Mechanical Booster Pumping Unit [YM-VD/YM

advertisement

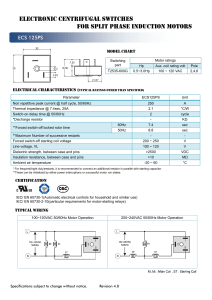

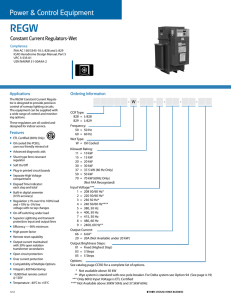

Low Vacuum Pump Mechanical Booster Pumping Unit [YM-VD/YM-VS Series] ULVAC mechanical booster pumping unit contains an oil-sealed rotary vacuum pump and a mechanical booster pump in a compact frame. All the connection piping are included. The unit has an ergonomic, user friendly design allowing for easy maintenance. The ULVAC YM-VD/YM-VS Series is perfect for any application from R&D to production. Feat ures Evaporation, Sputtering, Ion Plating Vacuum Packing, Vacuum Absorption, Vacuum Molding Vacuum Heat Furnace, Sintering Furnace, Blazing Furnace Easy Maintenance With a simple and efficient frame design from ULVAC, just the oilsealed rotary vacuum pump is removed from the pump set during normal maintenance. Optional Components Various options are available from ULVAC including oil mist traps, mountable operational panel, vacuum switches, vacuum circuit breakers. ULVAC mechanical booster pumping unit can be customized to suit your needs. Vacuum Drying, Freeze-drying, Vacuum Air Removal Gas replacement, packing, vacuum heat insulation, leak tester, etc. Low Vacuum Pump Comapct Design ULVAC mechanical booster pumping unit contains an oil-sealed rotary vacuum pump and a mechanical booster pump all in a compact frame including necessary vacuum piping. A p p lic a tio n s Mechanical Booster Pumping Unit [YM-VD/YM-VS Series] S p e c ific a tio n s Items Model Pump combination YM-VD-103C Mechanical booster pump YM-VD-103CM PMB-001C Cooling water Oil rotary vacuum pump Maximum pumping speed 50Hz m3 /hr L/min CFM 60Hz m3 /hr L/min CFM Maximum suction pressure 50Hz Pa Torr mbar 60Hz Pa Torr mbar Pa Ultimate pressure *1 Torr mbar kw (number of poles) Mechanical booster pump hp (number of poles) Motor power (number of poles) Oil rotary kw (number of poles) vacuum pump hp (number of poles) Mechanical booster pump Motor Oil rotary vacuum pump Mechanical booster pump Capacity (L) Oil Standard oil Oil rotary vacuum pump Capacity (L) Standard oil Cooling Mechanical booster pump method Oil rotary vacuum pump Primary side pressure Inlet/outlet differential pressure Cooling water temperature Cooling water volume L/min Inlet size JIS B 2290 Outlet size JIS B 2290 Weight kg Standard Accessories Options 8.5×10 3 6.4×10 2 85 4.5×10 3 33.8 45 PMB-001CM VD301 95 1580 55.91 115 1900 67.69 1.0×10 5 760 1000 1.0×10 5 760 1000 YM-VD-304C PMB-003C 7.0×10 2 5.3 7 7.0×10 2 5.3 7 0.4 (2) 0.54 (2) 0.35 YM-VD-304CM YM-VD-304A YM-VD-304AT PRC-003A PRC-003A PMB-003CM VD401 250 4100 147.14 290 4800 170.69 1.0×10 5 760 1000 1.0×10 5 760 1000 4.0×10 -1 3.0×10 -3 4.0×10 -3 → Atomospheric pressure operation model 7.0×10 2 5.3 7 7.0×10 2 5.3 7 1.0×10 5 760 1000 1.0×10 5 760 1000 0.75 (2) 1.0 (2) 1.5 (4) 2.0 (4) Totally enclosed fan cooled motor Drip-proof protected flange motor Canned motor 0.7 ULVOIL R-4 1.0 to 2.5 ULVOIL R-7 Air cooled Air cooled/Water cooled Water cooled Air cooled 0.1 to 0.3MPa (14.5 to 43.5psi) − 0.05MPa≦ (7.25psi≦) 0.01MPa≦ (1.45psi≦) − 5 to 30˚C (41 to 86˚F) − 2.0≦ − Corresponds to VG50 Corresponds to VG80 Corresponds