 0.514 0.472 0.428 Water dp (kPa) 11.5 10 8.6 7.3 Heat Air Off Output C (kW) C 19 36 17.6 39 16 42 14.8 45 0.4 Water flow rate (l/s) 0.424 0.392 0.36 0.32 Water dp (kPa) 7.1 6.3 5.4 4.6 Heat Air Off Output C (kW) C 10.8 41 10 44 9.2 47 8.4 50 0.2 Water flow rate (l/s) 0.242 0.224 0.206 0.188 Water dp (kPa) 2.74 2.40 2.08 1.78 22 mm -3 3 9 15 21.4 19.4 17.6 15.6 26 30 33 36 0.26 0.238 0.214 0.19 3.2 2.72 2.27 1.85 16 15 13.4 12 30 33 36 39 0.2 0.182 0.164 0.146 1.98 1.69 1.41 1.16 9.4 8.6 7.8 7 35 38 41 43 0.114 0.104 0.094 0.084 0.76 0.65 0.55 0.45 15 mm -3 3 9 15 14 12 10 8 16 20 23 26 0.17 0.146 0.122 0.096 1.53 1.18 0.87 0.58 10.6 9.2 7.6 6 19 22 24 27 0.13 0.112 0.092 0.072 0.95 0.74 0.53 0.35 6 5 4 3.6 21 24 26 28 0.072 0.062 0.05 0.046 0.35 0.27 0.19 0.16 15 mm ECOSMART BOXER Size 3 Air Volume Flow rate (m3/s) Water Heat Air Off on/off Air On Output C C C (kW) C -3 60 26 82/71 3 55 29 9 50 33 15 45 37 Connection size 80/60 Connection size TEC H NI C A L I NF O R MATI O N 2 ROW 1.7 Water flow rate (l/s) 1.32 1.22 1.1 0.97 Water dp (kPa) 11 9.6 8.2 7 Heat Air Off Output C (kW) C 54 31 50 35 46 38 41 41 1.3 Water flow rate (l/s) 1.2 1.1 1 0.92 Water dp (kPa) 9.4 8.3 7.2 6.2 Heat Air Off Output C (kW) C 46 35 43 38 40 41 36 44 1 Water flow rate (l/s) 1 0.96 0.88 0.8 Water dp (kPa) 7.4 6.6 5.8 5 1.25” -3 3 9 15 50 45 40 35 21 25 28 32 0.61 0.55 0.49 0.43 3.4 2.83 2.37 1.93 45 41 37 33 26 29 32 36 0.56 0.5 0.45 0.4 2.9 2.42 2.06 1.71 39 36 32 28 29 32 35 38 0.48 0.44 0.39 0.35 2.33 2.07 1.72 1.45 1” 60/40 -3 3 9 15 32 27 22 17 12 16 20 23 0.39 0.33 0.27 0.2 1.66 1.28 0.94 0.59 29 25 20 15 15 19 22 24 0.35 0.3 0.24 0.19 1.39 1.10 0.78 0.54 25 21 17 14 17 20 23 26 0.3 0.26 0.21 0.16 1.14 0.92 0.66 0.43 1” 2 ROW 2.1 Water flow rate (l/s) 2.1 1.9 1.78 1.62 Water dp (kPa) 12.9 11.3 9.8 8.4 Heat Air Off Output C (kW) C 86 36 79 39 73 42 67 45 1.8 Water flow rate (l/s) 1.9 1.77 1.63 1.48 Water dp (kPa) 11 9.7 8.5 7.3 Heat Air Off Output C (kW) C 72 39 67 42 61 45 56 48 1.4 Water flow rate (l/s) 1.6 1.48 1.36 1.24 Water dp (kPa) 8.2 7.3 6.4 5.5 80/60 -3 3 9 15 81 74 67 60 29 32 35 38 0.99 0.91 0.82 0.73 3.9 3.4 3.00 2.51 74 68 61 55 31 34 37 40 0.91 0.83 0.75 0.67 3.4 3.05 2.60 2.19 62 57 51 46 34 37 39 42 0.76 0.69 0.63 0.56 2.59 2.23 1.93 1.61 60/40 -3 3 9 15 54 47 39 32 18 21 24 27 0.66 0.57 0.48 0.38 2.15 1.71 1.31 0.91 49 43 36 29 19 22 25 28 0.6 0.52 0.43 0.35 1.84 1.48 1.10 0.80 41 36 30 24 21 24 26 29 0.5 0.43 0.36 0.29 1.35 1.07 0.81 0.58 ECOSMART BOXER Size 6 Air Volume Flow rate (m3/s) Water Heat Air Off on/off Air On Output C C C (kW) C -3 157 30 3 144 34 82/71 9 132 37 15 119 40 1.25” 1.25” 2 ROW 3.9 Water flow rate (l/s) 3.5 3.2 2.9 2.6 Water dp (kPa) 11.8 10.4 9.1 7.9 Heat Air Off Output C (kW) C 139 35 128 38 117 41 106 44 3 Water flow rate (l/s) 3.1 2.85 2.61 2.36 Water dp (kPa) 9.9 8.8 7.7 6.7 Heat Air Off Output C (kW) C 106 40 98 43 90 46 81 48 2 Water flow rate (l/s) 2.35 2.17 1.99 1.8 Water dp (kPa) 6.6 5.9 5.3 4.6 80/60 -3 3 9 15 131 118 106 93 25 28 31 35 1.6 1.44 1.29 1.13 3.9 3.4 2.92 2.42 116 105 94 83 29 32 35 38 1.42 1.28 1.15 1 3.3 2.87 2.47 2.03 89 81 72 64 33 36 38 41 1.1 0.99 0.88 0.78 2.28 1.97 1.67 1.41 60/40 -3 3 9 15 83 70 56 42 14 18 21 24 1 0.85 0.68 0.51 2.04 1.63 1.19 0.80 73 62 50 37 17 20 23 25 0.89 0.75 