Fall, 2010 Volume 22, No.3 - Nevada T2 Center

advertisement

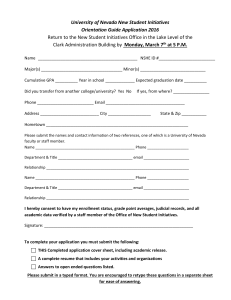

Fall 2010 Nevada’s Technology Transfer Quarterly Vol. 22 No. 3 FOCUS NIGHT PAVING ■ Time management plays crucial role in night paving a lways a critical factor in construction success, time management is even more so when paving at night. Night paving requires that you lay a certain number of tons in a prescribed amount of time. Plan, plan, plan! You cannot afford to lose time; you won’t have any way to make it up in the middle of a shift. You’re on and off the road in a certain time frame, so you’ve got to make sure that all your equipment’s working properly. You also need to plan for the possibility of breakdowns by having an extra roller and truck or two to avoid unnecessary waits. You might want to do cooling curves that tell you how long you’ve got before the mat cools to a certain temperature. You can determine: If you’re paving this wide, laying this many tons, you need this many compactors. It’s getting information, and sharing it, because the plan you make at night is different than what the crew is used to doing during the day. When it comes time to lay material, you can’t afford to make any mistakes because of the time restraints. Everybody has to be a little bit more vigilant at night, and it starts at the plant. As you will not be able to detect defects in the material, the plant’s quality control is even more crucial at night. You need to be able to count on the fact that the quality of the mix coming to you is the same, truck after truck. Intricate planning Saving a few minutes a few times over a night shift is what intricate planning is all about. Scenario 1: Vibratory compactors typically will need to resupply the water spray system once during the shift. If you’re going to refill the water spray system in, let’s just say, five hours, you want to know where you’re going to be on the project five hours from the start, and that’s where you’re going to have your water truck waiting. You don’t want to wait on somebody to run back to the start of the job and bring the water truck to that point. It’s a small detail, but maybe that saves you 10 minutes. Scenario 2: You’re working on a three-lane paving job in which the high-speed lane is paved for 1,500 feet. The crew then picks up, backs up and completes the middle lane for the same distance, and then ditto for the right lane. You calculate that 18 trucks hauling an average of 22 tons are going to cover this distance. You want to make sure that you have those 18 trucks show up in a slightly staggered pattern, so that you don’t have any stops — zero stops — especially during the first pull. The trick is to get through the first third of a particular phase of the project in less than one-third of the phase’s allotted time. You want to balance plant output, trucking, paving speed and compaction so that in that first pass, you can go as fast as you get the mix to it, without stopping and without outrunning the compactors. Then you’ve gained yourself a little breathing room moving forward. Trade-offs Paving at night actually represents an advantage because traffic is what hinders continuous paving. During the day you might have a plant that has sufficient production, you might have an adequate number of trucks, but traffic might hinder the flow of trucks to and from the job site. continued on page 2 IN THIS ISSUE ■ Factors to consider when paving at night is the focus (pp. 1, 7). ■ New UNR study evaluates performance of slurry seals on asphalt pavements (p 2). ■ Recycle Michael enumerates the benefits of using foundry sand in transportation projects (p. 6). ■ Guideline aids in the design, quality control, measurement and payment procedures for application of micro surfacing (p. 8). ■ Elko superintendent’s device rebuilds traffic control barriers (p. 14). ■ ROUTING SLIP Don’t file this Quarterly in your inbox. Please — read it, photocopy what you want, initial below, and send it on, especially to the frontline troops. _____________________ _____________________ _____________________ _____________________ _____________________ IN NEVADA TABLE OF CONTENTS Focus Time management crucial to night paving ................................1 Get compaction right at night .........7 Staying safe when the sun goes down ...........................................7 In Nevada Effectiveness of slurry seals on asphalt pavements .....................2 NDOT photos win national competition ................................3 Public works director puts experience into practice .............3 Spring Creek roundabout offers safety and creativity ....................4 Railroad agreement benefits Ely ..............................................4 Railport and industrial park help grow Elko economy ....................5 Mother Nature hinders Lamoille Canyon Bypass project...............5 I-15 express lanes completed ........5 Engines of bygone economic growth ........................................6 New phase of Carson City freeway .......................................8 Health Watch Steps to take to reduce stress .......9 Staying safe on Thanksgiving ........9 Whole grains reduce waistline .......9 Training Recommended performance guideline for micro surfacing.......8 Roads Scholars step into spotlight .............................10–11 Training pays off in tight times ......10 Web based training ......................11 New traffic control guidelines .......11 On the Job Nurturing “family relationships” at work ..........................................12 12 business skills essential to success ................................12 Job fulfillment ...............................12 Safety Roadside cheatgrass can ignite wildfires ....................................13 Safety edge reduces accidents ....13 Taking precautions with methamphetamine waste ........13 On the Horizon Emerging dynamics of ITS ...........14 Rear View Mirror Relive pioneer trail history at new I-80 heritage center ..........16 Humor Talking turkey .................................9 Bumper shtick ..............................12 Regular Features Road Smart Contest ......................4 Recycle Michael .............................6 Quotable Quotes ............................8 The Practical Man ........................14 2 Nevada Milepost • Fall 2010 New UNR study Effectiveness of slurry seals on asphalt pavements in the field t he Pavements/Materials Program at the University of Nevada, Reno has conducted a study for the Washoe Regional Transportation Commission to evaluate the field performance of slurry seals on asphalt pavements. Conducted recently under the pavement technology contract between UNR and RTC, the objectives of the study were to: Evaluate the field performance of asphalt pavements with and without slurry seal applications. Develop performance models for asphalt pavement without slurry seals and asphalt pavements receiving slurry seals at various times following construction. Identify the optimum time for the application of slurry seals on asphalt pavements. Evaluated sections Asphalt pavement sections were identified within the jurisdictions of Washoe County and cities of Reno and Sparks. The evaluation covered pavements that were newly constructed and pavements that received overlays. Residential streets were by far the highest number of pavement sections included in the study due to the high availability of such pavements within the urban area. The pavement sections were broken into the following categories: Do-nothing: a slurry seal was not applied to the pavement Slurry seal applied immediately after construction Slurry seal applied at one, three, five, seven and nine years after construction The performance of the various pavement sections were measured in terms of the pavement condition index that the agencies