Thin Solid Films 443 (2003) 115–119

Deposition of permalloy films by filtered cathodic vacuum arc

J.S. Chen1, S.P. Lau*, Y.B. Zhang, Z. Sun, B.K. Tay, C.Q. Sun

Ion Beam Processing Laboratory, School of Electrical and Electronic Engineering, Nanyang Avenue, Nanyang Technological University,

Singapore 639798, Singapore

Received 11 February 2003; received in revised form 14 May 2003; accepted 16 July 2003

Abstract

The filtered cathodic vacuum arc technique was employed to deposit magnetic films such as FeNi on silicon substrate. Using

the normal cathode design, tetrahedral amorphous carbon and metals films can be deposited. If a magnetic target is used, the arc

spot always preferably moves to the edge of the target and then extinguishes. Therefore, the arc is not stable and no film can be

deposited. A cathode was designed to obtain stable and continuous arc and uniform erosion pattern. The atomic force microscopy,

grazing X-ray diffraction and vibrating sample magnetometry were used to characterize the morphological, structural and magnetic

properties of the FeNi film. When the film deposited at substrate bias of y100 V, it exhibits a square magnetization–hysteresis

loop, the lowest coercivity and the highest saturated magnetization among all the investigated samples, which may be related to

its good surface roughness and crystallinity.

䊚 2003 Elsevier B.V. All rights reserved.

Keywords: Permalloy; Filtered cathodic vacuum arc; Magnetic properties

1. Introduction

For many years there has been considerable interest

in producing films of magnetic materials because of

their many exclusive applications such as magnetic

recording, microactuation and sensors and so on. Many

techniques have been employed to synthesize the magnetic films with varying amounts of success, which

include evaporation, sputtering, pulsed laser deposition,

and molecular beam epitaxy w1–3x. Among them, the

evaporation and sputtering are predominant in industrial

application because of their economy and simplicity.

But the need for new, high performance materials in

magnetic recording entails the development of a new

deposition technology for magnetic films. It is well

known that cathodic vacuum arc technology has proven

to be a very promising method for ultrathin film deposition. It offers several advantages over evaporation and

*Corresponding author. Present address: Data Storage Institute, 5

Engineering Drive 1, NUS, Singapore 117608, Singapore. Tel.: q6567906439; fax: q65-67933318.

E-mail addresses: esplau@ntu.edu.sg (S.P. Lau),

chen_jingsheng@dsi.a-star.edu.sg (S.P. Lau).

1

Present address: Data Storage Institute, 5 Engineering Drive 1,

NUS, Singapore 117608.

sputtering, and the principal advantages are the high

percentage of ions in the emitted flux (approx. 100%),

high kinetic energy of these ions (20–200 eV) w4,5x. In

the present time, it has been in wide-scale industrial use

for producing wear protective coatings of TiN and

related materials on cutting and forming tools, as well

as decorative coatings on plumbing fixture and jewelry.

Adding a magnetized torus macroparticle filter the highly tetrahedrcally bonded amorphous carbon films can be

synthesized with high deposition rate (5 nmys) at room

temperature w6x. The filtered cathodic vacuum arc

(FCVA) technique has also been used for depositing

optical thin films of metal oxides (TiO2 and Al2O3) and

semiconducting thin films (amorphous Si and SnO2)

w7–9x. To our knowledge, however, no paper has been

reported on the deposition of magnetic films by FCVA

technique yet. In this paper, the FCVA technique was

used to deposit FeNi films on Si substrate. A modified

cathode design for depositing magnetic films was

presented.

2. Movement of cathode arc spot and cathode design

The typical FCVA system has been described elsewhere w10x. Generally, a conductive target mounted on

0040-6090/03/$ - see front matter 䊚 2003 Elsevier B.V. All rights reserved.

