WALL MOUNTED

LLF

SERIES

LLF

L

o

w

L

e

v

e

l

F

l

o

o

d

l

i

g

h

50 - 100W HID • 42W Compact Fluorescent

t

s

Low Level Floodlight

Table of Contents

Six Fixture Systems

2-3

Mechanical Design

6

Installation

7

Ordering Information

8-9

Luminaire Specifications

10

Suggested Concrete

Pedestal Designs

12-13

Surface Reflectance

15

Recommended Fixture Spacing

for General Area Lighting

16

Photometrics for

General Area Lighting

17-18

Photometrics for

Cutoff Area Lighting

19-22

Stairway Lighting

24

Recommended Fixture Spacing

for Stairway Lighting

25

Explanation of Stairway

Photometrics

Stairway Photometrics

26

27-31

Lamp and Electrical Guide

32

Application

Engineering Services

33

SITE / AREA

PARKING STRUCTURE

ROADWAY

ARCHITECTURAL FLOOD

ACCENT

LANDSCAPE

MAILING ADDRESS:

P.O. BOX 60080

CITY OF INDUSTRY, CA

91716-0080

BUSINESS ADDRESS:

16555 EAST GALE AVENUE

CITY OF INDUSTRY, CA 91745

U.S. A.

PHONE 626 / 968 - 5666

FAX 626 / 369 - 2695

ENTIRE CONTENTS

© COPYRIGHT 2008 KIM LIGHTING, INC.

ALL RIGHTS RESERVED

REPRODUCTION IN WHOLE OR IN PART

WITHOUT PERMISSION IS STRICTLY PROHIBITED.

www.kimlighting.com

Printed in U.S.A.

5503010042

Version 1.2 (2/10)

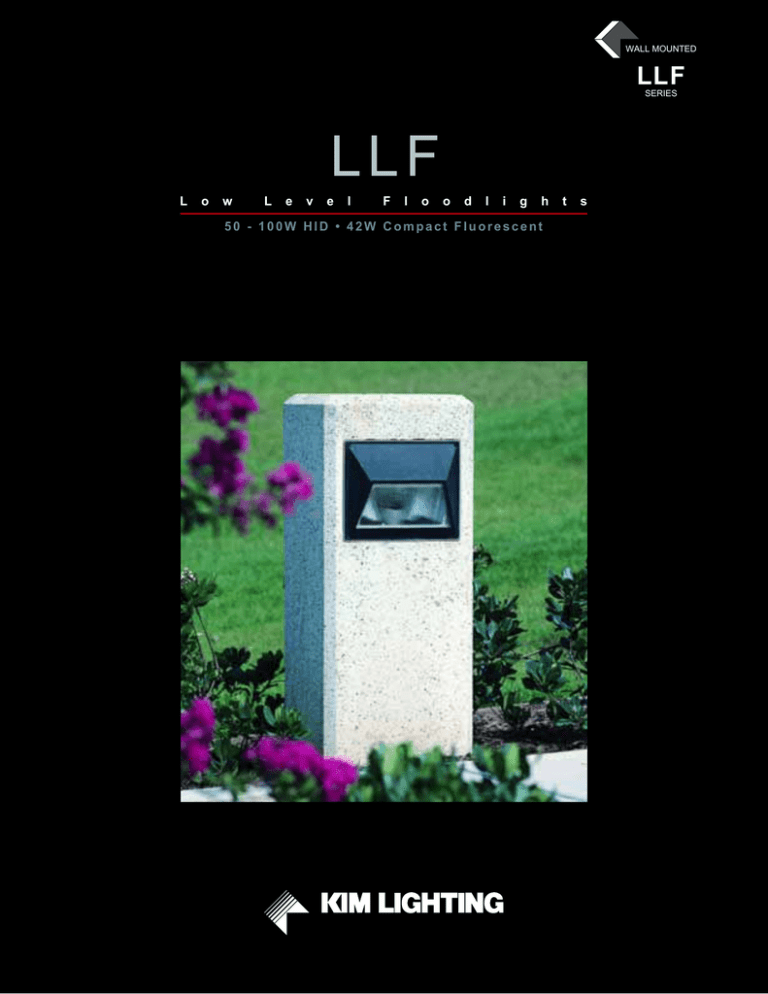

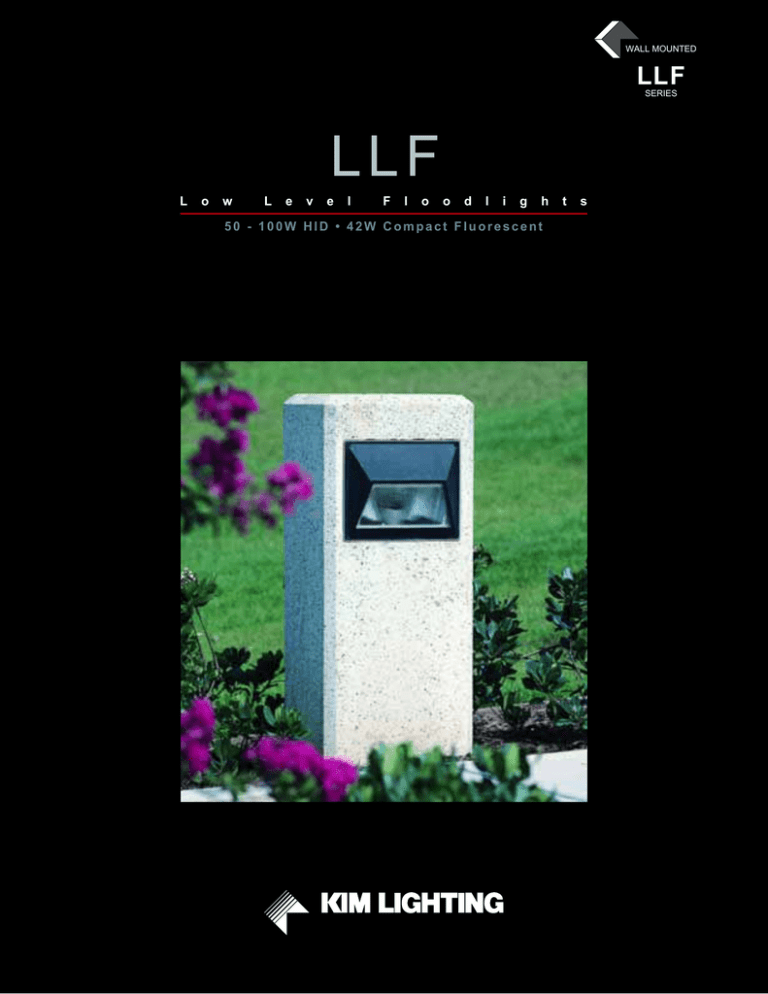

Before Kim invented the Low

Level Floodlight in 1979, pole

mounted luminaires were the

only way to efficiently light

outdoor areas. While valid for

parking lots or streets, pole

mounted fixtures cluttered

smaller areas with hardware

that interrupted a clear view of

the architectural statement.

The need was for an efficient

lighting system that could be

integral with the architecture

or site elements, thereby

preserving the design purity.

Kim’s Low Level Floodlight is

an architectural outdoor

lighting instrument built for

permanence as an integral

part of the site. It allows

uninterrupted viewing of the

landscape and architectural

design. The Low Level

Floodlight is outdoor lighting’s

missing link between parking

lot and building, providing

efficient lighting where design

sensitivity will not allow pole

mounted luminaires.

