Antifouling System Drawing for 4,150 TEU Container Ship

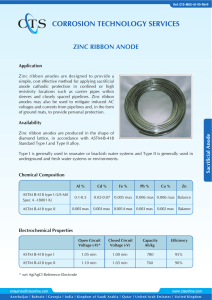

advertisement

Cathelco L I M I T E D ^ IMO 9298686 HHI 1630 S S ANTIFOULING SYSTEM (M.G.P.S) FOR 4,150 TEU CONTAINER SHIP HHI H.1630 FINAL DRAWING SEC. NO. C3D5 SHIP DESIGN OFFICE SHIP OUTFITTING DESIGN DEP'T 2 SHIP TYPE 4,150 TEU CLASS CONTAINER CARRIER TEL. NO. 3708 SHIP NO. SHIP NAME MAERSK GREENOCK (IMG 9298686) 1630 APPROVED Y. S. HAN CHECKED Y. S. KIM j NAME OF DRAWING M.G.P.S DRAWN DATE 2005.10.13 SCALE DRAWING NO. / / \ HYUNDAI HEAVY INDUSTRIES CO.,LTD ULSAN SHIPYARD, KOREA 6U-2846-193 CONSOLIDATED NO. IM-25 1 Cathelco m. L I M I T E D S S ANTIFOULING SYSTEM (M.G.P.S) FOR 4,150 TEU CONTAINER SHIP HHIH.1630 FINAL DRAWING Cathelco Limited Marine House, Hipper Street, Chesterfield S40 ISS, United Kingdom Tel: (44) (0126)235916/232375 Fax: (44) (0216) 206519 Web: www.cathelco.co.uk ANTIFOULING SYSTEM OPERATIONAL MANUAL INSTALLATION/VESSEL: HHI H.1630 OPERATOR: HHI / A.P.MOLLER CONTENTS:SYSTEM SPECIFICATION INTRODUCTION ANODE OPERATION ANODE MOUNTING SLEEVE TYPES ELECTRONIC CONSTANT CONTROL UNIT INSTRUCTIONS FOR MOUNTING CONTROL PANEL INSTRUCTIONS FOR MOUNTING ANODES (FLANGED SLEEVES) WIRING OF SYSTEM SYSTEM COMPONENTS & NETT WEIGHTS IN SERVICE INSTRUCTIONS & SETTINGS INSTALLATION SPARES KIT PAGE 2 3 4 5 6 7 8 9/10/11 12 13/14 15 DRAWINGS DRAWING No. ARRANGEMENT OF ANODE (FLANGED SLEEVE) A3312/21170 LAYOUT OF ANTI-FOULING SYSTEM A2710/21170 ARRANGEMENT OF EL/4D/ 6WAY CONTROL PANEL A2321/21170 PLANNING DIMENSIONS FOR CONTROL PANEL A1230/E WIRING DIAGRAM FOR ANTI-FOULING SYSTEM A3287/21170 INTERNAL WIRING CONNECTION DIAGRAM A1037/21170 DETAIL OF PLUG & RECEPTACLE TYPE JUNCTION BOX A3294/21170 Cathelco Limited Marine House Hipper Street South Chesterfield, United Kingdom S40 ISS Tel: (44) (01246) 235916/232375 Telex: 547534 Mussel G. Fax: (44) (01246) 206519 ANTI-FOULING MANUAL Please Quote CA 21170/A On All Correspondence CATHELCO SYSTEM SPECIFICATION SHEET CLIENT HHI VESSEL'S H.1630 CA No. CA 21170 SEA WATER TO BE TREATED 2 STRAINERS FLOW RATE = 3200m3/Hr (max) ANODE LOCATION 2 X MGS & 1 X TCS IN EACH OF 2 STRAINERS ANODE MOUNTING TYPE FLANGED MOUNTING SLEEVES ANODE SPECIFICATION No. OFF TYPE 4 MG 2 TC MATERIAL COPPER ALUMINIUM ANODE REF WVR27KB WVR28KB ALL ANODES SUPPLIED WITH 3.0M LG CABLE CONTROL PANEL 1 OFF TYPE EL/4D/6W 220V 1 ph 60 HZ POWER SOURCE 220V AC 60Hz IPH SPARES 1 SET OF ONBOARD SPARE ANODES 1 SET INSTALLATION SPARES 1 SET OFF ANODES AS ON BOARD SPARES ANODE LIFE 5 YEAR (2 X 2.5 Years) YARD SUPPLY MATING FLANGES CABLES FROM CONTROL PANEL TO JUNCTION BOX & VESSELS ALARM SYSTEM POWER SUPPLY CABLE EARTH RETURN CABLES ANTI-FOULING MANUAL CATHELCO INTRODUCTION The Cathelco System is a patented method developed specifically for :a) The Control of marine growth (MG) in sea water systems b) The reduction of corrosion of metal in contact with water. It is difficult to generalise on the economics, but it is normally no exaggeration to say that annual savings, taking in to consideration out of service time, are sufficient to cover the capital cost of the System in two years or less. Each Cathelco installation is designed for its particular task and should therefore not be regarded as just another mass produced gadget which will cure all ills with no further attention. Very little supervision is necessary, but we do ask for your co-operation in following the simple instructions contained in this manual. The Cathelco System, using our special anodes controls both