0.61 0.45 1.73 1.36 1.02 0.66 56 47 37 25 20 22 24 25 0.67 0.57 0.45 0.31 1.14 0.91 0.65 0.39 ECOSMART BOXER Size 7 Air Volume Flow rate (m3/s) Water Heat Air Off on/off Air On Output C C C (kW) C -3 201 31 3 184 35 82/71 9 168 38 15 151 41 2” 2 ROW 4.8 Water flow rate (l/s) 4.5 4.1 3.7 3.4 Water dp (kPa) 13 11.2 9.8 8.4 Heat Air Off Output C (kW) C 189 34 174 37 158 40 143 43 4.2 Water flow rate (l/s) 4.2 3.9 3.5 3.2 Water dp (kPa) 11.7 10.3 9 7.7 Heat Air Off Output C (kW) C 166 40 153 42 139 45 125 47 3.2 Water flow rate (l/s) 3.7 3.4 3.1 2.8 Connection size Air Volume Flow rate (m3/s) Water Heat Air Off on/off Air On Output C C C (kW) C -3 94 34 3 87 37 82/71 9 80 40 15 73 43 Water dp (kPa) 9.6 8.5 7.5 6.4 80/60 -3 3 9 15 161 145 128 111 25 28 31 34 1.97 1.77 1.56 1.36 4 3.5 2.95 2.43 152 137 121 106 27 30 33 36 1.86 1.67 1.48 1.29 3.8 3.3 2.72 2.24 134 121 107 93 32 34 37 39 1.64 1.48 1.31 1.14 3.2 2.66 2.24 1.85 60/40 -3 3 9 15 96 79 61 39 13 16 19 22 1.16 0.96 0.74 0.48 1.95 1.49 1.04 0.57 91 75 58 36 15 18 20 22 1.1 0.91 0.7 0.43 1.79 1.37 0.95 0.48 80 66 50 29 18 20 22 23 0.97 0.8 0.61 0.35 1.47 1.12 0.77 0.35 2” 1.5” 1.5” For further assistance please call Nuaire. Note: dp figures do not include 3 port valve. Approximately double these figures when valves are included. Connection size ECOSMART BOXER Size 5 Connection size 80/60 2” 1.5” 1.5” *Please note: above tables are based on indicative selections. For more specific selection, contact Nuaire. 108 029 2085 8200 Nuaire AHU_Layout 1 12/08/2011 10:30 Page 109 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMART B OXER A NC I L L A R I ES TEC H NI C A L I NF O R MATI O N SILENCER MODULES MOTORISED DAMPERS VERTICAL HEAT EXCHANGER Splitters are faced with perforated sheet lined to prevent particle migration and filled with high density mineral wool. Opposed blade design with quick fit flanges. 240V Open/Shut model (B) for efficient back draught protection and 24V modulating version (M) for balancing and control. A plate exchanger core assembly providing efficient heat transfer between supply and extract air streams. An integral drip tray is incorporated with a 22mm drain connection. The tray is insulated to prevent secondary condensation. B B A A A C B C C Unit Code A B C Weight (Kg) Unit A Weight (Kg) ESBSIL1 900 954 530 70 ESBD1 165 12 ESBSIL2 900 954 670 90 ESBD2 165 14 ESBSIL3 900 800 800 Length Width Height A B C Weight (Kg) ESBHX1 1000 954 1060 150 ESBHX2 1130 954 1340 180 ESBHX3 1200 800 1600 210 ESBHX4 1400 1000 1600 263 ESBHX5 2200 1000 2000 360 ESBHX6 2200 1300 2000 440 Also available: motor open/spring return option. Code: ESBD* MO/SR. ESBHX7 2500 1300 2600 594 ESBD3 95 165 19 ESBSIL4 900 1000 800 96 ESBD4 165 23 ESBSIL5 900 1000 1000 124 ESBD5 165 28 ESBSIL6 900 ESBSIL7 900 1300 1000 1300 1300 ESBD6 150 ESBD7 192 165 165 Unit 30 34 Note: Dimensions B & C are to suit unit supplied. DYNAMIC ATTENUATION VALUES (at maximum velocity) Length 125 250 500 1K 2K 4K 8K 900 6 8 18 22 20 16 15 FROST COIL = LPHW & ELECTRIC HORIZONTAL HEAT EXCHANGER 1200 7 11 26 31 30 23 20 600mm long section to suit unit size selected. For details contact Nuaire. Heat exchanger complete with integral drop tray with a 22mm drain connection. Note: silencer cross sectional area matches the Ecosmart