collect using the Micro-Paver system every two years for all three categories of pavements. Micro-Paver divides the road network into sections based on uniform properties of the pavement and traffic conditions. Each pavement section is further divided into units, and the units surveyed within a given section were identified randomly. The average PCI value of the surveyed units within each section was used to represent the condition of the entire section for the specific survey data. Conclusions and recommendations The performance data of slurry seals analyzed in this report supported the basic engineering principles of preventive maintenance of asphalt pavement as discussed below: Asphalt pavements should be allowed to cure for the first three years prior to the application of any surface treatment. This is proven by the low benefits of applying slurry seal at zero and one year after construction. The three years curing period of asphalt pavements allows the asphalt mix to gain strength and build up its resistance to early rutting and shoving. The application of surface treatment on asphalt pavements three years after its construction protects the asphalt mix from excessive aging and improves its resistance to cracking; e.g. fatigue, thermal and block. The application of the slurry seal immediately after or one year after construction of the asphalt layer is not effective in terms of both the benefit to the users and the benefit cost ratio for the agency. The optimum time of application of slurry seal depends on the type of construction activity. For newly constructed pavements, the optimum time to apply slurry seal is three years after construction. For pavements subjected to overlays, the optimum time to apply seal is between three years and five years after construction. However, for uniformity purposes, it is recommended that the agency apply slurry seal three years after the construction of the asphalt layer for both new and overlay constructions. For a copy of this study, go to the No-Brainer MailIn Page. Night paving continued from page 1 However, traffic control is a huge problem at night because of lack of visibility. The key is pre-project or pre-shift safety meetings that explain to everyone where traffic is going to be at all times, which lanes are closed, which lanes are open, how close the traffic will be to the cones or the barricades. In short, communication about safety is even more critical at night. If you’re doing a long night project, you’re probably better served by having one crew doing it instead of switching crews on and off nights. A single crew will have the chance to acclimate to working at night and resting during the day. IN NEVADA NDOT photos win national contest t NDOT Wellington Crew 235 members (left to right) Tony Gutierrez, Tom Stern, Brent Slobe, Robert Tracy and Supervisor Steve Stringham. wo photos portraying Nevada transportation have been named winners in the national “Face of Transportation” competition sponsored by the American Association of State Highway & Transportation Officials. Best overall photo was awarded to NDOT photographer Julie Duewel for her shot of the department’s Wellington maintenance crew. The caption reads: “Standing strong and united; ready to expertly maintain and make safe the network of vital rural roads, which crisscross the state’s 110,000 square miles.” Julie also placed third in the “improving quality of life” category for her September 2009 photo of Carson City’s fun run and walk. Nearly 100 photos from 24 state DOTs were entered in the national competition. “These photos truly depict the positive effects of transportation on individuals and their communities,” says AASHTO Executive Director John Horsley. “Thousands of men and women are working every day to make America’s transportation system work better, and we wanted this competition to honor them. Too often what they do is taken for granted; these photos show the real faces of transportation today.” At left, residents commemorate opening of second phase of the Carson City freeway with a fun run. Profile Public works director puts experience into practice p ublic works director for the City of Elko for three years, Dennis Strickland oversees 30 employees and manages the daily operations of the street, landfill, facilities and fleet departments. “A primary goal of mine is to see that tax dollars are spent wisely and efficiently, especially in the current downturn in the economy and shortage of funds for public works,” Dennis says. However, Elko is in much better economic shape with 8.5 percent unemployment than the rest of the state. “I’m thankful that there has been no reduction in my force and no furloughs,” Dennis says. “But we have undergone a 1 percent cut in pay.” Dennis contends that his 10 years of supervisory experience in the private sector has helped him deal with budget constraints. “I’ve undertaken cost savings practices in our preventive maintenance program,” he says. His previous work experience also includes four years as the city’s street superintendent and five years with the Elko County Highway Department. These positions further honed his managerial skills. “I’ve reorganized the agency which has made for better management and an improved work environment, especially in the landfill and fleet departments,” he asserts. Dennis praises the Nevada T2 Center for offering valuable training courses. “The City of Elko is a huge supporter of the program,” he says. “Most of the street department employees already are Roads Scholars.” Dennis and his boss, Assistant City Manager Delmo Andreozzi, who serves on the T2 Center Advisory Board, are Roads Scholars themselves. Born in Fallon, Dennis graduated from Churchill Country High School where he was a varsity athlete and attended Western Nevada and Great Basin colleges. A member of the Northern Nevada Golf Association, he travels around the state playing in local tournaments. ■ THE NEVADA T2 CENTER ADVISORY BOARD Delmo Andreozzi City of Elko Kevin Carnes USDA Forest Service Ken Chambers NDOT Kevin Lee Nevada DOT, Elko Shital K. Patel FAST, RTC Southern Nevada Patrick Pittenger Carson City Public Works Jim Poston Washoe County RTC Roger Sutton City of Winnemucca Kathy Sanchez City of Reno Paul Solaegui President, Solaegui Engineers Barbara Stearns NDOT, Training Division Hannah Visser FHWA 3 Nevada Milepost • Fall 2010 IN NEVADA Spring Creek roundabout offers safety and creativity a $2-milllion roundabout was completed in August at the intersection of Lamoille Highway and Spring Creek/Licht parkways in Spring Creek. Spring Creek Elementary School is located at the intersection, and the new roundabout makes it easier for students to cross the busy Lamoille Highway. Raised concrete median islands serve as refuge points for pedestrians. Welding students at Spring Creek High School created a threedimensional sculpture of the Ruby Mountains, which stands in the middle of the roundabout. New railroad agreement benefits City of Ely t he S&S Shortline Railroad recently rehabilitated Nevada Northern Railroad’s tracks from Shafter, which is the line’s connection to the Union Pacific main line, south for 40 miles to Currie. Under an agreement with the City of Ely and the White Pine Railroad Foundation, the S&S rehabilitated the tracks at its expense in exchange for the city storing Union Pacific rail cars. The city and foundation receive a portion of the storage fees and continue to own the tracks. The Union Pacific has delivered 336 rail cars for storage with 186 more on the way. “Road Smart” contest For each issue of the Nevada Milepost, field representative Larry Lunz (“L2 on the Road”) submits a photograph from his trips across the Silver State for the “Road Smart” contest. What’s your best guess as to the location of this road? Send in your answer on the “NoBrainer” Page. First correct answer by fax is the Road Smart winner! 