marine growth infestations and corrosion - the former being virtually eliminated, while the latter will be reduced to afi-actionofthat normally to be expected. The System is designed to give continuous and troublefi-eeprotection against marine growth and corrosion with the minimum maintenance. It will only operate for the full plaimed anode life and give complete protection, however, if the anode currents are maintained at the correct settings. Excessive anode current will result in an excessive rate of consimiption of the anodes, thus reducing their life and possibly leaving the water system unprotected if the anode is prematurely consumed Insufficient anode current will result in fouling of the water system. Incorrect current setting either way can result in expensive cleaning operations which should not be necessary if the system is operated correctly at all times. Sea water that has been treaded by a Cathelco system can be used as feed water for evaporators or reverse osmosis plants for producing drinking water, as the system will produce copper concentration well below that specified by the Department of Trade. ANTI-FOULING MANUAL CATHELCO ANODE OPERATION There are two types known as the Marine Growth (MG) Anodes and Trap Corrosion Anodes (TC) or (FE) being used depending on the material of the pipework/condenser system. MG Anodes are manufactured from copper. They release ions during electrolysis which combine with these released from the sea water to form an environment which discourages spat and any other minute organisms entering, and adhering in some area where they grow and start breeding. They are, instead, carried straight through to discharge and, provided that no untreated water is allowed to enter at some point subsequent to the anodes, freedom from infestation is assured. TC Anodes are manufactured from aluminium for use in a system with predominantly steel pipes where the reaction of the aluminium anode with seawater results in the formation of aluminium hydroxide. This disperses down the pipework positively charged, forming anti-corrosive barrier on the pipework. FE (Cast Iron) Anodes are used when the pipe work is mainly copper nickel or aluminium brass. Here, the reaction of the cast iron anode with the seawater releases Iron into the waterflowfor corrosion protection. In order for the system to prevent marine growth it is imperative that where there is more than one inlet, changeover of inlets occur. There must be a period of at least 2 weeks if possible between changeover. Any less than that may cause marine growth to appear. If in doubt, contact Cathelco. ANTI-FOULING MANUAL CATHËLCO TYPES OF ANODE MOUNTING SLEEVES These basically consist of three types :a) Weld-in sleeves for direct welding into the top plate of sea chests or strainers. b) Flange mounted type for bolting either directly onto the top plate of the sea chest or strainer, or bolting to pipe up stands. Note ; Both the above types of sleeve are supplied unpainted & covered with a rust prevention coating. This coating MUST be removed using either White Spirit/Turpentine before installation, welding in position or painting etc. c) Nylon mounting sleeves, these are used for strainer use only, generally when weld in sleeves cannot be used. Irrespective of the type of anode sleeve, the top of the sleeve is fitted with a safety cap which is pressure tested to 100 lbs per sq. inch. These are approved by Lloyds and the department of trade and industry. The caps are supplied complete with a