Boxer unit. A WEATHER ROOF FOR ECOSMART BOXER B For further information please contact Nuaire. C Length Width Height A B C Weight (Kg) ESBHX1H 1750 2000 530 150 ESBHX2H 1425 2000 670 180 ESBHX3H 1200 1600 800 200 ESBHX4H 1625 2000 800 280 ESBHX5H 2000 2000 1000 360 ESBHX6H 2200 2600 1000 600 ESBHX7H 2200 2600 1300 594 Unit Example of horizontal unit with weather kit. Example of stacked unit with weather kit. ESBBF2* - Available in a variety of lengths to suit unit sizes 1 - 7. BASE FRAME Z FAC TOR S FOR A N C I L L A R I E S Casing Module 1 2 3 4 5 6 7 Silencer 102 41 20 11 8 3.1 2 Damper 61 25 12 6.8 4.8 1.9 1.2 Frost coil LPHW 122 50 23 14 9.6 3.8 2.4 Frost coil electric 122 50 23 14 9.6 3.8 2.4 Weather cowl 61 25 12 6.8 4.8 1.9 1.2 Plate heat exchanger 612 148 117 68 48 1.9 12 (Please contact Nuaire for further details). Provided as standard on sizes 3 - 7. Optional extras on sizes 1 and 2. 80mm For further ancillaries please refer to Ducting and Ancillaries section or call Nuaire. Download specification from www.nuaire.co.uk/specifications nuaire.co.uk 109 Nuaire AHU_Layout 1 12/08/2011 10:30 Page 110 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMA RT B OXER W I R I NG TEC H NI C A L I NF O R MATI O N WIRING - ECOSMART BOXER SIZES 1 AND 2 WIRING - ECOSMART BOXER SIZES 1 AND 2 ESBHS1, ESBHS2, ESBHEX1 and ESBHEX2 ESBHS1-L, ESBHS2-L, ESBHS1-LD and ESBHS-2LD BMS signal Ecosmart N L SL Min 25 Fan 2 Coolin g Connections to Damper Fault Frost Fault signal Rx ON OFF Heat demand signal Run signal Fault signal NET connections for ECOSMART devices L N E 230V 50Hz 1ph mains Fan 1 Max SL run on Cooling Frost demand alarm signal signal Earth Cooling Fault 0 1 Frost Tx Trickle Test Rx NET connections for ECOSMART devices L N E 230V 50Hz 1ph mains Signal for DX2 coil if fitted Signal for DX1 coil if fitted Fan 2 Heating HEAT DEMAND Test Standby Min RET Tx Trickle Pw r FAULT RUN 1 AUTO HEATER/COOL Run signal DP CL N Heatin g 0 Ecosmart N L 0V 0-10V SL FAULT RUN Heat demand signal Max SL run on BMS signal 30 Fan 1 HEAT DEMAND Connections to Damper Pw r Standby DAMPER DP CL N RET Speed Controller 0V 0-10V 25 Speed Controller Remove this link wire if: 1. a switched live signal is connected. 2. an ES-PIR, ES-TC or BMS signal is connected. Set air off temperature of LPHW coil DAMPER Remove this link wire if: 1. a switched live signal is connected. 2. an ES-PIR, ES-TC or BMS signal is connected. Earth ESBHS1-E and ESBHS2-E Remove this link wire if: 1. a switched live signal is connected. 2. an ES-PIR, ES-TC or BMS signal is connected. Speed Controller BMS signal N L Do not set temperature above 30 OC SL DP CL N Connections to Damper Electric heater control 230V 50Hz 1ph mains L N E Trickle Test 0V 0-10V Pwr Standby Fan 1 Fan 2 Heating Cooling Fault Frost Tx Rx 5 6 7 8 9 10 11 12 13 14 15 Connections to Damper L3 L2 Brown 24 Vac Green 0 - 10 Vac Whi ite Common (U) L1 (V) (W) DP CL N RET This contact is not applicable to BMS models Run signal Fault signal NET connections for ECOSMART devices Earth A1 3 (V) 4 5 (W) 6 Earth Min 0 Max SL run on 1 Trickle Test Tx Test Rx NET connections for ECOSMART devices Earth 0V 0-10V Pwr Standby Fan 1 Fan 2 Heating Cooling Fault Frost Tx Rx 24 Vac Warning: connect via safety isolating transformer ~ 1 L3 Y1 0...10V