35.4L: Late-News Paper: Metal-Oxide Thin Film Transistor with High

advertisement

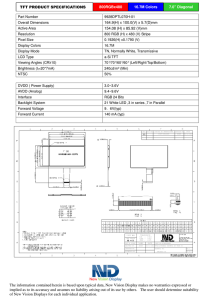

35.4L / G. Yu 35.4L: Late-News Paper: Metal-Oxide Thin Film Transistor with High Performance and Good Operation Stability Gang Yu, Chan-Long Shieh, Fatt Foong, Guangming Wang, Aaron Kuo, Kaixia Yang, Jian Wang, Frankie Chang, James Peng and Boo Nilsson CBRITE Inc., 421 Pine Ave., Goleta, CA 93117, USA 1. Introduction Although LTPS have been used for backpanels in portable AMOLED products, a low cost, high operation stability and high uniformity backpanel technology is still needed for next generation flat-panel TV products based on AMLCD or AMOLED. LTPS TFT does not provide competitive cost structure and amorphous silicon TFT does not provide the needed performance, neither mobility nor operation stability. Metal-Oxide Thin Film Transistor (MOTFT) has attracted significant attention for its high carrier mobility and potentials for next generation AMLCD and AMOLED [1]. Several demonstrations based on InGaZnO TFT have been disclosed recently with impressive performance [2]. However, the mobility and the Vth stability are yet to be improved to fulfill the demands for the next generation display applications. Other challenges include process stability, process simplicity and process compatibility with existing TFT manufacture lines. CBRITE has developed a metal-oxide TFT technology for advanced display applications. We have developed a series of non-InGaZnO type of MOTFT with electron mobility >80 cm2/Vsec, Ion/Ioff >1010 and S<0.2 V/dec. Such TFT shows excellent stability under OLED and LCD operation conditions. CBRITE has also developed a MOTFT process flow based on PVD and wet etching patterning. AMOLED and AMLCD backpanels have been demonstrated from a Gen-2.5 size, color filter production line. Bottom emission, full-color AMOLED is demonstrated in 4.8”, QVGA (320xRGBx240) with aperture ratio larger than 50%. Power efficiency over 6 lm/Watt and >20 lm/Watt were achieved in full pixel on condition and in video operation condition. 2. Experiments and Results Non-IGZO type metal-oxides were used for the channel layer. The device architecture and process steps are similar to that socalled 5 masks, bottom-gate, etch-stopper configurations known in a-Si TFT field. Figure 1 shows a typical Id-Vgs plot from a 10 -2 10 -4 10 -6 d Non-InGaZnO based metal-oxide TFT is developed with high performance and good stability. Manufacturability was demonstrated with a high capacity, Gen-2.5 size, color-filter production line. Superb TFT performance was achieved with >80 cm2/Vsec, Ion/Ioff >1010 and S<0.2 V/dec. This TFT shows high stability under OLED and LCD operation conditions. A 4.8” bottom emission AMOLED is demonstrated with aperture ratio larger than 50%. Power efficiency >6 lm/Watt at >500 nits was achieved with high display uniformity. The average power efficiency under video operation is beyond 20 lm/Watt. TFT with W/L=6.7 and Vds=10V. Id reached 1 mA at Vgs near 5V. The highest mobility recorded was > 80 cm2/Vsec. The device architecture and parameters have been tuned to best fit with AMOLED and AMLCD operation conditions with stability better than LTPS TFT reported in literature, sufficient for commercial applications. A TFT with W/L=6.7 was stressed at room temperature with initial current of 230 A (which is ~100x accelerated comparing to that needed for peak brightness in an OLED TV) for over 41 hours, the current varies within 1% during entire test time. Noticing the