doi:10.1016/S0040-6090(03)01031-9

116

J.S. Chen et al. / Thin Solid Films 443 (2003) 115–119

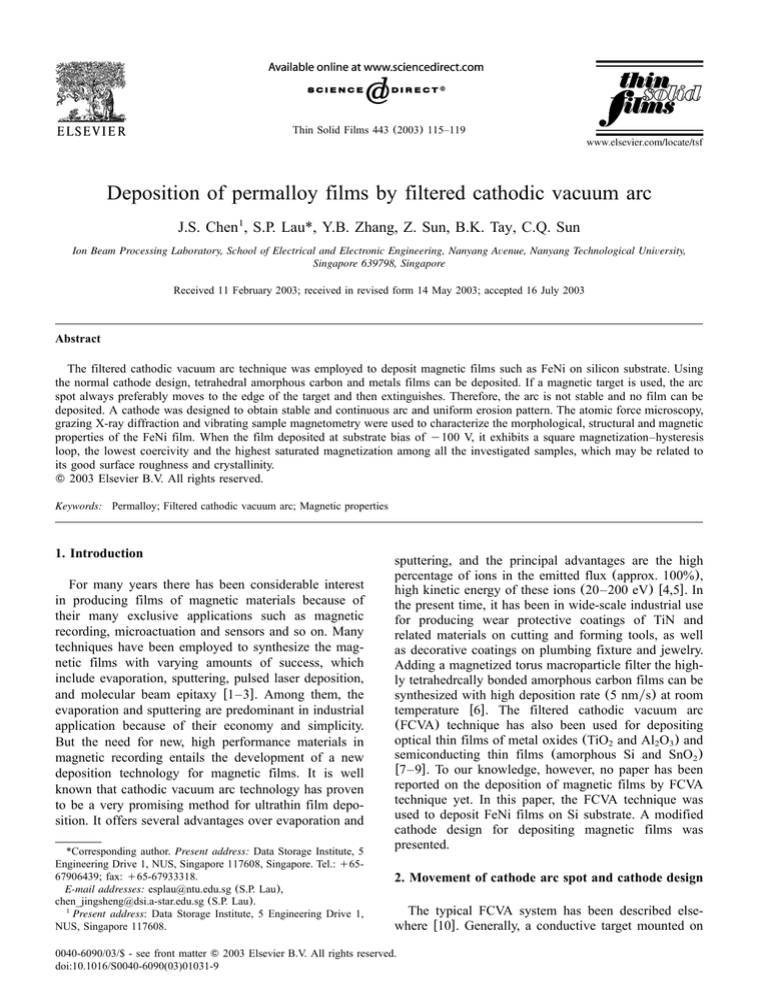

Fig. 1. The schematic diagrams of cathode (a) original and (b) modified design.

water-cooled copper block was used as a cathode as

shown in Fig. 1a. A tube-shaped stainless steel around

the outer of cathode was used as a shield to avoid

straying arcing and the space between them was approximately 2–3 mm. The cathodic arc is triggered with a

graphite electrode touching the cathode surface at an

initial background pressure of approximately 10y6 Torr

and the cathode is continuously water-cooled from the

back. The plasma beam produced by the cathode spots

passes through an off-plane double-bend macroparticles

filter into the deposition chamber w11x. This type of

filter bend has many advantages over the single bend,

for example, higher ion density, higher plasma transport

efficiency and significant reduction of macroparticles.

The anode is grounded and the shield and the bend are

under floating potential. The substrate can be biased up

to negative 400 V.

In such a cathode design, the arc spot on the surface

of magnetic materials moves away from the center to

the edge of the cathode after igniting the arc in the

center, and then the arc either sustains for a short time

(mostly less than a minute) or extinguishes immediately.

This is quite different from that of the Ti and Cu as a

cathode target. The behavior of the arc spot on the

surface of magnetic targets does not change even if the

filtering coils are not energized. It is well known that

the cathode spots apparently move randomly over the

cathode surface (Ti, Cu, Al, etc.) in the absence of a

magnetic field, but in the presence of a magnetic field

they have a direct velocity in the yJ=B direction, a

phenomenon known as ‘retrograde’ motion. At present,

most investigations on vacuum arc spot dynamics were

mainly focused on high current vacuum arc because of

its application for commercial vacuum circuit breakers.

Siemorth et al. have shown that the cathode spot at high

current should be considered as a multilevel organized

self-similar structure w11x. Sherman et al. w12x have

investigated the influence of self-generated magnetic

field on cathode arc spots movement for copper electrode at high current vacuum arc (2.7–6.9 kA), namely,

the influence of the magnetic field generated by other

vacuum arc spots on a vacuum arc. According to the

experimental results they derived a relationship between

the retrograde spot velocity (V) and magnetic flux

density (B), namely VsKØB, where K is the coefficient

depending on the cathode materials and is independent

of B. It has been generally believed that the arc current

self-generated magnetic field is a major factor that

governs the dynamics of arc spot in high-current vacuum

arc. However, it is believed that there is only a single

cathode spot with 10 mm in diameter in the low current

vacuum arc (approx. 100 A) w13x. For the arc spots on

the Ti and Cu cathodes there is no or little external

force imposed on them, so it moves randomly around

the surface of the cathode. The behavior of arc spot on

magnetic materials can be interpreted as follows: the

vacuum current is considered as a wire with current

flowing. According to Ampere’s law, vacuum arc current

generates an azimuthal magnetic field that can induce

magnetization of magnetic materials and then produce a

magnetic field. The magnetic field produced is due to

the magnetization of magnetic materials, which imposes

on the arc spot once it moves and makes a retrograde

motion, namely, the cathode arc spot moves outside in

the radial direction. In order to obtain continuous and

stable arc on magnetic materials and uniform erosion of

the target, it is necessary to re-design the configuration

of the cathode.