DC Y2 0...20V phase cut U 2...10V DC 2 3 4 5 L2 L1 N 029 2085 8200 Frost Trickle NET connections for ECOSMART devices 1 (U) 2 A2 110 1 Actuator head, type Belimo model SM24-SR Ecosmart N L SL 12 13 14 15 DAMPER FAULT RUN HEAT DEMAND Fault signal 1 Fault L N E 230V 50Hz 1ph mains Remove this link wire L1 L2 L3 E CONTACTER This contact is not applicable to BMS models Run signal 0 Max SL run on Earth BMS signal for fan speed Note: Do not reverse the polarity as it may cause damage to the circuit Actuator DP CL N RET DAMPER FAULT RUN HEAT DEMAND Connections to Damper Min Cooling 0 E 400V 50Hz 3ph +N mains T Ecosmart N L SL L3 L2 L1 N E Fan 2 Heating T BMS signal for fan speed Note: Do not reverse the polarity as it may cause damage to the circuit Max SL run on BMS MODES 3 TO 7 Actuator head, type Honeywell model M7410E1028 Remove this link wire Fan 1 HEAT DEMAND Fault signal Speed Controller Standby Min FAULT RUN Run signal WIRING - ECOSMART BOXER SIZES 3 - 7 BMS MODES 1 AND 2 Pw r RET Heat demand signal 400V 50Hz 3ph +N mains supply for fan and heater Ecosmart DAMPER Adjustment for air off temperature. 0V 0-10V ~ Y1 Y2 U SM24-SR Nuaire AHU_Layout 1 12/08/2011 10:30 Page 111 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMART B OXER W I R I NG TEC H NI C A L I NF O R MATI O N WIRING - ECOSMART BOXER SIZES 3 - 7 ESBHS3-L,ESBHS4-L, ESBHS5-L, ESBHS6-L AND ESBHS7, ESBHS3-LD, ESBHS4-LD, ESBHS5-LD, ESBHS6-LD AND ESBHS7-LD 0-10V Ecosmart Pw r L 10 11 N Coolin g 1 L3 Run signal Fault signal (U) (V) Trickle Test (W) 7 8 9 10 11 N Heat demand signal L3 Run signal L2 (U) L1 Max SL run on Fault signal (V) (W) Fan 2 Heatin g Coolin g Faul t 0 1 Frost RET 12 13 14 15 Rx FAULT L2 L1 Tx RU N HEAT DEMAND Heat demand signal 5 6 Frost CL Connections to Damper Faul t 0 RET 12 13 14 15 12 13 14 15 Tx RUN HEAT DEMAND 7 8 9 Fan 1 Min DP Trickle Test Rx NET connections for Ecosmart devices NET connections for Ecosmart devices A1 CONTACTER CONTACTER 5 (W) 6 3 (V) 4 Set outlet air temperature of CW cooling coil 25 A2 25 GREEN BROWN WHITE 3 2 1 Connect to LPHW actuator motor SM24 motor set at position A 25 Set outlet air temperature of LPHW coil 5 (W) 6 25 25 Set air off temperature of LPHW coil A2 1 (U) 2 30 3 (V) 4 25 1 (U) 2 30 A1 30 5 6 CL Connections to Damper 12 13 14 15 Pw r Standby Fan 2 SL run on Heatin g DAMPER DP Max Ecosmart N SL Fan 1 Min 0-10V L Standby SL 0V BMS signal DAMPER N Remove this link wire if: 1. a switched live signal is connected. 2. an ES-PIR, ES-TC or BMS signal is connected. L1 L2 L3 E 0V BMS signal FAULT Remove this link wire if: 1. a switched live signal is connected. 2. an ES-PIR, ES-TC or BMS signal is connected. L1 L2 L3 E WIRING - ECOSMART BOXER SIZES 3 - 7 ESBHS3-LC, ESBHS4-LC, ESBHS5-LC, ESBHS6-LC AND ESBHS7-LC GREEN 3 BROWN A 2 WHITE 1 GREEN 3 BROWN 2 WHITE 400V 50Hz 3ph +N mains N E Earth Frost alarm signal Signal for DX2 coil if fitted Signal for DX1 coil if fitted L1 400V 50Hz 3ph +N mains N E Inlet Outlet sensor sensor Cooling demand signal L2 Connect to inlet sensor after unit is assembled Inlet sensor Cooling demand signal A Frost alarm signal Signal for DX2 coil if fitted Signal for DX1 coil if fitted 1 ON OFF L1 L3 AUTO HEATER/COOL L2 Earth ON OFF AUTO HEATER/COOL L3 Connect to LPHW actuator motor SM24 motor set at position A A Connect to CW coil actuator motor SM24 motor set at position A A Outlet sensor Connect to inlet sensor after unit is assembled A ESBHS3-E, ESBHS4-E, ESBHS5-E, ESBHS6-E AND ESBHS7-E ESBHEX3, ESBHEX4, ESBHEX6 AND ESBHEX7 A Remove this link wire if: 1. a switched live signal is connected 2. an ES-PIR, ES-TC or BMS signal is connected. 