d. 1.3: g.en.esi methodology definition

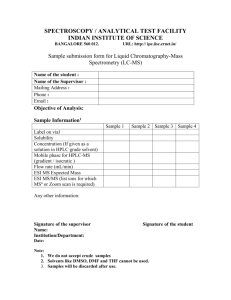

advertisement