Addressing Inadequate Investment in School Facility Maintenance

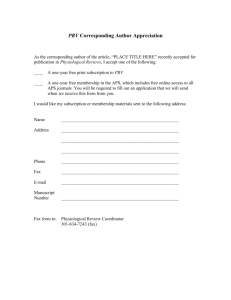

advertisement