Yushin Precision Industrial Co., Ltd.

advertisement

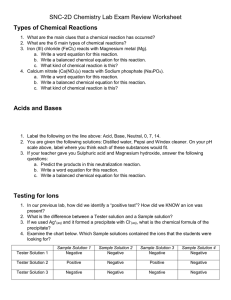

Yushin Precision Industrial Co., Ltd. CCC-1540 “Challenge, Change, Completion” Contents 1. Company Profile 2. Milestone 3. Organization 4. Production & Inspection Equipments 5. Major Products 6. Customers & Turnover 7. Design System 8. Status of Certification & Patent 9. Application & Case Study for Cost Saving 10. Production Improvement 11. Overseas plant profile CCC-1540 “Challenge, Change, Completion” 1. Company Profile Company Chairman CEO Establishment Address The number of employees Sales Main products Size of area Yushin Precision Industrial Co., Ltd. Dong Ah, Lee Incheon 인천 남동 Namdong Songdo Kyung Shik, Song Dec. 1975 Dangjin Seosan Head Office : 85, Gaetbeol-ro, Songdo, Yeonsu-gu, Incheon Namdong Plant : 125, Neungheodaero, 577beon-gil, Namdong Dangjin Plant : 197, Galsan-gil, Sunseong-myeon, Dangjin Gunsan Plant : 110, Sandannambuk-ro, Gunsan 520 Gunsan Head Office US$ 204M(2012) Disc Spring, Snap Ring, Drive Plate, Hose Clamp, Shim, Etc Ulsan Warehouse Plant Incheon - Head Office & Namdong Plant - R&D CENTER Dangjin - Dangjin Plant(Hose Clamp) Gunsan - Gunsan Plant(Wave Spring) Total 72,697㎡ (Head Office 5,500㎡, Namdong Plant 11,047㎡, Dangjin Plant 21,500㎡, Gunsan Plant 34,650㎡) CCC-1540 “Challenge, Change, Completion” Unit : M. US$ Year 2012 Sales Amount 7 Employees 87 POLAND BEIJING (Sales Office) YENCHING America (Sales Office) Total Description Sales Amount Employees Domestic 139 520 Overseas 65 873 TTL INDIA Unit : M. US$ 204 Year 2012 Sales Amount 18 Employees 350 Year 2012 Sales Amount 25 Employees 279 QINGDAO Shanghai (Sales Office) WUXI Year 2012 Sales Amount 15 Employees 157 1,393 Global Network 4 Countries / 4 Plants / 1 Sales Office → 873 Employees CCC-1540 “Challenge, Change, Completion” 2. Milestone • 94.06 : Manufacturing Hose Clamp • 94.10 : Registered as a KIA Supplier • 99.12 : ISO 9001, QS 9000 Certificate • 01.12 : Export Anti-rattle clip (TRW US) • 02.01 : Established Qingdao Factory in China • 03.07 : Export Snap-Ring(Borgwarner US) • 03.07 : Setup Batch Type Austempering • 04.08 : ISO/TS 16949 Certificate • 04.12 : Awarded the letter of Commendation from Presidential Commission on SME • 06.09 : BorgWarner Best Supplier Quality Award • 07.01 : Established Dangjin Plant (Hose Clamp) • 07.05 : Awarded the Prime Minister Prize (Single PPM Quality Innovation) • 75.12 : Established • 08.09 : Established Wuxi Plant in China • 76.01 : Retainer Ring • 08.09 : Established Chennai Plant in India • 78.02 : Registered as a HMC Supplier • 09.01 : Established factory in Poland • 89.07 : Manufacturing Snap-Ring, Drive Plate for A/T • 09.10 : Manufacturing Single Flex Plate • 10.12 : Established Gunsan Plant (Cushion Spring) CCC-1540 “Challenge, Change, Completion” 3. Organization Chairman 会長 CEO 社長 Administration Sales & Development Planning Production R&D Quality General Affair Sales & Marketing Business Planning Production R&D Quality Control Accounting Development Cost Analyzing Production Administration Production Engineering Quality Assurance Overseas Support Plant Renovation Material Purchasing I.T Tooling 6 Divisions & 17 Teams Office Worker Production Worker TOTAL 180 340 