oscillating type variation with 24 hours period, this ~1% variation was mainly due to temperature change in the test room rather than biasing field or charge motion. The corresponding Vth is < 0.2V, as shown in Figure 2 along with Id(t). A similar TFT was also stressed at 60 oC with initial current of 140 A for 21 hours, the current drops approximately 20 % with Vth shifts for less than 0.6 V during stress period. I (A) Abstract 10 -8 10 -10 10 -12 -15 -10 -5 0 5 10 15 Vgs (V) Fig. 1 Id-Vgs of a TFT with W/L=6.7 (Vds=10V). Such TFT is also stable under high voltage bias stress at Vgs=+20V and Vds=0.1V. Figure 3 shows an Id-Vgs data set collected during 48 hours stress at room temperature. The Id-Vgs data were collected every 30 minutes under Vds=10V. The Vth shifts at a rate of ~ 8.7 mV/h. The Id collected at Vgs=20V and Vds=10V drops only ~2%, from 1.93mA to 1.89mA, over 48 hours stress period. The mobility of this test device is ~ 35 cm2/Vsec and the Ion/Ioff is over 1010. PBTS at 60 oC has also been carried out under the same biasing condition. The Vth shifts ~ +0.8V after 17 hrs; i.e., a rate of ~47 mV/h. ISSN 0097-966X/11/4201-0483-$1.00 © 2011 SID SID 11 DIGEST • 483 35.4L / G. Yu The maximum processing temperature used in fabricating these TFT was below 300 oC. We note that such MOTFT can also be fabricated at temperature below 180 oC. TFT fabricated on PAN and PEN foils with 180 oC process shows similar IV characteristics as shown in Fig. 3 with S<0.2 V/dec and Ion/Ioff >109. -4 4 3 10 3 -4 2.5 10 2 -4 2 10 -4 0 1.5 10 -1 I(6V) V(t)@1nA 1 -4 1 10 -2 -5 5 10 -3 0 -4 0 10 20 30 40 Time (hour) Fig.2 Vth and Id as function of stress time (Vgs=6V and Vds=5V). 1.E-02 0 hr 1.E-03 4 hrs 8 hrs 1.E-04 12 hrs A process flow has been established on a Gen-2.5 size (370mmx470mm), color filter manufacture line; based on existing PVD tool, proximity photo exposure tool and wet etching patterning process used for color filter manufacture. Such approach enables AMOLED displays be made with a cost structure competitive to that for AMLCD. Figure 4 shows a photo of a completed backplane in Gen-2.5 size with several development vehicles on it. A major development vehicle used in the 12 months was a 4.8”, full-color QVGA display for AMOLED. The pixel circuit comprises two transistors and one capacitor. The pitch size was 300umx100um with 52 % aperture ratio. It is worth to note that such high aperture ratio has only been achieved previously in AMOLED with top-emission configuration [3]. Figure 5 and Table 1 shows the photo and the specification chart from a 4.8” AMOLED with a white OLED emitter. Power efficiency over 6 lm/W and >20 lm/Watt was achieved under 100% pixel on at full brightness and video operation conditions. This power budget is of great significance for battery powered portable electronic products [4]. This engineering prototype also confirms peak luminance over 600 nits with Vdd-Vcom less than 8 V, with 9 point uniformity over 89%. 16 hrs 1.E-05 20 hrs Id(A),Vd=10V 1.E-06 24 hrs 28 hrs 1.E-07 32 hrs 1.E-08 36 hrs 40 hrs 1.E-09 44 hrs 1.E-10 48 hrs 1.E-11 1.E-12 1.E-13 -20 -15 -10 -5 0 5 10 15 20 Vg(V),step=0.2V 5.0 2.5E‐03 4.0 2.0E‐03 3.0 Vg (Id=1E‐9) 1.0 1.5E‐03 Vth 0.0 Id ‐1.0 1.0E‐03 ‐2.0 ‐3.0 Id (A) at Vds=10V, Vgs=20V 2.0 5.0E‐04 ‐4.0 ‐5.0 0.0E+00 0 5 10 15 20 25 30 35 40 45 50 55 Stress Time (Hours) Fig.3 PBTS at Vgs=20V, Vds=0.1V, at RT: IdVgs (up-panel), and Vth and Id vs. stress time (low-panel). 