WWW.ROGERSCORP.COM

WWW.PORONXRD.COM

FEEL THE INTENSITY OF THE SPORT

NOT THE IMPACT

PORON® XRD™ Extreme Impact Protection Material is a breakthrough technology that has been

tested to absorb up to 90 percent of energy when impacted at high strain rates1. The extreme

impact protection developed by the Rogers Corporation High Performance Foams Research

and Development Team is ideal for use in sporting goods, outdoor industry products and other

applications where protection, comfort, and consistent performance are required.

PORON XRD material gives athletes the power to concentrate on the next play, and not be

inhibited by the last hit. It is an ideal added protection material for the shoulders, elbows, hips,

knees, shins and other common impact injury areas for athletes and outdoor adventurers.

g

onsistent repeated impact absorption for dependable protection

C

throughout the life of the product.

multi-purpose foam that outperforms the competition in a variety

A

of markets and test methods.

Wearable Protection Advantage

g

g

g

g

g

g

oft to the touch, but firm on impact, PORON XRD Material

S

conforms to your body’s every move, yet upon impact, forms a

comfortable shell that protects the body.

aintains all the standard PORON Cushioning properties that

M

you’ve come to rely on: open-cell, breathable technology, excellent

compression-set resistance, antifungal and does not contain latex,

PVCs, VOCs or heavy metals.

he PORON XRD design difference offers a thin and flexible

T

alternative to traditional padding, so your customers can say good

bye to uncomfortable, bulky protection.

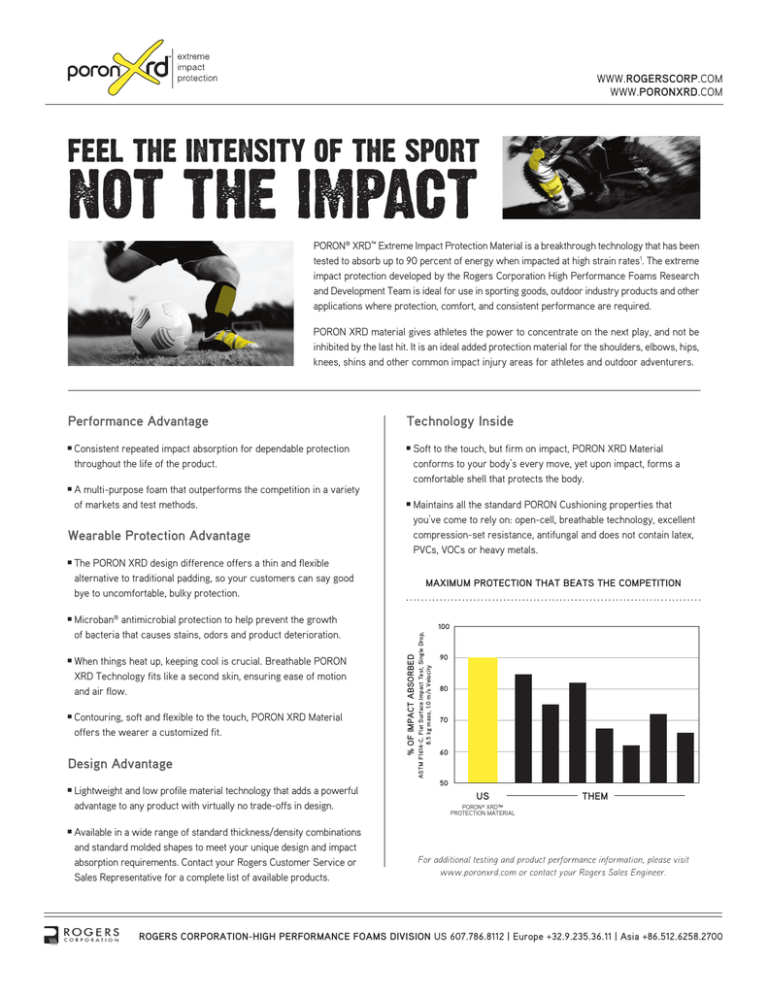

MAXIMUM PROTECTION THAT BEATS THE COMPETITION

icroban® antimicrobial protection to help prevent the growth

M

of bacteria that causes stains, odors and product deterioration.

hen things heat up, keeping cool is crucial. Breathable PORON

W

XRD Technology fits like a second skin, ensuring ease of motion

and air flow.

ontouring, soft and flexible to the touch, PORON XRD Material

C

offers the wearer a customized fit.

Design Advantage

g

g

L ightweight and low profile material technology that adds a powerful

advantage to any product with virtually no trade-offs in design.

vailable in a wide range of standard thickness/density combinations

A

and standard molded shapes to meet your unique design and impact

absorption requirements. Contact your Rogers Customer Service or

Sales Representative for a complete list of available products.