4 Nevada Milepost • Fall 2010 How to play To win a handsome prize that will make you the envy of all your coworkers, you need to be the first to identify the stretch of road in the accompanying photograph. Specifically, you need to identify the road and two nearest destinations. If you think you know the road and location, write it in where indicated on the NoBrainer Mail-In Page. If you’re the first person to fax the T2 Center with the correct information, you win! It’s that easy. Fame and esteem The winner will gain statewide fame and esteem when written up in the Winter 2010 issue. So keep a sharp eye when you’re out and about. Even if you don’t know the location this time, don’t lose heart. You’ll get ample chances with different locations in future issues of the Nevada Milepost. Thanks for playing! Las Vegas winner David Dwyer, P.E., president of Dwyer Engineering, Inc., is the latest Road Smart contest winner. He was the first to correctly identify the photograph in the Summer 2010 issue of Milepost as State Route 156 near State Route 158 and the Las Vegas Ski & Snowboard Resort. IN NEVADA Railport and industrial park in Elko help to grow the local economy t he new Northeastern Nevada Regional Railport is a 54-acre public-private partnership facility owned by Elko County and operated by a professional transloading firm. Located 4½ miles from the city of Elko, the railport has direct access to Interstate 80 and 3,700 feet of dedicated Union Pacific Railroad siding for rail service. The railport is in an excellent location for manufacturing and distribution industries at the geographic crossroads of Reno, Boise and Salt Lake City. It is also in the heart of the largest gold producing area in North America providing important rail access to support the mines. The adjacent industrial park that opened in March has already attracted three companies. “The companies employ 50 people and pay an average wage of $20 per hour, making for good paying jobs for the Elko economy,” says Pam Borda, executive director of the Elko County Economic Diversification Authority. The estimated economic benefit of the railport and industrial park to Elko County is $19 million, according to Pam, who says the combined facility is expected to pay $632,000 in local taxes and $261,000 in state taxes annually. A side benefit of the industrial park is that one of the companies, Pacific Steel & Recycling, has decreased the amount of recyclable items going to the county-owned landfill, and thereby extended its capacity. Mother Nature hinders Lamoille Canyon Byway reconstruction a fter enduring nature-caused delays, a $4.5-million partial reconstruction project funded by the U.S. Forest Service is under way on the Lamoille Canyon Scenic Byway within the Ruby Mountains near Elko. Upper end of Lamoille Canyon Road Last spring the contractor was eager to get a head start on the project because of the short construction season in the area known as “The Alps of Nevada.” NDOT obliged, opening the road with a rotary snow blower. However, within a matter of days three avalanches covered the road. The largest was 200 feet long and 12 feet high. The Bureau of Land Management brought in a front loader to clear the avalanches. On June 7 a mudslide closed the road once more. The mud on the road was 400 feet wide and 20 feet deep. The slide started on a steep slope above the road in soil saturated from the wet spring and sent thick mud and debris down the mountain. The Bureau of Land Management was called in again to remove this obstruction. The project involves rehabilitation, restoration and resurfacing 12.4 miles of the canyon access road and replacement of six roadway drainage culverts and addition of riprap to a seventh culvert. Mud slide area on The two-lane byway leads to the top of the high mountain Lamoille Canyon Road canyon. Interpretive signs that explain some of the natural features are found along the road. Several marked trail heads are starting points to small lakes and hidden valleys. ■ I-15 express lanes completed Alongside the Las Vegas Strip, NDOT recently completed two express lanes in each direction of Interstate 15 between Russell and Sahara avenues. Separated from regular travel lanes by 3-foot-high “candlestick” delineators, through traffic can now make the fiveplus-mile journey past the resort corridor in the designated express lanes. Separating through traffic from vehicles exiting within the resort corridor reduces weaving, merging and congestion. “The I-15 express lane project gives drivers a smoother ride and gives those exiting onto the Strip easier access and safer, more consistent traffic flow,” NDOT Assistant Project Management Chief Jeff Hale says, noting that approximately 250,000 vehicles drive through the area every day. These are Nevada’s first interstate express lanes. They’re eventually planned to become part of a larger high-occupancy vehicle network with dedicated carpool lanes connecting the major Las Vegas freeways. 5 Nevada Milepost • Fall 2010 IN NEVADA Engines of bygone economic growth t he steel link in the eastern Sierra was a Gold Rush era railroad built to ferry fortunes in silver and gold from the Comstock Lode. At its most robust during the 1870s, the Virginia & Truckee Railroad was known as the wealthiest short line in the world. It spurred development across Nevada and turned its shareholders into titans who routinely netted more than $100,000 a month. But by the 1920s, a highway had become the people’s choice for transportation; in the 1930s, competition from trucking dealt the line an even more serious blow. In the 1950s, the V&T died — and remained a ghost rail until 1976, when it returned to life as a tourist train. Along its winding three-hour round-trip route between Virginia City and Carson City, riders frequently see mustangs roaming the folds of the foothills. Memories of the Comstock silver strike literally surround passengers as the train chugs through a pair of tunnels dug mostly by hand, with picks and shovels, by Chinese laborers — some of the same workers who toiled in the mines. From $29, $20 for children 5–12, (775) 847-0380, www.virginiatruckee.com. RECYCLE MICHAEL Recycle Michael is as tight-fisted as his ol’ buddy the Practical Man is tight-lipped. He has the first dollar he ever earned and expects the government to be frugal as well. He’s always on the lookout for ways to reuse things to save a little money while helping to preserve the environment. Foundry sand saves energy, water m ore than nine million tons of foundry sand is produced each year in the United States, primarily composed of sands from iron, steel and aluminum foundries. A byproduct material generated by metal casting processes at metal foundries, it is high quality, fine silica sand used to make the molds for casting metal parts. However, it becomes physically degraded over time, at which point it is removed from the sand supply. Although it is no longer suitable for making molds, it is still high quality sand. Typically, foundry sand has a uniform gradation and has friction angle and cohesive strength similar to natural sand. The presence of bentonite clay may provide superior compaction and better freeze-thaw performance. Foundry sand can be used in most applications that require fine aggregate. It is particularly suitable for structural fills and embankments, road base layers and flowable fill. 6 Nevada Milepost • Fall 2010 Benefits Using foundry sand in transportation projects has a number of benefits. In general, foundry sand performs as well or better than natural sand, while substituting foundry sand for natural sand results in significant energy and water savings, in addition to reductions in greenhouse gas emissions and particulate matter emissions. Where foundry sand is locally