520 30% 70% 100% CCC-1540 “Challenge, Change, Completion” 4-1 Production Equipment Production Equipment (Incheon Plant) NO Equipment Production Equipment (Dangjin Plant) Qty Remarks NO 80 ~ 650ton 1 Equipment Qty Remarks Muti Slides Lines 17 (Ø200~Ø560) 2 Austempering Furnaces 2 1 Press 15 2 Coiling M/C 17 3 Double Disc Grinding M/C 5 Ø300~Ø760 3 Shot Peening Machines 2 4 CNC Lathe 10 Ø860 4 Geomet Coating Lines 2 5 Austempering Furnace 2 5 Auto Assembler for D/W Clamp 4 6 Barrel 9 20L ~ 200L 6 Clipper for Clipless Clamp 2 7 Fine-Blanking M/C 3 630ton, 800ton 7 Vision System for 100% Inspection 5 8 Batch Tempering Furnace 1 8 Auto Packing Equipment 1 9 Welding Line 2 (CO2, SPOT) 9 Return Spring 7 10 Single Flex Plate Line 1 P/F, Hb, Chp, & Etc. 10 TOTAL TOTAL 65 Production Capacity (Incheon Plant) NO ITEMS 32 Production Capacity (Dangjin Plant) Annual Capacity(Mil.) NO ITEMS Annual Capacity(Mil.) 1 Snap Ring 113 1 Hose Clamp 150 2 Washer/Spacer 78 2 Double Wrap Clamps 50 3 Drive Plate 3 3 Clip 16 4 Return Spring 2 4 TOTAL 194 TOTAL 218 CCC-1540 “Challenge, Change, Completion” Production Equipment (Gunsan Plant) NO Equipment Qty 1 Press 3 2 Deburring M/C 2 3 Induction Heating Die-Quenching M/C 25 4 Shot Peening M/C 24 5 Vision Tester 1 6 Washing & Load Tester 33 7 Mark’g M/C 2 TOTAL Remarks 450, 600 ton Tempering Furnace(3) 89 Production Capacity (Gunsan Plant) NO 1 ITEMS Disc Spring (D/Q Items) TOTAL Annual Capacity(Mil.) 25 25 CCC-1540 “Challenge, Change, Completion” 4-2 Inspection Equipment Inspection Equipments (Incheon, Dangjin, Gunsan) NO TYPES Namdong Dangjin Inspection Equipments (Incheon, Dangjin, Gunsan) Gunsan NO 1 13 Load Tester for Disc spring 1 14 Pulse Tester 1 15 Cutting M/C 1 1 1 16 Polishing M/C 1 1 1 17 Mounting Press M/C 1 1 1 18 Complex Durability Test M/C 1 1 19 Salt Spray Test M/C 1 1 20 Cyclic Corrosion Test 1 1 21 Cleanness Tester 1 22 Universal Tensile Tester 1 23 Disc Spring durability Tester 1 1 3D CMM 1 2 Hardness Tester (Rockwell & Vickers) 3 3 3 3 Metallographic Microscopes 1 1 1 4 Surface Roughness Tester 1 5 Clamp Force Tester 1 6 Contour Measuring M/C 1 7 Inductive Coating Thickness Tester 1 1 8 Leakage Tester (Air pressure) 1 1 9 Leakage Tester (Hydraulic pressure) 3 1 10 Profile Projector 1 1 11 Eddy Current Test Instrument 1 12 Cycle Impulse Tester 1 1 2 TYPES TOTAL Namdong 27 Dangjin Gunsan 1 1 1 3 15 16 CCC-1540 “Challenge, Change, Completion” 5. Products CCC-1540 “Challenge, Change, Completion” 5. Products – Transmission Parts 1 Snap Ring Material High Carbon Steel (SAE 1065~1085 / SK5M) Steel Wire(SWRH72B) Customer HMC, HPT, GM, Borg Warner, JATCO, TRW Core Manufacturing Process Remark Stamping / Coiling - Standard/Customized design available - Various notch profile - Rolling for raw material capable in house CCC-1540 “Challenge, Change, Completion” 5. Products – Transmission Parts 2 Disc Spring / Return Spring Material High Carbon Steel (SAE 6150 / 50CrV4) Customer HMC, HPT, GM, Borg Warner, JATCO, TRW Core Manufacturing Process Remark Stamping - Induction Heating - Shot Peening - Blackbox design capability for High/Low load disc spring - 100% load test for high load spring in the production line CCC-1540 “Challenge, Change, Completion” 5. Products – Transmission Parts 3 Shim & Washers Material High Carbon Steel (SAE 1065~1085/ SK5M) Customer HMC, HPT, Scheffler, NSK, Borg Warner Core Manufacturing Process Remark Stamping - Heat Treatment – (Grinding) - In-house capability for all process include heat treatment - Can control various selective parts CCC-1540 “Challenge, Change, Completion” 5. Products – Engine Parts Drive Plate / One Piece Flex Plate Material Medium Carbon Steel (SAE1035 / S35C) High Strength Steel (SPFH590) Customer HMC, KIA, Chrysler Core Manufacturing Process Pre Forming – Hobbing - Induction Heating – (Shot Peening) – Balancing – Run out Remark CCC-1540 “Challenge, Change, Completion” 5. Products – Hose Clamp Hose Clamp Material High Carbon Steel (SK5M, 50CrV4) Customer HMC, KMC, RSM, GM, Ford, Nissan, IDEAL/Tomkins, TRW Core Manufacturing Process Multi Forming - Austempering - Coating Remark - In-house capability for heat treatment and coating - Various design per applications (Standard, Stoptab, POPP, Sus Band) CCC-1540 “Challenge, Change, Completion” 5. Products- Others (Fine Press parts Etc.) Multi Forming Fine Press Others CCC-1540 “Challenge, Change, Completion” 6. Customers & Turnover 1)Customer Domestic Overseas CCC-1540 “Challenge, Change, Completion” 2) Turnover 2012 Korea & Overseas Plants Turnover India 18 Wuxi 15 Poland 7 Qingdao 25 Unit : M. US$ FY’12 : 204 FY’13 : 245 Korea (Domestic) 110 Korea (Export) 29 2012 Sales Share (Items) 2012 Sales Share (Customers) Etc., 16% ETC 18% Snap Ring, HPT 22% 27% Washer / Shim, 15% KIA 6% HYUNDAI 21% MOBIS 14% GM GLOBAL 14% Disc Spring, Drive Plate, 15% 17% Hose Clamp, 10% CCC-1540 “Challenge, Change, Completion” 8. Design System Design Tool Design Flow for Proto FEMFAT Finite Element Method FAT Product Design Tool Design Pre-Production TOTAL 5 10 7 22 Academic Background Ph.D 1 / Master 3 / Bachelor 15 / College Degree 3 CCC-1540 “Challenge, Change, Completion” Design Boundary Concept Design 3D Modeling 0.74 MIN HEIGHT STROKED 4.75 0.8 INSTALLED HEIGHT [ Lay Out] Just given the two things from the customer YSP’s Spring Design Sheet CCC-1540 “Challenge, Change, Completion” FE Modeling Stress Analysis Fatigue Analysis Max Stress 1182 MPa Spring height 1.84 mm Life = 983,172 cycles Max. Damage 5.289E-1 CCC-1540 “Challenge, Change, Completion” Tooling Proto Production Validation Test CCC-1540 “Challenge, Change, Completion” R&D Facility NO Proto Line Equipment Q’ty Test Equipment Q’ty 1 Induction Heating M/C 1 Disc Spring durability Tester 3 2 Shot peening M/C 1 RAD Hose clamp durability Tester 1 3 Milling M/C 1 Wave-plate Assembly durability Tester 1 4 Radial M/C 1 Vibration Test 1 5 Surface Plate 1 Hydraulic Stroke Tester 1 6 Flat Grinder 1 Hydraulic Leak Tester 1 7 Form Grinder 1 D/P Ignition Test M/C 1 8 Lathe M/C 1 D/P Vertical-load Tester 1 9 Grinding M/C 1 D/P Horizontal-load Tester 1 10 Bench Drill 2 D/P Torque Tester 1 11 Hose Clamp Proto M/C 1 Profile Projector 1 12 Lab Austempering Furnace 1 Total 13 Total 13 Proto Line Test Equipment CCC-1540 “Challenge, Change, Completion” 8. Status of Certification & Patent ◎ ISO / TS 16949:2009 Certificate Acquisition – 2004(Revised - July.2010) ◎ Awarded the letter of Commendation from Presidential Commission on SME – December.2004 ◎ ISO 14001 : 2009 Certificate Acquisition – November.2011 ◎ Awarded the letter of Commendation on Single PPM Innovation from the Prime Minister – May.2007 ◎ Patent Status – 9 Patents, 3 Utility Models, 3 Registered Designs (Total 15 registered Applications) CCC-1540 “Challenge, Change, Completion” 9.Application & Case Study for Cost Saving * Various Design of YSP’s Spring Cushion Spring Return Spring Coil Spring Pack Wave Spring Dished Spring 2 Turn Spring • Function : Piston Control by Hydraulic, and prevent vibration & Judder • Tech. Point : Durability and load • Cost Saving : 40% CCC-1540 “Challenge, Change, Completion” [Snap Rings (Selection Parts)] Special : Ellipse Ring Perfect circle at install state Laser Marking NC Coiling for identification • Process Improvement : Grade(Selection) Improvement of the identification of goods (Temper Color → Laser Marking) • Cost Saving : 20% [Thrust Washer] • Material Change : Copper → Steel (SK5M) • Cost Saving : 40% CCC-1540 “Challenge, Change, Completion” [Differential Washer] • Surface Treatment Change : Electroless Nickel Plating → Nitriding • Cost Saving : 30% [Locking Nut] • Process Change : Forging & Machining → Fine Blanking • Cost Saving : 40% CCC-1540 “Challenge, Change, Completion” 10. Production Improvement 1) Jig Tempering UPH : 30 Labor : 5 1st Generation Single Hot Press UPH : 120 Labor : 0.5 2nd Generation 6 Hot Press UPH : 150 Labor : 0.5 3. Quality Improved 3rd Generation Automatic Hot Press ※ 4th Generation Duel Hot Press is in test. 2. Labor ↓ 1. Cycle Time ↓ Through this Improvement, Productivity increased more than 100% CCC-1540 “Challenge, Change, Completion” 2) Improvement for Disc Spring OLD Bending Heat Treatment Jig Temper’g Shot Peen’g Blank’g & Deburr’g Shot Ball Parts Conveyer Belt Die-Quenching NEW Temper’g Parts Rotation Cost Saving : 20% Cost Saving and Improve Quality by Manufacturing Change CCC-1540 “Challenge, Change, Completion” 11. Overseas plants profile Main Item Company Qingdao Yushin Co., Ltd Establishment Jan. 2002 Address Tonghe Town, Pingdu City, Qingdao, Shangdong,, China Turnover 2012 US$ 25 M. Employee 279 Main Item T/M Support Plate, Airbag Door Ass’y Main Customers HMC, KMC, TOYOTA, NIDEC, DELPHI CCC-1540 “Challenge, Change, Completion” Main Item Company Wuxi Yuzhong Co.,Ltd Establishment Sep. 2008 Address #B-16、Koshin development district, W uxi, China Turnover 2012 US$ 15 M. Employee 157 Main Item Back Plate, Booster Shell Main Customers MOBIS, KMC CCC-1540 “Challenge, Change, Completion” Main Item Company YSI Automotive Private Ltd Establishment Sep. 2008 Address Chennai Tamil Nadu, India Turnover 2012 US$ 18 M. Employee 350 Main Item T/M Brackets, Seat Belt Main Customers HMC, KMC, TATA, UNIPRES TOKAI RIKA, TAKATA CCC-1540 “Challenge, Change, Completion” Main Item Company YSP &C Poland sp z.o.o Establishment Jul. 2009 Address ul, Poznanska 4, Pyskowice,Poland Turnover 2012 US$ 7 M. Employee 87 Main Item Back Plate, Booster Shell Main Customers HMC, KMC, MOBIS, FUJI KOYO NEXTEER BACK PLATE ASSEMBLY LH and RH START OF PRODUCTION : Feb. 2011 SHELL&STUD ASSEMBLY(ED/FD, EL/SL) START OF PRODUCTION CCC-1540 “Challenge, Change, Completion” Thank you. CCC-1540 “Challenge, Change, Completion”