Six Fixture Systems

LLF-10

LLF-20

LLF-30

2

KIM LIGHTING

LLF-10: Direct Lens, Symmetric Downward Lighting

Distribution, Wall or Ceiling Mounted

The LLF-10 is the basic lighting instrument for horizontal surfaces

or up to 10° sloped ramps. It may also be cast into ceilings or

overhangs for superb illumination of adjacent walls. The LLF-10

should be specified for low level floodlighting where architectural

permanence, superb glare control, and a quality cast-aluminum

architectural appearance is desired.

LLF-20: Direct Lens, Asymmetric Right-Downward

Lighting Distribution, Wall Mounted

The LLF-20 contains an exclusive optical system specifically

engineered to light stairs or ramps having greater than 10° slope.

It is so efficient at lighting inclined surfaces that often one fixture will

do the entire job. The LLF-20 should be specified for unsurpassed

lighting efficiency and glare control, with permanence and quality

to complement the finest architecture and site design.

LLF-30: Direct Lens, Asymmetric Left-Downward

Lighting Distribution, Wall Mounted

The LLF-30 is exactly equal and opposite to the LLF-20. As such,

the specifier has complete flexibility in lighting stairways or ramps

from the right, left, or both sides. Refer to the photograph on

page 23 as an example of how one LLF-30 or LLF-20 can light an

entire stairway. Specify the LLF-30 for performance, permanence,

and a strong architectural character.

LLF-40: Direct Lens, Symmetric Upward Lighting

Distribution, Wall Mounted

The LLF-40 superbly illuminates building overhangs and ceilings for

aesthetics or for indirectly lighting pedestrian areas below. It can be

used outdoors or indoors where a high quality, low maintenance

luminaire is dictated by the architectural design. The smooth outer

surface of the tempered glass lens will stay clean and clear in the

inverted position, and will not yellow like plastic fixtures.

LLF-50: Concealed Lens, Symmetric Downward

Lighting Distribution, Wall Mounted

With its concealed lens and front light baffle, the LLF-50 is designed

for sensitive areas requiring absolute minimum fixture brightness.

The LLF-50 produces excellent light distribution for illuminating

horizontal surfaces or short stairways. Its strong architectural

appearance will enhance quality site design that is built for

permanence. Specify the black finish for minimum fixture brightness.

LLF-40

LLF-50

Shop

LLF-60: Concealed Lens with Guard, Symmetric

Downward Light Distribution, Wall Mounted

The LLF-60 has all the features of an LLF-50, with the addition of a

cast aluminum lens guard, and translucent opal white lens to

eliminate guard shadows. It should be specified in areas requiring

a high degree of vandal resistance, concealed light source, and

the permanence of heavy cast-aluminum construction. Specify the

black finish for minimum fixture brightness.

LLF-60

KIM LIGHTING

3

Mechanical Design

Housing

A single housing is common to all six fixture systems. It is a

one-piece precision die-cast, low copper (<0.6% Cu) aluminum

alloy to prevent corrosion when cast in concrete. The housing is

shipped ahead as a pour item; it contains no electrical components

to be damaged during the concrete pour or vandalized during

construction. Located beneath the housing is a large junction box,

with 1" NPT taps for through-wiring using common low temperature

wire. The housing is further protected by a clear anodize.

Electrical Modules

Each LLF fixture system has a self contained factory prewired

electrical module that snaps into the housing using keyhole

slots. The electrical module is shipped to the jobsite, along with

the reflector and door frame, when the project is ready for

completion. This allows the housing to remain empty during

construction so these critical components are not damaged by

moisture or vandalism.

Reflectors

All reflectors for the six fixture systems are hydroformed in

one-piece for strength and dimensional consistency. To insure

maintained reflectivity over years of service, all reflectors are

finished with the Alzak ® process. Each reflector is optically

designed for the specific fixture to produce maximum efficiency

with low brightness.

Door Frames

LLF-10/40

LLF-60

(LLF-50 without louver)

There is no substitute for the permanence and quality

appearance of die-cast aluminum. All LLF door frames are cast

with an attractive pebbled finish, available in five Super TGIC

powder coat paint colors applied over a titanated zirconium

conversion coating. Direct lens models LLF-10, LLF-20, and

LLF-30 are furnished standard with a thick tempered borosilicate

glass lens capable of withstanding considerable abuse.

An optional polycarbonate lens is available for projects where

extreme vandalism is anticipated. Door frames are fully gasketed,

weathertight, and retained with flush stainless steel screws.

Eight Stage Finish

•

Aluminum

•

•

6

Titanated

Zirconium

Conversion

Coating

Powder Coat

KIM LIGHTING

The LLF is available in five

standard Kim colors plus

custom color options. Finish

is Super TGIC thermoset

polyester powder coat paint

applied over a titanated

zirconium conversion coating

as follows:

1. Power wash and degrease.

5. Clear water rinse bath.

2. Detergent tank bath.

6. Dry off oven.

3. Clear water rinse bath.

7. Powder coating, 2.5 mil

nominal thickness.

4. Premium titanated zirconium

conversion coating as used

in the automobile industry.

8. Bake for 20 minutes at 410°F.

2500 hour salt spray test rated.

Installation

Easy Installation

The Low Level Floodlight is specifically

designed for permanence, ideal for

installation in concrete or brick walls,

planters, columns, and pedestals.

1

2

3

Installation Process

1. Die-cast housings are stocked at the

factory, ready for quick shipment as a

pour item. Free of any electrical

components, the housing easily

attaches to forms with the supplied

screws, and can also be tied to the

reinforcing bar system. A large

junction box makes conduit entrance

and through wiring fast and simple.

When the forms are removed, a

protective cover keeps the housing

clean until the job is ready for

the finishing components.

2. When the project is ready for

completion, the finishing components

are quickly and easily installed. Self

contained and factory prewired, the

electrical module snaps into the fixture

using keyhole slots. Field wire

connections are made inside the

housing and inserted into the junction

box, where they are protected from

fixture heat.

3. The reflector is attached; a lamp is

inserted, and the fully gasketed door

frame is secured with flush captive

socket head screws.

8"

(203.2 mm)

Thick Wall Section

Form (by others)

Back of housing must

have 2" of concrete or

gunite if in contact

with soil or other

corrosive substance.

Screws (by Kim) use

protective cover as

template to drill forms.

Empty

Housing

Protective cover

(by Kim)

NOTE: Two luminaires

installed back-to-back

must have 1" of

concrete separation.

Conduit entry from

ends or bottom.1" NPT

provided for through

wiring.

A reinforcing bar

system (by others)

can support housing.

6"

(152.4 mm)

Housing

See pages 12 and 13 for suggested concrete pedestal designs.

KIM LIGHTING

7

Ordering Information

Low Level Floodlights

Fixture

Ordering Example:

Electrical Module

LLF-10

/

100HPS120

1

1 Fixture:

Cat. No. includes housing and

junction box, optical system,

and door frame with standard

tempered glass lens.

2

Finish

/

BL-P

Options

/

QS / SF

3

4-8

General Area Lighting

Cat. No.: LLF-10

Cat. No.: LLF-40

Direct Lens,

Symmetric Downward Light Throw,

Wall or Ceiling Mounted

Direct Lens,

Symmetric Upward Light Throw,

Wall Mounted

Arrows indicate main thrust of

light distribution, in elevation.