to VG40 145 150 175 180 185 − ①Oil return mechanism A or B ②Timing leak valve ③Cooling-water sensor ④Oil drain valve ⑤Control box ⑥Terminal block box ⑦Voltage except 200V/50Hz-60Hz, 220V/0Hz ⑧Fluorine oil ⑨Oil mist trap (Low or high loads) ⑩Vacuum pipe with gauge port and leak port ⑪Motor (Totally enclosed fan cooled motor, Pressure/explosion proof and increased safety explosion motor) * 3 → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → *1: Measured by pirani vacuum gauge *2: Water cooling is required in continuous operation at a pressure higher than 530Pa (4Torr). *3: Explosion proof option is only applicable with motor. Other electric system (optional timing leak valve, cooling-water sensor, control box, terminal block box) does not meet explosion proof specification. D im e n s io n s 580 140 YM-VD-304A (T) 4-φ14 Holes for foundation bolt Cooling Water Inlet Rc3/8 Cooling Water Outlet Rc3/8 4-φ14 Holes for foundation bolt 580 140 140 Outlet flange 4-M8 Tap, Central diameter φ85 JIS B 2290 VG40 equivalency Unit: mm 40 40 140 Outlet flange 4-M8 Tap, Central diameter φ85 JIS B 2290 VG40 equivalency 250 621 500 621 500 YM-VD-103C (M) 860 (870) Totally-Enclosed Fan-Cooled Flange Induction Motor 3 Phase 0.4kW 2P AC200V/50, 60Hz AC220V/60Hz Drip-proof protected Flange Induction Motor 3 Phase 1.5kW 4P AC200V/50, 60Hz AC220V/60Hz 250 Inlet flange 4-M10 Tap, Central diameter φ100 JIS B 2290 VG50 equivalency 286.2 447 40 40 447 Water-cooled Canned Induction Motor 3 Phase 0.75kW 2P AC200V/50, 60Hz AC220V/60Hz TM401 mounting (Option) TM201 mounting (Option) Inlet flange 4-M10 Tap, Central diameter φ135 306 860 JIS B 2290 VG80 equivalency (870) Drip-proof protected Flange Induction Motor TM401 mounting (Option) 3 Phase 1.5kW 4P TM201 mounting (Option) AC200V/50, 60Hz AC220V/60Hz Inverter for 0.75kW AC200V class YM-VD-304A (T) (676) (746) (925) 660 580 580 140 YM-VD-606A (T) 4-φ14 Holes for foundation bolt Cooling Water Inlet Rc3/8 135 40 140 40 690 Cooling Water Outlet Rc3/8 135 621 500 621 500 Drip-proof protected Flange Induction Motor 3 Phase 1.5kW 4P AC200V/50, 60Hz AC220V/60Hz 447 306 860 (885) Totally-Enclosed Fan-Cooled Flange Induction Motor 3 Phase 0.75kW 2P AC200V/50, 60Hz AC220V/60Hz Inlet flange 4-M10 Tap, Central diameter φ135 JIS B 2290 VG80 equivalency Inlet flange 4-M10 Tap, Central diameter φ135 JIS B 2290 VG80 equivalency 40 250 40 (14) TM401 mounting (Option) 405 Water-cooled Canned Induction Motor 3 Phase 2.2kW 2P AC200V/50, 60Hz AC220V/60Hz TM201 mounting (Option) 4-φ14 Holes for foundation bolt Outlet flange 4-M8 Tap, Central diameter φ85 JIS B 2290 VG40 equivalency Outlet flange 4-M8 Tap, Central diameter φ85 JIS B 2290 VG40 equivalency 960 (970) 386.5 Drip-proof protected Flange Induction Motor 3 Phase 2.2kW 4P AC200V/50, 60Hz AC220V/60Hz TM-2 mounting (Option) TM401 mounting (Option) Inverter for 2.2kW AC200V class 443 710 630 YM-VD-606A (T) Cooling Water Inlet Rc3/8 Cooling Water Outlet Rc3/8 (5) (5) 396 660 580 (676) (746) (925) YM-VD-304C (M) (793) (975) 1035 YM-VD-304C (M) (5) (5) 396 396 660 580 (676) (746) (853) YM-VD-103C (M) S p e c ific a tio n s → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → → YM-VD-606A YM-VD-606AT PRC-006A PRC-006A YM-VD-609A YM-VD-609AT YM-VS-600A PRC-006A PRC-006A PRC-006A Atomospheric pressure operation model VD601 450 7500 264.86 520 8670 306.06 1.0×10 3 7.5 10.0 1.0×10 3 7.5 10.0 490 8170 288.40 500 8330 294.29 1.0×10 5 760 1000 1.0×10 5 760 1000 1.3×10 3 10 13 1.1×10 3 8.3 11 4.0×10 -1 3.0×10 -3 4.0×10 -3 Atomospheric pressure operation model VD901 600 10000 353.15 2.2 (2) 2.95 (2) 2.2 (4) 2.95 (4) Drip-proof protected flange motor 1.5 PRC-012A PRC-012A 850 14200 500.29 1000 16700 588.58 VS2401 1000 16700 588.58 1200 20000 706.29 Totally enclosed fan cooled motor 7.5 (4) 10 (4) 1.9 8.0 to 10.5 Water cooled 0.1 to 0.3MPa (14.5 to 43.5psi) 0.05MPa≦ (7.25psi≦) 5 to 30˚C (41 to 86˚F) 2.0≦ Corresponds to VG80 Corresponds to VG40 3.7 (2) 4.96 (2) 5.5 (4) 7.47 (4) ULVOIL R-7 Water cooled 0.01MPa≦ (1.45psi≦) 1.3×10 3 10 13 1.1×10 3 8.3 11 6.7×10 -1 5.0×10 -3 6.7×10 -3 ULVOIL R-4 Air cooled 265 YM-VS-1202A VS1501 550 9200 323.72 660 11000 388.46 1.2×10 3 9.0 12.0 9.3×10 2 7.0 9.3 1.0×10 5 760 1000 1.0×10 5 760 1000 3.7 (4) 4.96 (4) Canned motor 2.5 to 4.0 260 550 9170 323.72 YM-VS-1201A 4.0 Corresponds 285 290 − ①Oil return mechanism A or B ②Timing leak valve ③Cooling-water sensor ④Oil drain valve ⑤Control box → ⑥Terminal block box ⑦Voltage except 200V/50Hz-60Hz, 220V/0Hz ⑧Fluorine oil ⑨Oil mist trap (Low or high loads) ⑩Vacuum pipe with gauge port and leak port ⑪Motor (Totally enclosed fan cooled motor) *2 G3 515 5.0 Corresponds to VG100 G4 550 630 Oil mist trap ①Vacuum switch ②Vacuum release valve D im e n s io n s Cooling Water Inlet Rc3/8 135 40 YM-VD-609A (T) 690 Cooling Water Outlet Rc3/8 135 YM-VS-1201A、YM-VS-1202A 4-φ14 Holes for foundation bolt 100 φ18 Gauge port Inlet flange 4-M10 Tap, Central diameter φ135 JIS B 2290 VG80 equivalency Water-cooled Canned Induction Motor 3 Phase 2.2kW 2P AC200V/50, 60Hz AC220V/60Hz 960 (970) Leak Port 437.5 30 40 405 Unit: mm 800 [950] 900 840 621 500 Outlet flange 4-M8 Tap, Central diameter φ85 JIS B 2290 VG40 equivalency Totally-Enclosed Fan-Cooled Flange Induction Motor 3 Phase 3.7kW 4P AC200V/50, 60Hz AC220V/60Hz 4-φ24 Holes for foundation bolt Inverter for 3.7kW AC200V class TM-2 mounting (Option) TM401 mounting (Option) 1000 [1150] 520 [630] Water-cooled Canned Induction Motor 3 Phase 3.7kW 2P AC200V/50, 60Hz AC220V/60Hz 300 Inlet flange 8-φ12 Holes, Central diameter φ160 JIS B 2290 VG100 equivalency (5) 820 1200 443 710 630 (793) (975) 1035 Inverter for 2.2kW AC200V class 100 800 175 YM-VS-600A YM-VS-1201A [ ]: YM-VS-1202A φ18 Gauge port Totally-Enclosed Fan-Cooled 100 150 Flange Induction Motor 3 Phase 5.5kW 4P [3 Phase 7.5kW 4P] AC200V/50, 60Hz AC220V/60Hz 900 840 Leak Port 175 820 Totally-Enclosed Fan-Cooled 100 150 Cooling Water Inlet G3/8 (PF3/8) Flange Induction Motor Cooling Water Outlet G3/8 (PF3/8) 3 Phase 5.5kW 4P AC200V/50, 60Hz AC220V/60Hz 280 750 290 (1375) 1180 4-φ24 Holes for foundation bolt Inverter for 2.2kW AC200V class Water-cooled Canned Induction Motor 3 Phase 2.2kW 2P AC200V/50, 60Hz AC220V/60Hz 1000 Inlet flange 550 270 4-φ12 Holes, Central diameter φ135 JIS B 2290 VG80 equivalency Cooling Water Inlet G3/8 (PF3/8) Cooling Water Outlet G3/8 (PF3/8) 280 750 290 (41) 1375 [1705] → 30 Mechanical Booster Pumping Unit [YM-VD/YM-VS Series] Pu m p in g S p e e d C u r v e s YM-VD-103C, 304C, 304A YM-VD-103CM, 304CM, 304AT m3/h 300 YM-VD-304C/304A (60Hz) YM-VD-304C/304A (50Hz) 200 150 Type :YM-VD-103C :YM-VD-304C :YM-VD-304A Power:AC200V 50/60Hz 3φ (ULVOIL R-4) Oil :MBP (ULVOIL R-7) Oil :RP Gauge:Pirani YM-VD-103C (60Hz) 100 Pumping Speed YM-VD-304CM (50Hz) 200 YM-VD-304CM/304AT (60Hz) 150 YM-VD-304AT (50Hz) YM-VD-103CM (60Hz) 100 YM-VD-103C (50Hz) YM-VD-103CM (50Hz) 50 50 0 10 –1 10 –3 1 10 10 –2 10 –1 10 2 10 3 1 10 Pressure 0 10 –1 10 4 10 5 Pa 10 2 760 Torr (Note : 1mbar=100Pa) Atmospheric pressure YM-VD-606A, 609A 10 –3 YM-VD-606A (60Hz) 600 YM-VD-606A (50Hz) 300 10 10 4 10 Pa 760 Torr (Note : 1mbar=100Pa) Atmospheric pressure 5 10 2 100 100 1 10 10 –2 10 –1 10 2 10 3 1 10 Pressure Type :YM-VD-606AT :YM-VD-609AT Power:AC200V 50/60Hz 3φ (ULVOIL R-4) Oil :MBP (ULVOIL R-7) Oil :RP Gauge:Pirani YM-VD-609AT (60Hz) YM-VD-606AT (50Hz) YM-VD-609AT (50Hz) 300 200 10 –3 10 3 1 Pumping Speed YM-VD-606AT (60Hz) 400 200 0 10 –1 10 2 500 Pumping Speed YM-VD-609A (50Hz) 400 10 –1 m3/h 700 Type :YM-VD-606A :YM-VD-609A Power:AC200V 50/60Hz 3φ (ULVOIL R-4) Oil :MBP (ULVOIL R-7) Oil :RP Gauge:Pirani YM-VD-609A (60Hz) 500 10 Pressure Pumping Speed 600 1 10 –2 YM-VD-606AT, 609AT m3/h 700 Pumping Speed Type :YM-VD-103CM :YM-VD-304CM :YM-VD-304AT Power:AC200V 50/60Hz 3φ (ULVOIL R-4) Oil :MBP (ULVOIL R-7) Oil :RP Gauge:Pirani 250 Pumping Speed 250 Pumping Speed m3/h 300 Pumping Speed 10 4 10 5 Pa 10 2 760 Torr (Note : 1mbar=100Pa) Atmospheric pressure 0 10 –1 10 –3 1 10 10 –2 10 –1 10 2 10 3 1 10 Pressure 10 4 10 Pa 760 Torr (Note : 1mbar=100Pa) Atmospheric pressure 5 10 2 YM-VS-600A,1201A, 1202A Pumping Speed (L/min) (m3/h) 25000 1500 1400 Pumping Speed YM-VS-1202A (60Hz) Type :YM-VS-600A :YM-VS-1201A :YM-VS-1202A Power:AC200V 50/60Hz 3φ (ULVOIL R-4) Oil :MBP (ULVOIL R-7) Oil :RP Gauge:Pirani 1300 20000 1200 YM-VS-1202A (50Hz) 1100 1000 15000 900 800 YM-VS-1201A (60Hz) 700 YM-VS-1201A (50Hz) 10000 600 YM-VS-600A (60Hz) 500 400 YM-VS-600A (50Hz) 5000 300 VS2401 200 VS1501 100 0 0 2 3 4 5 –1 10 1 10 10 10 10 10 Pa 10 10 2 10 –3 10 –2 10 –1 1 760 Torr (Note : 1mbar=100Pa) Pressure Atmospheric pressure www.ulvac.co.jp/eng w w w. u l va c. c o. j p ULVAC, Inc. Components Division Overseas Sales in Japan TEL +81-467-89-2261 USA : ULVAC Technologies, Inc. GERMANY : ULVAC GmbH CHINA : ULVAC (SHANGHAI) Trading Co.,Ltd. TAIWAN : ULVAC TAIWAN, Inc. KOREA : ULVAC KOREA, Ltd. SINGAPORE : ULVAC SINGAPORE PTE LTD TEL +1-978-686-7550 TEL +49-89-960909-0 TEL +86-21-6127-6618 TEL +886-3-579-5688 TEL +82-31-683-2922 TEL +65-6542-2700 PHILIPPINES : ULVAC Singapore Philippines Branch VIETNAM : ULVAC Singapore Vietnam Representative Office THAILAND : ULVAC (THAILAND) LTD MALAYSIA : ULVAC MALAYSIA SDN. BHD. INDIA : ULVAC, Inc., India Branch This catalog is subject to change without notice. This catalog is published in order to sell this product in overseas. Please see Japanese catalog when purchasing in Japan. TEL +63-2-828-7700 TEL +84-8-62556762 TEL +66-2-312-4447 TEL +60-3-5121-4700 TEL +91-40-27007006 1964E/2012062000UYO