water tight cable gland to ensure complete safety from the ingress of seawater. Instructions on fitting particvdar types of mounting sleeve are in later sections of the manual. NOTE:If the inside of the safety cap is filled with an electrical isolation grease (i.e. silicon grease), it will help to prevent corrosion inside the cap and lid. ANTI-FOULING MANUAL CATHELCO ELECTRICAL CONSTANT CONTROL UNIT SPECIFICATION EL/4D/6W TYPE a) Enclosure All steel construction with welded joints and flanges, fmished in matt enamel with locking perspex "window" door Panel is in three sections as foUows:Section 1 Mounting face with four 8mm holes for bulkhead mounting. This section carries gland mounting plate in bottom face. Section 2 Hinged at left hand face to section 1 carries all major electronic workings i.e. rack system housing modules, mains input, anode connections all accessible via open back. Section 3 Safety glass panelled door hinged at left side fiilly sealed and lockable. One key supplied. b) Modules As the name implies, all control systems in this unit are built up of 'plug in' components which are of brushed aluminium construction and require no maintenance. Each module controls one anode via frontal moimted amperage selector knob. The current level for each anode is shown in the digital display above each selector knob. c) Operation When all cormections have been made and anodes are fiilly immersed in solution (seawater) the digital display should be set at the recommended levels in the manual. ANTI-FOULING MA^fUAL CATHELCO INSTRUCTIONS FOR MOUNTING CONTROL PANELS EL/4D/6W TYPE Fixing Control panels EL/4D/1,2,3 and 4W planning dimensions shown on drawing number A1229/E. Control panels EL/4D/5,6,7 and 8W planning dimensions shown on drawing number A1230/E. Four holes are incorporated in each comer of the back plate of the panel, these are for mounting. We recommend a bulkhead mounting in close proximity to the sea chests/strainers to avoid voltage drop and cutting cable run costs. MAINS SUPPLY UNIT Run cable from available power source .... via gland to terminal marked "MAINS IN" SETTING UP Once all the cables have been run and connected, the system is ready to be switched on. NOTE - the following procedure can only be carried out with the anodes in seawater. a) Switch mains on at power switch on bottom left hand of front panel. A green neon to right of switch will light up to register power on. b) Set all anode currents as specified in Operation Manual by turning the knobs to prescribed settings, confirmed by reading in the digital display ammeter directly above each setting knob. c) If the vessel is in fresh or brackish water the digital display may not reach the recommended current settings. This can be ignored & should correct it's self when the vessel is at sea in (salt water). d) Switch off xmtil Ship starts engine(s) up. ANTI-FOULING MANUAL CATHELCO INSTRUCTIONS FOR DN150 PN16 FLANGE MOUNTING ANODES FITTED DIRECT TO SEA CHEST TOP PLATE OR STRAINER LID It is important that anodes are mounted in the vertical position unless otherwise stated on the Cathelco drawings for specific vessels. DN150 PN16 MATING FLANGE Drill and tap 8 holes M20 on 240 pitch circle diameter for 8 x M20 studs x 90 long complete with nuts and lock nuts. FITTING 1 a) If Cathelco have supplied drawings for your specific system, bum a hole in the sea top plate 200mm diameter in position stated on drawing. Weld mating flange in position (weld on both sides) and fit 8 studs to mating flange. 