available, it usually is very competitively priced and also may reduce aggregate transportation costs and impacts. In the end, using foundry sand in highway projects makes good sense from engineering, economic and environmental points of view. The link below leads to a database that contains a list of references related to the use of foundry sand in highway or infrastructure applications: http://www.refworks.com/refshare/?site=047211195200000000/RWWS4A1029997/FoundrySand The following link leads to another database that contains a list of standards and specifications related to the use of foundry sand in highway or infrastructure applications: http://www.refworks.com/refshare/?site=047211195200000000/RWWS4A1029997/ Foundry%20Sand-%20State%20Specifications FOCUS NIGHT PAVING Get compaction right at night c ompaction of a new road surface for optimum smoothness, rideability and density can be challenging enough during the day given the number of variables that affect them. Coupled with a veil of darkness at night, the goal can become even more difficult. But like a growing number of transportation agencies nationwide, NDOT is undertaking more night rebuilding projects, due in part to the driving public’s aversion to bottlenecks and detours during periods of high traffic volume. Monitor temperature Monitoring the temperature drop in asphalt material is very important to the success of the compaction process. The rapid fall in temperature has to be handled differently at night than during the day. The level of temperature drop between day and night operations varies depending on the region of the country. For example, a compaction crew in Las Vegas will need to handle asphalt much differently at night, when temperatures may be about 50 degrees F, than during the day when the ambient temperature is 110 degrees F. That asphalt is going through a much more rapid cooling off process, which means you have a shorter period of time for compaction. In extreme cases in Nevada, a dramatic temperature drop may require that more rollers be brought onto the job site. Operators also may have to run their rollers at higher speeds. Higher frequency machines can allow the operator to work at faster speeds while maintaining optimum impact spacing, which is important for density and smoothness. If the mix cools beyond a certain point, you can’t compact it anymore. You may break the rock in the mix because it can’t take the energy that the drum is trying to put into it. If that happens, you’re making paths for water to get in. You also may damage the machine. Superpave mixes have helped minimize some of the challenges of nighttime operation. Because they can be successfully compacted at lower temperatures, they provide crews with a longer window of opportunity to achieve optimum results. When compacted properly and at the right time, polymer modified asphalt also can give you an excellent riding surface as far as smoothness and degree of compaction. Maintaining visibility to the work surface and around the machines is critical to safe, successful night compaction. Light it up Generally, the process of compacting asphalt at night is the same as during the day. Equipment sizing, drum width, drum diameter, etc., remain unchanged. However, required precautions are different. One of the main precautions is the need to obtain an ■ Staying safe when adequate and acceptable means the sun goes down for quality lighting, so workers truly can see what they’re placNight paving always comes with risks. But there are measures you can take to minimize the risks. ing, compacting and finishing. In the absence of daylight, that can Hold frequent safety meetings — nightly if be a challenge. needed — to raise employee awareness of work zone safety. Complacency is the enemy. For instance, if you don’t notice that the water spray bars Create a buddy system. Match newcomers with veterans. The veteran passes along information quit working, you can get a piece throughout the first few shifts. of asphalt caught on the roller Place greenhorns on the non-traffic side. drum. Once it sticks, it can scar the asphalt. You could more eas Spacing the work zone’s cones or barricades ily see it during the day. But at even more closely than specified can help prevent impatient drivers from jumping into your night you have to more closely space behind the cones. If the specification calls watch for it and have as much for 120-foot intervals, you might want to use lighting as possible. 60-foot intervals. Many manufacturers Use one or more state patrol cars, or police provide special light packages cars — with their light bars flashing — in critical for their compaction equipment. locations near your work zone. Patrol cars can even do “rolling road blocks” by cruising through In addition to standard work the zone at a reduced speed. lights on the front and back of Use plenty of light. But don’t shine lights toward the machines, high intensity traffic. Some project officials have determined discharge lighting can be added that light towers are distracting to traffic and to simulate daytime conditions. rely almost solely on extra equipment lights. Experience shows that motorists’ eyes are easily Additional trapezoid lamps and diverted to a light source. drum edge lighting provide maximum illumination to the work Stay together. Keep everyone working right around the paver, where there are lights. That surface around the machine. might mean going slower, but the improved Balloon lights are becomsafety is worth it. ing popular due to their ability Even with vests, sometimes drivers can’t see to provide glare-free lighting. you. Stay in the light. The diffused light is softer than Signage and message boards usually make traditional tower lights, and there flaggers unnecessary on high-volume highway is no reflection of the ground or projects. If flaggers are necessary, it’s important equipment. And because they to light them well. cast no shadows, construction workers and drivers are not blinded if they look directly at them. The lights also are highly transportable and have no outriggers to set, masts to crank or lights to position. When mounted to a piece of equipment, they easily move with the job. 7 Of course, traditional light towers are still a popular source of light because they provide a wide area of light coverage, plus you can tilt them Nevada Milepost • Fall 2010 to illuminate other areas. IN NEVADA Step by step New phase of Carson City freeway t New Koontz Lane Bridge over Carson Freeway he next phase of the Carson City freeway will cost $7.5 million. This phase of construction, which does not include an extension of the freeway, will involve erecting bridges on Clearview Drive and Koontz Lane, which eventually will carry cars over the freeway. Also, a portion of Colorado Street between Blue Haven Lane and Edmonds Drive in Carson City will be permanently closed. A cul-de-sac will be constructed on Colorado Street to help ease traffic flow. The final phase of the freeway, which currently ends at Fairview Drive, will extend to Highway 50 on South Carson Street. Construction on the final leg of the freeway is not expected to start until 2014. TRAINING Recommended performance guideline for micro surfacing ■ Quotable quotes: Funny money Money is better than poverty, if only for financial reasons. — Woody Allen If you want to know what God thinks of money, just look at the people He gave it to. — Dorothy Parker Someday I want to be rich. Some people get so rich they lose all respect for humanity. That’s how rich I want to be. — Rita Rudner I finally know what distinguishes man from other beasts: financial worries. — Jules Renard However top-lofty and idealistic a man may be, he can always rationalize his right to earn money. — Raymond Chandler 8 Nevada Milepost • Fall 2010 t he intent of this guideline