100

% OF IMPACT ABSORBED

g

Technology Inside

ASTM F1614-C. Flat Surface Impact Test, Single Drop,

8.5 kg mass, 1.0 m/s Velocity

Performance Advantage

90

80

70

60

50

US

THEM

PORON® XRD™

Protection Material

For additional testing and product performance information, please visit

www.poronxrd.com or contact your Rogers Sales Engineer.

ROGERS CORPORATION-HIGH PERFORMANCE FOAMS DIVISION US 607.786.8112 | Europe +32.9.235.36.11 | Asia +86.512.6258.2700

WWW.ROGERSCORP.COM

WWW.PORONXRD.COM

PORON® XRD™ EXTREME IMPACT PROTECTION - Typical Physical Properties

PROPERTY

TEST METHOD

PRODUCT

9

12

15

20

25

0.14

0.19

0.24

0.32

0.40

*Density, lb. / ft3

Specific Gravity

ASTM D3574-95 Test A

Tolerance, %

± 10

See Product Availability

*Standard Thickness

Tolerance, %

± 10

Vivid Yellow (65)

Standard Color

Air Permeability

Internal using Gurley Densometer

Open-Cell, Breathable

*Compression Set, % max.

ASTM D3574 Test D @ 158°F (70°C)

< 10

*Compression Force Deflection, psi

0.2”/min. Strain Rate Force

Measured @ 25% Deflection

kPa

1.1-3.4

1.5-5.5

4-9

5-12

10-20

8-23

10-38

28-62

34-83

69-138

10

19

32

Hardness, Durometer

Shore “O”

Hydrolysis Resistance

ASTM D3574 Test J / Test D after

autoclaved 5 hrs @ 250°F (121°C)

<5

ASTM D 2632-96, Vertical Rebound

**

Compression Set, % Max

Resilience, Shore Instrument

Resiliometer, avg (Ball Rebound Tester)

Water Vapor Transfer, Typical

g/ft2/24hrs (g/m2/24hrs)

Sample Thickness, inches (mm)

Based on ASTM E96-00

Upright/37˚C/0% RH

**

0.158 (4.0)

0.118 (3.0)

0.118 (3.0)

**

4150

3400

3100

**

Water Absorption, % Wt Gain

Based on ASTM D570 - 2hr water

immersion @ room temperature

Typical Value 10

Skin Contact

Primary Skin Irritation – FHSA.

Based on ISO 10993-10 (2002), ISO

10993-12 (2007), ISO/IEC 17025 (2005)

Negligible Irritant. Primary Irritation Index = 0

Tear Strength, pli, min.

kN/m

*Tensile Elongation, % min.

*Tensile Strength, psi, min.

kPa

restricted substances

compliance

ASTM D624 Die C

4.5

5

5

10

14

0.8

0.9

0.9

1.8

2.5

ASTM D3574 Test E

ASTM D3574 Test E

Restricted substances requirements of

Nike and Adidas; Restrictions on Latex,

PVC, Heavy metals, Ozon depleting VOCs

>145

30

45

70

100

140

207

310

483

689

965

Meets the requirement

PORON Urethanes are unaffected by mild organic acids and bases.

They show modest swelling with oils and greases and other linear hydrocarbons.

Strong polar solvents will greatly swell PORON Urethanes. In most cases,

physical properties recover to a great extent as the solvents evaporate.

Chemical Resistance

AATCC TM90

Antimicrobial Protection

JIS Z 2801

PASS

AATCC TM30(iii)

Notes: 1. ASTM F1614-C. Flat Surface Impact Test, Single Drop, 8.5 kg mass, 1.0 m/s Velocity 2. All metric conversions are approximate. 3. Additional technical services are available. 4. Information listed based on typical physical properties.

5. *Standard testing property; Certificate of Compliance available per lot. 6. **Indicates testing in progress to confirm reported results

Additional PORON® XRD™ Material variations may be available upon special order. Rogers recommends textile or leather covering for additional comfort wear and strength.

Please contact your Rogers Customer Service Representative for more details.

ROGERS CORPORATION-HIGH PERFORMANCE FOAMS DIVISION US 607.786.8112 | Europe +32.9.235.36.11 | Asia +86.512.6258.2700

The world runs better with Rogers, the Rogers logo, PORON and XRD are licensed trademarks of Rogers Corporation. All rights reserved. Printed in U.S.A. © 2011 Rogers Corporation. The information contained in this Sell Sheet is intended to assist you in designing with Rogers’ PORON® XRD™ Extreme Impact

Protection. It is not intended to and does not create any warranties, express or implied, including any warrant of merchantability of fitness for a particular purpose or that the results shown in this Sell Sheet will be achieved by a user for a particular purpose. Each user must develop its own design and should

determine the suitability of Rogers’ products for that design. MICROBAN is a registered trademark of Microban Products Company. ®Registered trademark of MICROBAN PRODUCTS COMPANY. © 2004 MICROBAN PRODUCTS COMPANY. All rights reserved. WARNING: No impact absorbing material can prevent

all injuries that may occur when the body is subjected to impact. Rogers makes no representation or warranty that PORON XRD Extreme Impact Protection material will prevent such injuries. The user of protective gear containing Rogers’ materials should be aware of the limitations of the gear and should exercise

reasonable care and caution in the undertaking of activities that may result in impact to the body.