4K"

(114.3 mm)

LIGHT

CENTER

LIGHT

CENTER

4K"

(114.3 mm)

Cutoff Area Lighting

Cat. No.: LLF-50

Cat. No.: LLF-60

Concealed Lens,

Symmetric Downward Light Throw,

Wall Mounted

LIGHT

CENTER

Concealed Lens with Guard,

Symmetric Downward Light Throw,

Wall Mounted

LIGHT

CENTER

6"

6"

(152.4 mm)

(152.4 mm)

Stairway Lighting

Cat. No.: LLF-20

Cat. No.: LLF-30

Direct Lens,

Asymmetric Right Downward Light Throw,

Wall Mounted

LIGHT

CENTER

8

KIM LIGHTING

Direct Lens,

Asymmetric Left Downward Light Throw,

Wall Mounted

LIGHT

CENTER

4K"

4K"

(114.3 mm)

(114.3 mm)

2 Electrical Module:

HPS = High Pressure Sodium

PMH = Pulse Start Metal Halide

PL = Compact Fluorescent

Pulse Start Metal Halide

High Pressure Sodium

70PMH120

70PMH208

70PMH240

70PMH277

70PMH347

50HPS120

50HPS208

50HPS240

50HPS277

100PMH120

100PMH208

100PMH240

100PMH277

100PMH347

70HPS120

70HPS208

70HPS240

70HPS277

70HPS347

Compact Fluorescent

100HPS120

100HPS208

100HPS240

100HPS277

100HPS347

42PL1201

42PL2081

42PL2401

42PL2771

1

Lamp Lamp Line

Watts Type Volts

100

HPS

42PL Operates one 26W, 32W, or 42W

triple tube compact fluorescent lamp at

120 thru 277 volts (50-60 Hz).

120

3 Finish:

Super TGIC powder coat

paint over titanated zirconium

conversion coating.

Color:

Cat. No.:

Black2

BL

Dark Bronze Light Gray Platinum Silver Stealth Gray®

DB

LG

PS

SG

White

WH

Custom Colors

CC

Consult representative

for custom colors.

Specify on LLF-50 and LLF-60 when minimum fixture brightness is desired.

2

4 Optional

Cat. No.: PL

Polycarbonate Lens:

Available on LLF-10, LLF-20, and LLF-30 only.

Injection molded, identical in appearance to standard tempered glass lens.

CAUTION: Use only when vandalism is anticipated to be high. Useful life is limited due to

yellowing caused by U.V. from sunlight and Metal Halide lamps.

5 Optional Quartz

Cat. No.: QS

Standby:

Available on LLF-10, LLF-20, LLF-30, and LLF-40 only.

Integral electronic device energizes a T-4 mini-can socket during lamp warm-up and

after a power interruption. Socket de-energizes prior to the HID lamp reaching full

brightness. T-4 mini-can Halogen lamp by others; 100 watt maximum.

Not available on PL version.

6 Optional Single Fusing:

Cat. No.: SF

Single fusing for 120V, 277V, and 347V primary.

7 Optional Double Fusing:

Cat. No.: DF

Double fusing for 208V and 240V primary.

8 Optional Battery

Cat. No.: EM

Internal battery pack provides 90 minutes of supplemental light at 750 lamp lumens on

42 watt compact fluorescent lamps.

Back-up:

For compact fluorescent only.

KIM LIGHTING

9

Luminaire Specifications

See pages 8-9 for complete ordering information.

Dimensions

LLF-10

LLF-20

LLF-30

LLF-40

6"

2B"

(152.4 mm)

(54.0 mm)

9L" (247.7 mm)

height at back

of housing

11C"

(288.9 mm)

Optional

QS

12K" width

(317.5 mm)

1" NPT;

(1) in each end

(2) in bottom

3G"

1N"

(87.3 mm)

3"

(39.7 mm)

(76.2 mm)

13E"

(352.4 mm)

LIGHT

CENTER

4K"

(114.3 mm)

5K"

(139.7 mm)

LLF-50

LLF-60

6"

2B"

(152.4 mm)

(54.0 mm)

9L" (247.7 mm)

height at back

of housing

11C"

(288.9 mm)

12K" width

(317.5 mm)

1" NPT;

(1) in each end

(2) in bottom

3G"

(87.3 mm)

1N"

3"

(76.2 mm)

13E"

(352.4 mm)

LIGHT

CENTER

(39.7 mm)

Housing and Junction Box: Die-cast, low copper (<0.6% Cu) aluminum to prevent

corrosion when cast in concrete. Junction box shall have an internally removable

cover, a volume of 25 cu in., and four 1" NPT conduit taps. Two taps in the bottom

and one in each end, all with removable plugs. Housing and junction box further

protected for permanence by a clear anodize coating. Cover furnished to keep the

housing clean until the electrical components are installed.

Door Frame (LLF-10, LLF-20, LLF-30, LLF-40): Die-cast, low copper (<0.6% Cu)

aluminum with a fine pebbled texture on the outer surface. Trapezoidal outer contour

tilts the lens 18° from vertical. Door frame secured to housing by four captive

stainless steel countersunk socket head screws.

Door Frame (LLF-50, LLF-60): Die-cast, low copper (<0.6% Cu) aluminum with a

fine pebbled texture on the outer surface. Trapezoidal outer contour tilts the lens 18°

from vertical. Cast aluminum recessed baffle that conceals the lens from normal

view. Baffle shall be internally welded to door frame and internally sealed with black

RTV. Door frame secured to housing by four captive stainless steel countersunk

socket head screws. LLF-60 has an additional cast aluminum lens guard.

Gasketing: One-piece molded silicone between the door frame and housing.

A neoprene gasket provided between the junction box and housing. The entire

fixture is weather tight.

Lens (LLF-10, LLF-20, LLF-30, LLF-40): Tempered borosilicate glass, F" min.

thickness, with a smooth outer surface flush with the door frame, and vertical inside

flutes. For LLF-20 and LLF-30, a shield is provided behind the lens to control fixture

brightness when viewing up the stairway or lamp. Lens is fully sealed around the

perimeter with a silicone gasket and is retained by zinc plated steel clips. (Optional

polycarbonate lens (PL) available on LLF-10, LLF-20, and LLF-30 only), one-piece

injection molded, F" min. thickness, identical in appearance to the standard glass

lens, and contains a UV inhibitor.

Lens (LLF-50): Tempered clear glass, F" min. thickness, with full silicone

gasketing around the perimeter. Lens shall be retained by zinc plated steel clips.

Lens (LLF-60): Tempered diffused opal white glass, F" min. thickness, with full

silicone gasketing around the perimeter. Lens shall be retained by zinc plated steel clips.

Reflector (LLF-10, LLF-40, LLF-50, LLF-60): One-piece hydroformed aluminum

with Alzak® finish. For LLF-10 and LLF-40, Bottom reflector surface is matte black to

prevent any escape of light in the viewer’s direction.

Reflector (LLF-20, LLF-30): One-piece hydroformed aluminum with Alzak® finish.

Reflector is engineered specifically for stairways or ramps greater than 10° slope,

producing either a right-downward or left-downward light distribution depending on

the fixture specified. Bottom reflector surface is matte black to prevent escape of

upward light.