is to aid in the design, testing quality control, measurement and payment procedures for the application of micro surfacing. Micro surfacing Micro surfacing is a mixture of polymer-modified emulsified asphalt, aggregate, water and additives which are proportioned, mixed and uniformly spread over a properly prepared surface. It can be used in ruts, scratch courses and milled surfaces. It is applied as a homogeneous mat which adheres to the surface and has a skid-resistance texture. Traffic can resume shortly after placement, usually within an hour. There are a number of tests that can be performed, but not all tests are needed for every project. For example, if the mixture to be used in the project has a record of good performance, an individual test could be waived. Materials Emulsified asphalt: The emulsified asphalt should be polymer modified. The polymer material is milled or blended into the asphalt or emulsifier solution prior to the emulsification process. In general, 3 percent polymer solids, based on asphalt weight, is considered minimum. The emulsified asphalt and emulsified asphalt residue shall meet the requirement of AASHTO208 or ASTM D 2397. For exceptions to this rule see Recommended Performance Guideline for Micro Surfacing. Aggregate: The aggregate should be crushed stone such as granite, slag, limestone, chat or other high-quality aggregate, or a combination of them. The aggregate should meet agency specified polishing values and some minimum requirement as specified in the Guideline for Micro Surfacing. Mineral filler: Portland cement, hydrated lime, limestone dust, fly ash or other approved filler can be used to improve the mixture consistency and to adjust its properties. Other approved filler meeting the requirements of ASTM D 242 can be used if required by the mix design. Typical use levels are 0-3 percent and may be considered part of the aggregate gradation. Water: The water must be free of harmful salts and contaminates. If the quality of the water is in question, it should be submitted to the laboratory with the other raw materials for the mix design. Additives: Additives may be used to accelerate or retard the break/set point of the micro surfacing. Appropriate additives should be approved by the laboratory as part of the mix design. Laboratory evaluation Before the works begins, the contractor needs to submit a mix design covering the specific materials to be used in the project. Compatibility of all materials has to be evaluated. The materials used for this evaluation need to be consistent with those that will be used in the project. The recommended tests are mix time, wet cohesion, wet stripping, wet-track abrasions loss, lateral displacement, excess asphalt by LWT sand adhesion and classification compatibility. To receive a copy of the booklet Recommended Performance Guideline for Micro Surfacing, go to the No-Brainer Mail-In Page. HEALTH WATCH Steps to take to reduce stress o ur work lives are often filled with what can seem like unbearable amounts of stress. And although some of those stresses are unavoidable, there’s a lot you can do to start to whittle those high levels of stress down to something that feels at least manageable. Here are a few suggestions: Know when to say no. That means you have to first understand your own limits. Then set limits on others so they don’t encroach on your time by pressuring you to take on tasks or responsibilities that will throw you out of balance. If possible, avoid people who consistently stress you out. If your boss is the culprit, you might not be able to do this. And you can’t steer clear of everyone who inadvertently or occasionally causes you anxiety. But you can avoid people who have a history of leaving you feeling stressed after you’ve tried to change the situation, and they haven’t responded. Don’t expose yourself to unnecessary stresses. For instance, if you read the news on the Internet during your break, but it leaves you feeling tense, stop reading the news on your break. Do something that relaxes you instead. Go for a short walk, knit, meditate, work a puzzle. Learn to manage your time. Letting projects go until the deadline is upon you will undoubtedly cause you stress. Work at a steady pace — and don’t procrastinate. Procrastination can affect the quality of your work and leave you feeling anxious and strained for prolonged periods. ■ Talking turkey Who is not hungry at Thanksgiving? The turkey — he’s already stuffed. Why can’t you take turkeys to church? Because of their fowl language. What do hippies put on their turkey? Groovy. Staying safe on Thanksgiving w hen you fire up the oven to roast your Thanksgiving turkey, you’re probably not thinking about tragedy. But home fires are the most common disaster in the United States, according to the American Red Cross — one is reported every 79 seconds. Cooking is the leading cause of these fires, and Thanksgiving Day is the unfortunate host of about 4,000 fires each year. The following safety tips will keep your Thanksgiving fire-free. Stay in the kitchen and keep watch while you are cooking. Use a timer if you have something in the oven or are boiling or simmering something on the stove. Don’t wear loose sleeves or clothing when cooking. Keep anything that can catch on fire — potholders, oven mitts — away from your stovetop or oven. Turkey fryers are extremely dangerous, and most safety organizations do not recommend their use. Make sure you have a smoke alarm installed with working batteries. Push the button every month to check that it’s working and install new batteries at least once a year. After your guests leave, do a home safety check to make sure that all candles and cigarettes are extinguished. Whole grains reduce waistline i f you want to reduce your waist size, it could be as simple as eating the right whole grain cereal or bread. Penn State University researchers recently found that people who were counseled in healthy eating and exercise lost weight, but those who were advised to get their grain servings from whole grains rather than refined grains lost significantly more weight in their abdominal region. Foods that can be beneficial for waist circumference loss include oatmeal, whole grain cereal, brown rice, whole wheat pasta and snacks such as granola bars, popcorn and whole wheat crackers. Foods in which at least 51 percent of the grain comes from whole grains are recommended. 9 Nevada Milepost • Fall 2010 TRAINING Roads Scholars step into spotlight ■ Setting course To become a Roads Scholar you need to complete 10 designated courses during four years. They consist of four required and six elective classes. Upon completing the requirements, you receive a Roads Scholar certificate, and your supervisor is notified in writing about your achievement. Required courses Roadway Drainage Tort Liability Workplace Safety Work Zone Safety & Traffic Control Course electives (choose six) Aggregate Properties & Characteristics Asphalt Binder Technology Asphalt Pavement Maintenance Asphalt Pavement Rehabilitation Avalanche Control Design of Concrete Pavements Dust Control Effective Communication Skills Engineering for Safety Gravel Road Maintenance Leadership Techniques Pavement Management Systems Road Materials Snow & Ice Control Soils Sampling & Testing Summer Survival Winter Safety For information To request registration materials or a brochure on the Roads Scholar Program, please contact Lisa Cody at (775) 784-1433. You also can reach her by fax at (775) 7841429 or by e-mail: lacody@ unr.edu. 10 Nevada Milepost • Fall 2010 t here are 236 transportation personnel currently enrolled in the Roads Scholars Program. Since the beginning of the program in 1994, 200 employees have become Roads Scholars. Among these are a dozen of the most recent graduates; half of them are from the Reno Public Works Department, who