®

Publication # 15C-068

The world runs better with Rogers.

WWW.PORONXRD.COM

PORON® XRD™ MATERIAL

PORON® XRD™ MATERIAL

COMPETITOR A

COMPETITOR B

COMPETITOR C

PORON® XRD™ MATERIAL

COMPETITOR A

COMPETITOR B

COMPETITOR C

500

500

500

.

.

.

........................................................................................................

500

PRESSURE (PSI)

COMPETITOR C

..............

THE TEST

COMPETITOR B

..............

..............

..............

THE RESULTS

COMPETITOR A

400 ............................................................................................................................................

.......................................................................................

400 ............................................................................................................................................

....................................................................................

400 ............................................................................................................................................

.................................................................................

400 ............................................................................................................................................

....................................................................................................

300 ............................................................................................................................................

........................................................................................

300 ............................................................................................................................................

.....................................................................................

300 ............................................................................................................................................

..................................................................................

300 ............................................................................................................................................

.........................................................................................................

200 ............................................................................................................................................

........................................................................................

200 ............................................................................................................................................

....................................................................................

200 ............................................................................................................................................

.................................................................................

200 ............................................................................................................................................

........................................................................................................

100 ............................................................................................................................................

.......................................................................................

100 ............................................................................................................................................

......................................................................................

100 ............................................................................................................................................

..................................................................................

100 ............................................................................................................................................

0

0

0

1

2

0

0

1

2

0

0

1

2

0

1

2

.......................................................................................................................................

.......................................................................................................................................

.......................................................................................................................................

.......................................................................................................................................

DISTANCE (IN.)

DISTANCE (IN.)

DISTANCE (IN.)

DISTANCE (IN.)

PORON® XRD™ MATERIAL

COMPETITOR A

COMPETITOR B

COMPETITOR C

ROGERS CORPORATION-HIGH PERFORMANCE FOAMS DIVISION US 1-607-786-8112 | Europe +32-9-235-3611 | Asia +86-512-6258-2700

WWW.PORONXRD.COM

..............

THE TEST

You’ve seen the backyard bowling experiment, now see the testing behind the demo. To measure the effectiveness of PORON® XRD™ Extreme Impact

Protection Material, a bowling ball is dropped onto various pieces of foam that sit atop a pressure-sensing device. The test compared PORON XRD

Materials and three other popular shock-absorbing materials used in protective equipment and apparel.

During the test, the ball is dropped on the foam and the pressure-sensing device measures the

impact. It then color-codes the magnitudes of the pressures, from purple (lowest) to red (highest).

THE RESULTS

ENERGY ON IMPACT: PORON XRD Materials absorb more energy than competitive materials—

nearly twice as much in some cases. The impact is also distributed over a greater area of the

material, as opposed to directly through the material and to the other side (i.e. you).

........................................................................................................

500

PRESSURE (PSI)

400 ............................................................................................................................................

....................................................................................................

300 ............................................................................................................................................

.........................................................................................................

200 ............................................................................................................................................

IMPACT DISPERSION GRAPH: The amount of pressure detected along a line through the

center of the area of impact was created and mapped. The distance recorded on the x-axis is

a measurement of the diameter of the impact area, and the y-axis measures the pressure detected

at that distance along the line.

......................................................................................................

100 ............................................................................................................................................

0

0

1

2

.......................................................................................................................................

DISTANCE (IN.)

Results shown are not from experimental bowling ball demonstration, but represent data collected under laboratory conditions.

FOR ADDITIONAL TESTING INFORMATION PLEASE VISIT WWW.PORONXRD.COM

ROGERS CORPORATION-HIGH PERFORMANCE FOAMS DIVISION US 1-607-786-8112 | Europe +32-9-235-3611 | Asia +86-512-6258-2700

The world runs better with Rogers. The Rogers logo, PORON and XRD are licensed trademarks of Rogers Corporation. All rights reserved. Printed in U.S.A. Publication #15C-076

The information contained in this Sell Sheet and all Preliminary Data Information are intended to assist you in designing with Rogers’ PORON® XRD™ Extreme Impact Protection. It is not intended to and does not create any

warranties, express or implied, including any warrant of merchantability of fitness for a particular purpose or that the results shown in this Sell Sheet will be achieved by a user for a particular purpose. Each user must

develop its own design and should determine the suitability of Rogers’ products for that design.

WARNING: No impact absorbing material can prevent all injuries that may occur when the body is subjected to impact. Rogers makes no representation or warranty that PORON XRD Extreme Impact Protection material will

prevent such injuries. The user of protective gear containing Rogers' materials should be aware of the limitations of the gear and should exercise reasonable care and caution in the undertaking of activities that may result

in impact to the body.