0V BMS signal SL DP N RET (U) (V) (W ) Heat demand signal Run signal Fault signal Frost Test L3 Coolin g N (U) L1 (V) Fault signal 5 L3 (W ) 6 L2 L1 N A2 E 400V 50Hz 3ph +N mains 1 Test Rx 1 (U) 2 3 (V) 4 T Adjustment for air off temperature. Do not set temperature above 30OC NET connections for ECOSMART devices 5 (W) 6 LINE 1 LINE 2 L1 L2 LINE 3 Earth L3 E 400V 50Hz 3ph supply for heater B A2 L3 L2 L1 N E Download specification from www.nuaire.co.uk/specifications R Frost Tx Trickle HEAT SENS NET connections for ECOSMART devices Earth 3 (V) 4 Electric heater control Fault 0 (W) Run signal 1 2 Fan 2 Heating Heat demand signal L2 SL run on CL RET Rx CONTACTER A1 CONTACTER Trickle Max DP Connections to Damper A1 1 (U) 2 Fan 1 Min Faul t 1 Heater over-temperature stat Standby SL 10 11 12 13 14 15 Coolin g 0 Tx HEAT DEMAND L2 5 6 7 8 9 Heatin g RUN L3 L1 CL DAMPER Connections to Damper Fan 2 FAULT 12 13 14 15 Max SL run on Pw r L Fan 1 Min 10 11 DAMPER 9 Ecosmart N 12 13 14 15 400V 50Hz 3ph +N mains Make connection after the unit has been assembled Note: these controls are located in the electric heater section nuaire.co.uk 111 Sensor Standby HEAT DEMAND 7 8 Make connection after the unit has been assembled BMS signal Pwr L 5 6 Remove this link wire if: 1. a switched live signal is connected HTR 2. an ES-PIR, ES-TC or BMS signal 0V is connected. 0-10V 0-10V Ecosmart N 12 13 14 15 B L1 L2 L3 E FAULT RUN L1 L2 L3 E Nuaire AHU_Layout 1 12/08/2011 10:30 Page 112 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMA RT B OXER W I R I NG TEC H NI C A L I NF O R MATI O N ECOSMART BOXER WITH CONSTANT PRESSURE CONTROLS Airflow D 2D min Silencer Fan Heater Filter Control Locate Pressure Tapping here EXTRACT FANS SIZE 1 AND 2 SUPPLY FANS SIZE 1 AND 2 Pressure Sensor Pressure Sensor Pressure setting pot Pressure setting pot Set differential Pressure Set differential Pressure High Low Max SL run on Connector Min 0 Pre-wired in factory to main control PCB via PVC Tubing connector labelled 'P in' (supplied) To fan outlet, connection to be made on site To atmosphere through fan casing 1 Trickle Pwr Standby Fan 1 Fan 2 Heating Cooling Fault Frost Tx Rx Test Ecosmart High Low 0 Pre-wired in factory to main control PCB via connector labelled 'P in' Main control PCB Test Main control PCB EXTRACT FANS SIZE 3 AND ABOVE Pressure setting pot Set differential Pressure Set differential Pressure Max SL run on Connector Min 0 1 Trickle Pwr Standby Fan 1 Fan 2 Heating Cooling Fault Frost Tx Rx Ecosmart Inverter Max SL run on 0 1 Trickle Test Pwr Standby Fan 1 Fan 2 Heating Cooling Fault Frost Tx Rx Test Main control PCB Main control PCB To fan outlet; connection to be made on site To atmosphere through fan casing Min Connector Ecosmart Pre-wired in factory to main control PCB via connector labelled 'P in' To atmosphere through control casing Pre-wired in factory to main control PCB via connector labelled 'P in' To fan inlet