Electrical Module: Self-contained, factory prewired, and attached to the housing

using keyhole slots. All electrical modules are universally mountable in a single housing.

Ballasts are high power factor for -20°F. starting. Sockets UL Listed for the appropriate

lamps, with High Pressure Sodium and Pulse Start Metal Halide sockets rated 4KV.

26W, 32W, 42W Fluorescent: High power factor with starting temperature of 0°F.

Finish/Color: (On door frame only): Finish is TGIC thermoset polyester powder

coat paint, 2.5 mil nominal thickness, applied over a titanated zirconium conversion

coating; A.S.T.M. 2500 hour salt spray test endurance rating. Standard colors are

Black, Dark Bronze, Light Gray, Platinum Silver, Stealth Gray®, or White. Custom

colors are available.

Pour Items: Die-cast, low copper (<0.6% Cu) aluminum housing and junction box

only, less any electrical or optical components.

Finishing Items: Electrical module, reflector and door frame. Each set of finishing

items shall be in one container, clearly marked for the fixture catalog number.

CAUTION: Fixtures must be grounded in accordance with national, state and/or

local electrical codes. Failure to do so may result in serious personal injury.

Listings and Ratings

CE

25C Ambient

IP66 Rated

LLF10, LLF20, LLF30 = Semi-Cutoff2

LLF40 = Non-Cutoff

LLF50, LLF60 = Full-Cutoff2

1

UL cUL 1598

6"

(152.4 mm)

5K"

(139.7 mm)

10

KIM LIGHTING

Suitable for wet locations

Dark Sky Legislation Compliant

1

2

Suggested Concrete Pedestal Designs

Concrete pedestals are an

excellent way to utilize the LLF

in areas where walls or

planters are not available or

feasible. Photographs on the

opposite page and throughout

this catalog show successful

projects that have used these

designs. The four designs

shown here are just ideas to

stimulate the imagination,

since virtually any design can

be cast in concrete.

19M"

(490.5 mm)

19M"

(490.5 mm)

LIGHT

CENTER

48" based

on 36"

light center

60°

36"

(914.4 mm)

Concrete Pedestal (by others)

20"

(508.0 mm)

16"

(406.4 mm)

LIGHT

CENTER

60°

36"

48" based

on 36"

light center

(914.4 mm)

Concrete Pedestal (by others)

18"

(457.2 mm)

14" (355.6 mm)

for two fixtures

10" (254.0 mm)

for one fixture

LIGHT

CENTER

47" based

on 36"

light center

36"

(914.4 mm)

Concrete Pedestal (by others)

16"

(406.4 mm)

18" DIA.

(457.2 mm)

LIGHT

CENTER

60°

36"

48" based

on 36"

light center

(914.4 mm)

Concrete Pedestal (by others)

12

KIM LIGHTING

Application Guidelines

Surface Reflectance

Every LLF installation will have

surface reflectance contributing

to overall illumination. The

amount of this contribution

is impossible to accurately

predict absolutely. However,

the importance of this additional

source of illumination is great

enough to warrant the following

rough guidelines for estimation.

Approximate Reflectance of

Some Common Surfaces

Material

Reflectance

Bluestone, Sandstone

18%

Brick, light buff

48%

Brick, dark buff

40%

Brick, dark red

30%

Cement

27%

Concrete

40%

White Marble

45%

White Paint, new

75%

White Paint, old

55%

Glass, clear

Glass, reflective

Glass, tinted

7%

20-30%

7%

Asphalt, clean

7%

Earth, average

7%

Granolite Pavement

17%

Grass, dark green

6%

Gravel

13%

Macadam

18%

Slate, dark clay

8%

Snow, new

74%

Snow, old

64%

Vegetation, average

25%

Reflections from the horizontal surface will provide illumination for nearby vertical surfaces such

as walls, planters, people, trees, and shrubbery. Even the fixture mounting wall will be partially

illuminated by reflection from nearby surfaces.

Shop

A stairway surrounded by vertical surfaces induces increased illumination on the stairway.

In addition, the vertical surfaces will be illuminated by reflections derived from the horizontal

surfaces.

KIM LIGHTING

15

Application Guidelines

General Area Lighting

LLF-10 Recommended Fixture Spacing

The Low Level Floodlight is a unique new concept in outdoor lighting. There are no industry guidelines to use in the application of

this luminaire. In 1979, Kim introduced the LLF concept, and offered our own guidelines based on experience and test installations.

With years of successful and diverse installations now to our credit, we are confident that the recommendations offered on this

page will satisfy your lighting needs.

ENVIRONMENT 1

ENVIRONMENT 2

ENVIRONMENT 3

ENVIRONMENT 4

• Protected areas with

minimum public access

or use after dark.

• Semi-protected areas

with moderate public

access and use after

dark.

• Unprotected areas of

high public access for

business, shopping, or

recreation.

• Unfenced business,

shopping, or recreation

areas.

• Unfenced installations.

• Unprotected areas

where very high light

levels are required for

visibility, security,

safety, or maximum

sales impact.

• Private property.

• Fenced or guarded

installations.

• Low light level needed

for minimum visibility

only.

• No safety or security

problems.

Approximate minimum

maintained light level:

0.2 Fc

LAMP

50 Watt

HPS

70 Watt

HPS

100 Watt

HPS

70 Watt

MH

100 Watt

MH

42 Watt

PL

• Moderate light level

needed for visibility,

safety, and security.

Approximate minimum

maintained light level:

0.5 Fc

• High light level needed

for good visibility,

safety, and security.

• Areas that require

delineation as main

pathways or entrances.

• Optional Polycarbonate

Lens recommended.

Approximate minimum

maintained light level:

1.0 Fc

Approximate minimum

maintained light level:

5.0 Fc

MOUNTING

HEIGHTS

LONGITUDINAL

SPACING

LATERAL

SPACING

LONGITUDINAL

SPACING

LATERAL

SPACING

LONGITUDINAL

SPACING

LATERAL

SPACING

LONGITUDINAL

SPACING

LATERAL

SPACING

2'

2.5'

3'

2.5'

3'

3'

4'

2.5'

3'

2'

2.5'

3'

_

NR

NR

41'

NR

NR

NR

NR

31'

34'

32'

36'

NR

_

NR

NR

29'

NR

NR

NR

NR

28'

31'

23'

25'

NR

_

25'

29'

30'

34'

34'

41'

46'

24'

26'

25'

29'

30'

_

19'

21'

23'

25'

25'

29'

34'

22'

24'

15'

17'

20'

_

22'

24'

26'

29'

29'

33'

37'

19'

21'

22'

25'

27'

_

16'

18'

20'

20'

20'

25'

28'

19'

21'

13'

15'

17'

_

12'

12'

NR

18'

18'

20'

21'

NR

NR

12'

12'

NR

_

11'

13'

NR

14'

14'

17'

21'

NR

NR

10'

11'

NR

_

NR = Not recommended because the lamp is either too strong for good uniformity of illumination, or too weak for good fixture spacing.

42PL - For recommended spacing, contact your local Kim Lighting Sales Representative or Hubbell Application Engineer in

Greenville, SC - yyeager@hubbell-ltg.com

Lateral spacing based on a staggered fixture arrangement.