484 • SID 11 DIGEST Fig. 4 370mmx470mm MOTFT backpanel processed from a Gen-2.5 color filter production line (left); and a 4.8” FC AMOLED backpanel on 5”x5” glass (top-right). >50% aperture ratio is well seen from the high transmission of the 4.8” panel. 35.4L / G. Yu The aperture ratio has been improved further to 65% in a recent AMOLED design (see the top-center portion of the Gen-II panel in Fig. 4 with higher transmission). The power efficiency and the operation lifetime showed corresponding improvement. Such MOTFT backpanel enables the full-color OLED technology used in current PM OLED products being upgraded for AMOLED products without further development. CBRITE AMOLED Module 11” EDTV (480p) 18.5” HDTV (720p) 26” FHDTV (1080p) Fig. 5 A photo of the 4.8” AMOLED with a white OLED emitter. This display is equivalent to a tile in 11” EDTV (480p), or 18.5” HDTV (720p), or 26” FHDTV (1080p). Table 1. Specification Table of 4.8” AMOLED panel 3. Discussion and Remarks The data showing in this paper demonstrate that CBRITE’s MOTFT is an ideal technology for next generation flat-panel displays. It offers mobility > 30 cm2/Vsec with superb operation stability necessary not only for pixel drivers but also for peripheral driver circuits. Data from Figure 2 is equivalent to a total charge of 34 Coulombs passed through the TFT. These data suggest that an AMOLED TV with pixel peak current of 2 A, can be operated continuously with 100% pixels on at full brightness for over 4,700 hours without noticeable circuit parameter change. Using a mean usage factor of 20% for video contents, such OLED display can be used for OLED TV for continuously operating over 23,000 hours. Assuming 8 hours per day operation, such TV can be operated over ~ 7 years. The data shown in Figure 3 also confirms that CBRITE MOTFT can also be used for next generation AMLCD products with advanced liquid crystal technologies. It is also worth to note that such high mobility, stable MOTFT was made with a non-IGZO based metal-oxide channel layer. The process demonstrated in a Gen-II size, high capacity color filter line confirmed that MOTFT can be made with a production line with substantially lower capital investment than that used for a-Si TFT. It also confirms that existing a-Si TFT lines can be upgraded for MOTFT when the time arrives. The performance table also implies that a 48” OLED TV panel can be operated with mean power substantially less than 50 Watt. Display Size 4.8” diagonal Display Format FC QVGA: 320x3x240 Total Pixel Count 230.4K Pitch Size (sub-pixel) 300 µm x 100 µm Active Area 96 mm x 72 mm Architecture Bottom emission Aperture Ratio >50 % 5. Frame Rate 60, 120, 240 Hz Sub-pixel current >3µA @ Vds<3V [1] For early IGZO works, see, for examples, K. Nomura et al., Nature 432, 488 (2004); H.Q. Chiang et al., Appl. Phys. Lett. 86, 13503 (2005) Vds(T2)@Ipixel=3 µA <3V Peak Brightness >600 nits Power efficiency 6 lm/W (~ 20 lm/W Movie) Homogeneity >89% (5 and 9 point tests) 4. Summary In summary, we presented a MOTFT technology with performance and stability better than IGZO and LTPS TFTs; and with manufacture cost as good as, or even better than that for a-Si TFT. The mobility, the operation voltage and the operation stability meet the specifications for next generation OLED/LCD TV applications. References [2] For engineer prototypes based on IGZO TFT, see the corresponding works presented in Digest of the Technical Papers in SID2009 and SID2010. [3] Specification of SONY XEL-1 OLED TV, User’s manual. [4] G. Yu, invited talk, Asia FPD 2000, August 26-28 (2000) Guangzhou, China SID 11 DIGEST • 485