The cathode configuration designed for deposition of

magnetic materials is schematically shown in Fig. 1b.

A cylinder made of a soft magnetic material such as

pure Fe surrounds the magnetic target. A boron nitride

(BN) ceramic ring was placed on top of the magnetic

target. The design was mainly based on the following

principles: when a BN ring is placed on a magnetic

material, the arc spot moves randomly within the ring

and the target erosion is uniform. The BN ring is used

to confine the motion of arc spot within the ring. BN

ceramic has a low surface energy for most metals and

low emission efficiency of secondary electrons, which

can prevent the arc spot from moving on the surface of

the BN ring and reduce the deposition of the target

material on the surface of the BN ring. Using this new

cathode design, a stable and continuous arc can be

J.S. Chen et al. / Thin Solid Films 443 (2003) 115–119

117

Fig. 3. The surface roughness of the FeNi films as a function of

substrate bias.

Fig. 2. AFM images of FeNi films deposited at (a) y100 V and (b)

y400 V.

function of bias conditions. The rms roughness decreases

from floating condition (0 V) to y100 V, and then

increases as the bias increases from y100 to y400 V.

The XRD spectra of the films deposited at various

biases are shown in Fig. 4a. For the sample prepared at

floating condition, the FeNi(111) and (200) peaks are

observed. When a bias of y100 V is applied, the

intensity of FeNi(111) and (200) peaks increases. By

further increasing the substrate bias, the intensity of

obtained and the erosion pattern is uniform for magnetic

target.

3. FeNi films deposition and properties

In this work, permalloy Fe0.2Ni0.8 films were deposited on Si (100) substrate at room temperature using the

new cathode design and the arc current was set to 100

A. The toroidal magnetic field was fixed at 40 mT. The

substrate was negatively biased from y100 to y400 V

with respect to the ground (anode). The deposition rate

was approximately 0.1 nmys. The surface morphology

and roughness of the films were examined using atomic

force microscope (AFM, Digital Instruments) in tapping

mode. The value of root-mean-square (rms) surface

roughness was evaluated in the area of 2=2 mm. The

crystallographic structure of films was determined by

Rigaku grazing X-ray diffractometer (GXRD) with Cu

˚ at 50 kV and

Ka1 excitation (wavelength of 1.5406 A)

20 mA. The angle between the incident X-ray and the

surface of the films was fixed at 0.58 and the diffraction

pattern was obtained by changing the position of the

counter with a step of 0.058. Magnetic properties were

measured at room temperature by Lakeshore vibrating

sample magnetometer (VSM, Model 7300).

The typical AFM images of the films deposited with

the substrate bias of y100 and y400 V are shown in

Fig. 2. All of the images show island-like features. Fig.

3 shows the root mean square (rms) roughness as a

Fig. 4. (a) XRD spectra and (b) FWHM of peak (111) of FeNi films

deposited at various substrate bias.

118

J.S. Chen et al. / Thin Solid Films 443 (2003) 115–119

FeNi(111) and (200) peaks decreases. Fig. 4b presents

the variation of the full width at half maximum

(FWHM) of peak (111) with the substrate biases. The

FWHM as a function of the substrate bias has a trend

similar to the roughness. With a bias of y100 V, the

FWHM reaches its minimum, reflecting the optimal

crystalline quality of the films. One of the most important factors affecting the morphology and structure of

the films is the lateral mobility of the adatoms on the

substrate. With a bias of y100 V, most of the ions

energy is changed into the lateral energy after bombardment on the substrate and adatoms mobility increases.

So the film at the bias of y100 V shows smoother

morphology and better crystallinity than that of the

sample under floating condition. Although lateral ion

energy also increases with further increase of the bias,

the ion energy along normal component is increased

more, which causes the increase of the roughness.

The magnetization–hysteresis (M–H) loops of FeNi

films with various substrate biases are shown in Fig. 5.

The films deposited at lower substrate bias (0 and

y100 V) have the expected square M–H loops while

the films deposited at higher substrate bias have poor

M–H loops with two distinctive slopes before saturation.