chamber Low High Low High Pressure Sensor 029 2085 8200 1 Trickle To fan inlet chamber Pressure setting pot 112 Max SL run on Pwr Standby Fan 1 Fan 2 Heating Cooling Fault Frost Tx Rx To atmosphere through fan casing SUPPLY FANS SIZE 3 AND ABOVE Inverter Min Connector Ecosmart Pressure Sensor Nuaire AHU_Layout 1 12/08/2011 10:30 Page 113 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMART B OXER W I R I NG TEC H NI C A L I NF O R MATI O N i There are no inrush starting currents quoted because the Ecosmart control incorporates a soft starting speed control feature. ii. The inverters are preset to match the fan requirements. Under normal circumstances it should not be necessary to adjust them. iii. Pay particular attention to the model type, recorded on the product rating plate and connect as follows. ECOSMART BOXER FAN CONTROL ONLY Power requirements Model Flc fan only (1) BHSEX1FC, BHS1FC-L 4.8A BHS1FC-E 4.8A BHSEX2FC, 7.3A BHS2FC-E 7.2A BHSEX3FC, BHS3FC-L 4.6A 6.1A BHS4FC-E 6.1A BHSEX5FC, BHS5FC-L 7.8A BHS5FC-E 7.8A BHSEX6FC, BHS6FC-L 8.2A BHS6FC-E 8.2A BHSEX7FC, BHS7FC-L BHS7FC-E 18 25A 24 33A 27 38A SIZES 1 AND 2 36 Note: Inter connections between circuit boards are made in the factory. Remove this link wire if: 1. a switched live signal is connected. 2. A ES-PIR, ES-TC or BMS signal is connected. Speed Controller 50A 0V BMS signal 54 75A 0-10V Ecosmart N Pwr L Standby SL 54 75A 11.4A 11.4A 54 Fan 1 Min DP Connections to Damper 75A N RET Heat demand signal Note: (1) Sizes 1 and 2 fans are rated at 230V ac, 50Hz single phase. All other sizes are rated at 400V ac 50 Hz 3 phase. (2) All electric heaters are rated at 400V ac 50 Hz 3 phase. Max Fan 2 SL run on Heating Cooling CL Run signal HEAT DAMPER DEMAND 4.6A BHSEX4FC, BHS4FC-L Flc heater (2) Fault 0 1 Frost Tx Trickle Test Rx FAULT RUN BHS3FC-E Electric heater max Kw Fault signal NET connections for ECOSMART devices L 230V 50Hz 1ph mains N Earth E SIZES 3 TO 7 TYPICAL ELECTRIC HEATER WIRING Note: Inter connections between circuit boards and inverter/contactor are made in the factory. Connect over temperature trip to control circuit L1 L2 L3 E Remove this link wire if: 1. a switched live signal is connected. 2. A ES-PIR, ES-TC or BMS signal is connected. Bus bar clamp 0V BMS signal 12 13 14 15 7 8 9 L3 L2 Heat demand signal Max SL run on N Fan 2 Heating Cooling CL RET Fault 0 1 Frost Tx Trickle Test Rx (V) (W) Run signal Fault signal L3 FAULT RUN (U) Fan 1 Min DP Connections to Damper L1 Standby SL 10 11 12 13 14 15 400V 50Hz 3 phase Pwr L HEAT DAMPER DEMAND 5 6 L2 Ecosmart N L1 0-10V A1 E CONTACTER NET connections for ECOSMART devices 1 (U) 2 3 (V) 4 5 (W) 6 Earth L3 L2 L1 N A2 Download specification from www.nuaire.co.uk/specifications 400V 50Hz 3ph +N mains E nuaire.co.uk 113 Nuaire AHU_Layout 1 12/08/2011 10:30 Page 114 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMA RT B OXER TEC H NI C A L I NF O R MATI O N CO NSULTA NT S SP E CI F I C ATION ECOSMART BOXER UNITS SIZE 3 TO 7 AIR HANDLING UNIT SPECIFICATION The Air Handling Unit shall be configured and arranged as detailed on the drawings and in accordance with the schedule of equipment. The units shall be manufactured from a highly rigid pentapost framework with 25mm double skinned infill panels. The panels shall contain