1 b) If Cathelco have not supplied drawings Determine the position of the anode moimting flange and bum hole in top plate of the sea chest 200mm in diameter. The anodes must be positioned between the inlet grid and the main suction outlet. Recommended centres of anodes 450mm minimum centres and 250inm fi-om nearest steel work. Ic) Weld mating flange in position on top of the top plate (weld on both sides) and fit 8 studs to mating flange. Id) Coat both pipe up stand and flanged mounting sleeve to same specification as the sea chest/strainer lid. 2) Bolt flange mounting complete with anode to mating flange. Remember to fit gasket between flanges. Remove lidfiromtop of mounting flange and check brass nut and lock nut are tight. Maximum torque - 701bs (10 Kgs/m). Fill space with an electrical isolating grease (silicon or similar). Ensure 'O' ring is fitted to top of sleeve, replace lid and tighten gland. ANTI-FOULING MANUAL CATHELCO WIRING OF SYSTEM SOLID STUD ANODES Client to supply all cables and connection boxes between:a) Power isolation switch and control panel b) Control panel and anodes including earth return leads. Minimum Recommended Cable Specification Marine rubber double insulated. Use one core per anode and one core per earth return. The minimum core size for all cables is as follows :0-25 Metre cable run Use 4.0sq mm core. 25 - 50 Metre cable run Use 6.0sq mm core. 50-100 Metre cable run Use 10.0sq mm core. If the cable run is above 100 metres it is recommended to use separate control panel. For ease of identification, cables supplied as part of anode assemblies are coloured as follows :MG (copper) Anode Cable - Grey Outer/Red Inner PVC covering. or Red Outer/Red Inner PVC covering TC (Aluminium) - Grey Outer/Black Inner or Black Outer /Black Inner PVC covering FE (Cast Iron) - Grey Outer/Black Inner or Black Outer /Black Inner PVC covering MG Anode stud has a 3mm long unscrewed section at the top of the stud TC & FE Anodes studs are fully screwed to top. Before tightening mounting sleeve lid 8c cable gland. Ensure that all anode cables are securely fixed to the top of the anode mounting stud, with a cable eyelet & M6 setscrew. ANTI-FOULING MANUAL CATHELCO WIRING UP SOLID STUD ANODES An earth (-ve) return must be installed at each separate anode location i.e. if the system supplied is designed for 2 sea chests/strainers then 2 earth returns must be used. Use a miri of 1 earth retvim for every 4 anodes Ensure that a separate cable is used for this purpose. Use cable as specified above. Connect to the terminals available in the rear of the control unit marked 'earth returns'. We suggest the cable connections are made by welding a bolt on to the strainer or sea chest close to the anodes (but no nearer than 250mm). Fit junction box close to the anodes and wire to control panel using recommended cable as per attached wiring diagram and control box drawing. It is recommended to fill junction box with a silicon grease or similar nonhardening electrically isolating compound as a protection against corrosion. After switching on, check the polarity of the anodes in relation to the hull. All anodes are to be positive, relative to a negative hull. TROUBLE SHOOTING NO LIGHTS ON AT ALL A) Check mainsfiisein thefirontof the control panel (above on-off switch). B) Check circuit breaker in distribution box. ANY ONE DISPLAY WILL NOT SHOW A READING A) Check anodefiiseat the rear of the module. B) Check ifany cable has been severed. C) Check anode lead joint at the sea chest. D) Change over any two modules to check if fault is in module or rest of system. ALARM L.E.D. LIGHTS UP A) If digital display is showing zero treat as above B) If digital display is not showing a reading but led is light, fault with module Return For Repair. 