Cover Page - Essex Industries

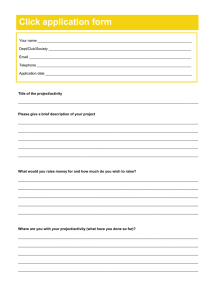

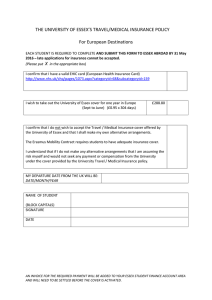

advertisement