Longitudinal

Spacing

Longitudinal

Spacing

Lateral

Spacing

Optional Polycarbonate Lens recommended.

16

KIM LIGHTING

Spacings are calculated

disregarding areas next to

wall midway between fixtures.

Objects in these areas will be

adequately lighted by surface

reflections. See page 15.

Application Guidelines

General Area Lighting

LLF-10 / LLF-40 Photometrics

50 Watt High Pressure Sodium

ED-17 Clear, 4000 lumens

70 Watt High Pressure Sodium

LLF-10

ED-17 Clear, 6300 lumens

LLF-40

100 Watt High Pressure Sodium

ED-17 Clear, 9500 lumens

70 Watt Pulse Start Metal Halide

ED-17 Clear, 5280 lumens

100 Watt Pulse Start Metal Halide

ED-17 Clear, 6912 lumens

42 Watt Compact Fluorescent

LLF-40 photometrics

are inverted

versions of LLF-10.

Available upon request

Light Center

Mounting Height

Illuminated Surface

Mounting Height is the vertical distance from the fixture light center

to the illuminated surface (see page 10).

50 Watt

High Pressure Sodium

70 Watt

High Pressure Sodium

ED-17 Clear

4000 Lumens

I.T.L. Test No. 30517

ED-17 Clear

6300 Lumens

I.T.L. Test No. 30518

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

2.5'

2'

Wall 2

11

5.6

20

10

29

14

45

23

2.8

5

7.2

11

1.1

2

2.9

4.5

.56

1

1.4

2.3

.28

.5

.72

1.1

.11

.2

.29

.45

.06

.1

.14

.23

.03

.05

.07

.11

4

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

10

4'

3'

2.5'

2'

Wall 2

2

11

5.6

2.8

20

10

5

29

14

7.2

45

23

11

1.1

2

2.9

4.5

.56

1

1.4

2.3

.28

.5

.72

1.1

.11

.2

.29

.45

8

.06

.1

.14

.23

8

10

.03

.05

.07

.11

10

Typical Half

6

8

4

4

Typical Half

6

8

10

2

4

6

6

KIM LIGHTING

17

Application Guidelines

General Area Lighting

LLF-10 / LLF-40 Photometrics

NOTE: 42 Watt Compact Fluorescent Photometrics available upon request.

100 Watt

High Pressure Sodium

70 Watt

Pulse Start Metal Halide

ED-17 Clear

9500 Lumens

I.T.L. Test No. 30519

ED-17 Clear

5280 Lumens

I.T.L. Test No. 33043

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

Wall 2

112

21

45

23

11

8.4

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

2.5'

2'

Wall 2

28

50

72

11

5.6

2.8

20

10

5

29

14

7.2

1.1

2

2.9

4.5

.56

1

1.4

2.3

.28

.5

.72

1.1

4

Typical Half

6

8

10

2

4

2.5'

2'

38

55

85

15

22

34

4.3

2.1

7.6

3.8

11

5.5

17

8.4

.84

1.5

2.2

3.4

.43

.76

1.1

1.7

.21

.38

.55

.84

.2

.29

.1

.14

100 Watt

Pulse Start Metal Halide

ED-17 Clear

6912 Lumens

I.T.L. Test No. 33042

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

Wall 2

2.5'

2'

28

50

72

112

11

20

29

45

5.6

2.8

10

5

14

7.2

23

11

1.1

2

2.9

4.5

.56

1

1.4

2.3

.28

.5

.72

1.1

4

Typical Half

6

8

10

2

4

6

.11

.2

.29

.45

.06

.1

.14

.23

8

10

18

10

2

4

.08

.15

.22

.34

.05

.08

.11

.17

8

.23

10

3'

8

.45

8

.06

6

6

6

.11

4

Typical Half

KIM LIGHTING

10

Application Guidelines

Cutoff Area Lighting

LLF-50 Photometrics

50 Watt High Pressure Sodium

ED-17 Clear, 4000 lumens

70 Watt High Pressure Sodium

ED-17 Clear, 6300 lumens

LLF-50

100 Watt High Pressure Sodium

ED-17 Clear, 9500 lumens

70 Watt Pulse Start Metal Halide

ED-17 Clear, 5280 lumens

100 Watt Pulse Start Metal Halide

ED-17 Clear, 6912 lumens

42 Watt Compact Fluorescent

Available upon request

Light Center

Mounting Height

Illuminated Surface

Shop

Mounting Height is the vertical distance from the fixture light center

to the illuminated surface (see page 10).

50 Watt

High Pressure Sodium

70 Watt

High Pressure Sodium

ED-17 Clear

4000 Lumens

I.T.L. Test No. 30523

ED-17 Clear

6300 Lumens

I.T.L. Test No. 30524

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

2.5'

2'

Wall 2

11

5.6

2.8

1.1

.56

.28

20

10

5

2

1

.5

29

14

7.2

2.9

1.4

.72

45

23

11

4.5

2.3

1.1

.11

.06

.2

.1

.29

.14

.45

.23

.03

.05

.07

.11

.01

.02

.03

.04

4

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

2.5'

2'

Wall 2

28

11

5.6

2.8

50

20

10

5

72

29

14

7.2

112

45

23

11

1.1

.56

.28

2

1

.5

2.9

1.4

.72

4.5

2.3

1.1

.11

.2

.29

.45

.06

.1

.14

.23

6

.03

.05

.07

.11

6

8

.01

.02

.03

.04

8

Typical Half

6

8

10

2

4

4

Typical Half

6

8

10

2

4

10

10

KIM LIGHTING

19

Application Guidelines

Cutoff Area Lighting

LLF-50 Photometrics

NOTE: 42 Watt Compact Fluorescent Photometrics available upon request.

100 Watt

High Pressure Sodium

70 Watt

Pulse Start Metal Halide

ED-17 Clear

9500 Lumens

I.T.L. Test No. 30525

ED-17 Clear

5280 Lumens

I.T.L. Test No. 33046

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

2.5'

2'

Wall 2

56

28

11

5.6

2.8

1.1

.56

.28

100

50

20

10

5

2

1

.5

144

72

29

14

7.2

2.9

1.4

.72

225

112

45

23

11

4.5

2.3

1.1

.11

.2

.29

.45

.06

.1

.14

.23

.03

.05

.07

.11

4

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

10

4'

3'

2.5'

2'

Wall 2

2

43

21

8.4

4.3

2.1

.84

.43

.21

76

38

15

7.6

3.8

1.5

.76

.38

109

55

22

11

5.5

2.2

1.1

.55

171

85

34

17

8.4

3.4

1.7

.84

2

4

.08

.15

.22

.34

4

.05

.08

.11

.17

.02

.04

.05

.08

.01

.02

.02

.03

Typical Half

6

8

6

.01

.02

.03

6

8

10

6

8

8

10

10

.04

100 Watt

Pulse Start Metal Halide

ED-17 Clear

6912 Lumens

I.T.L. Test No. 33047

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

2.5'

2'

Wall 2

56

28

11

5.6

2.8

1.1

.56

.28

100

50

20

10

5

2

1

.5

144

72

29

14

7.2

2.9

1.4

.72

225

112

45

23

11

4.5

2.3

1.1

2

.11

.2

.29

.45

4

.06

.1

.14

.23

.03

.05

.07

.11

.01

.02

.03

.04

4

Typical Half

6

8

10

6

8

10

20

4

Typical Half

KIM LIGHTING

Application Guidelines

Cutoff Area Lighting

LLF-60 Photometrics

50 Watt High Pressure Sodium

ED-17 Clear, 4000 lumens

70 Watt High Pressure Sodium

ED-17 Clear, 6300 lumens

LLF-60

100 Watt High Pressure Sodium

ED-17 Clear, 9500 lumens

70 Watt Pulse Start Metal Halide

ED-17 Clear, 5280 lumens

100 Watt Pulse Start Metal Halide

ED-17 Clear, 6912 lumens

42 Watt Compact Fluorescent

Available upon request

Light Center

Mounting Height

Illuminated Surface

Mounting Height is the vertical distance from the fixture light center

to the illuminated surface (see page 10).