10 ANTI-FOULING MANUAL CATHELCO EL/DD/6W CONTROL PANEL MALFUNCTION ALARM RELAY If specified by the client each control panel can be supplied as original equipment (at extra cost) with a flashing warning beacon and/or zero voltage relay to indicate a malftinction when any of the following occur :1) No electrical supply to the panel i.e. power module fuse blown 2) Current supply to one or more anodes being less than approx. 0.2 amps 3) Current supply to one or more anodes being greater than approx. 4.0 amps ALARM RELAY A relay with zero voltage contacts is fitted to the control panel module with 2 wiring points being clearly marked on the wiring connection block inside the control panel NOTE:- The relay can be supplied with either normally open contacts or normally closed contacts (Client to specify) Cathelco recommend normally closed relay contacts. 11 ANTI-FOULING MANUAL CATHELCO CATHELCORef CA 21170 SCOPE OF SUPPLY AND WEIGHTS PER HULL No. Off 8 4 12 1 ITEM / DESCRIPTION Wt. Each Total Weight Anodes Ref:WVR27KB 77.8 kg 24.4 kg Anodes Ref:WVR28KB Anode Mounting (Flanged Sleeve) 27.2 kg Control Panel EL/4D/6W 230V 36.5 kg Installation spares (see below) Anode Installation /Removal tool ref TIM-9 Total nett weitght of System 622.4 kg 97.6 kg 326.4 kg 36.5 kg 1082.9 kg NOTE: Installation Spares are for use if required during initial fitting only. (see separate sheet for itemised detail) ON BOARD SPARES Only spares required for first 5 years operation are: One full set of onboard spare anodes 2 off 3.15 amp fuses for control panel modules and 2 off 5 amp fuses for control panel power unit, spare fuses fixed to inside rear of control panel casting. For replacement anodes required after 2.5 years, see list above (only anodes required) Replacement anodes or guarantee work if required contact: Cathelco Ltd (see first page) SPARE PARTS LIST NO. NAME SKETCH SUPPLY PER HULL 3.15 AMP FUSES FOR CONTROL PANEL MODULES 5 AMP FUSES : CONTROL PANEL POWER UNIT • SPARES PART REF F3.15A L250V T5A 250V ] 178 mm BOX SPANNER TA 25 12 ANTI-FOULING MANUAL REMARKS SPARES FUSES INSIDE SPARE BOX SPARES FUSES INSIDE SPARE BOX BOX SPANNER INSIDE SPARE BOX CATHELCO CA 21170 IN SERVICE INSTRUCTIONS - STRAINER MOUNTED ANODES DESCRIPTION ONCE THE SYSTEM HAS BEEN INSTALLED IT WILL PERFORM TWO FUNCTIONS:A) Eliminate marine growth and reduce the corrosion rate in the seawater service lines. B) The system uses impressed current sacrificial anodes which are designed to last 2.5 years approx. Once in service the anodes will require renewal every 2.5 years. Renewal can be carried out with the vessel afloat. For the first 2.5 years replacement anodes have been supplied as on board spares. After this Please ensure a reasonable despatch time when ordering replacement anodes. You will require the foUovnng :4 off only Anodes Ref WVR27KB 2 off only Anodes Ref WVR28KB WHEN RE-ORDERING PLEASE QUOTE DRGNo. A3312/21170 ADJUSTMENTS The control panel is fully automatic and therefore dose not require any adjustment in service. CHECKING We suggest that as a matter of course the Control panel be checked every two (2) weeks. When checking, see that all the digital display ammeters are working, this will determine all is correct. When the anodes have nearly wasted, the digital display above the corresponding anode will start to fall. When this happens, turn the anode current knob back to zero and leave it until the anode renewal. Reset once again at sea after renewal to current settings given previously. 