inert high density infill. Panel materials are heavy gauge Aluzinc corrosion resistant steel. The units shall provide exceptional thermal and acoustic insertion. The general construction is to class A leakage. The fan impeller and motor shall be selected to provide the most energy efficient solution conforming to part L regulations and shall be direct or belt drive with IE2 high efficiency motors to BS5000 as standard. The fan impeller shall be a high efficiency forward or backward curved centrifugal design, manufactured in galvanised steel. The Fan unit shall have a 5 year warranty. The unit and ancillaries shall be of the Ecosmart Boxer type as manufactured by Nuaire Ltd. All other components shall be in accordance with the manufacturer’s specification. CONTROL SPECIFICATION The Air Handling Unit shall be supplied with one of the following control options:- 1. ECOSMART CONTROLS The compact Ecosmart control system complete with all necessary controls to facilitate the operation of the ventilation system. It shall be come complete with an integral factory fitted Ecosmart PCB which will control the fan unit within the desired design parameters and provide the interface between all external control devices and the unit itself. ECOSMART SYSTEM OPERATION The Ecosmart controls will enable the unit to automatically vary its speed as it receives signals from one of the interconnected sensors. When the signal is received the fan shall either increase speed gradually until the required level is achieved or it will work on a trickle and boost principle. This will then and move the fan duty point from trickle/background ventilation rate to the required boost ventilation rate. Both the trickle and boost rates are infinitely variable, easy to adjust and remove the need of a main balancing damper. 2. BMS INTERFACES The fan unit shall be provided with the following integrated BMS interfaces • 0 - 10 volt contacts to provide a full BMS interface. This will enable the following functions:Switch the unit on/off. Switch from low speed to high speed. Full speed control facility. Switch the heating function on/off. Switch the cooling function on/off. • 2 No. Volt free contacts to provide fan run and failure indication to provide system status. • An integrated commissioning/speed control to accurately commission the system, with minimum and maximum speeds easily adjusted via a miniature dial, as recommended in Part L. This will enable the unit to be configured to run between set parameters thus saving motor power and limiting noise. • Commissioning set up - The fan unit shall be provided with an integrated commissioning/speed control to accurately commission the system, as recommended in Part L, minimum and maximum speeds easily adjusted via miniature dial. The commissioning set up facility directly controls the integrated speed control/frequency inverter. 