50 Watt

High Pressure Sodium

70 Watt

High Pressure Sodium

ED-17 Clear

4000 Lumens

I.T.L. Test No. 30529

ED-17 Clear

6300 Lumens

I.T.L. Test No. 30530

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

2.5'

2'

Wall 2

5.6

2.8

10

5

14

7.2

23

11

1.1

.56

2

1

2.9

1.4

4.5

2.3

.28

.5

.72

1.1

.11

.2

.29

.45

.06

.1

.14

.23

.03

.05

.07

.11

.01

.02

.03

.04

4

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

10

4'

3'

2.5'

2'

Wall 2

2

11

5.6

2.8

20

10

5

29

14

7.2

45

23

11

1.1

2

2.9

4.5

.56

1

1.4

2.3

.28

.5

.72

1.1

.11

.2

.29

.45

.06

.1

.14

.23

.03

.05

.07

.11

Typical Half

6

8

4

6

4

Typical Half

6

8

10

2

4

6

8

8

.01

.02

.03

.04

10

10

KIM LIGHTING

21

Application Guidelines

Cutoff Area Lighting

LLF-60 Photometrics

100 Watt

High Pressure Sodium

70 Watt

Pulse Start Metal Halide

ED-17 Clear

9500 Lumens

I.T.L. Test No. 30531

ED-17 Clear

5280 Lumens

I.T.L. Test No. 33049

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Distance in

Mounting Heights

4'

3'

2.5'

2'

Wall 2

11

5.6

2.8

20

10

5

29

14

7.2

45

23

11

1.1

2

2.9

4.5

.56

1

1.4

2.3

.28

.5

.72

1.1

.11

.2

.29

.45

.06

.1

.14

.23

.03

.05

.07

.11

.01

.02

.03

.04

NOTE: 42 Watt Compact Fluorescent Photometrics available upon request.

4

Typical Half

6

8

10

2

4

6

4'

3'

2.5'

2'

Wall 2

5.6

2.8

10

5

14

7.2

23

11

1.1

.56

2

1

2.9

1.4

4.5

2.3

.28

.5

.72

1.1

.11

.2

.29

.45

.06

.1

.14

.23

.03

.05

.07

.11

.01

.02

.03

.04

4

8

10

2

4

6

10

KIM LIGHTING

2.5'

2'

Wall 2

4.3

2.1

7.6

3.8

11

5.5

17

8.4

.84

1.5

2.2

3.4

.43

.76

1.1

1.7

.21

.38

.55

.84

.08

.15

.22

.34

.05

.08

.11

.17

.02

.04

.05

.08

.01

.02

.02

.03

4

6

8

10

2

4

6

10

8

22

3'

10

Typical Half

6

4'

Typical Half

8

ED-17 Clear

6912 Lumens

I.T.L. Test No. 33048

Distance in

Mounting Heights

Distance in

Mounting Heights

8

100 Watt

Pulse Start Metal Halide

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Initial Horizontal

Footcandles at

Listed Mounting

Heights

Application Guidelines

Stairway Lighting

LLF-20 / LLF-30

Special Optical System

The LLF-20 and LLF-30 contain optical systems that are specifically

designed to light stairways or ramps greater than 10° slope. They

are individually hydroformed reflectors engineered for maximum

light efficiency on the stairway. The photograph on the top of

page 23 shows an LLF installation where the entire stairway is

illuminated by just one fixture. This photograph illustrates the correct

fixture placement, approximately 3' from the top stair, and 2' above

the stairway plane. Notice the entire stairway is illuminated, including

the vertical walls. This is partially due to surface reflections, which

are discussed on page 15.

Right and Left Light Distributions

For complete application flexibility, both right and left distributions

are offered. Most stairways can be lighted from one side only, since

the LLF-20 and LLF-30 produce a very wide light pattern.

Photometric curves shown in this catalog are for the LLF-20.

The LLF-30 is equal and opposite.

Tread Shadows

Longitudinal spacing of the LLF-20 and LLF-30 is primarily

controlled by the amount of tread shadow that is acceptable. When

Kim created the LLF concept, there were no established guidelines

to use in the application of this luminaire. Based on our lighting

experience and test observations, we recommend that fixture

spacing should not create a shadow greater than 75% of the tread

width. With a history of successful LLF jobs, the 75% tread shadow

rule appears to be a sound recommendation. Therefore, all LLF-20

and LLF-30 photometric charts show a dashed line where 75% of

the tread will be in shadow. Remember, longitudinal spacing must

also consider the lighting contribution from the lower fixture, if more

than one fixture is used.

ANGLE OF

STAIRWAY PLANE

Handrail

Angle of

Stairway

Plane

Light Center

2' Mounting Height (b)

75% of last tread in shadow (a)

Longitudinal Spacing

will not exceed 75% tread shadow rule

24

KIM LIGHTING

Angle of Stairway Plane

RUN TO RISE

RATIO

EXAMPLES

RUN

RISE

7.27

6.54

5.82

20°

2.75:1

20

18

16

25°

2.14:1

18

16

14

8.41

7.47

6.54

30°

1.73:1

16

14

12

9.25

8.09

6.94

35°

1.43:1

14

12

10

9.79

8.39

6.99

a. 75% tread shadow is established by

Kim, based on field observations for

optimum visibility.

b. Mounting height of 2' is considered

ideal, as it will place fixture just

below the handrail. Higher mounting

heights should only be used if

fixture will not interfere with handrail.

LLF-20

Application Guidelines

Stairway Lighting

LLF-20 / LLF-30 Recommended Fixture Spacing

LLF-30

ENVIRONMENT 1

ENVIRONMENT 2

ENVIRONMENT 3

ENVIRONMENT 4

• Protected areas with

minimum public access

or use after dark.

• Semi-protected areas

with moderate public

access and use after

dark.

• Unprotected areas of

high public access for

business, shopping, or

recreation.

• Unfenced business,

shopping, or recreation

areas.

• Unfenced installations.

• Unprotected areas

where very high light

levels are required for

visibility, security,

safety, or maximum

sales impact.

• Private property.

• Fenced or guarded

installations.

• Low light level needed

for minimum visibility

only.

• No safety or security

problems.

Approximate minimum

maintained light level:

0.2 Fc

LAMP

50 Watt

HPS

70 Watt

HPS

100 Watt

HPS

70 Watt

PMH

100 Watt

PMH

42 Watt

PL

• Moderate light level

needed for visibility,

safety, and security.