13 ANTI-FOULING MANUAL CATHELCO IN SERVICE ADJUSTMENTS AND CURRENT SETTINGS CA 21170 The effective working of the system can only be determined by inspection and it is suggested that if after 6 months of operation the opportunity to examine a strainer, length of pipe or heat exchanger, presents itself, this should be done. In the event of there being signs of infestation, the current to each anode in this section should be increased by a maximum of 0.2 amps, but if no fouling is present the current to each anode within this section may be reduced by a maximum of 0.2 amps. This routine can be repeated at intervals, the current being adjusted accordingly. NOTE: The higher the current setting the shorter the anode life. The lower the current setting the greater the anode life. SEA CHEST ANODE REF ANODE SIZE IN OPERATION CURRENT SETTINGS NOT IN OPERATION CURRENT SETTINGS PORT SIDE SEA CHEST MG 1 TC 1 MG 2 WVR27KB WVR28KB WVR27KB 2.7 amps 2.9amps 2.7 amps 0.4 amps 0.4 amps 0.4 amps STARBOARD SIDE SEA CHEST MG 3 TC 2 MG 4 WVR27KB WVR28KB WVR27KB 2.7 amps 2.9amps 2.7 amps 0.4 amps 0.4 amps 0.4 amps Anode life 5 years dependent on use 14 ANTI-FOULING MANUAL CATHELCO LIST OF INSTALLATION SPARES USE WITH 120 DIAMETER ANODE M3Q SOLID STUD SYSTEM 1 OFF Watertight cable gland type T & B 9521 (fit to sleeve lid) 1 OFF ' 0 ' Ring 3mm sec x 110 mean diameter (fit between lid and mounting sleeve) 1 OFF Neoprene washer 120mm diameter x 1.6mm thick The next two items connect anode power cable to anode stud 1 OFF Brass M6 hex head set screw x 10 Ig 1 OFF Brass M6 flat washer The next 4 items are used to bolt anode to mounting sleeve 1 OFF M30 brass full nut 1 OFF M30 brass half nut 1 OFF M30 plated steel washer 1 OFF UPVC Top Hat washer 55 o/d x 6 thk ANODE MOUNTING TOOL This tool to remain onboard to facilitate anode installation and removal. 1 OFF Box spanner TA 25 (Used to tighten/slacken M27 anode stud nuts) 15 ANTI-FOULING MANUAL o CNJ Lül-^ _i • O ro O CNi to <: cs>Ö C3-^ Ï^ Q O r^ CNJ ÜJ < o; iï mm ^ >^ CS I ^ OO CM CN ^% U. Li_ UJ LÜ a: a: UJUJ Q Q <: o OO 2 Z << § •0120- 1J_U_ U. Li_ O O -<*• 04 CO ^$$^ FINISH C L I E N T T O P A I N T S L E E V E A F T E R WELDING. TO S A M E S P E C I F I C A T I O N A S S T R A I N E R A F T E R WELDING. A N O D E S T O B E FREE FROM P A I N T A N D G R E A S E . DESCRIPTION No 8 X 02Z QTY REMARK FLANGE JIS10K-150A, M.S MATING FLANGE JIS10K-150A. M.S No. DESCRIPTION QTY REMARK MAKER M6 B R A S S SET SCREW MAKER YARD MG A N O D E MAKER STUD YARD 10 FULL & HALF BRASS NUTS MAKER MAKER 11 P R O T E C T I O N P L A T E MAKER 5 MILD S T E E L P L A T E D G L A N D MAKER 12 M O U N T I N G S L E E V E MAKER 6 MILD S T E E L LID MAKER 13 H E A T S H R I N K MAKER _3_ S T R A I N E R T O P P L A T E 4 7 6mmSQ CABLE TAIL 0' RING 3M MAKER 16 SLEEVE CC Ï 8 S Ö EL/4D/6W CONTROL PANEL MINIMUM CABLE SPECIFICATION: «o o Jçk Ä ALARM TO VESSELS CONTROL PANEL ^1 MARINE RUBBER DOUBLE INSUUTED USE 1 CORE PER ANODE AND 1 CORE PER EARTH RETURN MINIMUM CORE SIZES POWER IN 220V 1PH 4 CORE MINIMUM CABLES BY CLIENT ALL CABLES: 00 - 25m CABLE RUN USE 4.0mm SQ CORE 25 - 50m CABLE RUN USE 6.0mm SQ CORE 50 - 1 0 0 m CABLE RUN USE 10.0mm SQ CORE EARTH 4 ANODES REF : WVR27KB 2 ANODES REF : WVR28KB 6mm SQ CORE x 3.0M LG ANODE LEADS....BY MAKER