will be introduced to you first. Reno Public Works graduates Maintenance Worker III Danny Buzzetti has been with the agency for five years. “Challenges on my job include dealing with traffic while working on the streets and repairing damaged sewer pipes,” he says. Danny plans to take additional T2 Center classes. “They are a great source of information to help further my career and to do my job more efficiently,” he contends. With public works for four years, Maintenance Worker I Mark Mariucci performs various duties including operating the sign, crack sealing, pavement patching, right-of-way maintenance and snow plowing. Mark expresses concern for the safety of his crew and the public in work zones. “My goal is to get promoted, and I hope what I’ve learned in T2 Center classes will help me,” he says. Maintenance Worker I Jimmy Murphy, who has worked for the department for three years, shares the goal of getting promoted. He also wants to learn how to run more equipment and supervise crews. “The biggest challenges for me on the job are working and dealing with all the weather and terrain conditions,” he says. Jimmy adds that he “enjoyed and learned much” from the T2 Center classes and recommends them to all his co-workers. Also a Maintenance Worker I with the agency for three years, Jeremy Swanson does street maintenance, crack sealing, painting and operates the sign truck. “I take pride in my work,” he says. “My biggest challenge is understanding traffic control and safety. “The T2 Center classes have been a great learning experience.” Daniel Tresley has been with Public Works for four years and performs every duty involving the maintenance of city streets. “My goal is to get promoted,” he says. “My challenges on the job are solving the problems that arise within my everyday duties.” Daniel says that the T2 Center does a “great job” of putting on the classes. With Public Works for 20 years, Jack Wilson is the general supervisor for the street crews for the south side of Reno. “My primary goal is to help my crews “My primary goal is to help my crews produce a quality end product.” — Jack Wilson Training pays off in tight times c utting back on employee training has a measurable downside. Budget-strapped transportation agencies that eliminate training altogether or rely on minimal on-the-job training will see the hidden costs as the lack of technical training keeps new hires from getting up to speed quickly and leaves other employees in a rut. Economizing on training might save money in the short term, but over the long haul the approach can undermine productivity and morale. Studies show that employees energized by programs where they learn something new go back to work with valuable ideas for getting things done more efficiently and effectively. Targeted training also helps agencies retain good people. Researchers say one of the main reasons valued employees move to other organizations is a lack of opportunity to learn new things and develop and grow on the job. TRAINING produce a quality end product,” he says. “Another goal of mine is to help institute a salt brine program for snow and ice removal.” Jack says the most difficult aspect of his job is working within the budget restraints facing the department. “The T2 Center program,” he maintains, “is a great way to enable employees to work together using common information.” “The success of the T2 Center classes depends on the employees and how much they want to get out of them,” he contends. An 11-year departmental veteran, Don Stephens is a Highway Maintenance Worker IV in Fernley. He is working toward moving up to supervisor and identifies his main job challenge as traffic safety. “The T2 Center classes have been very helpful to me on the job,” he says. NDOT graduates With the agency for six years, Antonio Gutierrez is a Maintenance Worker III in Wellington. He says that he wants to learn all he can to advance his career and that the T2 classes are very helpful in this regard. “Even when a topic was discussed that I was familiar with, there was always some new useful information.” With the department for nine years, Amy Hann works in Fallon and is a Highway Maintenance Worker III. “My greatest challenge on the job is effective communication with my supervisors and fellow workers,” she says. Amy says her goal was to graduate from the Roads Scholar Program. “I’ve learned a lot from the T2 classes and apply what I’ve learned to my job,” she says. A Highway Maintenance worker III in Las Vegas, Chris Hansen has worked for the agency for three years. His career goal is to become a Maintenance Manager and recognizes that requires the ability to deal with many different personalities. Chris says that the T2 Center offers good classes. With the department for 24 years, Maintenance Supervisor II Ren (Buzz) Jackson works for the department in Wells. He says that the toughest part of his job nowadays is dealing with the furloughs to make certain that the supervisors under him have the personnel available for overtime to ensure coverage during emergencies. Dave Burns has worked for the department in Las Vegas for two years and is a Highway Maintenance Worker III. His job goals are to perfect his concrete finishing skills, develop the ability to design and construct drop inlet boxes and gain a better understanding of concrete applications. “I try to leave each job looking better than when it was first installed,” he says. Dave maintains that the T2 Center provides a “great experience with great instructors” and provides a lot of information that relates to his job. Web based training t he National Highway Institute has developed a number of FREE Web-based trainings that can be completed in one, two or three hours. Whether you are working in the field, have limited time for training or just want to improve your skills, these courses provide a way to enhance your knowledge in key areas. Current topics include: Preventive Maintenance & Pavement Preservation Concrete Pavement Evaluation Slab Stabilization & Slab Jacking Partial-Depth Repairs Full-Depth Repairs Retrofitted Edge Drains Load Transfer Restoration Diamond Grinding & Grooving Joint Resealing & Crack Sealing Strategy Selection Training is geared for design engineers, quality control personnel, contractors, suppliers, technicians and trades people. Projected outcomes, continued education units and length of classes are described on the NHI Website. Additional information on subject matter is available from christopher.newman@dot.gov. ■ New traffic control guidelines The 2010 Temporary Traffic Control Guidelines booklet is now available. Prepared by the Nevada T2 Center in cooperation with NDOT, it has been updated with the 2009 MUTCD changes. The cost of the booklet is $5. To order copies go to the NoBrainer Mail-In Page. 11 Nevada Milepost • Fall 2010 ON THE JOB Nurturing “family relationships” in your work environment y our coworkers aren’t your family, but the same rules that ensure a warm relationship with your family members apply to the workplace. Here are some guidelines for communication and respect that will create a positive atmosphere at work: ■ HUMOR: Bumper shtick Some bumper stickers are inspiring and motivational; others not so much. Steer clear of these vehicular affirmations: I assume full responsibility for my actions, except the ones that are someone else’s fault. My intuition nearly makes up for my lack of good judgment. Joan of Arc heard voices, too. I’m just grateful that I am not as judgmental as all those self-righteous people around me. Why suffer in silence while I can still moan, whimper and complain? Forgiveness is cheaper than a lawsuit. But not nearly as gratifying. I am at one with my multiple personalities. I find humor in my everyday life by looking for people I can laugh at. Nevada Milepost • Fall 2010 