3. NO CONTROL IS AVAILABLE (Example code BHS7NC-E). The Air Handling Unit shall have the following energy saving components integrally mounted, pre-wired to interface with the purpose made PCB, all components pre-wired, configured and factory fitted by the manufacturer: • Integral Frequency inverter/speed controller. • Integral maximum and minimum speed adjustment for commissioning. • Integral adjustable run on timer. • Integral BMS interfaces – summer/winter switching, heating control, 0-10V speed adjustment. • Volt free failure and status indication. • Integral air off temperature adjustment. • Facility for remote temperature control. • Integral background ventilation switch (trickle switch). • Multiple IDC sockets for interconnection of sensors or fans using pre-plugged 4-core low voltage cable. • Volt free frost alarm/heat demand interface. • Frost protection/hold off stat. 114 029 2085 8200 COIL TYPES, HX AND CONTROLS The control for the coils shall be fully integrated and shall maintain a constant off coil temperature. The system shall have frost protection which shall, at temperatures below 4 degrees C, fully open the 3-port valve and only start the fan when the temperature at the filter has risen above the designated set point. Unit to have contacts which will act as frost alarm and/or signal boiler to switch on. Nuaire AHU_Layout 1 12/08/2011 10:30 Page 115 A I R H A NDL I NG UNI TS ( A H U’S) EC O SMART B OXER TEC H NI C A L I NF O R MATI O N CO NSULTA NT S SP E CI FIC ATION HEATING COILS - LOW PRESSURE HOT WATER The Low Pressure Hot Water heating coil shall be manufactured from copper tubing with high efficiency aluminium fins contained within a galvanised steel frame, shall be factory fitted with a 3-port motorised diverting valve assembly comprising the 3-port valve, double regulating valve, drain cocks aactuator controlling the 3-port valve shall be control via the on-board PCB by the off coil temperature sensor. All components pre-piped, assembled and tested by the manufacturers. HEATING COILS - ELECTRIC The Electric Heater Battery shall be factory fitted and pre-wired to an integral closed loop thyristor control. The heat output can be configured on site to suit the specific requirements. COOLING COILS - CHILLED WATER The Chilled Water Coil shall be manufactured from copper tubing with high efficiency aluminium fins contained within a galvanised steel frame, it shall be factory fitted with a 3-port motorised diverting valve assembly comprising the 3-port valve, drain cocks and air vents. The actuator controlling the 3-port valve shall be control via the on-board PCB by the off coil temperature sensor. Coil supplied complete with an insulated condensate tray and moisture eliminator. All components pre-piped, assembled and tested by the manufacturer. COOLING COILS – DX COILS The DX Coil shall be manufactured from copper tubing with high efficiency aluminium fins and droplet eliminator contained within a galvanised steel frame. The coil shall be filled with dry nitrogen with the pipe connections capped. It shall be factory fitted and tested by the AHU manufacturer. Note: Fan control only example code is BHS7FC-LD. HEAT EXCHANGER The cross flow heat exchanger shall be complete with a motorised summer bypass; this will be activated when the heating, cooling or ventilation switch on the user control is switched to the ventilation position. The Ecosmart controlled fan unit shall have a 5 year warranty. Non Ecosmart fan controlled units will have a 3 year warranty. All equipment shall be as manufactured by Nuaire Ltd. *Suitable for 95% RH non condensing. Download specification from www.nuaire.co.uk/specifications nuaire.co.uk 115