EARTH RETURN LEADS BY YARD TITLE: CATHELCO LIMITED m m HOUSE, 18 HIPPER STREET SOUTH, CHESTEREIELD, DERßfSHIRE, S40 ISS, UK.REV: PLUG IN TYPE JUNCTION BOXES BY MAKER PA NO: 21170 m-mwE SYse LAYOUT SHOING DRAWN: 3 ANODES IN EACH OF 2 SRAINERS DATE: SIG: MODinCATlON: MDA SCALE: DATE: 15:11:99 NONE TECH MAN: nop DMcG NO:A2710/21170 LOCK CX) 4 FIXING HOLES 8mm DIA IN BACK PUTE FOR DETAIL OF WIRING CONNECTION BLOCK SEE DRG No. A 1 0 3 7 / G / 2 1 1 7 0 ENCLOSURE - SPEC LP. 55 TITLE: CATHELCO LIMITED ® miN[ HOUSE, 18 HIPPER SJREEJ SOUÎH, CHESJEPflEU), OEmSHIPE, S40 ISS, UK. REV: CATHELCO CONTROL PANEL TYPICAL EL/4D/6W (4AyP) UNIT DATE: SIG: MODinCATlON: PA NO: 21170 DRAWN: MDA SCALE: DATE: 17:01:97 TECH MAN: DMcG 1:5 Sa A2321/21170 AOo POSITION OF ADDITIONAL SUPPORT BRACKETS IF REQ;D DO NOT BOLT TO INTERMEDIATE SECTION ACCESS REQ'D TO CABLE GLAND PLATE MAY BE TOP MOUNTED IF REQ'D STEEL GLAND PUTE 320 X 70 EFECTIVE AREA FOR CABLE GUNDS N E n WEIGHT 36Kg DOOR OPENING RADIUS 6 2 0 PANEL OPENING RADIUS 6 5 7 ACCESS REQUIRED FOR WIRING ETC. TITLE: CÅTHELCO LIMITEB ® miHE mSE, 18 HIPPER STREH SOUTH, REV: CHESTEREIELD, DERBÏSHIRE, S40 ISS, (IK. PLANNING IN DIMENSIONS FOR CONIROL PANELS E L / 4 D / 5 , 6 , 7 AND 8W DATE: SIG: MODIFICATION: PA NO: 21170 DRAWN: MDA DATE: SCALE: 15:11:99 TECH MAN: DMcG m 1:10 A1230/E Ol O m C^ CD ^nii :d Ô >: rn nnn>i />m i n/viiii-r> N L Ikl rti zzuv ounz ruwtix in to g m m — 9 m S of» CO o ALAKM KLLAT tUNIALIb J ^ / ^=1^ ?J / " ^ - ^ H" kinniiiiiv 1^1 nc-rn -rrnn \irwre- ^ ^ -o z æ o z—1 EARTH 1— m X > z AURM ALARM i 1 m r— m MG2 ANODE + «W TC2 ANODE + TCl ANODE + s:^^ ' — ^ MG2 ANODE + N J TCI ANODE + f~> —1 f~ ^ - k MG1 ANODE + 2 ^ EARTH RETURN >z CD m NS O —1 MG1 ANODE + 1 EARTH RETURN I— z <^ o o z z m c: 30 z - BUNK GO O —1 lO o ;:3 r ^ s« lUZ ANUUL + MG4 ANODE + ) LL ^ft s^r MG4 ANODE + r MG3 ANODE + 1 EARTH RETURN - L MG3 ANODE 4EARTH RETURN EARTH RETURN \ 1 to BLANK CDO -S.J»00 1 -<r>.m TITLE: CÅTHELCO UMITED ® Mff rosf, M »fif sim mu, CHEi/i/l'//£[iIDtmmt, 54(/ /65; (//f. REV: 3- . PLANNING IN DIMENSIONS FOR CONTROL . P A N F I S F l / 4 n / 5 . 6 . 7 AND RW DATE: SIG: MODinCATlON: DATE: PA NO: 21170 DRAWN: MU/ TECH MAN: r SCALE: 15:11:99 DMcG 1:10 ' /911"7n !ofA3 9R1 ZO11L\\ EARTH ^ N ^ L POWER INPUT 220V 1PH ALARM ALARM TO 2 - A U R M RELAY CONTACTS NORMALLY CLOSED ZERO VOLTS — MG 2 TC 1 MG 1 EARTH RETURN - S E E NOTES — NOTES: 1 .^.^ 2 3 -SEE NOTES CABLES FROM ANODES SHOWN THUS: MG (COPPER) ANODE LEAD DENOTED TC (ALUMINIUM) AND FE (CAST IRON) ANODE LEAD DENOTED ENSURE EARTH RETURN LEADS ARE CONNECTED TO CORRECT BLOCK DRAWING TO BE READ IN CONJUNCTION WITH THE RELEVANT WIRING DIAGRAM. MG 4 MG 3 EARTH RETURN CATHELCO LIMITED ® mifiE mS[, 18 HIPPER SIREH SOUJH, CHESîEmu), mmmE, S4Q JSS, UK. REV: DATE: TITLE: O i E C l N BLOCKS FOR CONIROL PANELS REF EL/4D/5 TO 8 WAY SIG: MODinCATlON: PA NO: 21170 DRAWN: MDA SCALE: DATE: 15:11:99 NONE TECH MAN: nRr DMcG NO: AI 037/21170 »JUNCTION BOX COVER 170 152 9 — © «> éJUNCTION BOX FOR M.G.P.S CM CSl o ©- e- 4M-4 NOTE : ® <2) Q) ® ® © ® ® ® TITLE: CÅTHELCO LIMITED ® miNE mS[, 18 HIPPER SJREH SOM, REV: CHESJERFIELI), DERBÏSHIRE, S4ÖISS, UK. POLYCARBONATE BOX (HI-BOX) POLYSTERE CABLE GLAND SUITABLE FOR H-TPYCY6 CABLE(CABLE OUTDIA 19mm) BAKELITE TERMINAL BOARD WITH BRASS TERMINALS SOLDERING 3EA RECEPTACLE SOLDERING(INDSIDE) RECEPTACLE CAP 6 m m ' SINGLE CORE ANODE CABLE TERMINAL BLOCK mmw m FOR y,G.p.s DATE: SIG: MODinCATION: PA NO: 21170 DRAWN: MDA SCALE: DATE: 15:11:99 NONE TECH MAN: DMcG NTA3294/21170