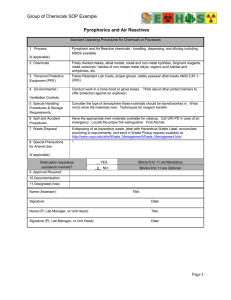

Chemical Hygiene Plan For the University at Buffalo

advertisement