It has been recognized that the smaller slope before

saturation is due to a perpendicular anisotropy component normal to the plane of the film w14–16x. The

mechanisms for producing perpendicular anisotropy

include the following: (1) magnetocrystalline anisotropy—if the FeNi films is (100) textured, the film’s

normal is the easy axis in the absence of shape aniso-

Fig. 6. The saturated magnetization 4pMS and coercivity Hc of the

FeNi films as a function of substrate bias.

tropy; (2) microshape anisotropy—the columnar structure of the magnetic grains separated by a non-magnetic

phase or voids can produce a microshape anisotropy

along the column axis; (3) magnetoelastic anisotropy—

when the film is under a compressive stress, the magnetoelastic energy favors the magnetization orientated

out of the plane of the film. Further investigation is

currently under way to determine which kind of anisotropies play the dominant role.

The saturated magnetization 4pMS and coercivity Hc

as a function of substrate bias are shown in Fig. 6.

When the bias is y100 V, the film shows the lowest

coercivity and the largest saturated magnetization. The

X-ray photoelectron spectroscopy (XPS) results (not

shown) indicate that the composition of the films of

permalloy, fcc-FexNi1yx, where x ranging from 0.19 to

0.21, is nearly independent on the substrate bias. Thus

the changes in saturated magnetization and coercivity

Fig. 5. M–H loops of FeNi films deposited at various substrate bias, (a) 0; (b) y100 V; (c) y200 V; (d) y400 V.

J.S. Chen et al. / Thin Solid Films 443 (2003) 115–119

with bias are not induced by the slight variation of

composition. The film with good soft magnetic properties has the lowest surface roughness and better crystallinity, which are consistent with Fe films deposited by

dual ion beam sputtering w17x.

4. Conclusions

In summary, magnetic Fe0.2Ni0.8 films have been

successfully deposited on silicon substrate using the

modified cathode design. A stable and continuous arc

with uniform target erosion can be obtained. When the

substrate bias is y100 V, the film exhibits the lowest

coercivity and highest saturated magnetization among

all the investigated conditions, which may be related to

its good surface roughness and crystallinity.

References

w1x S. Iwatsubo, T. Takahashi, M. Naoe, J. Appl. Phys. 83 (1998)

6667.

w2x T.T. Honda, K.I. Arai, M. Yamaguchi, J. Appl. Phys. 76 (1994)

6994.

w3x J.C. Huang, Y.M. Hu, C.C. Yu, J. Appl. Phys. 83 (1998) 7046.

119

w4x W.D. Davis, H.C. Miller, J. Appl. Phys. 40 (1969) 2212.

w5x H.C. Miller, J. Appl. Phys. 66 (1989) 1107.

w6x I.I. Aksenov, S.I. Vakula, V.G. Padalka, V.E. Strel’nitskii, V.M.

Khoroshikh, Sov. Phys. Tech. Phys. 25 (1980) 1164.

w7x T.D. Schemmel, R.L. Cunningham, H. Randhawa, Thin Solid

Films 181 (1989) 597.

w8x P.J. Martin, R.P. Netterfield, T.J. Kinder, L. Descotes, Surf.

Coat. Technol. 49 (1991) 239.

w9x R.L. Boxman, S. Goldsmith, A.B. Shalom, L. Kaplan, D.

Arbilly, E. Gidalevich, V. Zhitomirsky, A. Ishaya, M. Keidar,

I. Beilis, IEEE Trans. Plasma Sci. 23 (1995) 939.

w10x X.L. Xu, S.P. Lau, B.K. Tay, Thin Solid Films 398–399 (2001)

244.

w11x P. Siemroth, T. Schulke, T. Witke, IEEE Trans. Plasma. Sci.

25 (1997) 571.

w12x J.C. Sherman, R. Webster, J.E. Jenkins, R. Holmes, J. Phys.

D: Appl. Phys. 8 (1975) 696.

w13x E. Hantzsche, B. Juttner, IEEE Trans. Plasma Sci. 13 (1985)

230.

w14x K. Sin, C-T. Wang, S.X. Wang, B.M. Clemens, J. Appl. Phys.

81 (1997) 4507.

w15x B. Viala, M.K. Minor, J.A. Barnard, J. Appl. Phys. 80 (1996)

3941.

w16x N. Satio, H. Fujiwara, Y. Sugita, J. Phys. Soc. Jpn. 19 (1964)

1117.

w17x S. Iwatsubo, T. Takahashi, M. Naoe, Thin Solid Films 67

(1999) 343.