Respect boundaries. Understand that people have their own concepts of personal space and privacy. Don’t assume you can open someone’s desk without her permission. Stay out of your coworkers’ personal lives and don’t share too much of your own. Keep promises. Family members and coworkers both want to know they can depend on you. Don’t make commitments you can’t keep. If something prevents you from doing what you’ve said you will, be honest and explain it at once. And do everything reasonable to live up to the promises you make. You’ll build a reputation for trustworthiness that will aid your career. Don’t waste people’s time. We’re all busy with our jobs or our chores. Although a certain amount of informal chat helps build and maintain a friendly atmosphere, don’t overdo it, and don’t let your coworkers waste your time on irrelevant discussions. Keep an eye on your priorities, and other people’s, so everyone can concentrate on getting work done. Pay attention to people. No one likes to be ignored, whether it’s by your spouse reading the paper while you’re trying to talk about your day or by a coworker checking his BlackBerry during a meeting. Give people your full attention when they’re speaking to you. Eliminate distractions. This shows you respect their time and intelligence. 12 business skills essential to success 12 Response inhibition — the ability to think before you act. Working memory — remembering information while you are performing complex tasks. Emotional control — not giving in to anger, anxiety or other counterproductive feelings. Sustained attention — the ability to focus on the immediate job. Task initiation — just get started. Planning and prioritizing — knowing what’s important and what to do first. Organization — having all the tools and resources available whenever you need them. Time management — using your time as efficiently as possible. Goal-directed persistence — setting goals and moving steadily toward them. Flexibility — the ability to adapt to changing circumstances. Perspective — seeing the big picture and your role in it. Stress tolerance — ability to deal with stress. Job fulfillment i s your job fulfilling, or just a way to pay the bills? The latest nationwide survey of more than 500 working Americans found that for 60 percent of employees, work serves mainly to provide income to enjoy other aspects of life. Twenty-six percent view work as a major source of happiness and fulfillment, while just 11 percent find their jobs a major drain on their energy and happiness. The highest level of job satisfaction was expressed by employees in mid-career: 30 percent of those ages 45–54 said they felt fulfilled, compared with just 2 percent of those 18–34. SAFETY Roadside cheatgrass can ignite wildfires i n the summer and fall, dry cheatgrass is easily ignitable along roadsides and can fuel wildfires. Cheatgrass fires can be started by catalytic converters on vehicles, cigarette butts, welding activities, lawn mowers, fireworks and ricocheting bullets. Do not park your vehicle over dry cheatgrass and properly dispose of cigarettes and matches. Cheatgrass can be from several inches to more than 18 inches tall. Typically, it has a nodding seed head that resembles a shepherd’s crook. It is bright green in the early spring but quickly dries out as the summer progresses. It competes with more desirable perennial grasses for moisture because of its winter and spring growth habit. After maturity it becomes a nuisance and a fire hazard. If cheatgrass is near your home or workplace, remove it for at least 30 feet around all structures. Use a lawn mower with a mulching blade or cut it with a weed eater, rake it up and remove it. Make sure there’s a connected garden hose with a spray nozzle attached in case an accidental fire starts. Safety edge Precautions with reduces accidents meth waste w hen a driver drifts onto the roadway shoulder and tries to steer back onto the pavement, the vertical pavement edge can create a “tire scrubbing” condition that may result in over-steering. If drivers over-steer to return to the roadway without reducing speed, they are prone to lose control of the vehicle. A simple and cost-effective way to promote pavement edge safety is to: Adopt a standard specification for all resurfacing projects that requires a 30-degree to 35degree safety edge. After paving, the adjacent material is graded flush with the top of the pavement. Routinely resurface shoulders when roadways are resurfaced and add the safety edge. Maintain edge drop-off depths at 2 inches or less on high-speed roadways. Attach a device to the screed of the paver that confines the material at the end gate and extrudes the asphalt material in such a way that results in a compacted wedge-shaped pavement edge of approximately 30 degrees (not steeper than 35 degrees). Maintain contact between the device and road shoulder surface and allow for automatic transition to crossroads, driveways and obstructions. Recent research shows that nearly all drivers can recover if the roadway edge is tapered to 30 degrees from the horizontal. This durable taper is easy to include in the paving process, provides a safer roadway edge and a stronger interface between the pavement and the graded material. m aintenance crews need to watch along roadsides for an increasing danger: methamphetamine waste. The traditional method of making meth involves some type of lab setup, filthy containers, foul odors and high flames. In the past these labs were often in rural areas that helped conceal the dealers as they “cooked” their drugs. However, portable labs can be found in urban areas, in hotel rooms and even in cars. Although this method is as dangerous as ever, drug users and makers have found a much faster, cheaper and simpler way to make meth in small batches that can be carried in a small bag and mixed on the run. Known as the “shake and bake” method, it is becoming increasingly popular. Bottles used in this type of production are being discarded on roadsides, and are a hazard for road crews. The batches can produce powerful explosions and release drug ingredients that must be handled as toxic waste. Bottles that don’t explode contain a poisonous brown or white sludge that maintenance crews must be aware of and look for before handling any discarded waste, particularly two-liter bottles. If you discover discarded bottles containing an unknown brown or white sludge, do not open them, pick them up, kick them, roll them over or touch them. Leave them alone and contact your supervisor immediately. Your supervisor should contact law enforcement personnel with the exact location of the possible meth waste. ■ Trivia: Famous stutterers These people are famous for having stuttered. They made a name for themselves with their contributions to society, art and culture. Aesop — Storyteller Lewis Carroll — Novelist Nat King Cole — Musician Stephen Hawking — Scientist Thomas Jefferson – U.S. President James Earl Jones — Actor Greg Louganis — Olympic diver Theodore Roosevelt — U.S. President Carly Simon — Musician Chris Zorich — Football player Clara Barton — Founder of the American Red Cross Winston Churchill — British Prime Minister George Washington — U.S. President 13 Nevada Milepost • Fall 2010 THE PRACTICAL MAN The Practical Man tolerates no nonsense and minces few words. He doesn’t stand on formality and isn’t easily amused. He grudgingly appears here to offer you hard-bitten practical advice to make your job easier. Savvy superintendent develops sturdy and eco-friendly device i want you to meet my good buddy Darren Skelton, Public Works Superintendent for the City of Elko, who has come up with an ingenious way to rebuild damaged Type II traffic control barricades. Not only can this mechanical whiz save you the $135.50 cost of buying a new replacement; his is better. As you may know, the legs and uprights on the new Type II barricades are lightly constructed and easily damaged. Instead of sending it to the landfill when it’s no longer usable, he strips off the cross panels to be used again. Doing this makes Darren an eco-star in Recycle Michael’s eyes. Taking damaged Telespar breakaway sign posts, Darren builds a new heavy duty frame for the old six-foot panels. He then bolts the old panels to his homemade frame and slaps on new reflective tape. Presto! My man has created a rugged, serviceable barricade. Legs on rebuilt barricade Darren Skelton with rebuilt barricades ■ Trivia: Fall Classic It’s World Series time again; the competition that every baseball fan looks forward to all summer. What’s the “winningest” baseball team in history? The New York Yankees. 