Approximate minimum

maintained light level:

0.5 Fc

ANGLE OF

STAIRWAY

PLANE

LONGITUDINAL

SPACING

LATERAL

SPACING

LONGITUDINAL

SPACING

LATERAL

SPACING

20°

25°

30°

35°

20°

25°

30°

35°

20°

25°

30°

35°

20°

25°

30°

35°

20°

25°

30°

35°

_

20'

16'

13'

12'

45'

48'

50'

53'

20'

16'

13'

12'

20'

16'

13'

12'

39'

41'

43'

45'

38'

40'

42'

45'

NR

NR

NR

NR

NR

NR

NR

NR

_

_

NR

NR

20'

16'

13'

12'

20'

16'

13'

12'

_

36'

37'

38'

39'

45'

48'

50'

52'

_

• High light level needed

for good visibility,

safety, and security.

• Areas that require

delineation as main

pathways or entrances.

• Optional Polycarbonate

Lens recommended.

Approximate minimum

maintained light level:

1.0 Fc

Approximate minimum

maintained light level:

5.0 Fc

LONGITUDINAL

SPACING

LATERAL

SPACING

LONGITUDINAL

SPACING

LATERAL

SPACING

NR

NR

NR

NR

20'

16'

13'

12'

20'

16'

13'

12'

20'

16'

13'

12'

20'

16'

13'

12'

_

34'

35'

37'

39'

36'

39'

40'

42'

22'

23'

23'

24'

38'

41'

44'

45'

_

NR

NR

20'

16'

13'

12'

27'

29'

30'

31'

NR

NR

NR

NR

_

_

NR = Not recommended because the lamp is either too strong for good uniformity of illumination, or too weak for good fixture spacing.

42PL - Available upon request

NOTE: Mounting height of 2' is considered ideal for a fixture placed just below a handrail. Higher mounting heights should only be

used if fixture will not interfere with handrail.

Lateral spacing based on opposed fixture arrangement on

stairway.

Longitudinal

Spacing

For lateral light coverage with fixtures on one side of

stairway only, divide lateral spacings in chart by 2.

Longitudinal

Spacing

Longitudinal

Spacing

Longitudinal

Spacing

Lateral

Spacing

Lateral

Spacing

KIM LIGHTING

25

Application Guidelines

Explanation of Stairway Photometrics

LLF-20 / LLF-30

LLF-20

LLF-20

LLF-30

LLF-30

All LLF-30 photometrics

are mirrored versions

of LLF-20.

Stairway Photometrics

The LLF-30 is exactly equal and opposite to the LLF-20.

As such, the specifier has complete flexibility in lighting

stairways or ramps for the right, left, or both sides. For LLF-30

photometrics, simply visualize the LLF-20 charts inverted.

Stairway photometrics are not accurate for ramps because light

falling on horizontal stair treads is calculated differently than for

a sloped ramp surface. The LLF-10 should be used for ramps

up to 10° slope. Ramps greater than 10° should be lighted with

the LLF-20 or LLF-30. Consult representative for ramp

applications.

30°

3

Lateral Distance in Mounting Heights

All stairway photometrics shown on pages 27-31 are for the

LLF-20, right-downward light distribution. Each chart is a plan

diagram of lighting on the stairway, allowing direct correlation to

your plot plan. A dashed line shows where 75% of the stair

tread will be in shadow. Photometrics are presented for stairway

angles of 20°, 25°, 30°, and 35°. If your stairway falls between

these angles, use the closest chart or linear interpolation.

1

2

2

1

30° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

100

50

.2

20

3

4

.5

5

10

6

1

7

5

8

9

10

.2 .5 1

2

2

75% Tread

Shadow

Plan View

I.T.L. Test No. 33044

Tread Shadow Distance

To calculate the tread shadow distance or any other

percentage of last tread shadow, use the following formula:

(Assume 2' mounting height.)

Tread Shadow Distance in ft. =

2S

TAN ∝ (1-S)

Tread Shadow Distance is shown

in plan view as a dashed line.

75% Tread

Shadow Distance

(See formula at left)

Where S is the acceptable amount of last-tread shadow

(75%=.75) and ∝ is the angle of the stairway plane.

NOTE: Each step is a horizontal surface. Therefore, all light

values are in horizontal footcandles as they would fall on the

stair treads.

2' Mounting Height

Light Center

Horizontal

∝ Angle of

Stairway Plane

ELEVATION

26

KIM LIGHTING

Application Guidelines

Stairway Lighting

LLF-20 / LLF-30 Photometrics

50 Watt High Pressure Sodium

LLF-20

ED-17 Clear, 4000 lumens

20°, 25°, 30°, 35° Stairway Planes

Assume 2' Mounting Height.

LLF-30

LLF-20

20°

3

2

1

LLF-30

20° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

25°

3

2

1

25° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

2

3

10

4

.5

5

5

6

2

7

1

8

9

.5

.2

10

Plan View

30°

3

1

2

1

75% Tread

Shadow

20

2

3

10

5

2

5

.5

6

7

1

8

9

10

.5

4

10

5

5

6

7

2

8

9

3

.2

4

3

.1 .2

35°

.1

.2

20

2

.5

1

2

3

2

1

1

1

75% Tread

Shadow

Plan View

I.T.L. Test No. 30535

30° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

50

50

1

10

.5

I.T.L. Test No. 30535

Lateral Distance in Mounting Heights

.2

20

Lateral Distance in Mounting Heights

50

Lateral Distance in Mounting Heights

Lateral Distance in Mounting Heights

.1

1

35° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

50

20

.1

10

.2

5

4

2

5

1

6

7

.5

8

9

10

.1 .2

I.T.L. Test No. 30535

.5

1

Plan View

.1 .2 .5

75% Tread

Shadow

1

I.T.L. Test No. 30535 Plan View

75% Tread

Shadow

KIM LIGHTING

27

Application Guidelines

Stairway Lighting

LLF-20 / LLF-30 Photometrics

70 Watt High Pressure Sodium

LLF-20

ED-17 Clear, 6300 lumens

20°, 25°, 30°, 35° Stairway Planes

Assume 2' Mounting Height.

LLF-30

LLF-20

Lateral Distance in Mounting Heights

3

2

1

20° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

100

50

1

2

25°

3

.2

3

20

4

.5

10

5

5

6

2

7

1

8

9

.2

Lateral Distance in Mounting Heights

20°

20

.2

Lateral Distance in Mounting Heights

2

.2

3

20

.5

4

10

5

1

6

5

7

8

2

9

2

1

30° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

100

50

35°

3

.2

3

20

.5

4

10

5

1

5

6

7

8

9

1

2

3

2

1

.5

1

75% Tread

Shadow

Plan View

I.T.L. Test No. 30536

10

35° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

.1

100

50

.2

20

4

.5

5

10

6

1

7

5

8

9

10

.2

I.T.L. Test No. 30536

28

100

50

1

.2

75% Tread

Shadow

Lateral Distance in Mounting Heights

30°

2

1

.5

Plan View

I.T.L. Test No. 30536

1

2

25° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

10

10

3

LLF-30

KIM LIGHTING

.5

1

Plan View

2

2

75% Tread

Shadow

.1 .2 .5 1

I.T.L. Test No. 30536 Plan View

2

2

75% Tread

Shadow

Application Guidelines

Stairway Lighting

LLF-20 / LLF-30 Photometrics

100 Watt High Pressure Sodium

LLF-20

ED-17 Clear, 9500 lumens

20°, 25°, 30°, 35° Stairway Planes

Assume 2' Mounting Height.

