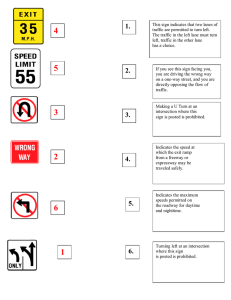

general regulations index

advertisement