14 Nevada Milepost • Fall 2010 ON THE HORIZON Emerging dynamics of ITS t he promise of intelligent transportation system technology is the high-tech transformation of automobile and truck travel, making it faster, safer and more efficient, helping optimize the traffic-carrying capacity of our congested highway infrastructure. ITS encompasses a huge variety of applications over very wide segments of the soft-wheel transportation sector. Examples of ITS applications include vehicle collision avoidance technologies, E-Z Pass and “open road” tolling, real-time traffic and transit information, GPS equipped navigational devices, “smart” traffic signals and parking systems, congestion pricing systems, weigh-inmotion truck inspection, electronic reservation and payment for transportation services and advanced traffic management systems. Applications include improvement of traffic flow, reduction of congestion and emissions, detection and response to highway emergencies and warning of drivers of impending danger; also improving freight security, provision of on-demand travel services and the checking of registration documents for commercial vehicles. “Intelligent technologies are emerging to enable transportation networks and users to communicate with each other, improving system performance, safety and convenience, making IT just as important to 21st Century transportation as airplanes, asphalt and petroleum were in the last century,” says Samuel Palmisano, chairman and CEO of IBM. “The idea is simple. The traveler’s time, safety and experience should be the initial design point. And a system’s design point matters. What you optimize it for — the way you envision its end state — will determine the value it ultimately delivers.” No-Brainer Mail-In Page Your Name: ___________________________________________________________________ Phone: __________________________________Fax: _________________________________ Company/Organization: __________________________________________________________ Address: ______________________________________________________________________ City: _________________________________________State: _________ZIP: _____________ If you have changed your address, telephone or fax number, please write them below and fax changes to (775) 784-1429 or e-mail to lacody@unr.edu. Circle YES where appropriate 1. Do you want a free copy of “Paving at Night” by Asphalt Contractor? YES 2. Do you want a free copy of “Paving Safety at Night” by Better Roads YES 3. Do you want a free copy of “Highway Contractor: A hard day’s night paving” by Better Roads? YES 4. Do you want to borrow a DVD Safety Basics Video by Caterpillar? YES 5. Do you want to barrow a DVD Avoiding Runovers and Backovers by ARTBA? YES 6. Do you want to receive the Nevada Infrastructure Concrete Conference brochure? YES 7. Do you want to purchase the new 2010 Temporary Traffic Control Guidelines? YES 8. Do you want to receive workshop information by e-mail? Please provide e-mail address_________________________________ The T2 Center would like to be able to communicate with you by e-mail. Do you have an e-mail address? If so, please enter it here. _______________________________________________________________________________________________ Please provide your answer to the “Road Smart Contest.” Identify the road and two nearest destinations. ___________________________________________________________________________________________________ FAX this form to (775) 784-1429. Or fold it in three, close with tape and mail. ______________________________________ PLACE STAMP HERE ______________________________________ ______________________________________ University of Nevada, Reno T2 Center/257 Reno, NV 89557-0179 Nevada T2 Center University of Nevada, Reno/0257 Reno, NV 89557-0257 NONPROFIT ORGANIZATION U.S. Postage PAID Reno, NV Permit No. 26 ADDRESS SERVICE REQUESTED Nevada Milepost is published quarterly by the Transportation Technology Transfer Center at the University of Nevada, Reno. Its purpose is to provide the latest information on transportation in a way that is useful to local and county highway personnel. Nevada Milepost contains original and rewritten material compiled from reliable sources. It assumes no responsibility for the correctness of the information. The Nevada T 2 Center is part of the nationwide Local Technical Assistance Program. It is financed jointly by the Nevada Department of Transportation, the Federal Highway Administration and the Washoe County Regional Transportation Commission. Nevada Milepost Nevada T2 Center/257 University of Nevada, Reno Reno, NV 89557 Ph: (775) 784-1433 FAX: (775) 784-1429 http://www.t2.unr.edu T2 Center Staff Maria Ardila-Coulson Peter Sebaaly Lisa Cody Larry Lunz Elie Hajj Nevada Milepost: Editor: Maria Ardila-Coulson Photojournalist: Larry Lunz Graphic Design: KCJ Creative 16 Nevada Milepost • Fall 2010 Relive pioneer trail history at new I-80 heritage center m otorists driving across Northern Nevada on Interstate 80 can stop at the new California Trail Center at the Hunter Interchange eight miles west of Elko to get insight into the hardships pioneers faced 150 years ago as they followed nearly the same route on the old California Trail. Phase one of the center is complete and includes site improvements, the building and outdoor plaza with interpretive panels and relief sculptures. A limited number of exhibits also are in place. Scheduled for completion in 2012, the main purpose of the center is to greet motorists and let them know the significance of the route they are traveling. The center tells the story of the 250,000 emigrants who traveled westward to California between 1841 and 1869 in search of free land, gold and adventure. In 1849, the lure of instant wealth beckoned at the end of hundreds of miles of trail with the discovery of gold at Sutter’s Mill in the Sierra foothills near Sacramento. The deserts of the Great Basin and the barrier of the Sierra Nevada made the California Trail the most difficult of all overland trails. An important source of water, the Humboldt River, got more sluggish and alkaline as it bent west and south until it finally disappeared into the Humboldt Sink, leaving the emigrants to face a 40-mile stretch of desert without water. In 1869, the Union Pacific from the east and the Central Pacific from the west connected their rail tracks at Promontory Point in Utah. A symbolic golden spike was struck to celebrate the union that hailed a new and exciting way to traverse the continent. It also signaled the demise of the wagon trails to the West. Although the dust from the wagons settled long ago, the California Trail’s heritage lives on with people who are intrigued by its history. For the early pioneers it took 4½ months to complete the 2,000-mile journey with their oxen pulling wagons. Later, by stagecoach the trip took 20 days and by 1869 it took only four days by rail. Nowadays by rail it takes 41 hours, by car 72 hours and by airline 3 hours and 45 minutes. Pictured below, the California Trail Interpretive Center