LLF-30

LLF-20

20° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

2

1

1

.2

100

2

.5

3

50

4

1

20

5

10

6

5

7

8

2

9

1

10

.5

.2

3

2

1

1

75% Tread

Shadow

2

2

4

1

6

10

7

2

8

5

9

10

20

5

10

6

7

5

8

9

2

.5 1

1

2

2

1

2

.5 1

I.T.L. Test No. 30537

2

Plan View

35° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

100

.2

50

3

.5

4

20

5

6

1

7

10

8

9

5

.2 .5 1

75% Tread

Shadow

75% Tread

Shadow

Plan View

10

.2

1

4

3

.5

20

.5

50

3

35°

50

3

.2

100

I.T.L. Test No. 30537

.2

5

1

.2

100

2

1

10

30° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

30°

2

1

Plan View

I.T.L. Test No. 30537

Lateral Distance in Mounting Heights

3

Lateral Distance in Mounting Heights

Lateral Distance in Mounting Heights

3

25° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

25°

Lateral Distance in Mounting Heights

20°

LLF-30

I.T.L. Test No. 30537

2

2

Plan View

75% Tread

Shadow

KIM LIGHTING

29

Application Guidelines

Stairway Lighting

LLF-20 / LLF-30 Photometrics

70 Watt Pulse Start Metal Halide

LLF-20

ED-17 Clear, 5280 lumens

20°, 25°, 30°, 35° Stairway Planes

Assume 2' Mounting Height.

LLF-30

LLF-30

LLF-20

25°

20°

2

1

76

1

.4

3

4

15

.8

7.6

5

3.8

6

.2

38

2

3

.4

4

15

.8

5

7.6

6

7

3.8

8

9

2

1

30° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

35°

3

76

38

2

.2

15

3

4

.4

5

7.6

6

.8

7

3.8

8

9

1

2

2

1

1.5

.8

75% Tread

Shadow

Plan View

I.T.L. Test No. 33044

35° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

76

38

.2

15

3

4

5

7.6

6

.4

7

8

3.8

9

.8

10

10

.2 .4 .8

I.T.L. Test No. 33044

30

76

1

.2 .4

9

1

1

1.5

8

3

2

10

7

30°

Lateral Distance in Mounting Heights

.2

38

2

Lateral Distance in Mounting Heights

Lateral Distance in Mounting Heights

3

20° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

Lateral Distance in Mounting Heights

3

25° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

KIM LIGHTING

1.5

Plan View

1.5

75% Tread

Shadow

.2 .4 .8

I.T.L. Test No. 33044

1.5

Plan View

1.5

75% Tread

Shadow

Application Guidelines

Stairway Lighting

LLF-20 / LLF-30 Photometrics

100 Watt Pulse Start Metal Halide

LLF-20

ED-17 Clear, 6912 lumens

20°, 25°, 30°, 35° Stairway Planes

Assume 2' Mounting Height.

LLF-30

LLF-20

20° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

Lateral Distance in Mounting Heights

3

2

1

100

50

1

2

25°

3

.2

.5

3

20

4

1

10

5

5

6

7

2

8

9

Lateral Distance in Mounting Heights

20°

.2

.5

I.T.L. Test No. 33044

Lateral Distance in Mounting Heights

2

1

100

50

1

2

.2

3

.5

4

20

1

5

10

6

7

5

8

9

2

1

.2 .5

1

Plan View

75% Tread

Shadow

30° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

100

50

35°

3

.2

20

3

4

.5

5

10

6

1

7

5

8

9

1

2

2

1

2

1

75% Tread

Shadow

Plan View

I.T.L. Test No. 33044

Lateral Distance in Mounting Heights

30°

1

2

25° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

10

10

3

LLF-30

35° Angle of Stairway Plane.

Initial Horizontal Footcandles.

Downstairs Distance in Mounting Heights

1 2 3 4 5 6 7 8 9 10

100

50

.2

20

3

4

5

10

6

.5

7

8

5

9

1

10

10

.2 .5 1

I.T.L. Test No. 33044

2

2

Plan View

75% Tread

Shadow

.2 .5 1

I.T.L. Test No. 33044

2

2

Plan View

75% Tread

Shadow

KIM LIGHTING

31

4000

ED-17 Clear

Medium Base

70

S-62

24000+

6300

ED-17 Clear

Medium Base

100

S-54

24000+

9500

70

M-98

11000+

5500

100

M-90

11000+

8300

42

–

10000+

3200

70HPS

100HPS

PULSE START METAL HALIDE

70PMH

ED-17 Clear

Medium Base

100PMH

ED-17 Clear

Medium Base

COMPACT FLUORESCENT

42PL

Coated

GX24q-4 Base

Max.

Amps.

Initial

Lumens

24000+

Starting

Amps.

Life

(Hours)

S-68

Open

Circuit

ANSI

Ballast

Type

50

HIGH PRESSURE SODIUM

50HPS

ED-17 Clear

Medium Base

Operating

Amps.

Lamp

Watts

Lamp

Voltage

Lamp and Electrical Guide

120

208

240

277

120

208

240

277

347

120

208

240

277

347

0.55

0.33

0.30

0.26

0.81

0.47

0.40

0.35

0.30

1.15

0.67

0.58

0.50

0.39

1.24

0.60

0.52

0.45

1.45

0.85

0.75

0.65

0.55

2.20

1.25

1.10

0.85

0.70

0.58

0.35

0.31

0.25

0.75

0.45

0.37

0.35

0.30

1.30

0.75

0.65

0.60

0.45

1.24

0.60

0.52

0.45

1.45

0.85

0.75

0.65

0.55

2.20

1.25

1.10

0.85

0.70

120

208

240

277

347

120

208

240

277

347

0.80

0.46

0.40

0.35

0.28

1.15

0.66

0.58

0.50

0.40

1.90

1.00

0.90

0.80

0.65

2.30

1.40

1.15

1.00

1.00

0.55

0.30

0.25

0.25

0.20

1.20

0.80

0.65

0.60

0.40

1.90

1.00

0.90

0.80

0.65

2.30

1.40

1.15

1.00

1.00

120

208

240

277

0.39

0.23

0.20

0.17

–

–

–

–

–

–

–

–

0.39

0.23

0.20

0.17

NOTE: For lamp/ballast information outside of the U.S.A. and Canada, please consult your local Kim representative.

WARNING: Fixtures must be grounded in accordance with national, state and/or local electrical codes. Failure to do so may result in serious personal injury.

Lamps by others.

32

KIM LIGHTING

Application Engineering Services

Applications Assistance

Kim Lighting utilizes the latest computer technology and

software to provide specifiers with reliable evaluations of

lighting system performance.

Kim can analyze a proposed luminaire layout or provide

recommendations based on performance criteria.

Hard copies of plans can be sent directly to the

Kim Applications Department via fax, express or

regular mail. Any .dwg or .dxf file can be e-mailed

(kim.apps@kimlighting.com), or placed on CD and forwarded

to Kim Lighting, c/o Applications Dept.

Photometric Files

Kim Lighting electronic photometric files include .pdf file format

pages for printing and .ies files for use in lighting calculation

software. The complete .ies / .pdf library is available on the

internet at www.kimlighting.com.

KIM LIGHTING

33